Project Category: Chemical

Asphaltenes to High Performance Carbon Fibre

Come Join Our Presentation!

About our project

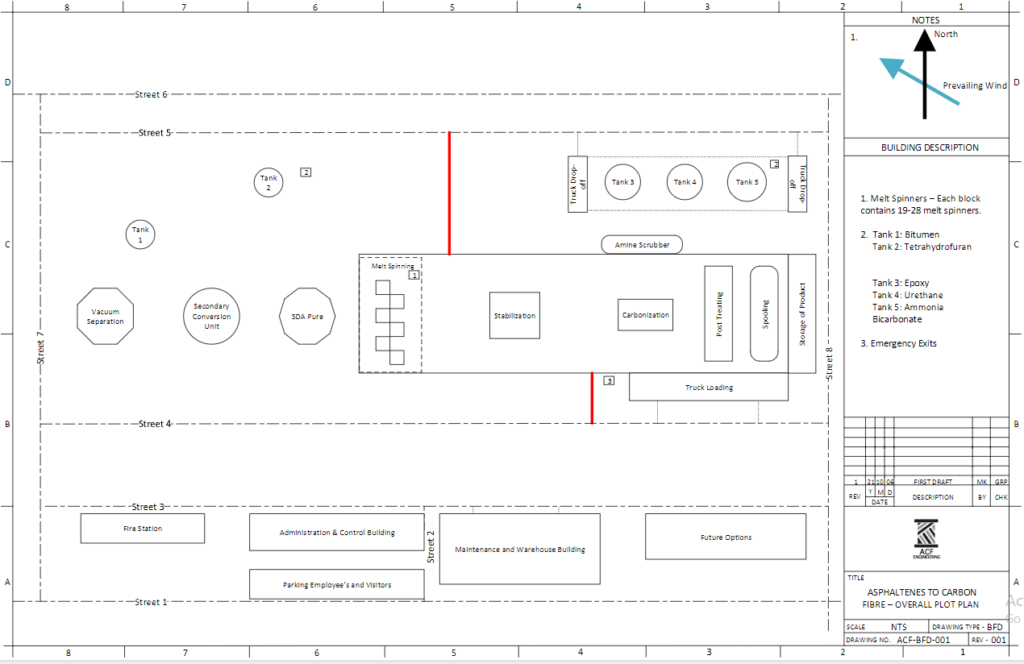

ACF Engineering developed the enhanced usability of the average Carbon Fibre into High-Performance Carbon Fibres that is both high producing and economically feasible. In today’s industry, the high cost of feedstock to produce carbon fibers, traditionally polyacrylonitrile (PAN), has been a major economic factor in market use. However, ACF Engineering implemented the design of High-Performance Carbon Fibres by using asphaltenes, which is a by-product from heavy oil refining. This then reduces environmental impacts and create economic diversification with the availability of asphaltenes within Alberta.

Meet our team members

Taha Diwan

Tyler Horton

Mohsin Khan

Ayah Metwali

Asad Rehman

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

- SAGD applications of usage of the bottom of the barrel into high performance carbon fibre. The asphaltenes are not very usable and convertible into other materials. The disposal of asphaltenes can cause harmful effects on the environment with some reasons including their poor biodegradability.

- Our process address this issue by using those asphaltenes and converting them into carbon fibres used for transportation, aerospace, and more and addressing a need for high performance carbon fibre in an industry dominated by PAN.

WHAT MAKES OUR DESIGN INNOVATIVE

- The creation of high-performance carbon fiber (HPCF) is an intricate process which utilizes six units to refine raw bitumen towards viable HPCF. The way our process is innovative is due to the nature of refining bitumen into 98% wt carbon concentration and removal of impurities and metals from the surface of the carbon.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

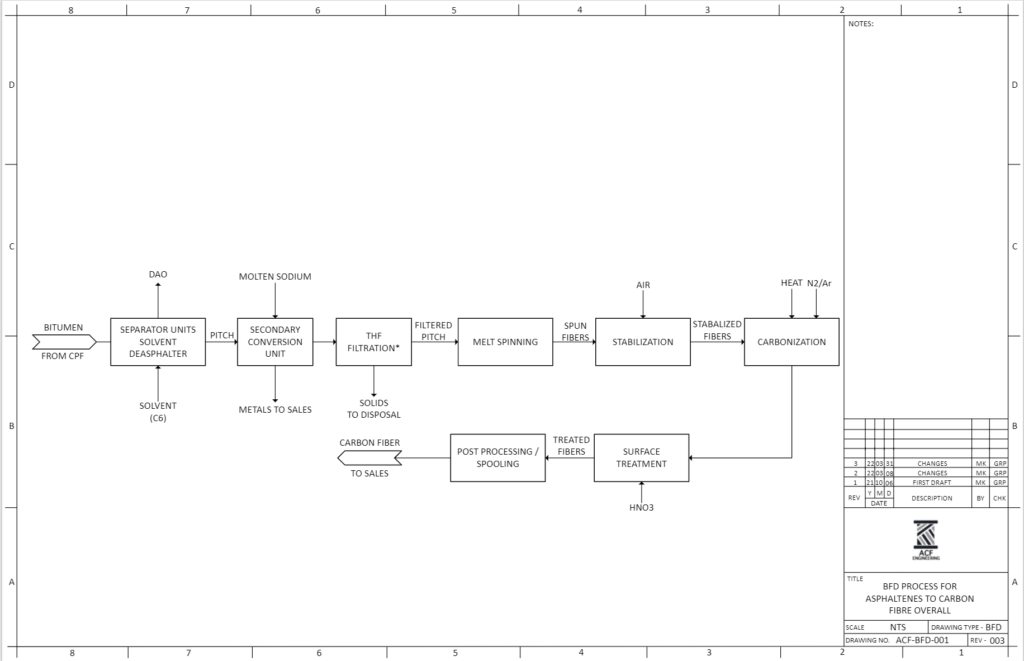

Process Overview

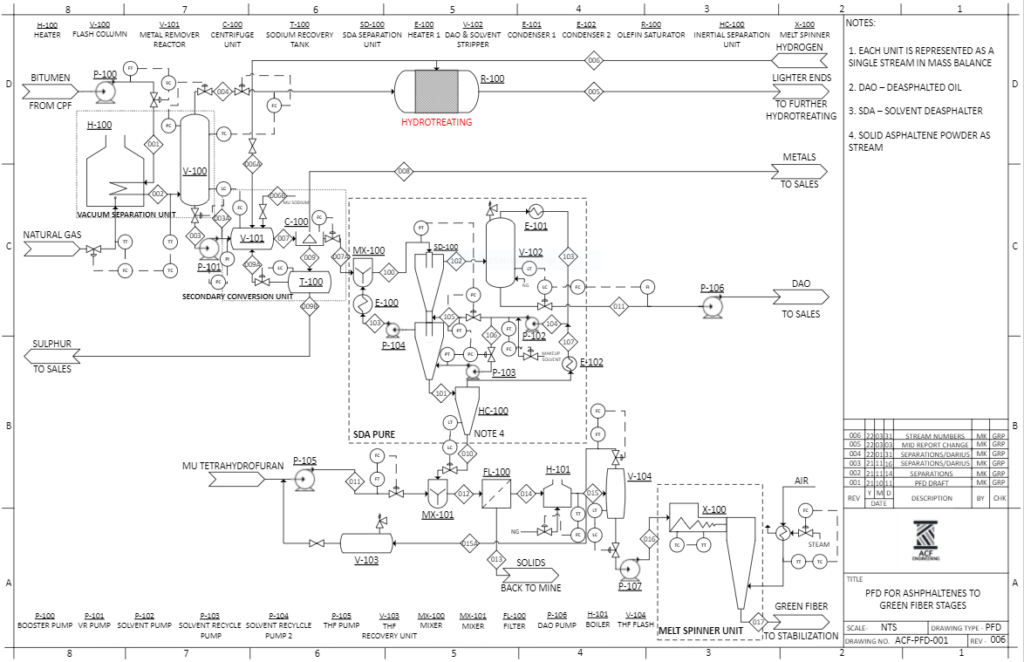

Vacuum Separations Unit

- We have fresh Athabasca Thermal Bitumen that is pumped through a booster pump into a fired heater to heat up the bitumen to appropriate temperature. This heated bitumen will start to separate the lighter components, which is then fed into a vacuum column to further separate the 2-phase stream from lighter hydrocarbons and olefins as vapours to the heavy hydrocarbon known as vacuum residue. The lighter hydrocarbons and olefins can be further treated in a hydrotreater and sold off as product, where the vacuum residue is further sent along the process to get more asphaltenes.

Secondary Conversion Unit

- This important unit in the CF process utilizes the addition of molten sodium and hydrogen to remove heavy metals such as vanadium, nickel, iron, and sulphur to purify the vacuum residue as desulphurized oil. The main objective is to allow the sodium to preferentially select out the metals and sulphur, leaving behind the vacuum residue with hydrogen capping the open bonds of the hydrocarbons. A centrifuge is used to allow gravitational separation of the desulphurized oil and metals, where the reaction between sodium and sulphur as Na2S can be sent into an electrolytic cell to separate the sodium and used as a recycle for additional vacuum residue coming in. The separated sulphur out of the electrolytic cell can be sold as a product.

Solvent Deasphalting Unit

- With a cleaner desulphurized oil being mixed in with hexane (solvent) it enters the main separations section to differentiate asphaltenes from deasphalted oil (DAO). As the oil is mixed in with the solvent, it enters a 3-stage separations unit as solvent is being pumped into the three zones, which the first separation zone separates out the DAO from the asphaltenes, the middle section injects fresh solvent, and the bottom section clarifies the asphaltenes from remaining DAO. The DAO is then sent to a solvent stripping system to recover solvent and the DAO can be sold as a product, whereas the asphaltenes are sent to an inertial separation unit to separate out the remaining solvent and the asphaltene will precipitate out as solid powder. Solvent is continuously recycled, and fresh make-up solvent can be injected to increase solvent to oil ratio.

THF/Filtration Unit

- The addition of tetrahydrofuran (THF) as a solvent helps the filtration aspect as it is sent through a sintered metal filter to remove fines, clays and other particulates which would cause the purity of carbon concentration to drop. The THF is flashed off at 70°C and is recycled, and the asphaltene powder is sent into the melt spinning.

Melt Spinning

- The solidified powder is extruded going up to temperatures as high as 350°C. The melted material is then sent to a spinneret containing multiple individual capillaries that send out the melted fibres into filament strands. There will be a quenching region between the capillaries and the take-up winder to form solid strands targeting an exiting diameter of 16µm that will be sent into the stabilization unit.

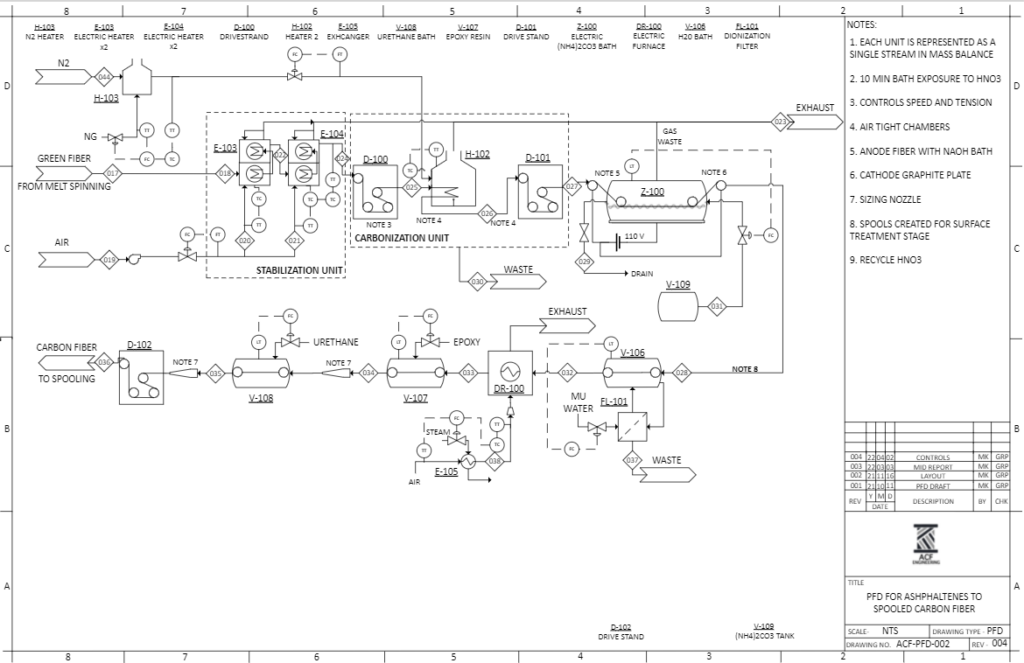

Stabilization

- Melt spun green fibres are immediately subjected to a process called stabilization in which the green fibre is heated under an overflow of oxygen to cross link individual asphaltenes. The stabilization process occurs within four isothermal ovens that ramp the green fibres temperature from 100°C to 300°C over the course of 45 minutes. Temperature is increased gradually to ensure that oxygen can diffuse to the centre of the fibre. Ramping up temperature too fast causes oxygen to react on the surface instantly, drastically limiting the rate of diffusion, resulting in uneven oxidation.

- Stabilization is the most energy intensive process in carbon fiber manufacturing. Conventional ovens operate for approximately 6-8 hours, utilizing about 8 MW of energy. Therefore, ACF Engineering will be using the latest ovens from Despatch which brings down the total residence time to 45 minutes for four ovens. This contributes to approximately 90% in energy savings.

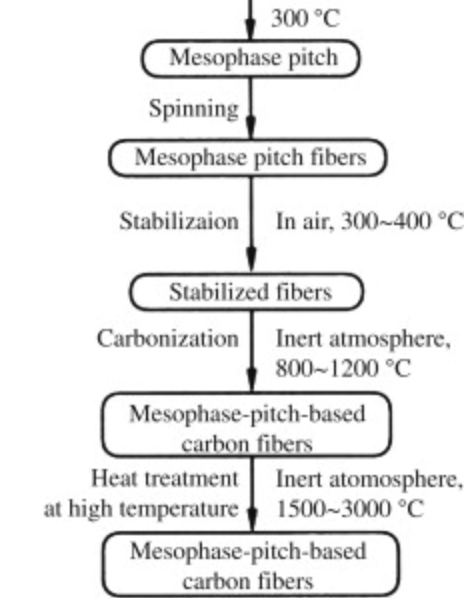

Carbonization

- In order to produce almost pure carbon fiber (97% + Carbon wt. %), we heat the oxidized fibers to 1800°C to volatilize any non-carbon component. To ensure the fibers do not break due to thermal shock, the fibers are heated using 5 heating zones that operate at, 500°C, 800°C, 1000°C, 1400°C and finally, 1800°C. The incremental heating increases the axial orientation of the carbon molecules leading to high strength alongside ensuring minimal thermal shock.

Surface Treatment

- Since carbon fiber is chemically inert, the surface must be treated to increase the fibers bonding properties. A 4 wt.% solution of ammonium bicarbonate is used to treat the fibers for 10 seconds with a charge density of 125 As/m2 applied across the Fiber; this breaks an electron free leading to a reaction with the ammonium bicarbonate resulting in a higher concentration of carboxyl groups found on the surface. The surface is then washed and dried before being coated with a 1µm coating of epoxy and a 0.25µm urethane coating. The coating saves the product from being damaged as well as increased bonding to other materials.

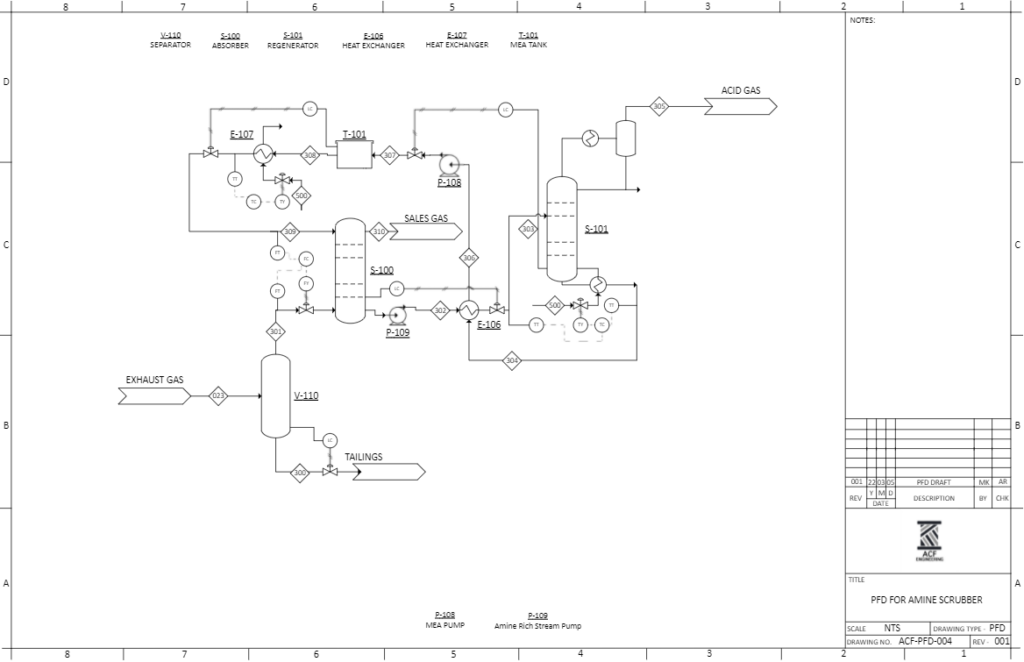

Amine Scrubbing Unit

- Due to the release of high concentrations of H2S and CO2 in the waste gas from carbonization, an amine scrubber is used to sweeten the gas prior to venting. A 24 wt.% solution of mono-ethanolamine (MEA) was chosen for this task since the high reactivity of this compound can scrub CO2 alongside H2S. Using 8 theoretical stages absorbing and a 6 theoretical stage regenerating column with a loading ratio of 0.39kmol acid gas/kmol of amine we were able to scrub 97% of H2S and 81.90% of the CO2 in the waste gas from carbonization.

HOW WE VALIDATED OUR DESIGN SOLUTION

- Through literature review, patent review, simulations, and having industry experts to help validate design of our carbon fiber process plant. This includes unit sizing, hand calculations, various process simulating via Symmetry, material and energy balances, and PFDs.

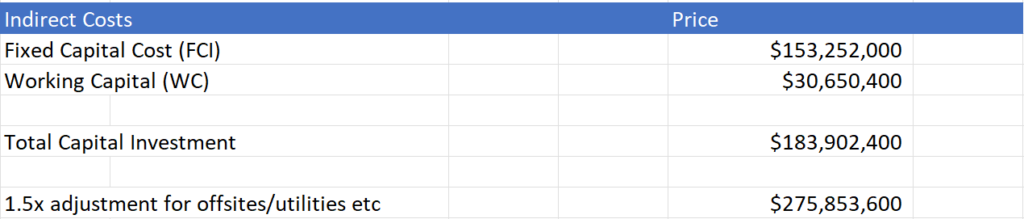

FEASIBILITY OF OUR DESIGN SOLUTION

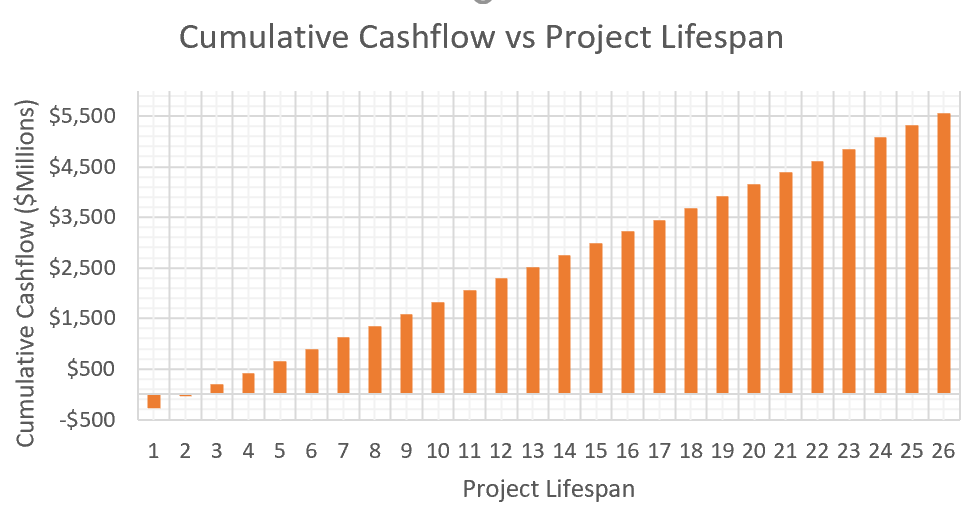

We have performed an economic analysis of our design to assess the feasibility of this innovative project. A capital cost estimation reveals that the total capital investment required to construct the plant is $183 million, with a discounted payback period of 2.8 years. We anticipate our internal rate of return (IRR) to be 54.42%. Our analysis also shows a net present value of $496 million, indicating financial viability – which is based on a continuous in-flow of investment cash of $238 million.

Partners and mentors

ACF Engineering would like to thank the following individuals for their limitless support in the assistance of this project:

Our clients Dr. Darius Remesat and Derrick Bakuska for their knowledgeable experience in industry and taking the time out of their busy schedules to guide us through the industrial standards and processes.

Additionally our supervising professor Dr. Qingye Lu for providing useful constructive feedback and the availability for providing any type of inquires to the requirements of our design.

Our photo gallery

References

Guida, Paolo, et al. “Chemical Kinetics of Asphaltene Pyrolysis.” ACS Publications, https://pubs.acs.org/doi/10.1021/acs.energyfuels.0c04358.

Leistenschneider, Desirée, et al. “A Mechanism Study of Acid-Assisted Oxidative Stabilization of Asphaltene-Derived Carbon Fibers.” Carbon Trends, Elsevier, 8 Aug. 2021, https://www.sciencedirect.com/science/article/pii/S2667056921000675.

T. Corscadden, D. Remesat, and D. Denton, “Combined Process to Produce Both A Pipelineable Crude and Carbon Fiber from Heavy Hydrocarbon”, 16-Feb-2021.

T. Corscadden, J. Kearns, G. Diduch, D. Hocking, and D. Remesat, “Separation of solid asphaltenes from heavy liquid hydrocarbons using novel apparatus and process (IAS),” 22-May-2018.