AB Products Engineering (Chemical)

Join our presentation by clicking on the zoom link below

HTTPS://UCALGARY.ZOOM.US/S/99828085383

”Design is not just how it looks like and feels like. Design is how it works”

–Steve Jobs.

About our project

Aniline Production

Aniline is an organic component that is mostly used for methylenediamine and dyes production. It also used in pharmaceutical industry. The rising demand for aniline and positive forecasts created a great opportunity for aniline production in Alberta.

AB Products Engineering completed a design of a plant capable of producing 51,000 metric tons of aniline per year with purity of 99wt%. The aniline is produced using phenol ammonolysis, where phenol reacts with excess ammonia to produce aniline. The phenol ammonolysis process was found to be the most environmentally friendly, simple and relatively safe way of producing aniline.

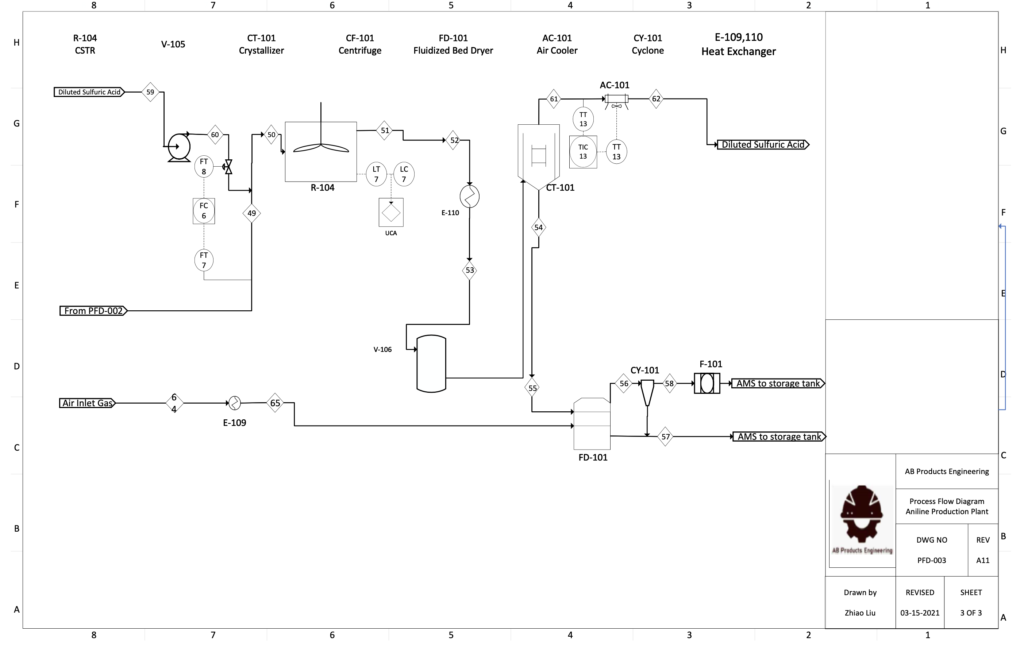

The phenol ammonolysis process uses excess of ammonia, that needs to be treated. Some part of the ammonia is separated from product stream and is recycled. Other part of Ammonia mixed with water is used in the ammonia treatment process, where ammonium bisulfate is produced.

Meet our team!

Aimen Aldarkhobi

“Engineering is the closest thing we have to magic”

Dmytro Shershniuk

“Highest productivity of an engineer is at the last minute”

Huiying Han

“Engineering is the best way to express an idea”

Zhiao Liu

“The numbers look good to me!”

Details about our design

WHAT MAKES OUR DESIGN INNOVATIVE

1. The phenol ammonolysis process was selected due to it being most environmentally friendly, simple with relatively safe operating conditions.

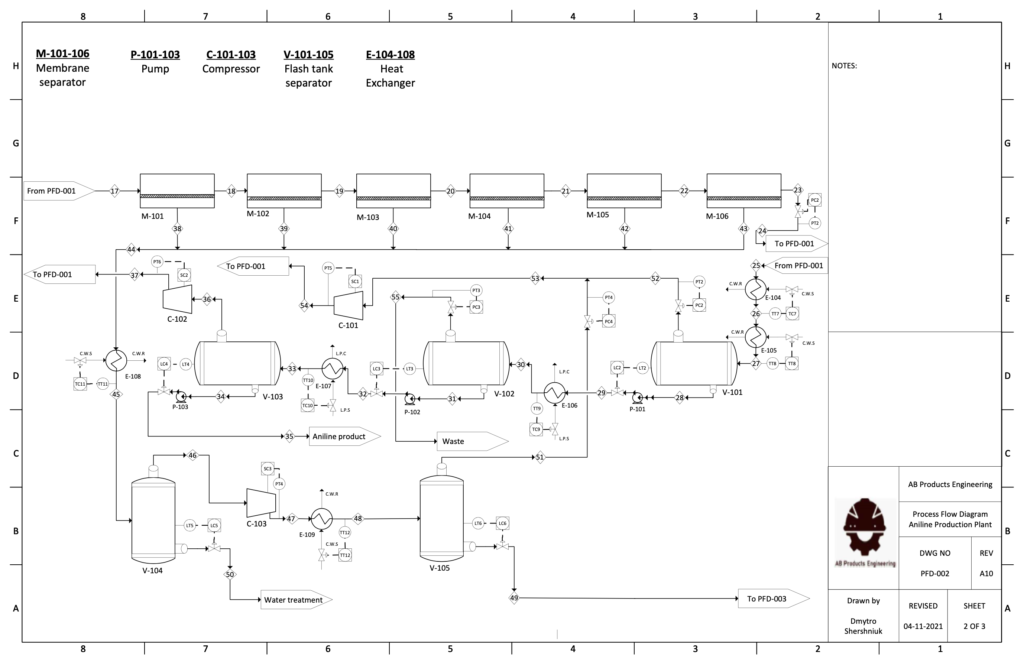

2.The process involves phenol and excess ammonia reacting in the fixed bed multitubular reactors. Unlike conventional process in the industry where distillation column is used, our process implemented multiple separation units, such as high performance 6FDA-based polyimide membrane, and two-phase separators to obtain aniline product with high purity(>98%).

3.The only waste stream that was left after producing aniline was ammonia/water mixture with high amounts of water in it. It was decided to use another process to produce ABS from leftovers. This resulted in extra cash flow as well as solving issue with waste treatment

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

The phenol ammonolysis process uses excess ammonia, which means that there is a lot of ammonia leaving plug flow reactors. Series of multiple membrane separators and two phase separators were used to achieve >98 wt% purity of aniline as well as 98wt % ammonia, that is recycled. The only stream left is ammonia/water mixture, that is very hard to separate. The solution for this issue was to add another process that uses the ammonia/water mixture to produce ABS (ammoniumbysulfate), that can be sold to generate extra income for the plant. Adding another process to the plant also minimized amounts of waste streams leaving the process.

Heat integration was also implemented in the process to make it more efficient.

HOW WE VALIDATED OUR DESIGN SOLUTION

Symmetry software was used to simulate the process. You can see the screenshot from the Symmetry attached below.

Matlab was used to simulate plug flow reactors, HTRI software was used to perform detailed design of heat exchangers and generate specification sheets for them.

FEASIBILITY OF OUR DESIGN SOLUTION

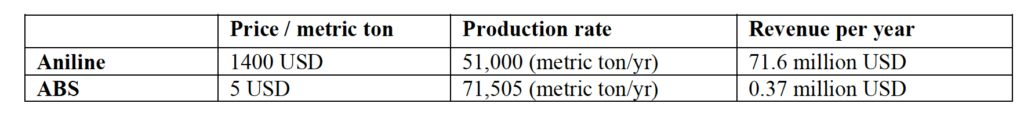

Process produces 51,000 metric tons of Aniline and 71,505 metric tons of ABS (by-product). Revenues from selling both by-product and product are listed in the table below.

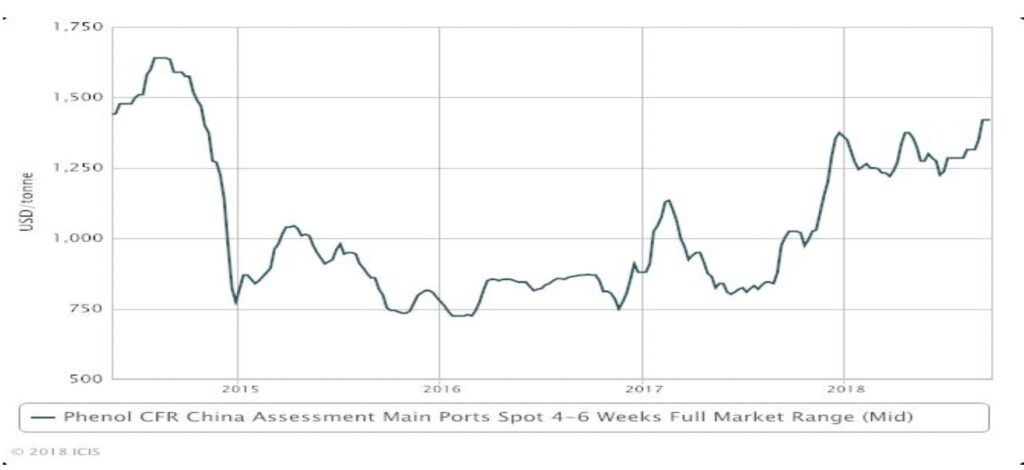

The Biggest expense is the phenol reactant, 54.4 million USD / year is spent on phenol out of 60.67 million USD / year of total expenses. This concludes that phenol expenses account for 90% of all expenses. Phenol prices are found to be quite unstable, as it depends on oil prices which tend to fluctuate in the recent years, but however, it is assume that the average price of phenol in the nearest future based on the market will be around 1000 USD / metric tons.

figure 1 shows phenol price fluctuations in the past year. Phenol price is estimated to be around 1000 USD per ton. As phenol price accounts for 90% of all expenses and aniline product price is considered stable, breakeven point was determined based on phenol price. Breakeven point is at phenol price of 1250 USD / metric ton. As seen in the figure 2 below, phenol had prices over 1200 USD / metric ton, reaching 1650 USD / metric ton in 2014. However, these record phenol prices were aligned with oil prices. Since 2014, oil prices were never over 80 USD / barrel and in the nearest future are projected to be lower than 60 USD / barrel. This would hold phenol prices from going over 1200 USD / metric ton. As of right now and in the nearest future, this facility is projected to have a rate of return of over 135%. However, if oil prices bounce back in 5-10 years, phenol expenses would rise therefore decreasing the profitability.

Partners and mentors

We want to thank the all people who helped us with this project. Special thanks to our supervisor Micheal Foley and professor Hector De la Hoz Siegler

Our photo gallery

PFD-001

PFD-002

PFD-003

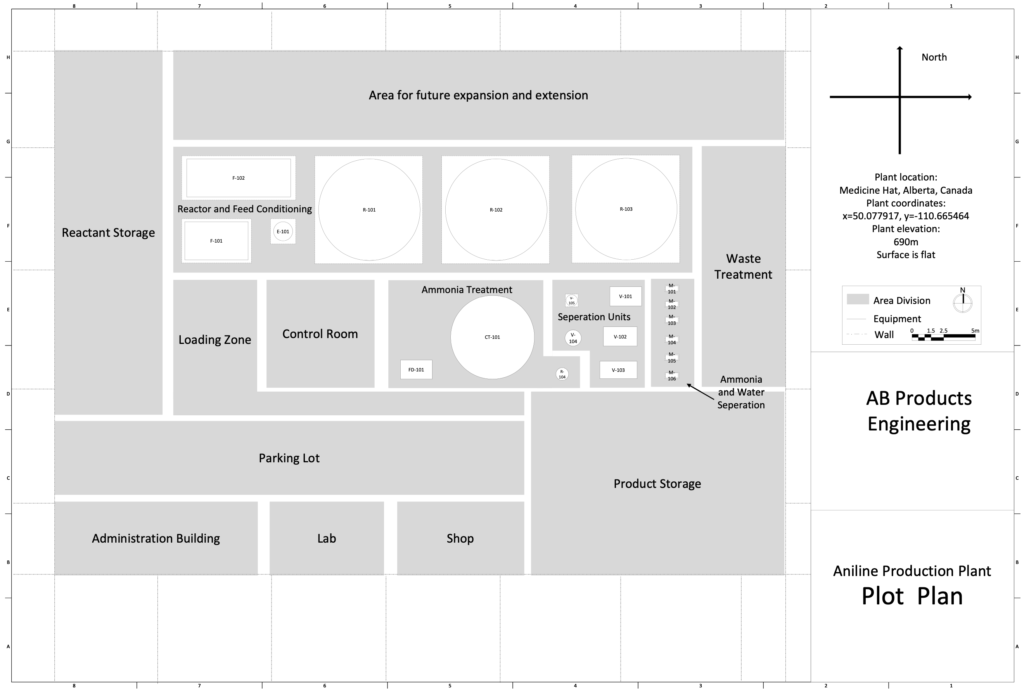

Plant plan

4×4 risk assessment matrix