Project Category: Chemical

About our project

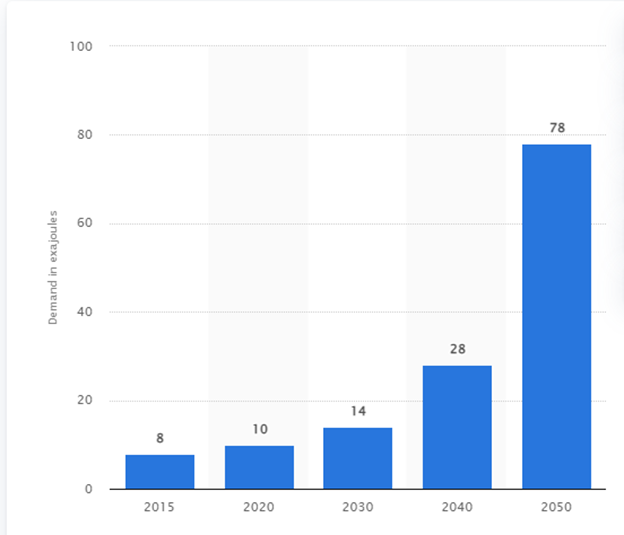

The interest and demand for Hydrogen as energy have been experiencing growth over the past few years due to the worldwide concerns surrounding the environmental impact of fossil fuels. The diagram below shows a projected global demand for hydrogen in a +2 degree Celsius global warming scenario from 2015 to 2050. ( in exajoules) [1]

The global consumption of hydrogen gas was around 87 million mt in 2020, but this is expected to rise to 528 million mt by the year 2050 [2]. Hydrogen can be used as energy to produce electricity, power vehicles, rocket ships and more [3].

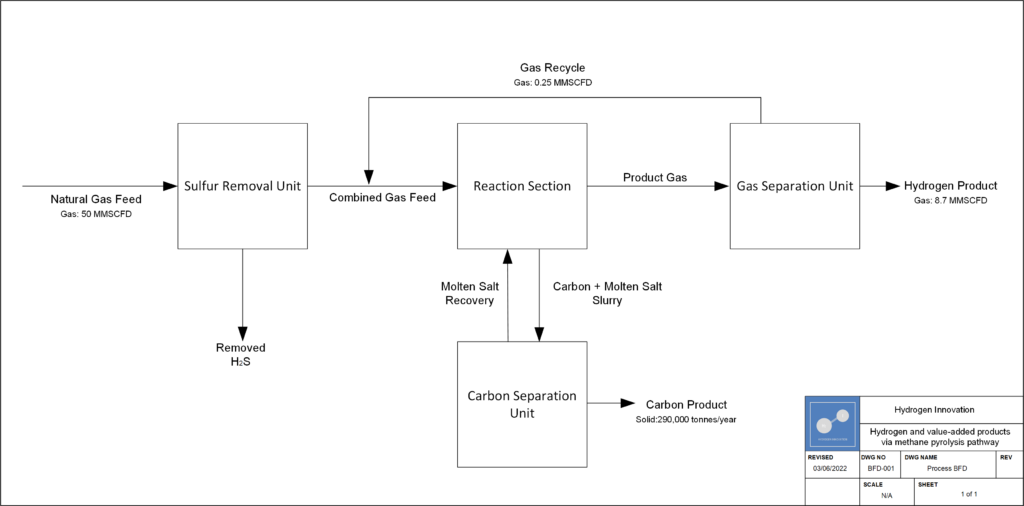

Methane pyrolysis is a potential pathway for hydrogen production. It is more environmentally friendly [2] as well as efficient [2] compared to its biggest competitor: steam methane reforming with or without carbon capture. Hydrogen Innovation will take the role of processing 50 MMSCFD of pipeline specification natural gas to produce 8.7 MMSCFD of 99.95% pure hydrogen in addition to 290 000 tonnes/year of carbon black that can be sold as co-product

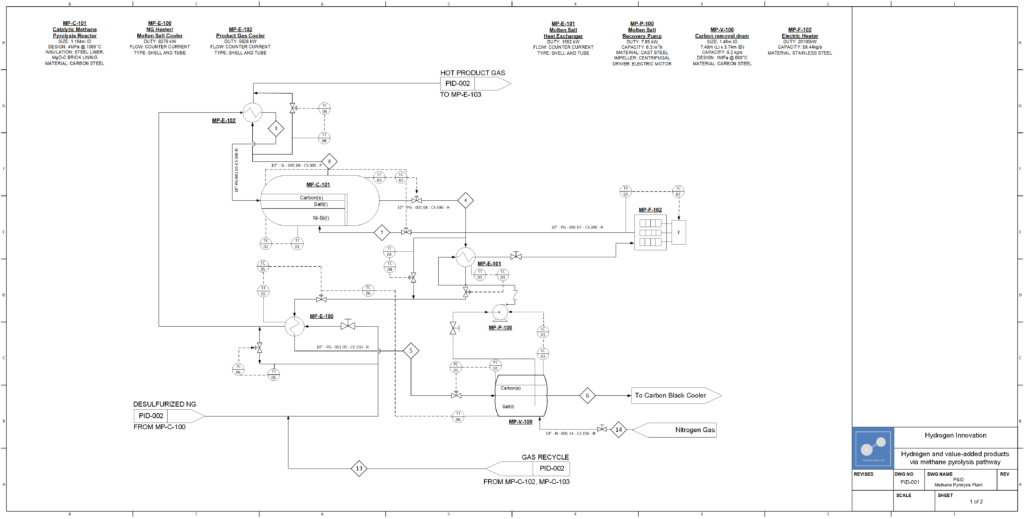

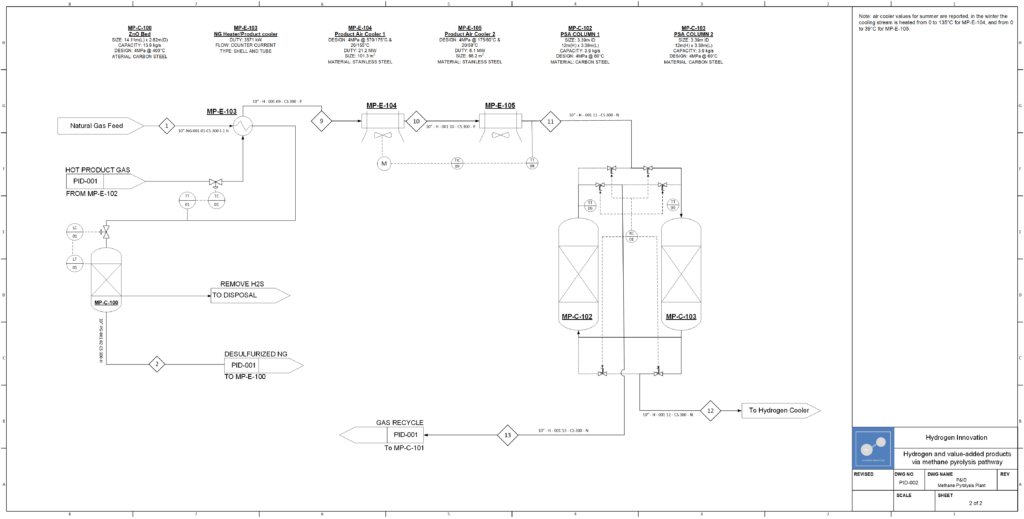

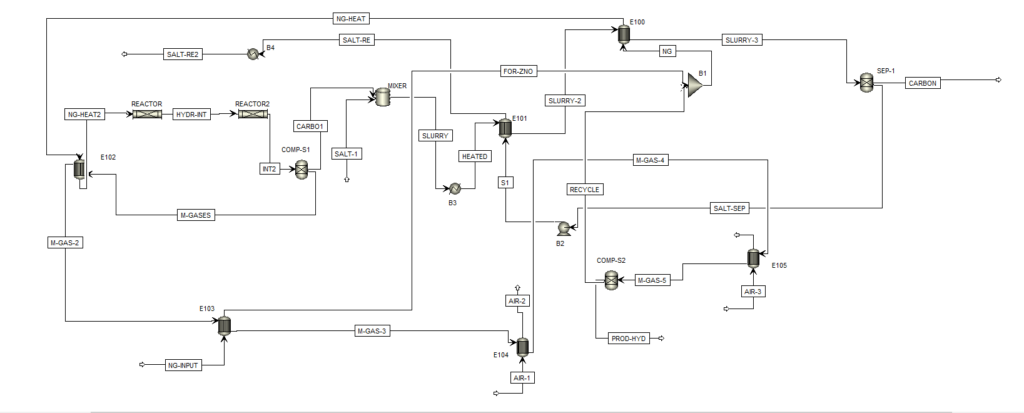

Our project consists of 4 main sections. The first section involves the sulfur removal unit to eliminate hydrogen sulfide in the feed stream. H2S could be harmful to the catalyst as well as further processes downstream. The hydrogen sulfide free feed stream would then enter into the reaction section where catalytic pyrolysis of methane will produce hydrogen along with carbon black. The carbon black is collected and dried in the carbon separation unit while the hydrogen with the unreacted methane will enter the gas separation section. The gases will be separated to produce methane that will be recycled back into the inlet stream, and high purity hydrogen as our final product.

Meet our team members

Miranda Abel

Daphne Eilers

Keeliana Hopkins

Sang Lee

Rebecca Park

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

A common issue facing all industries today is how best to manage and eliminate the negative environmental effects we cause. Although it would be ideal, this change to sustainable human activity cannot happen overnight, and requires bridging the gap between current practices and innovation towards this goal. Our design does just that. Using natural gas, a resource readily available, we aim to shift its application to drive change in a positive environmental direction.

Hydrogen, such as that produced from our process, is the future of many sustainable technologies, for example, fuel cells for transportation. While the fuel cell market catches up to the requirement, we plan to sell this product to nearby upgrading facilities that currently require hydrogen for their processes. This meets current demand for hydrogen, while also allowing for expansion into other groundbreaking industries as the market allows.

Unlike other technologies currently being employed to produce hydrogen, such as SMR and ATR, methane pyrolysis does not produce any greenhouse gases. The only co-product is carbon black, a substance required for the manufacture of many products. In the next 10 years, it is planned that our process will be run solely by renewable energy. This transition to sustainable practices is crucial, and our process offers the flexibility of fulfilling current hydrogen requirements while also being ready for the imminent shift from fossil fuels to sustainable hydrogen technology.

WHAT MAKES OUR DESIGN INNOVATIVE

The fossil fuel industry is an important part of the Alberta economic landscape. Alberta has alternatively been working to find a way to reduce CO2 emissions. Due to the nature of the energy industry, these two things have been difficult to reconcile.

Our hydrogen production pathway utilizes fossil fuels in a way that does not produce CO2 during the process. They are broken down into hydrogen, and a co-product carbon black, through high temperature catalytic reactors with no additional by-products. This is in comparison to more traditional methods of producing hydrogen using fossil fuels, like steam methane reforming, which require produced CO2 to be captured.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

Reduced CO2 Emission:

Our design eliminates the need for conventional post-combustion CO2 capture technology as methane pyrolysis does not produce CO2 as a by-product. Hydrogen Innovation believes that methane pyrolysis is a key to step forward to net-zero emission which makes the hydrogen as a potential decarbonized fuel source.

Recycling:

Our design contains recycle streams and heat recovery to minimize energy requirements as well as emissions from the process. This heat recovery system through heat exchangers also allows to maintain a high operating temperature of 1065°C.

Carbon as co-product:

The methane pyrolysis also produces Carbon Black as a co-product. Our carbon separator completely recovers the carbon black which will then be cooled down, packed, and transported to automobile companies or tire-making companies. This makes it more economically attractive compared to other hydrogen production techniques.

HOW WE VALIDATED OUR DESIGN SOLUTION

For the main reaction of our design, we chose to use a high-temperature catalytic reactor. This unit breaks down the natural gas into hydrogen and carbon. To develop our model, we used thermodynamic and kinetic data and hand calculations as the preliminary method. We validated our hand calculations using Aspen HYSYS simulation software. We chose the purity of hydrogen that needed to be produced and worked our way backwards from there to find the the various sizing requirements.

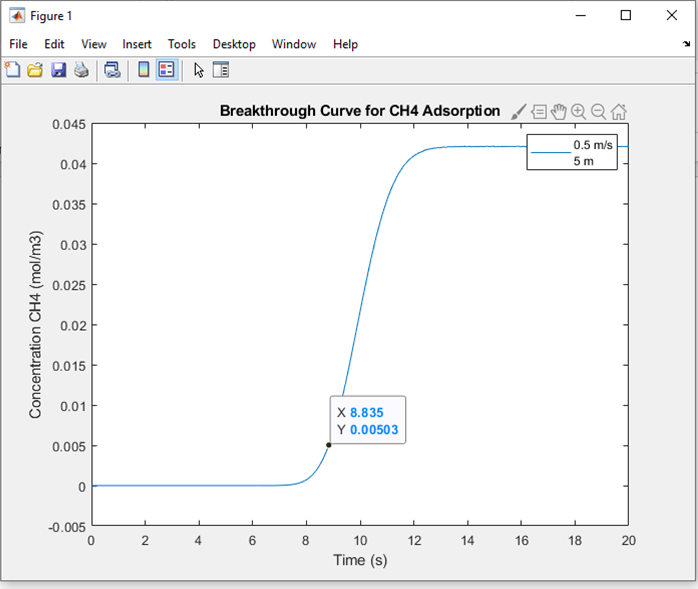

In the development of the purification section of our process, we decided on using a pressure swing adsorption system in order to purify our final hydrogen product due to its wide industry use. To develop and validate our solution, first an approximation is used and the system is modelled using calculations in excel. Once this was fully developed, a more in depth analysis taking into account equilibrium, mass transfer and material balance effects was conducted using MATLAB. Both models attained similar results which validated both of our solutions, but the MATLAB analysis provided accurate concentration profiles and smaller sizing which contributed to a more economically feasible design.

For the carbon separation of our design, the froth flotation method was chosen. Nitrogen gas will form bubbles and float up in the salt slurry filled tank and will capture the carbon solids on the way up. Validation was done with data from Aspen HYSYS simulation software as well as from a design research paper. Simulations were able to give valid numbers and specific design parameters were chosen with recommended numbers.

FEASIBILITY OF OUR DESIGN SOLUTION

This project yields promising economics. We have determined that this project will be profitable in current market conditions. However, our sensitivity analysis did find that increasing the price of natural gas by 10% would mean that it is no longer a profitable business. This is particularly important to consider with the increasing natural gas costs in today’s economy. However, we predict that current price trends are an anomaly and once the market settles over time, it will remain economically feasible.

Further, this project requires that the hydrogen be transported by pipeline. Because the produced hydrogen is over 99% pure, the infrastructure required to move it through a pipeline may present some challenges. The location of the plant is therefore a large consideration in its feasibility. Building this plant in Northern Alberta where it can easily be utilized for upgrading bitumen without needing to travel large distances is what we would recommended.

Partners and mentors

We want to thank the many people who helped us with this project. Our ENCH 531 Professor Dr. Hector De la Hoz Siegler, our supervisor Dr. Maen Husein and our industry representative Patrick Mraz were of great help guiding us through each step in creating our process, and providing us critical critique on our design decisions to allow us to create the best design.

Our photo gallery

References

[1] M.Jaganmohan, “Projected global demand for hydrogen 2015-2050.”Statista.com, Jan 27 2021. [Online]. Available: https://www.statista.com/statistics/435467/hydrogen-demand-worldwide/ [Accessed 03 31 2022]

[2] N.Hunter, “Hydrogen use needs to hit 212 million mt by 2030 for net-zero:IEA,” 18 May 2021. [Online]. [Accessed 03 31 2022]

[3] U.S Energy Information Administration, “Hydrogen explained, Use of hydrogen”, Jan 27 2022. [Online]. Available: https://www.eia.gov/energyexplained/hydrogen/use-of-hydrogen.php [Accessed 03 31 2022]

[4] N. Sánchez-Bastardo, R. Schlögl and H. Ruland, “Methane Pyrolysis for CO2-Free H2 Production: A Green Process to Overcome Renewable Energies Unsteadiness,” Chemie Igenieur Technik, 2020.