Project Category: Chemical

Join Our Presentation

The Capstone Design Fair zoom link will be active between 10am and 12:30pm.

Meeting ID: 973 9973 5941

If technical difficulties are encountered please contact heather.booth@ucalgary.ca.

About Our Project

Reducing carbon emissions to slow or halt the effects of climate change is of the utmost importance for securing a sustainable future. This has sparked renewed interest in developing low-carbon energy. Hydrogen has enormous potential as an energy carrier due a variety of emerging technologies that promise low carbon or carbon-neutral production. Because blue hydrogen has reached industrial maturity, it is leading the way.

Blue hydrogen is an extension of fossil fuel-derived gray hydrogen with the key addition of an appended carbon capture unit that redirects a majority of direct CO2 emissions. Combining this with strategies for carbon usage and sequestration is known collectively as carbon capture, utilization, and storage (CCUS). To what extent this adaptation yields an overall reduction in the global warming potential of hydrogen was fully investigated during the duration of our project.

Meet the Hamilton Consultants

Heather Booth

Heather is in her final year of chemical engineering with a biomedical specialization. Heather is currently completing an undergraduate thesis in which she studies the isolation of exosomes from mesenchymal stem cells. Heather contributed greatly to novel programs that informed reactor design and managed the project schedule.

Liam Boutin

Liam is completing his final year of chemical engineering. With experience gained while interning at Nutrien’s Carseland Nitrogen Operation, Liam’s knowledge of process simulation using Python was instrumental in the success of our design. Moving forward his mission is to improve the state of carbon capture technology, fueled by his passion for environmental conservation and his abilities in rigorous process design.

Thomas Bradley

Thomas is in his final year of chemical engineering. He completed an internship with CNRL and the experience he gained was critical in ensuring the success of the overall design, PFDs and P&IDs for the air separation unit in the project. Thomas will begin working as an EIT for CNRL starting in the fall.

Ioannis Kandilierakis

Ioannis is graduating from chemical engineering this year. His work experience includes a process engineering internship at Imperial Oil, supporting operations at the Strathcona Refinery in Edmonton. His business acumen was critical to the success of the economic evaluation and optimization of our design.

Mark Spahl

Mark is wrapping up his final year of chemical engineering after completing internships in digitalization and process optimization at BASF and R&D in the biopolymers department at Fraunhofer IAP, both in Germany. Mark was involved in the simulation of the reforming train and carbon capture units. Mark will be pursuing a PhD at the Laboratory for Metabolic Systems Engineering (LMSE) at the University of Toronto in the fall.

Details About Our Design

The Problem – Solving Practical Issues

Evidence dictates that blue hydrogen is an economically feasible option for hydrogen production in Canada due to the availability of low-cost fossil fuels and ideal geological formations to sequester captured CO2 [Minli et al., 2021; Gov. of Canada, 2020]. However, recent research has identified concerns about the life cycle carbon footprint of blue hydrogen [Howarth and Jacobson, 2021].

Our project aims to address this knowledge gap and produce a comprehensive examination of the carbon intensity of a blue hydrogen plant in Canada. To this end, a state-of-the-art blue hydrogen plant has been fully designed. In doing so, a typical blue hydrogen plant and its environmental impacts can be studied in detail and assessed for further improvement opportunities.

Our Solution – What Makes Us Effective

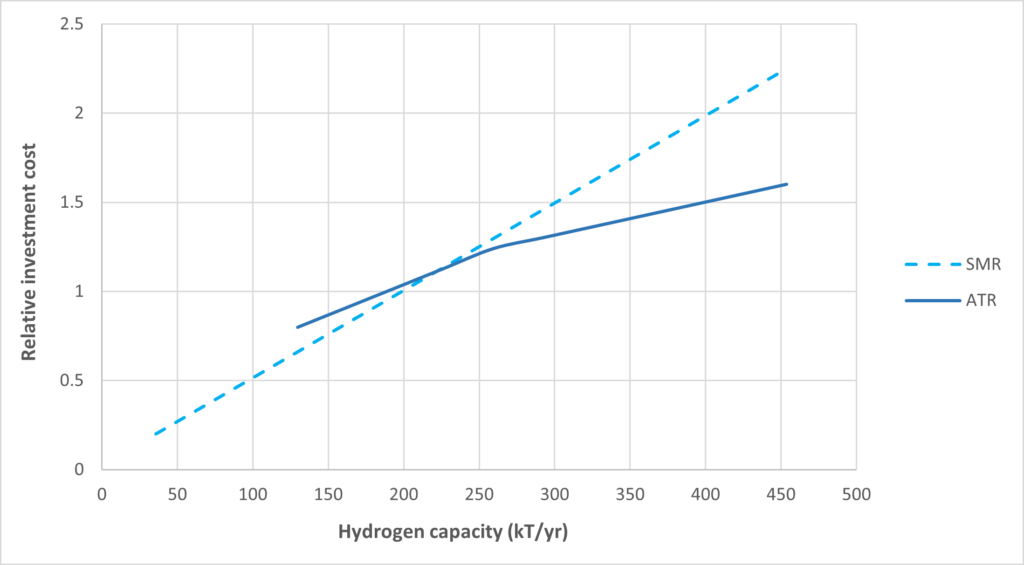

Hamilton Consulting has designed a blue hydrogen plant centered around an autothermal reformer (ATR). The proposed plant capacity of 310 000 tonnes per year of hydrogen takes advantage of the economies of scale that benefit autothermal-based blue hydrogen plants. Our plant will be located in the Greater Edmonton Area, as the region has many customers for our products and provides easy access to the Alberta Carbon Trunk Line (ACTL). This also allows our plant to be representative of future blue hydrogen ventures in Western Canada. Furthermore, the integration of an air separation unit allows for independent operation and export of product, effectively making our design a merchant plant.

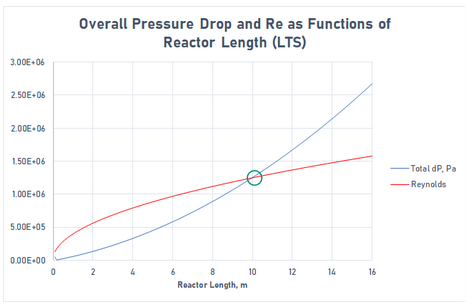

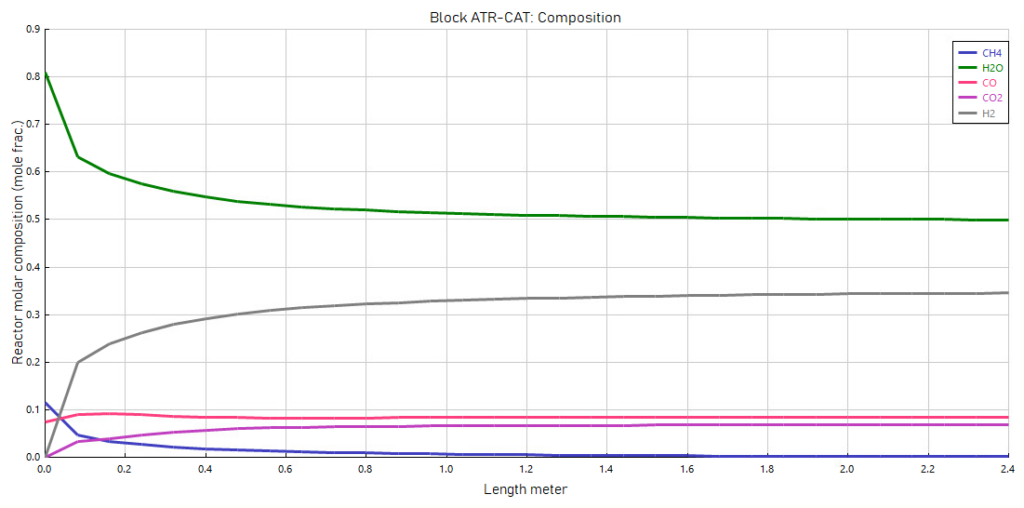

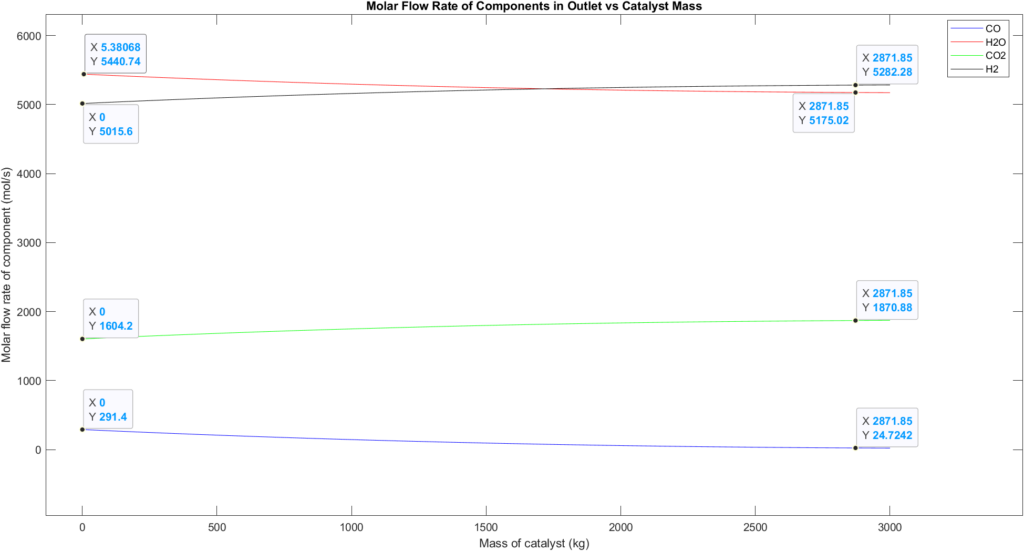

We have guaranteed the success of our design and solidified our confidence in its accuracy and precision by holding paramount rigorous design practices. In addition to modeling the plant in its entirety in Aspen Plus, we have validated equipment sizing with a series of novel MATLAB and Python programs. These programs were especially instrumental in guiding the design of each reactor within the plant, as well as the cyclical operation of the carbon capture unit.

Design Details – What Sets Us Apart

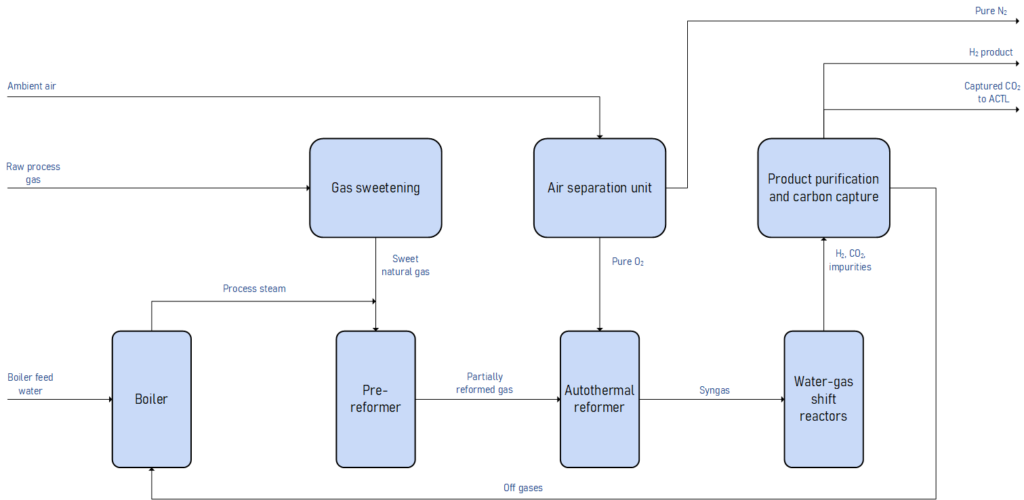

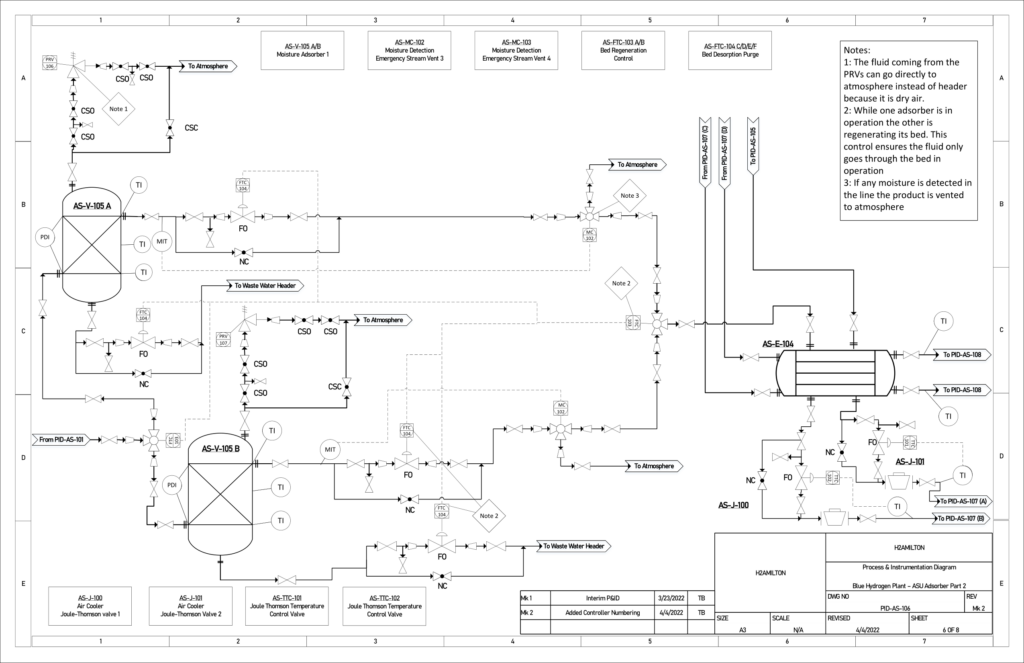

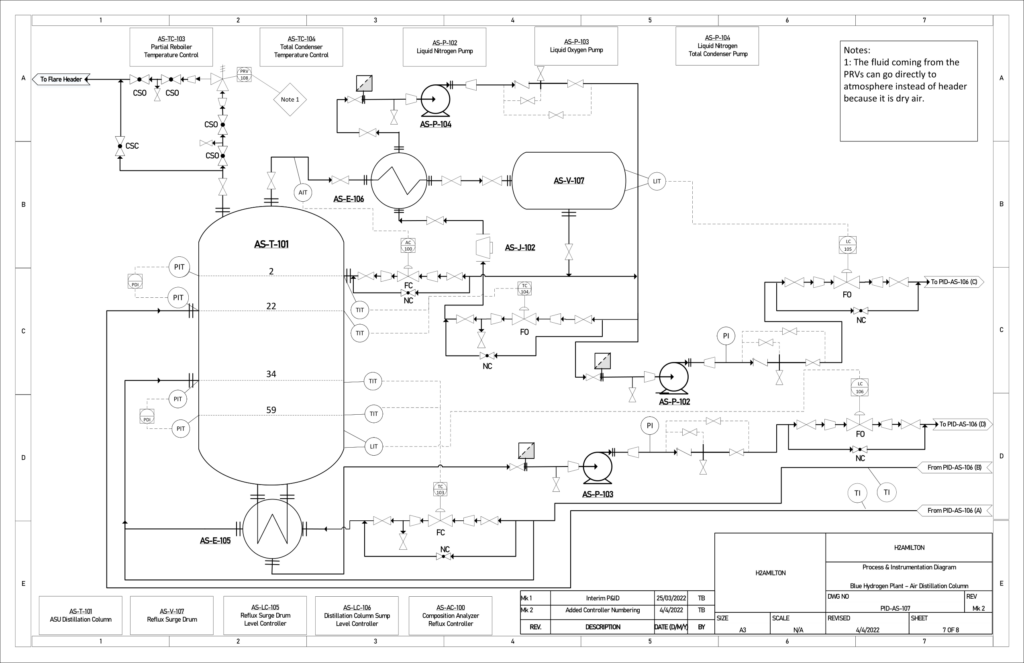

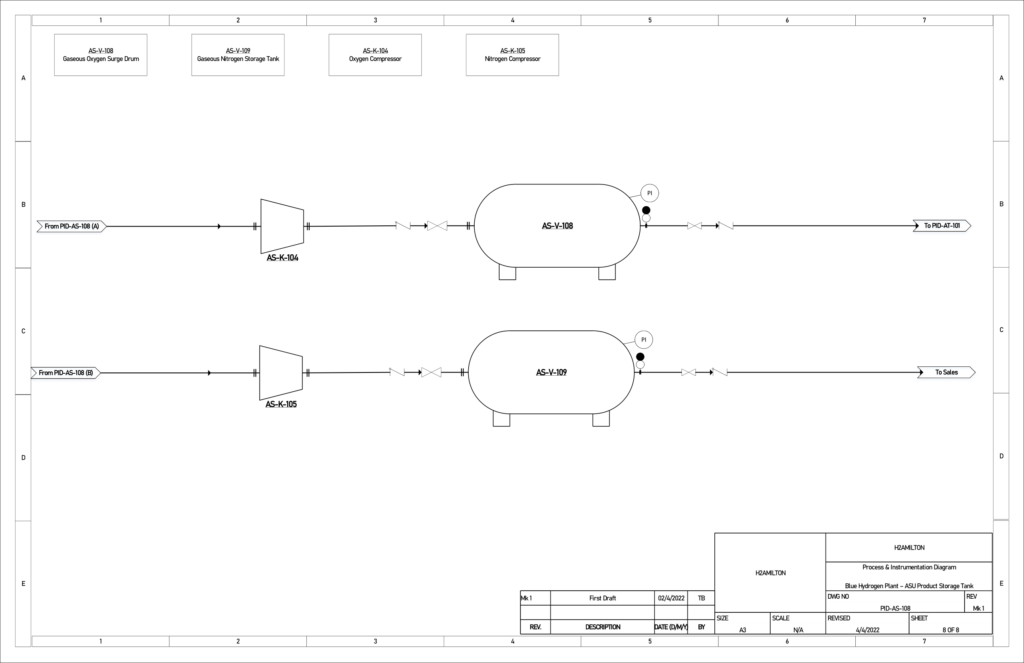

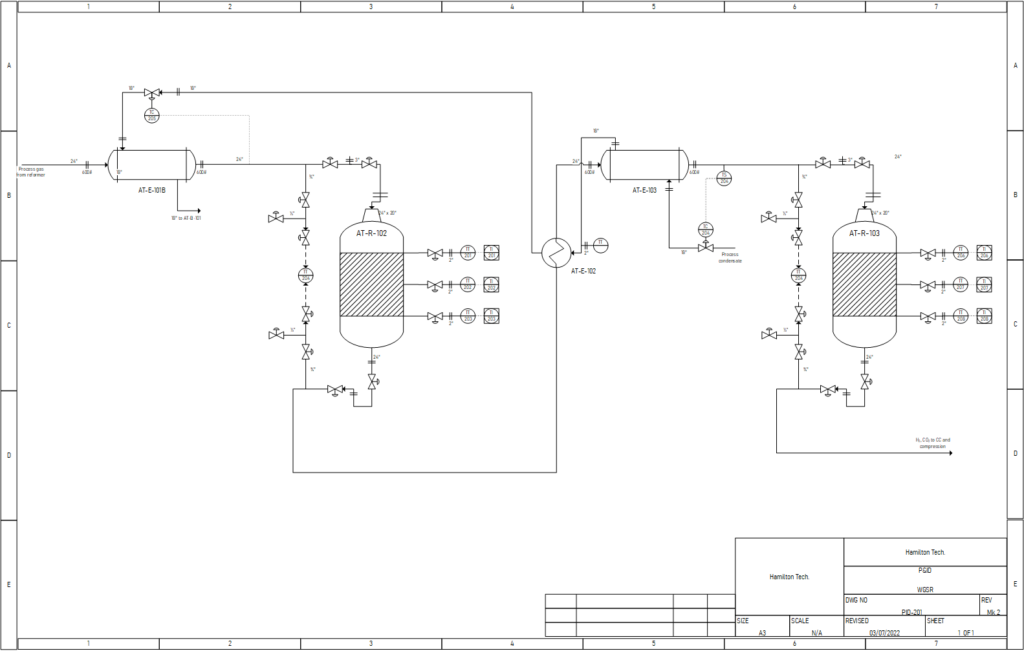

Our plant consists of three distinct sections – the reforming section, the air separation unit (ASU), and the carbon capture section. The reforming train converts our main feedstocks, steam and methane, to hydrogen and CO2. while fueled by a supply of pure oxygen. The oxygen is supplied by a standalone ASU, which produces it from ambient air, while also generating a stream of high purity nitrogen as a valuable byproduct. The CO2 produced by the reforming train is selectively captured by a vacuum pressure swing adsorber (VPSA) to be redirected for utilization or storage.

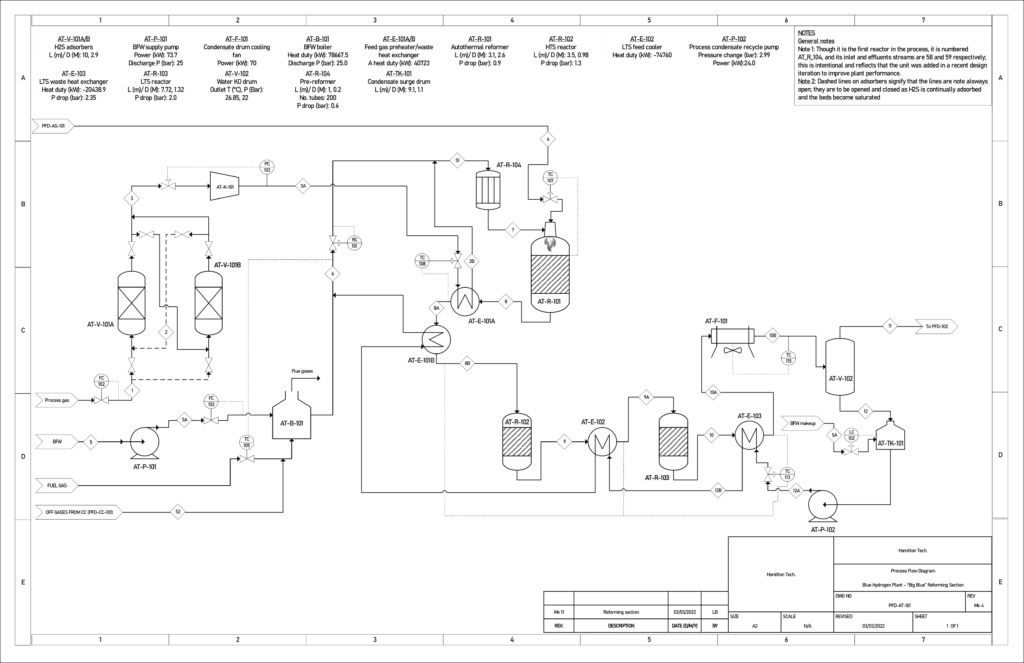

The Reforming Section

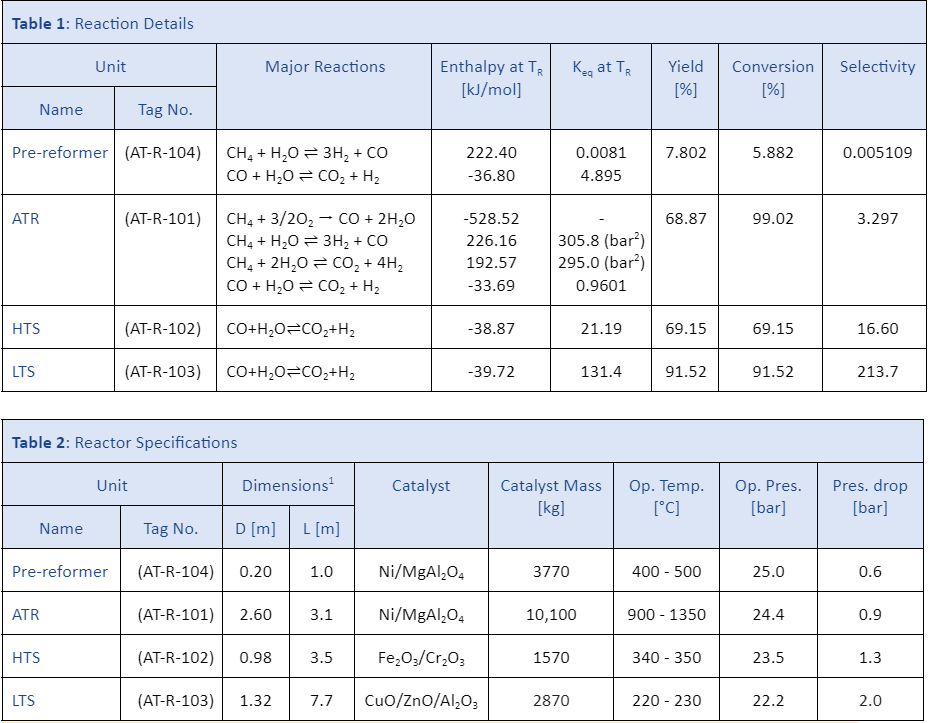

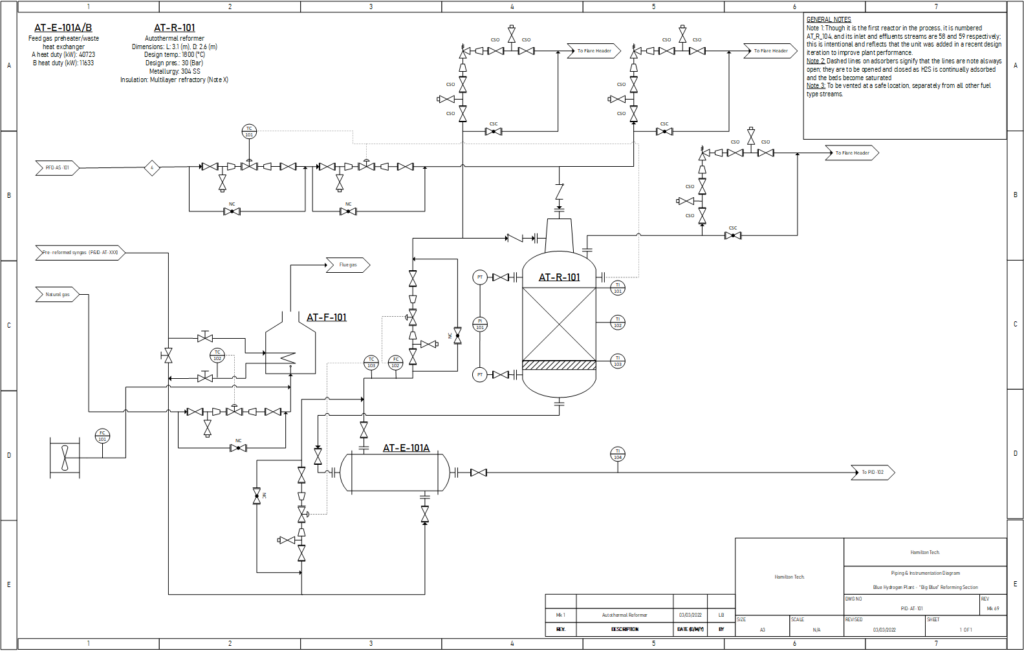

At the heart of our plant is the reforming train. Natural gas is first desulfurized, pre-heated, and partially reacted in the pre-reformer, before being sent to our primary reformer, the ATR. The ATR is central to this section, and is fueled by high purity oxygen and reforms natural gas and steam to yield a stream of synthesis gas, or syngas. This stream consists of our desired products of hydrogen and CO2, along with unreacted CO and excess water. High and low temperature water-gas shift reactors then convert this remaining CO and water to CO2 and additional hydrogen.

Where existing plants employ the traditional steam-methane reformers with an external furnace, our plant incorporates oxidation and combustion reactions into the main reformer, which allows us to capture over 90% of the CO2 we generate. Furthermore, the reactor provides all of its own heat (hence auto-thermal), this heat is conserved in the product stream, and is used to meet the heating duty requirements of several other pieces of equipment by way of heat integration.

The ASU

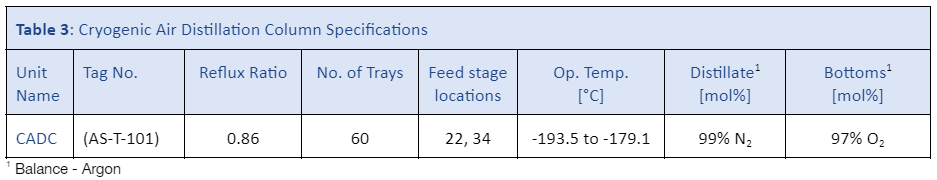

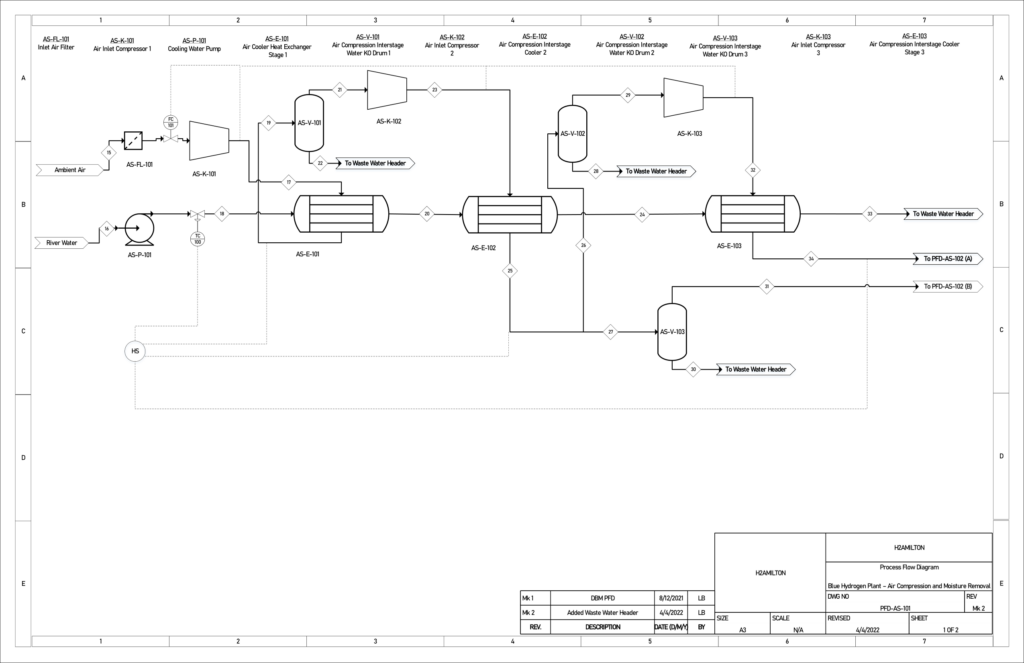

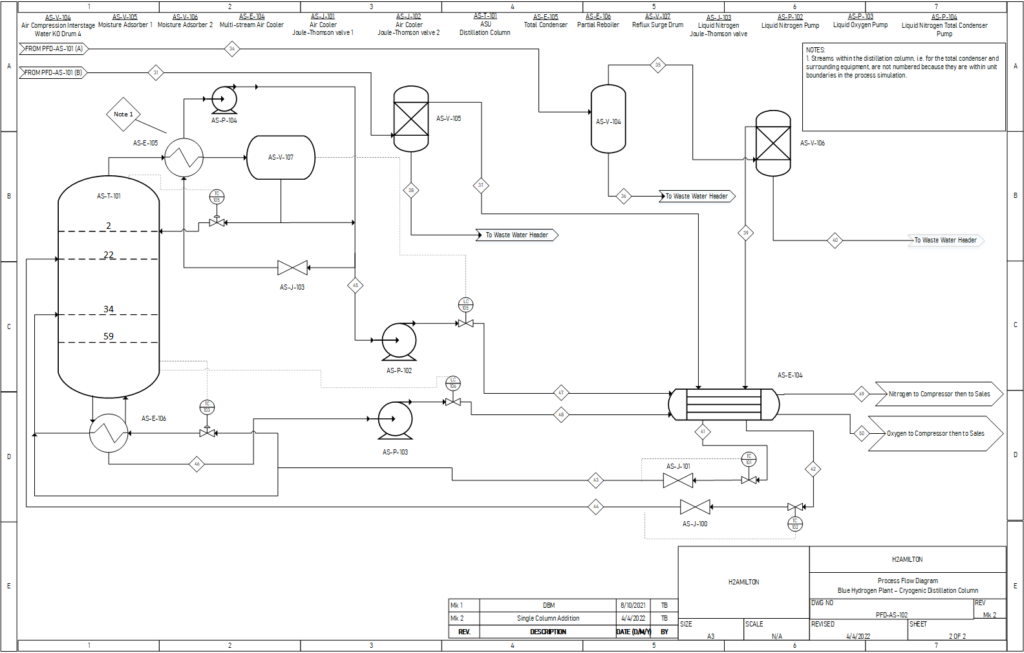

The ASU uses cryogenic distillation to separate oxygen and nitrogen from a stream of compressed dried air. Air distillation was chosen as a means to produce oxygen because it is the most cost-effective process when a high volume of oxygen and/or nitrogen is needed [Kolmetz, 2013]. The ASU meets the oxygen demands of the ATR and also produces valuable nitrogen as a by-product that can be sold to industrial customers in the area. Its operation can be split into 2 phases:

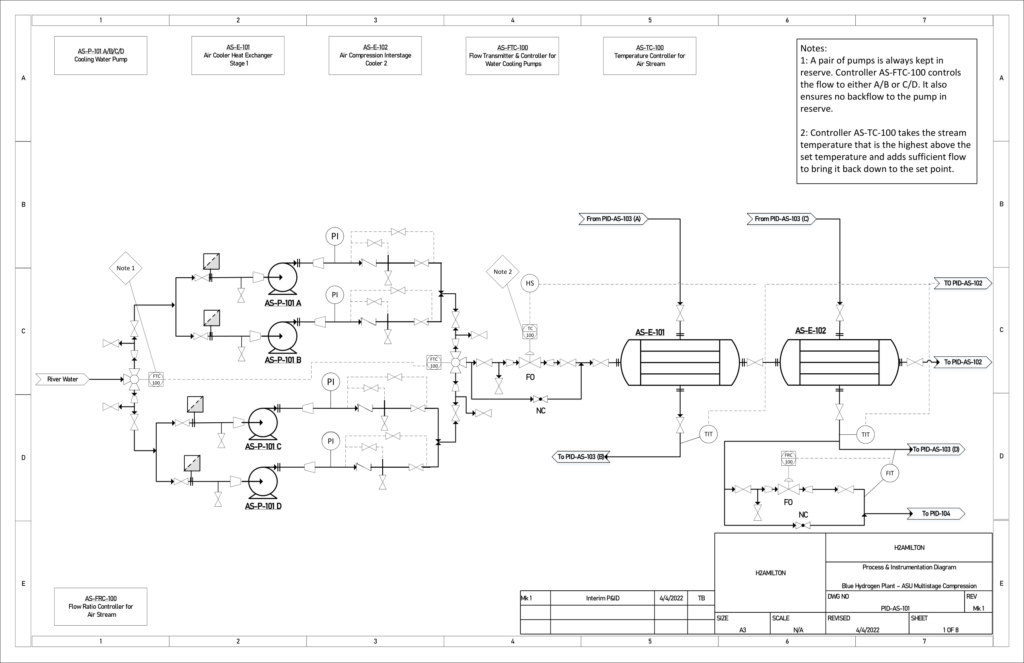

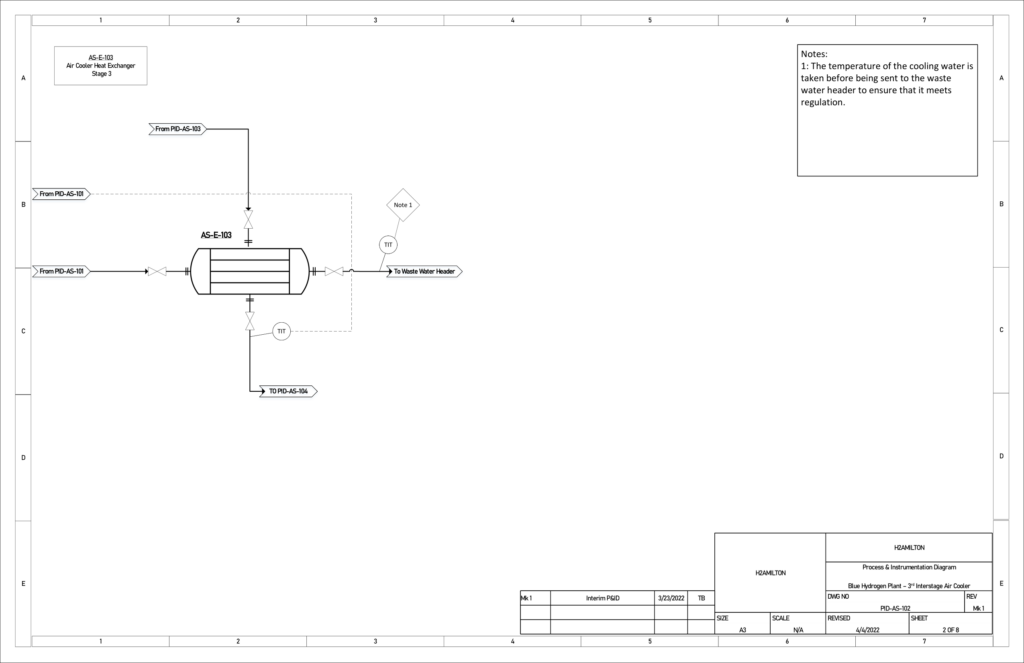

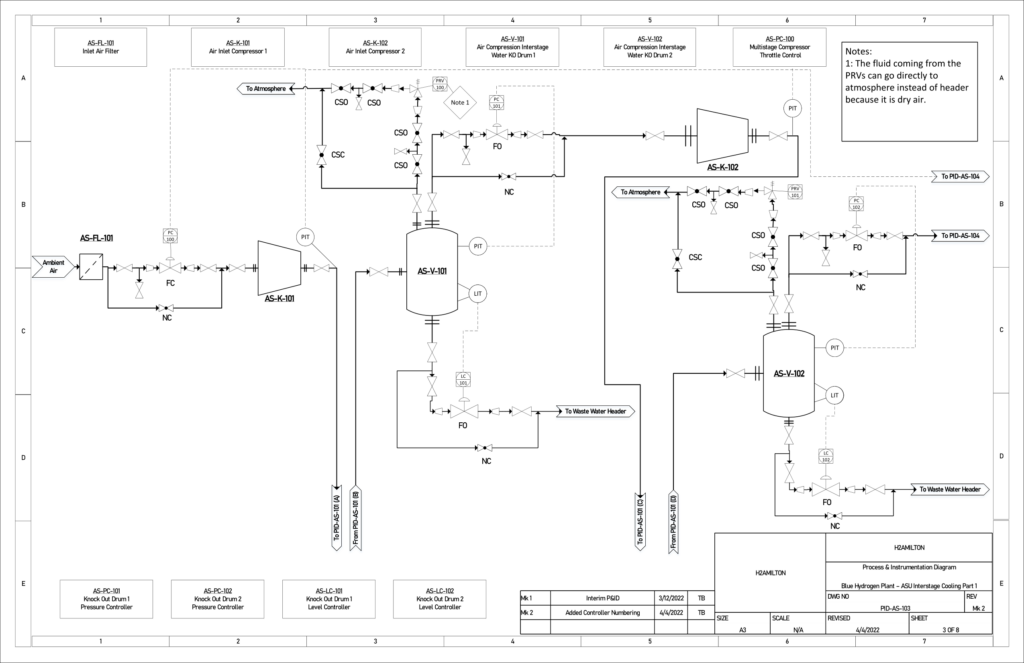

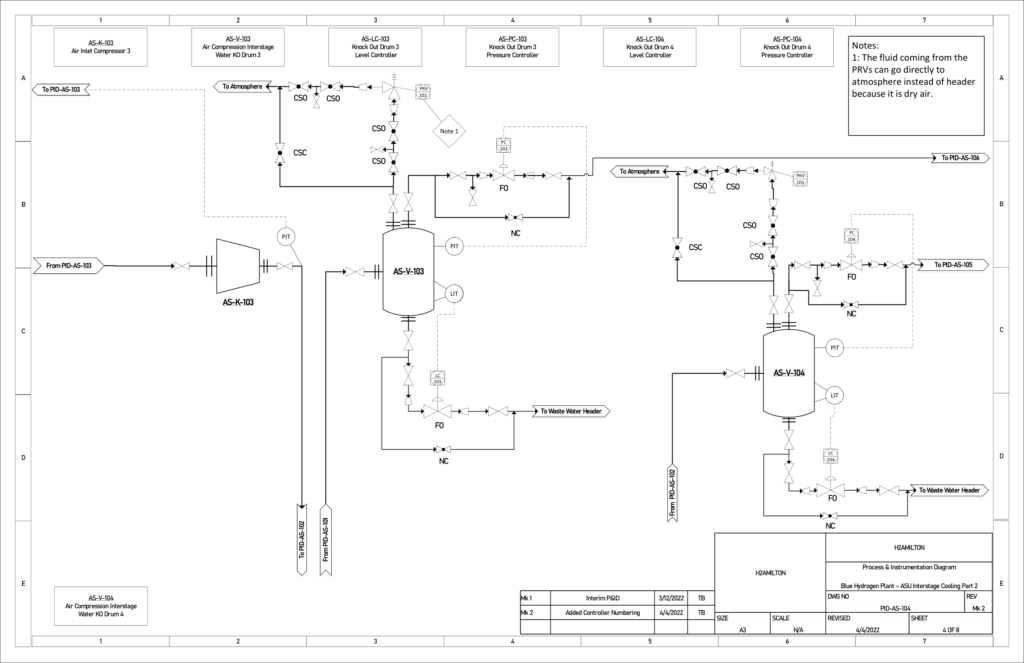

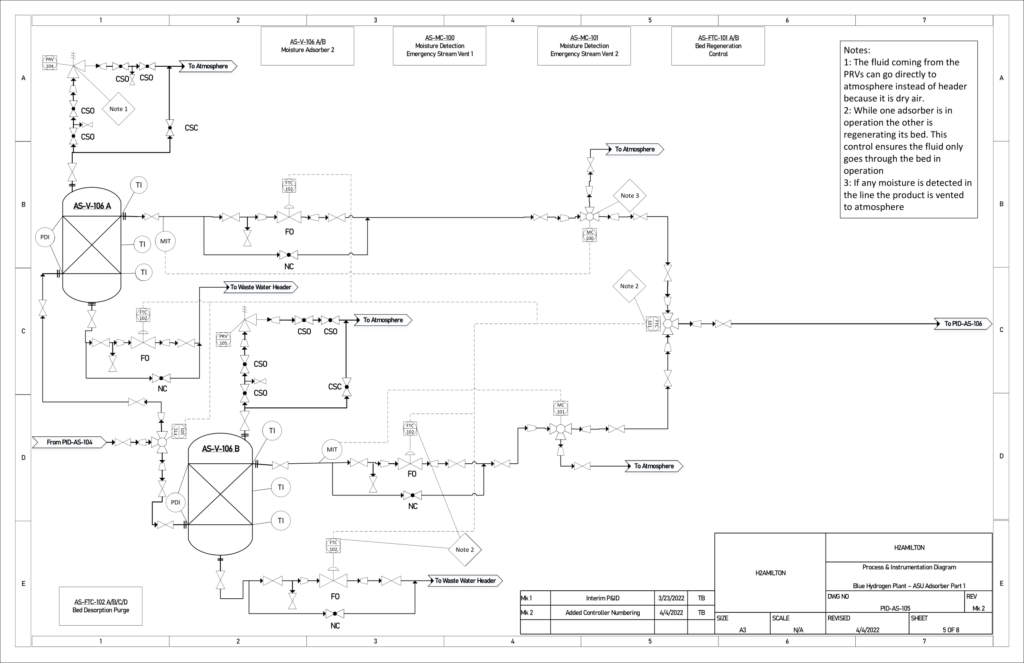

Phase 1 – Pressurization and Drying: In the first phase, air is pressurized and dried. This is done through 3 stages of compression facilitated by intercoolers and water knockout drums. The pressurized dry air then flows through an adsorber to remove any residual moisture before heading into phase two of the process – cryogenic distillation.

Phase 2 – Cryogenic Distillation: The dry air is first cooled via a multi-stream heat exchanger. The chilled air then passes through a Joule-Thomson valve for further cooling before being fed to the cryogenic air distillation column (CADC). The distillate product consists of high purity nitrogen while the bottoms product is high purity oxygen.

Heat integration has been extensively employed throughout the ASU, allowing for significant energy savings. Four path cross-flow sieve trays are used for the internals of the column due to savings in capital cost and their separation efficiency [Schoenmakers and Gorak, 2014].

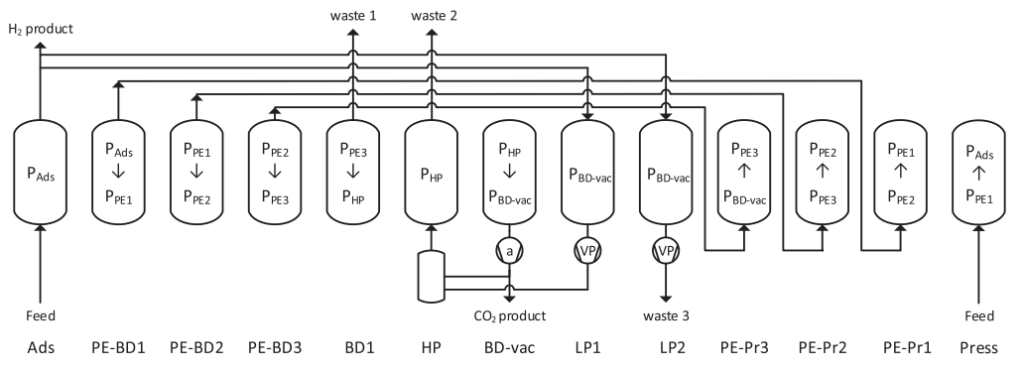

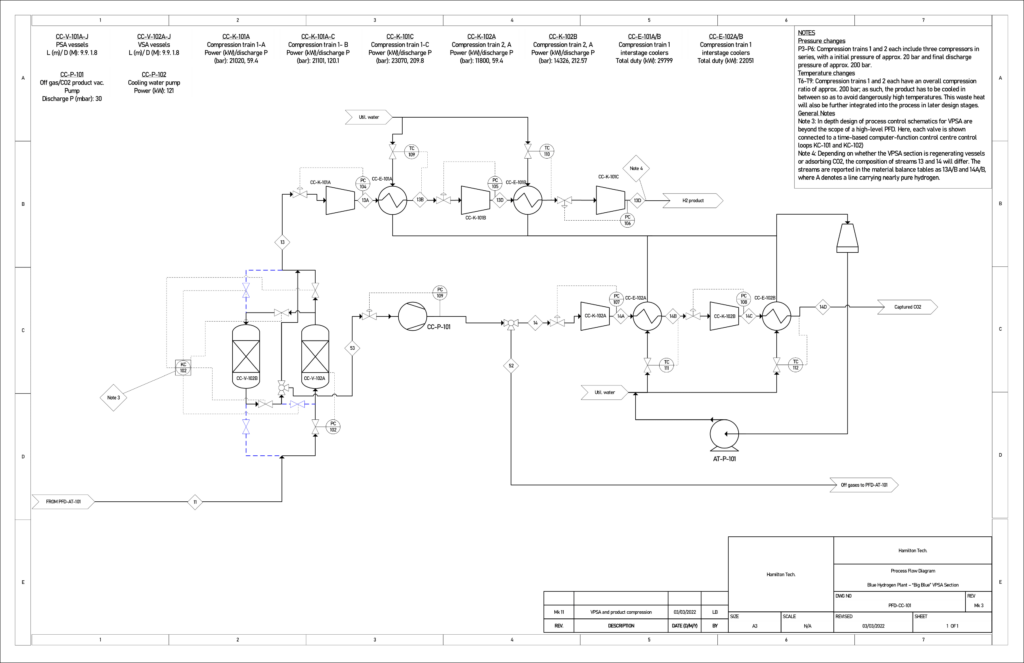

VPSA Carbon Capture

The stream of syngas produced by the reforming train consists almost entirely of hydrogen and CO2. With this final composition it is passed to a set of 16 VPSA vessels, which operate on a cyclic basis to continually and selectively adsorb CO2 and other impurities from hydrogen, yielding high-purity streams of each product. The cycle consists of a high pressure adsorption step to produce high purity hydrogen, pressure equalization and recycle steps, and a vacuum blowdown step at 30 mbar that produces high purity CO2.

VPSA is employed rather than traditional amine-based CO2 absorption due to significant advantages in lifetime costs, as well as plant energy efficiency and simplicity. Our VPSA units ensure that the carbon originally bound to hydrogen in the form of natural gas is as it should be – contained, pure, and ready to be stored or utilized.

The Innovation – What we do Differently

ATR

Autothermal reforming was chosen as the reforming technology due to its potential for offering high rates of carbon capture and economy of scale. During the last decades, the technology has matured for use in industry in the form of secondary reformers, placed after the main steam methane reformer to maximize conversion. Recent innovations have resulted in using an ATR as the primary reforming train which removes the external furnace, improving energy efficiency and consolidating a vast majority of the carbon produced by the process in a single stream to provide ease of capture.

CCUS

Carbon capture with utilization and storage (CCUS) is the removal of carbon dioxide from the product stream to either be used in applications such as enhanced oil recovery (EOR) or permanent sequestration. This allows the carbon emissions of a plant to be dramatically reduced and produces additional value.

The purification of hydrogen and carbon dioxide will be accomplished in a single unit by means of a novel vacuum pressure swing adsorption (VPSA) cycle. The cycle is able to absorb carbon dioxide and off gasses to produce pure hydrogen, and then selectively desorb CO2. As a result of this technology we are able to produce hydrogen at 99.5% purity and CO2 at 95% purity, making the carbon suitable for export to the ACTL and subsequent use in EOR operations.

Design Feasibility – Economic Data

Market Outlook

The global market outlook of blue hydrogen is expected to remain in a very competitive and highly consolidated landscape in the years ahead [Emergen Research, 2020]. Blue hydrogen production is projected to reach 3.3 Mt annually by 2028 versus its current rate of 0.6 Mt per year [S&P Global, 2020]. Its market size is anticipated to reach $3.10B by 2027 versus $1.02B in 2019, at a compound annual growth rate (CAGR) of 14.8% [Emergen Research, 2020]. The key factors influencing the market include growing demands for clean hydrogen energy with low carbon content, blue hydrogen as an enabler of the green hydrogen, increasing usage of hydrogen fuel as an active propulsion system in automotive industry, and increasing usage of the hydrogen as an active energy source [Emergen Research, 2020].

Blue Hydrogen in Western Canada

Western Canada is in a leading position to produce blue hydrogen and has a series of unique advantages compared to competing locations like Europe, the Middle East and Asia. The advantages include appropriate geological formations with strong carbon storage capacity, a reliable and low cost natural gas supply, existing technology and infrastructure for Carbon Capture and Storage (CCS) as well as an increasing federal carbon tax. Western Canada’s advantage is also evident by the existing investment in Alberta’s blue hydrogen sector with companies like Air Products, Suncor, ATCO and ITOCHU Corporation proposing the construction of new facilities in the Edmonton Metropolitan Region (EMR) [Government of Alberta, 2021].

Economic Evaluation

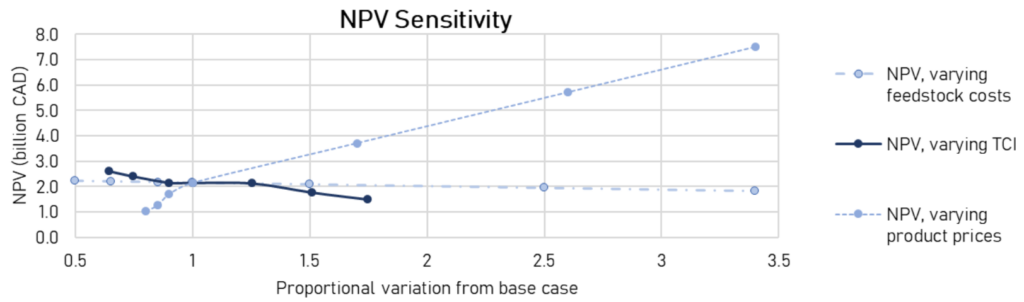

Our economic analysis has resulted in a very positive financial outlook. Based on our calculations, the required total capital investment (TCI) for our plant is $590MM, with annual operating expenses (OPEX) equal to $98.8MM. The estimated after-tax net annual income is $204.8MM and the annual cash flow after tax is $215.5MM, using straight-line depreciation with an interest rate of 10%. The net present value (NPV) over a 30-year-long service life is calculated to be $2.1B. The payback period was found to be equal to 3 years and the discounted rate of return (DROI) was calculated to be 36.5%. All major financial indicators have shown that our proposed plant is economically feasible and would be profitable.

Our team also performed a sensitivity analysis to explore the effects of important parameters on the economic potential of our proposed facility. These parameters include variations in the price of the natural gas feedstock, the equipment and overall project cost in the TCI, and even the selling price of hydrogen. As shown in the figure below, our plant remains profitable even at the worst-case-scenarios, with a minimum NPV being equal to $1.0B.

The Impact – Environmental Considerations and Life Cycle Analysis

The objective of this project is two fold. The first is to determine how much of a reduced carbon footprint blue hydrogen has in comparison to gray hydrogen. The second is to determine if there is an advantage to producing blue hydrogen in Canada due to the relatively cheap natural gas and geological formations ideal for geosequestration.

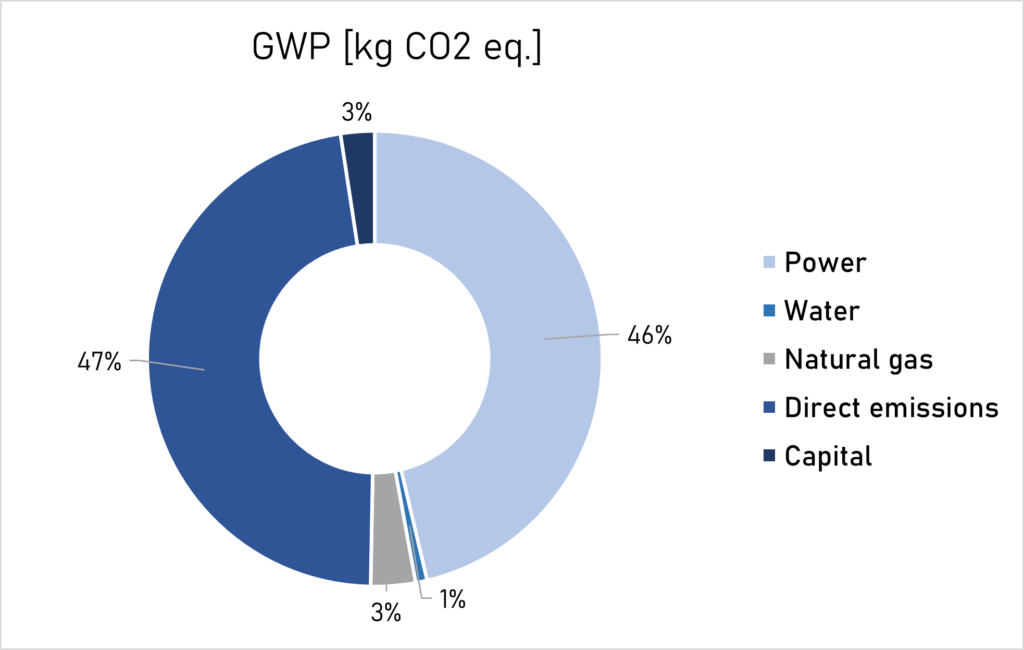

A life cycle analysis (LCA) using a harmonized framework was used to complete the aforementioned project objective by comparing the proposed blue hydrogen plant with similar hydrogen production plants around the world. The life cycle analysis returns a global warming potential and cumulative non-renewable energy demand value that is compared with others evaluated using the same framework. The LCA has been done on a cradle to gate basis and accounts for the carbon footprint of multiple parameters, as can be seen in the figure below.

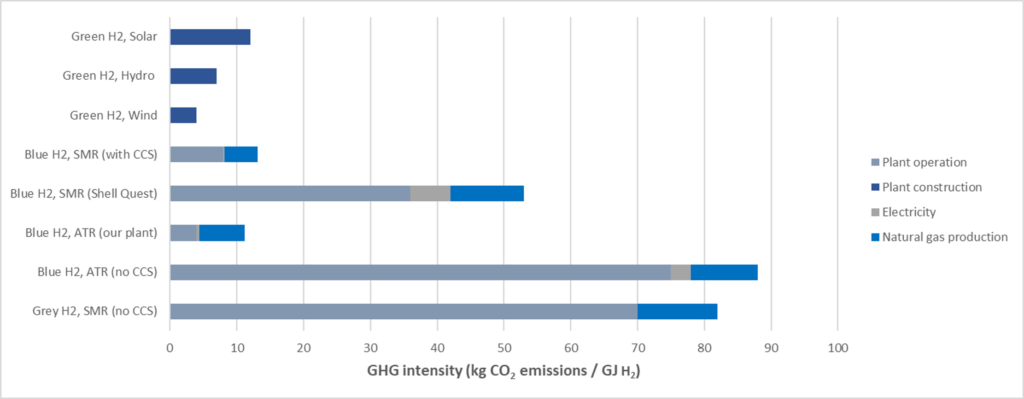

The outcome of our LCA was compared to values from other hydrogen production plants evaluated within the same framework. The figure below shows that there is significant emissions savings to be had by implementing state-of-the-art carbon capture technology with an autothermal reformer. If blue hydrogen is to be pursued in Alberta, it will most likely be with an ATR plant and VPSA carbon capture, akin to the one we have designed [Gorsky et al, 2021].

Partners and Mentors

We want to thank the many individuals who guided and supported us during the formulation of this design project, especially our supervisor Dr. Md Kibria, PhD candidate Muflih Adnan (for his guidance on reactor design) and the course coordinator Dr. Hector De la Hoz Siegler. Your time, patience and assistance are greatly appreciated.

Compendium of Figures

PFDs

P&IDs

Reactor Design

References

Emergen Research. Blue Hydrogen Market Size, Share, Trends, By Technology (Steam Methane Reforming (SMR), Autothermal Reforming (ATR), Gas Partial Oxidation), By End-Use (Power Generation, Petroleum Refinery, Others), Nov. 2020,

J. Gorski, K. T. Wu and T. Jutt, “Carbon intensity of blue hydrogen production,” Pembina Institute, Vancouver, 2021, https://www.emergenresearch.com/industry-report/blue-hydrogen-market

Ministry of Energy. Alberta Hydrogen Roadmap, Government of Alberta, 2021, https://www.alberta.ca/hydrogen-roadmap.aspx

Kolmetz, Karl. “Kolmetz Handbook of Process Equipment Design Air Separation Units Selection, Sizing and Troubleshooting.” KLM Technology Group, Jan. 2013, https://www.klmtechgroup.com/PDF/EDG-SPE/ENGINEERING-DESIGN-GUIDELINES-air-separation-unit-Rev1.2web.pdf

Schoenmakers, Hartmut. Distillation: Operation and Applications. Edited by Andrzej Gorak, Elsevier Inc., 2014, https://doi.org/10.1016/C2010-0-67739-X

Howarth, R. W., & Jacobson, M. Z. (2021). How green is blue hydrogen? Energy Science & Engineering, 9(10), 1676–1687. https://doi.org/10.1002/ese3.956

Zen and the Art of Clean Energy Solutions, “Hydrogen Strategy for Canada,” Government of Canada, Ottawa, 2020

Yu, M., Wang, K., & Vredenberg, H. Insights into low-carbon hydrogen production methods: Green, blue and aqua hydrogen. International Journal of Hydrogen Energy, 2021, 21261-21273. https://doi.org/10.1016/j.ijhydene.2021.04.016

S&P Global Commodity Insights. Cost, Logistics Offer ‘Blue Hydrogen’ Market Advantages over ‘Green’ Alternative, 19 Mar. 2020, https://www.spglobal.com/commodity-insights/en/market-insights/latest-news/electric-power/031920-cost-logistics-offer-blue-hydrogen-market-advantages-over-green-alternative?utm_campaign=corporatepro&utm_medium=contentdigest&utm_source=bluehydrogen