Project Category: Chemical

Make plastic clean. Choose Pol-E Green.

Join our presentation

About our project

There is growing incentive every year to develop sustainable products and deviate from petroleum-based processes and products. While traditional plastic production has revolutionized the word it has come at the cost of polluting the environment and a large carbon footprint. With rising pressure on industries and governments to reduce greenhouse gas emissions and create sustainable processes, a growing market has emerged for bio-based polymers.

These polymers have the potential to replace conventional fossil-fuel derived polymers with environmentally responsible production, however at what cost?

Is it possible to use bio-based polymers to create plastic that is structurally and functionally similar to traditional plastic?

Economically, is there potential for high output or profitability?

Meet our team members

Our Design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

SUSTAINABILITY VS. FUNCTIONALITY, DO YOU HAVE TO CHOOSE?

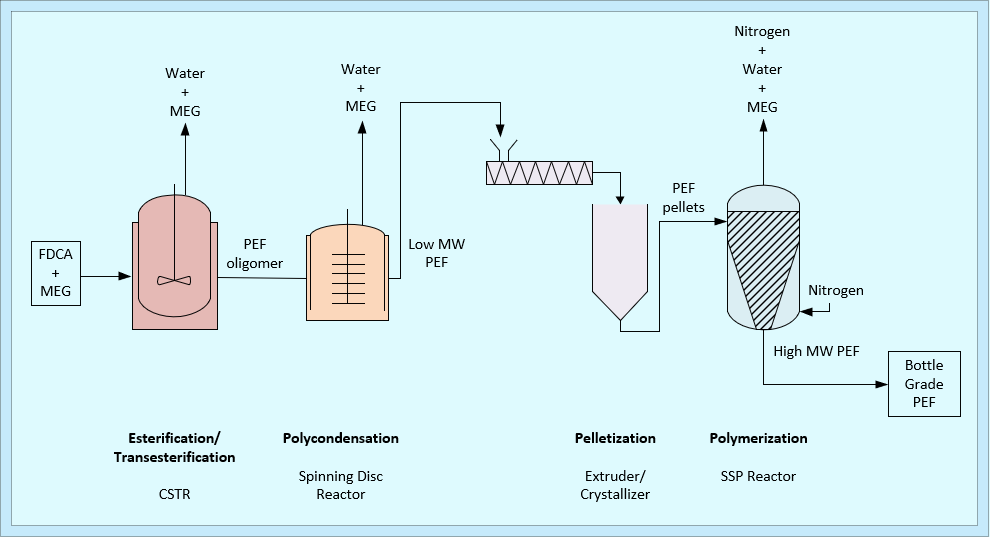

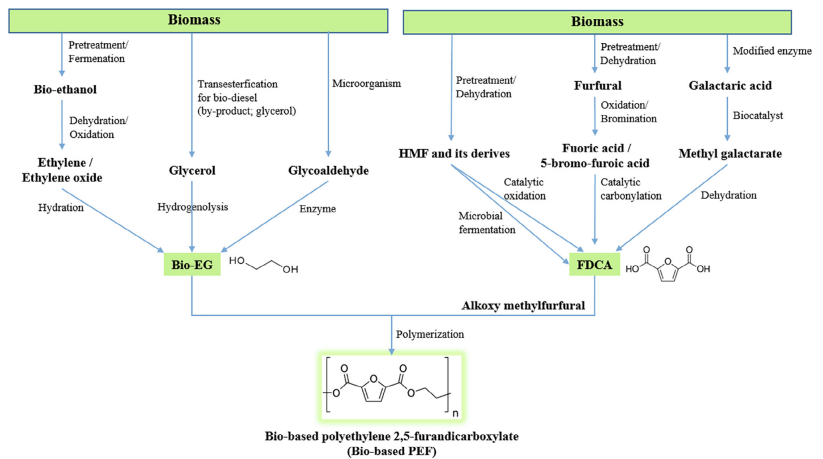

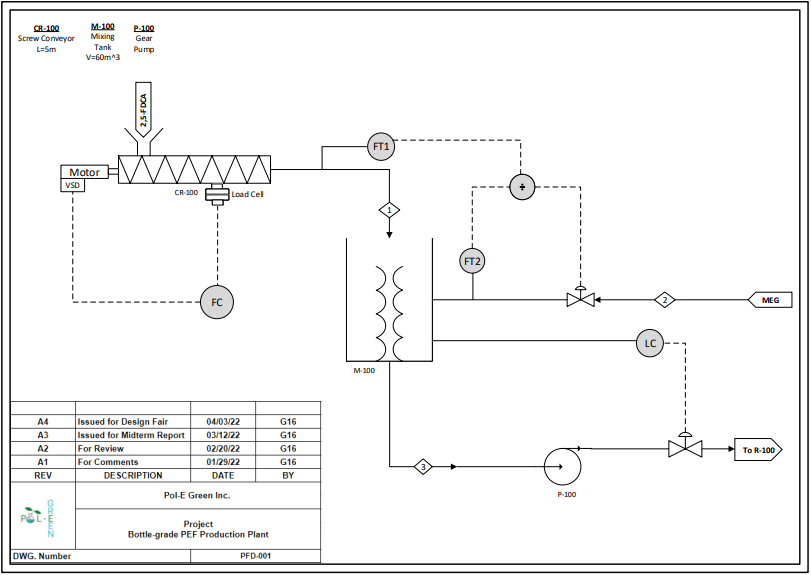

Our design replaces traditional petroleum-based packaging to mitigate environmental concerns and address rising sustainability issues through using bio-based polymers. The bio-based polymer we are creating is polyethylene furanoate (PEF). This polymer is created through the polymerization of two monomers, mono-ethylene glycol (MEG) and 2,5-furandicarboxylic acid (2,5-FDCA) with the biomass source being raw sugar.

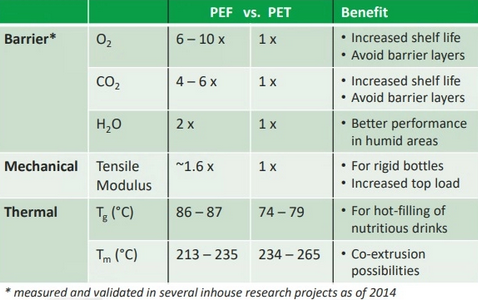

PEF is structurally and functionally similar to PET with a similar production process and reduces the need for multi-material functionality in packaging. It has superior barrier, mechanical, and thermal properties thus making it an attractive replacement. PEF has an increased shelf life compared to PET with better performance in humid areas and co-extrusion possibilities with the advantage of being 100% recyclable.

PEF is not classified as a hazardous material with no suggestion for bioaccumulation. Pol-E Green’s production of PEF and subsequent cooling is in place to prevent undesired exposure or reactions from taking place.

WHAT MAKES OUR DESIGN INNOVATIVE

PEF SHIFTS THE DEPENDENCY FROM FOSSIL FUELS

Pol-E Green identified a need for sustainably sourced and processed plastic that will not compromise on functional ability and structural integrity. The ability to not compromise on these two factors is what sets us apart. Through our production process a high quality grade of PEF is produced and allows for better bio-degradation/chemical recycling thus lowering overall lifecycle emissions.

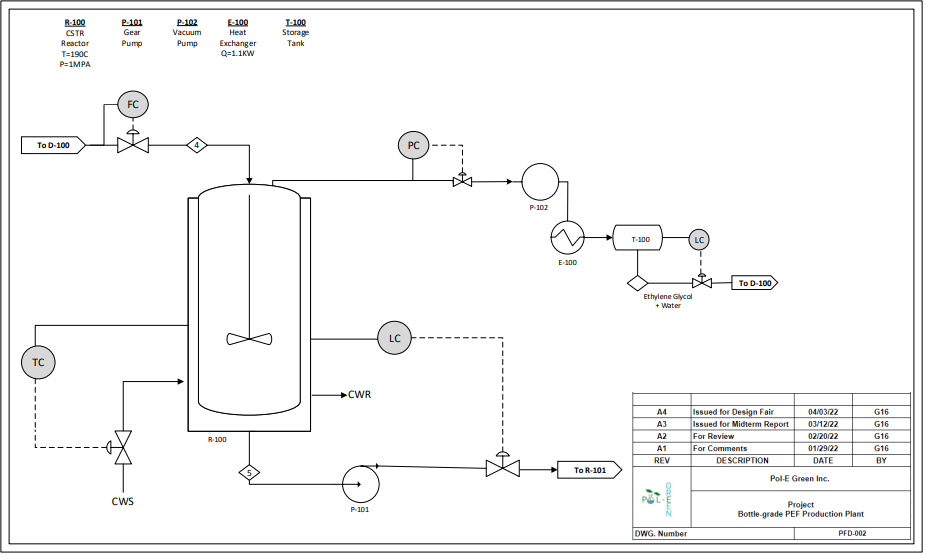

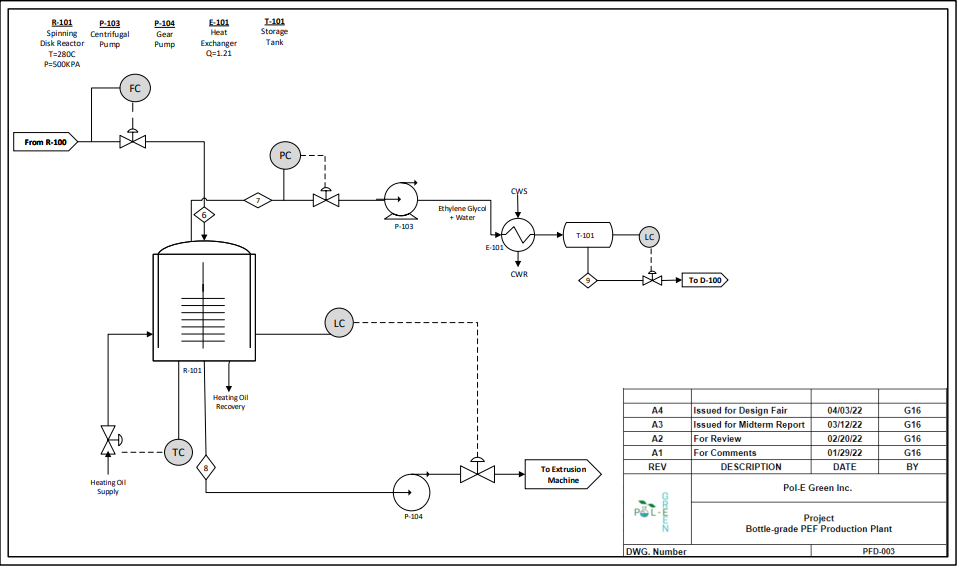

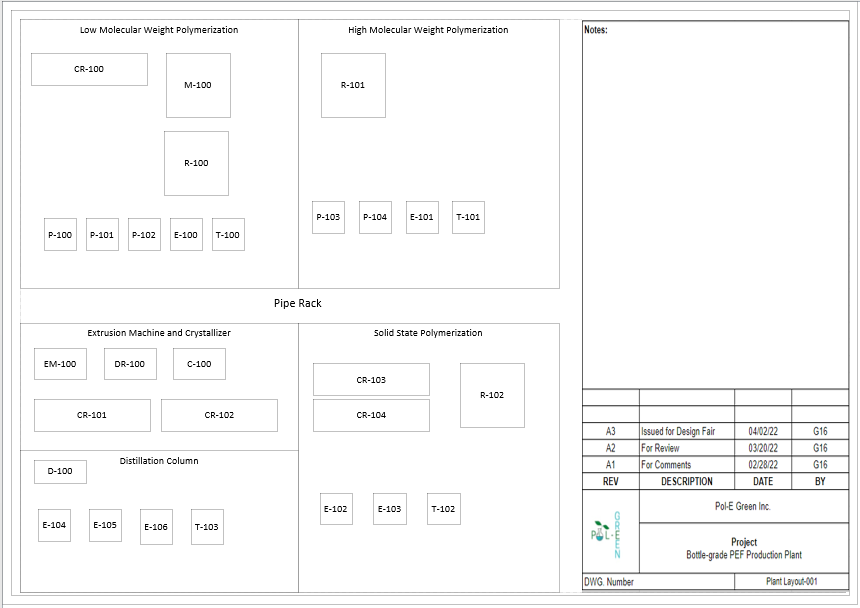

The reactors used in our process also differentiate Pol-E Green from other companies through the use of unconventional reactors that increase product grade, conversion, and mass and heat transfer. The two unique reactors we are using are the spinning disc reactor (SDR) and the solid state polymerization reactor (SSP).

The SDR was chosen in order for increased mass transfer and heat transfer coefficients thereby decreasing the residence time needed for reaction thus improving conversion. This reactor allows us to have a continuous process as opposed to the currently used batch process.

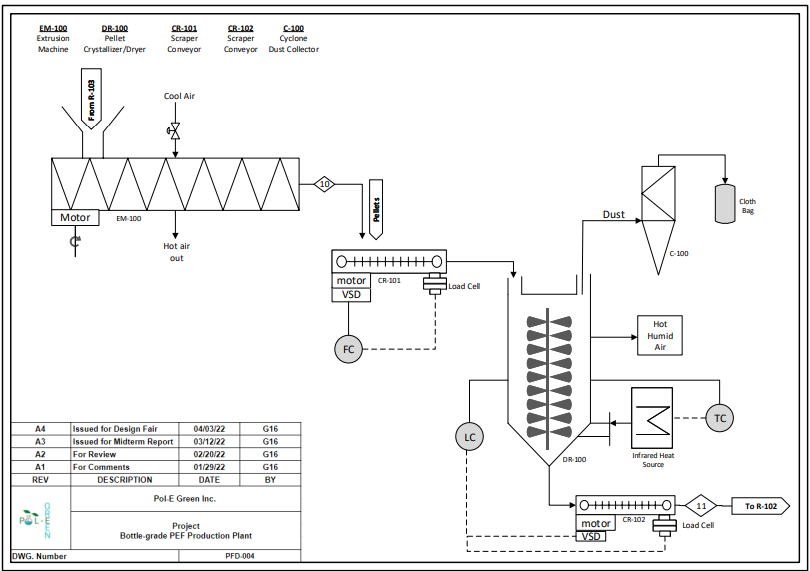

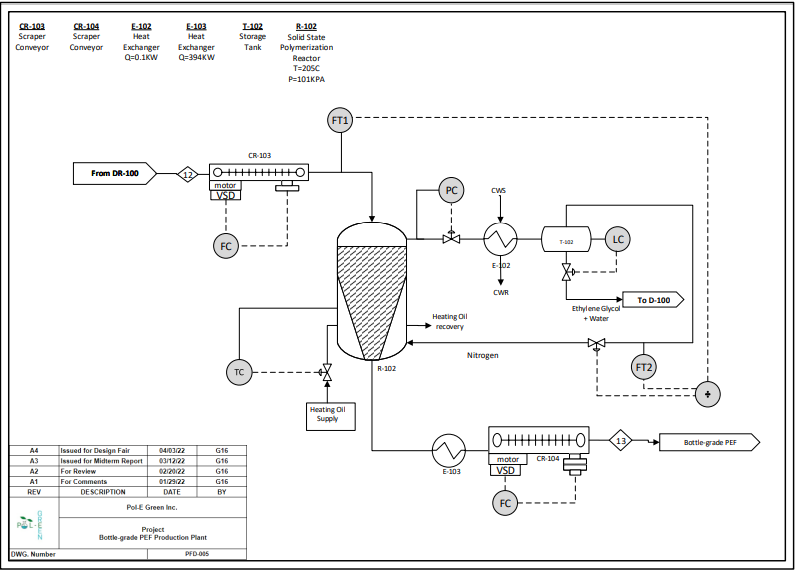

The SSP was chosen in order to reach bottle-grade PEF which is a minimum molecular weight of 30kg/mol. The SSP reactor further polymerizes the solid pellets and the longer residence time ensures that more of the by-products of ethylene glycol and water diffuse into the carrier gas and exit the reactor.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

ENVIRONMENTALLY CONSCIOUS AND HIGH QUALITY PRODUCTION GO HAND-IN-HAND AT POL-E GREEN

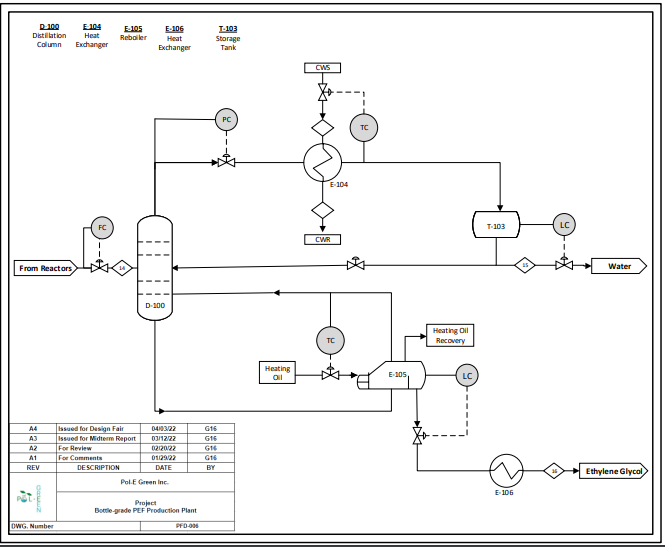

Pol-E Green boasts a design solution that produces high quality PEF while ensuring our production process is renewable and environmentally conscious, ensuring no high risk to ecological wildlife or the surrounding environment. Multiple polymerization reactions in our design increase the molecular weight of PEF, ensuring that the by-products of ethylene glycol and water are removed from the product until over 95% conversion is achieved. These by-products are then recycled back into our process, thus ensuring no waste and sustainability is kept at the forefront of our entire process.

Our selected monomers of MEG and 2,5-FDCA ensure our polymer is derived from renewable sources and our production process exceeds governmental regulations. PEF is not classified as a hazardous material so there is no high risk to ecological wildlife and the surrounding environment during the production process or bio-degradation. There need to be measures in place to avoid accidental release into the environment and water systems, however there is no suggestion of bioaccumulation for this product. PEF is chemically stable so it will be stored in cool, well-ventilated environments and in the case of an unwarranted release the appropriate measures will be observed, such as reporting it to the Alberta Environment Director and informing the community in the surrounding area and plant owner and operator.

Products made of PEF can easily be recycled or converted back to atmospheric CO2 by incineration. Eventually, that CO2 will be taken up by grass, weeds and other plants, which can then be used to make more PEF. PEF can be separated from PET by IR sorting and recycled to ‘rPEF’ using the same steps as PET (mechanical or chemical recycling).

HOW WE VALIDATED OUR DESIGN SOLUTION

NOVEL PROCESSES REQUIRE INNOVATIVE MODELLING SOLUTIONS

Extensive theoretical research was needed to understand how to model our design and incorporate the SDR and SSP reactors. The kinetics of PEF production and design equations were based on critical assumptions and an understanding of how PET is formed in current industry. As PEF is formed through solid polymerization the majority of software available was unable to model our design process and it was necessary to individually examine each reactor.

To validate these equations and assumptions MATLAB was used to model the differential equations and simulate different conditions. Significant changes were made to the design equations used in MATLAB based on constructive feedback received.

FEASIBILITY OF OUR DESIGN SOLUTION

DOES THE END JUSTIFY THE MEANS?

While renewable and sustainable plastic alternatives are needed and necessary in the world, the hard reality is that without economic profitability traditional petroleum-based products will not be replaced. Will the Pol-E Green design break through this barrier?

As PEF is an upcoming bio-polymer and our design uses unconventional reactors a pilot plant is necessary to test commercial SDR and SSP reactors. At present, this design is not feasible due to economic and design challenges. However, extensive research shows that in the future it will be viable through technological advancements, increased investments and higher environmental awareness.

Capital and operating cost estimations were done by analyzing PEF at an annual production rate of 50kt/yr, and a discounted cumulative cash flow (DCCF) analysis was performed using Excel. Our minimum selling price is $2.70 USD/kg.

Table 1: Financial Indicators and Values

| Financial Indicators | Financial Values |

| Total Capital Investment (FCIL+L+WC) | $78M CAD |

| Net Present Value | -$25M CAD |

| Discounted Rate of Return | 2.52% |

| Discounted Payback Period | 30 years |

| Annual cost of manufacturing | $68M CAD |

| Projected Cash Flow over the lifetime of the project | $550 M |

Partners and mentors

We want to thank the many people who helped us with this project. Our mentor and capstone supervisor Dr. Kunal Karan guided us throughout the entire process with patience and great advice. The feedback received from Dr. Hector De la Hoz Siegler and Dr. Michael W. Foley was invaluable to our engineering design experience.

Our photo gallery

References

- Polyethylene furanoate (PEF) – The rising star amongst today’s bioplastics. https://omnexus.specialchem.com/selection-guide/polyethylene-furanoate-pef-bioplastic (accessed Oct 1, 2021).

- Hydrodynamic voltammetry. https://www.ceb.cam.ac.uk/research/groups/rg-eme/Edu/hydrodynamic-voltammetry (accessed Oct 3, 2021).

- Hwang, K.-R.; Jeon, W.; Lee, S. Y.; Kim, M.-S.; Park, Y.-K. Sustainable Bioplastics: Recent Progress in the Production of Bio-Building Blocks for the Bio-Based next-Generation Polymer PEF. Chemical Engineering Journal 2020, 390, 124636.

- Loos, K.; Zhang, R.; Pereira, I.; Agostinho, B.; Hu, H.; Maniar, D.; Sbirrazzuoli, N.; Silvestre, A. J. D.; Guigo, N.; Sousa, A. F. A Perspective on PEF Synthesis, Properties, and End-Life, 2020.