Project Category: Chemical

Join Our Presentation

Questions? Just click the link above!

Our Goal

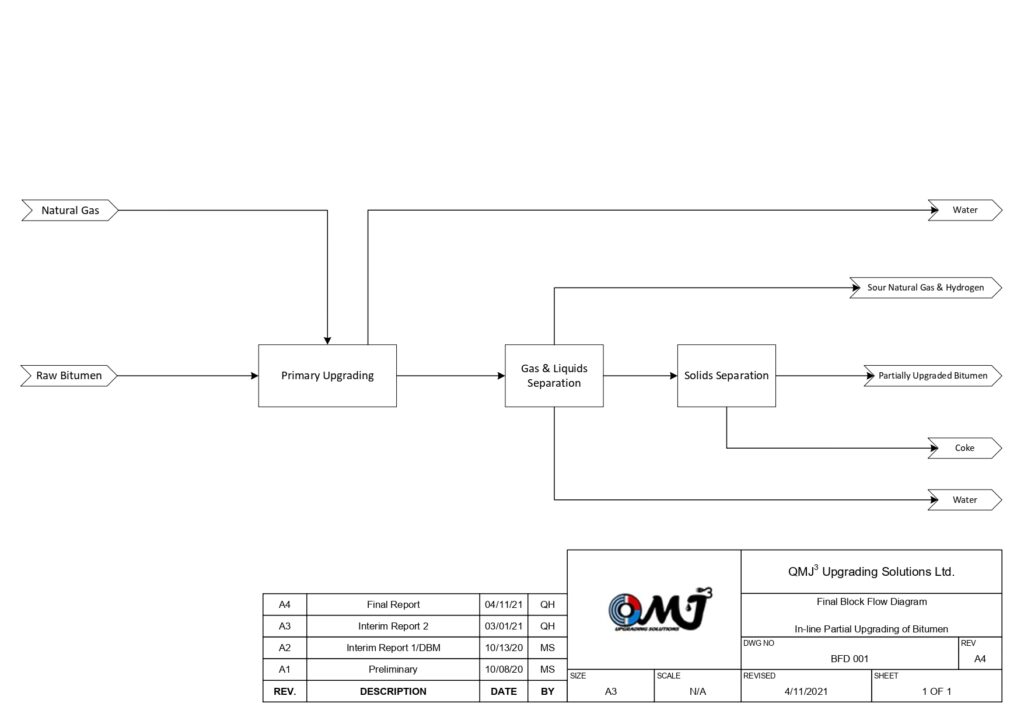

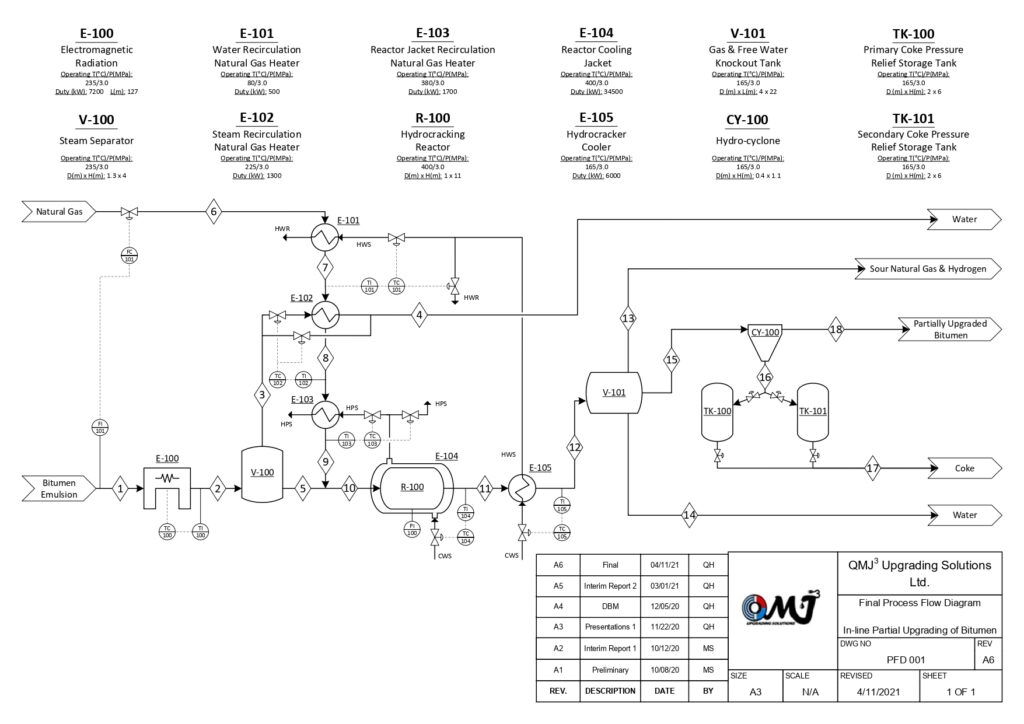

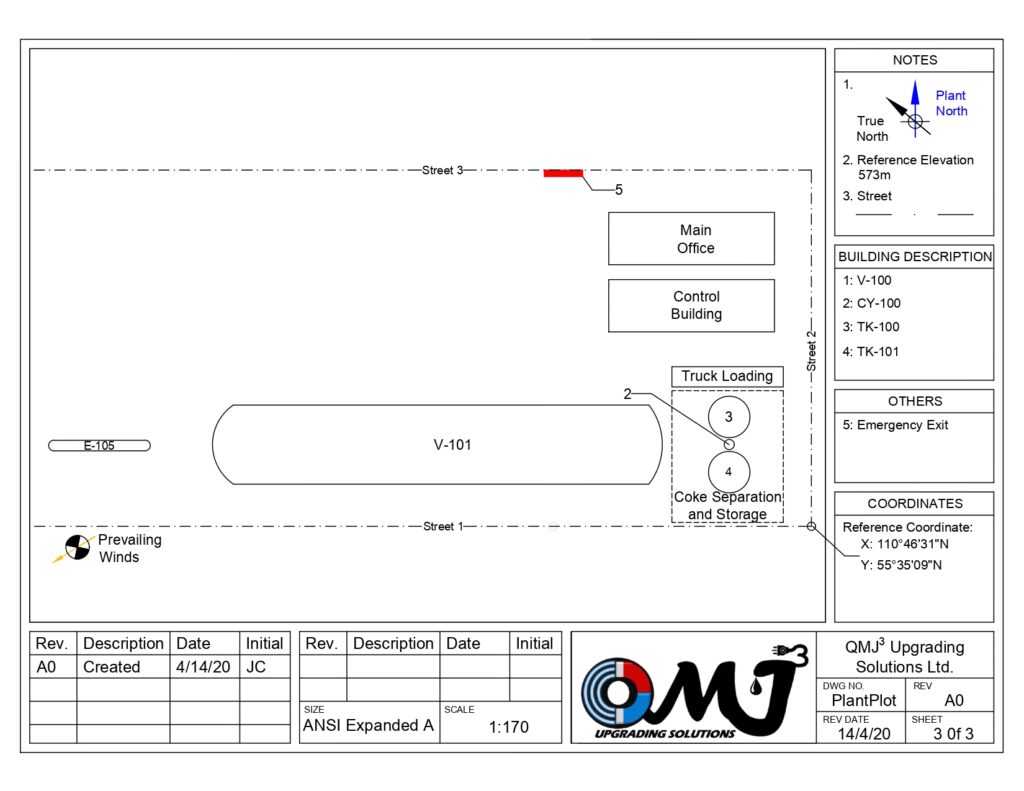

At QMJ3 our goal was to evaluate the technical, environmental, and economic feasibility of a process which partially upgrades bitumen using an in-line modular process driven by electromagnetic (EM) radiation and methanotreating. Approximately 2000 m3/day of bitumen emulsion from a Steam Assisted Gravity Drainage (SAGD) process (500 m3 Bitumen/day) will be upgraded through our proposed process.

The motivation to develop a process to partially upgrade bitumen comes from the ability of the process to potentially reduce bitumen viscosity, in turn reducing diluent costs. This would eventually lead to an increase in pipeline capacity while also offering the possibility of lower emissions.

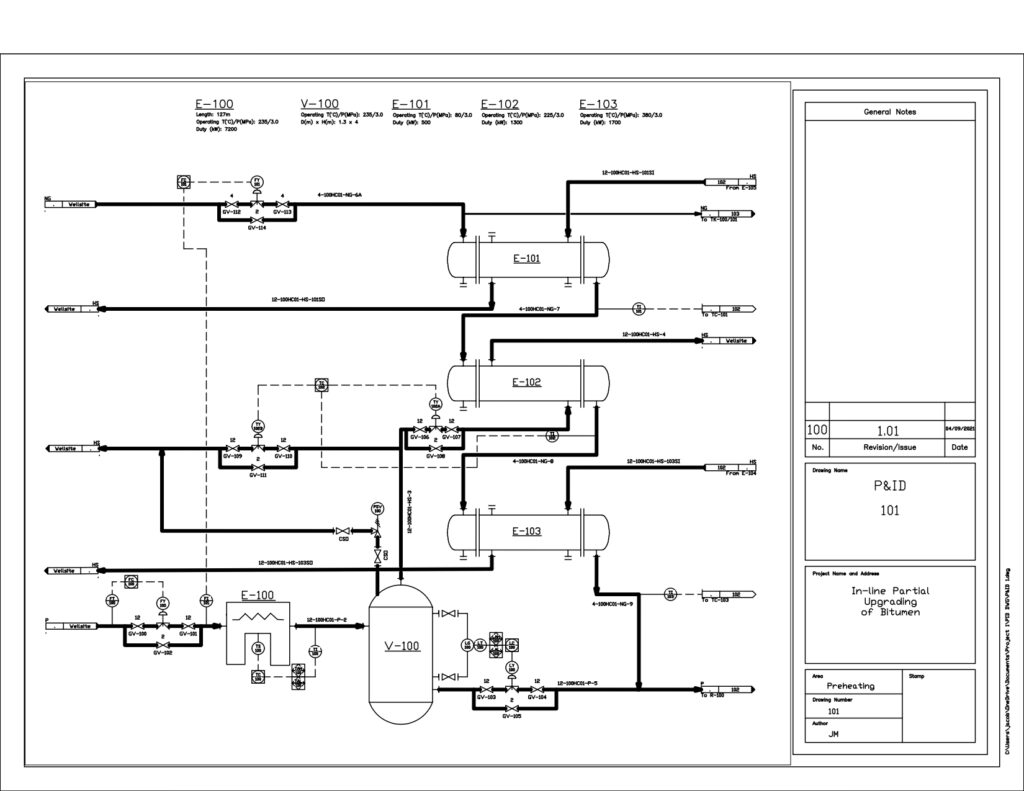

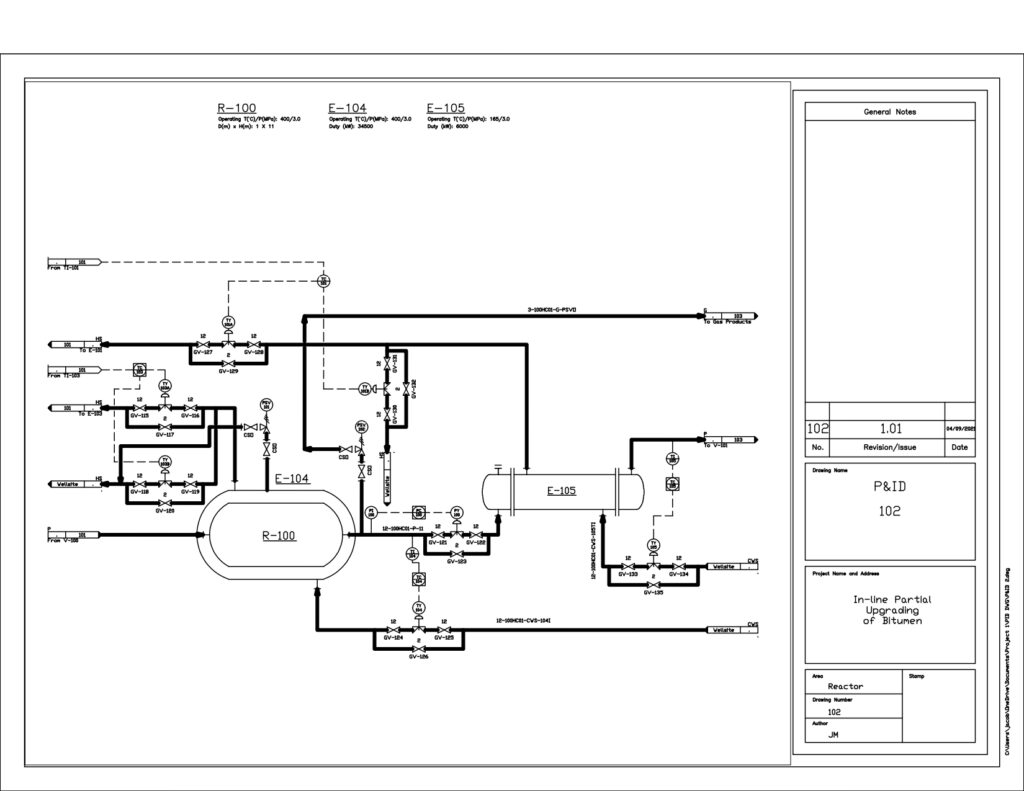

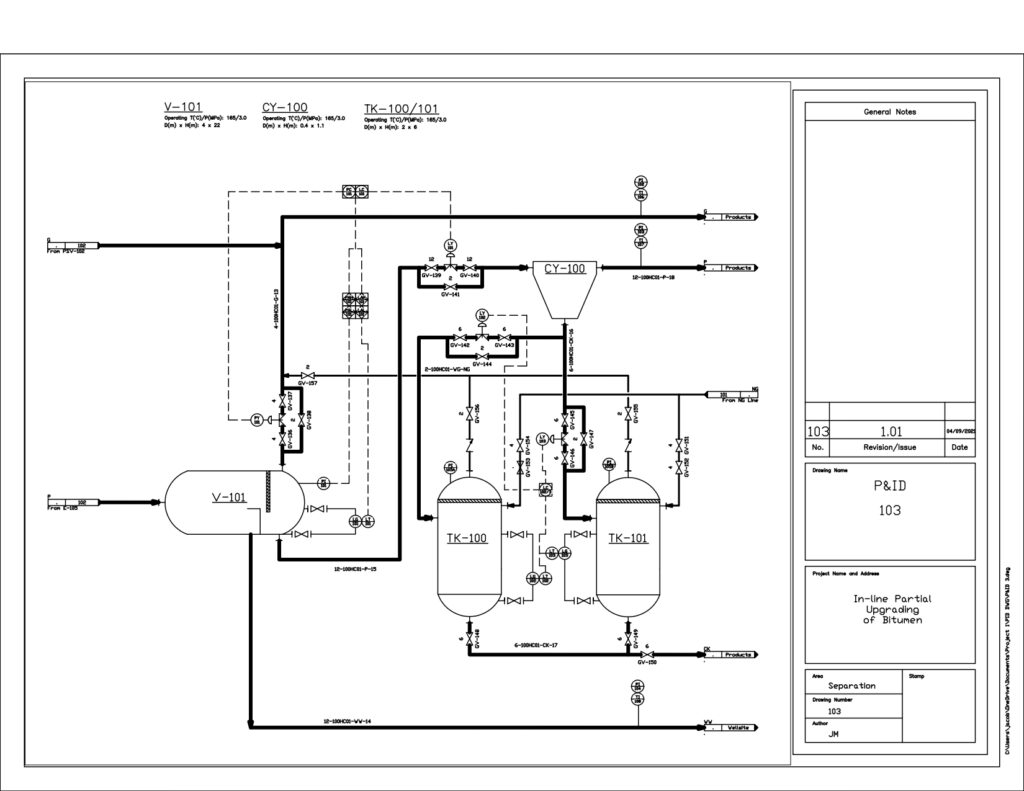

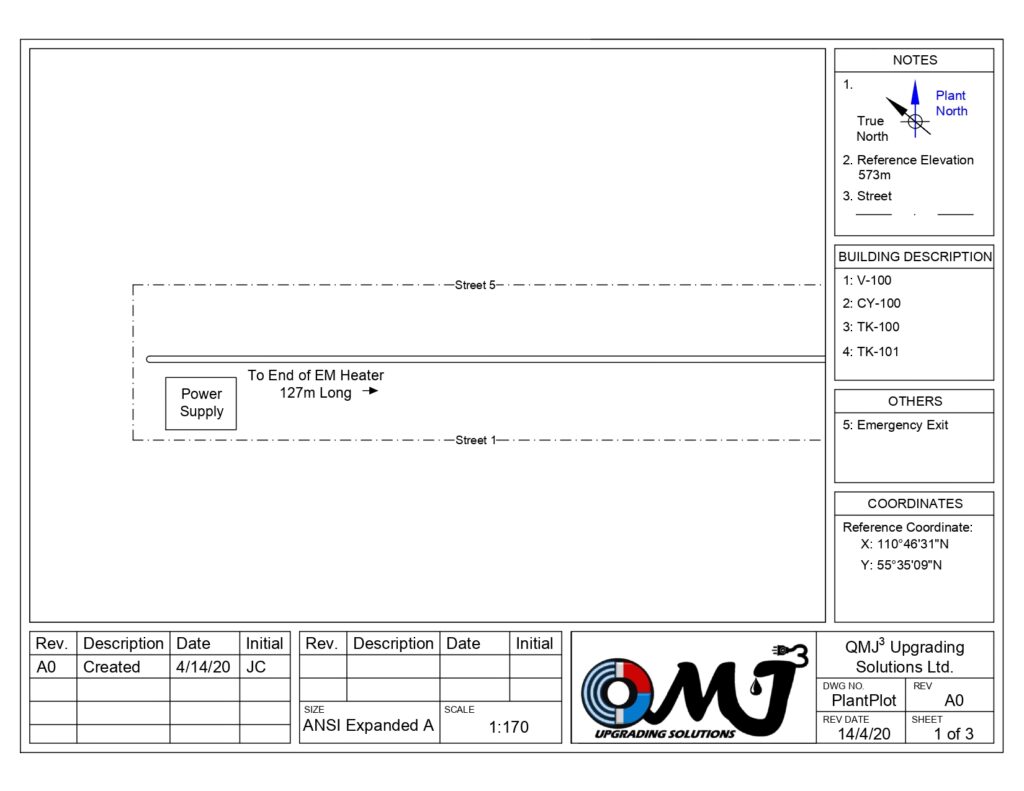

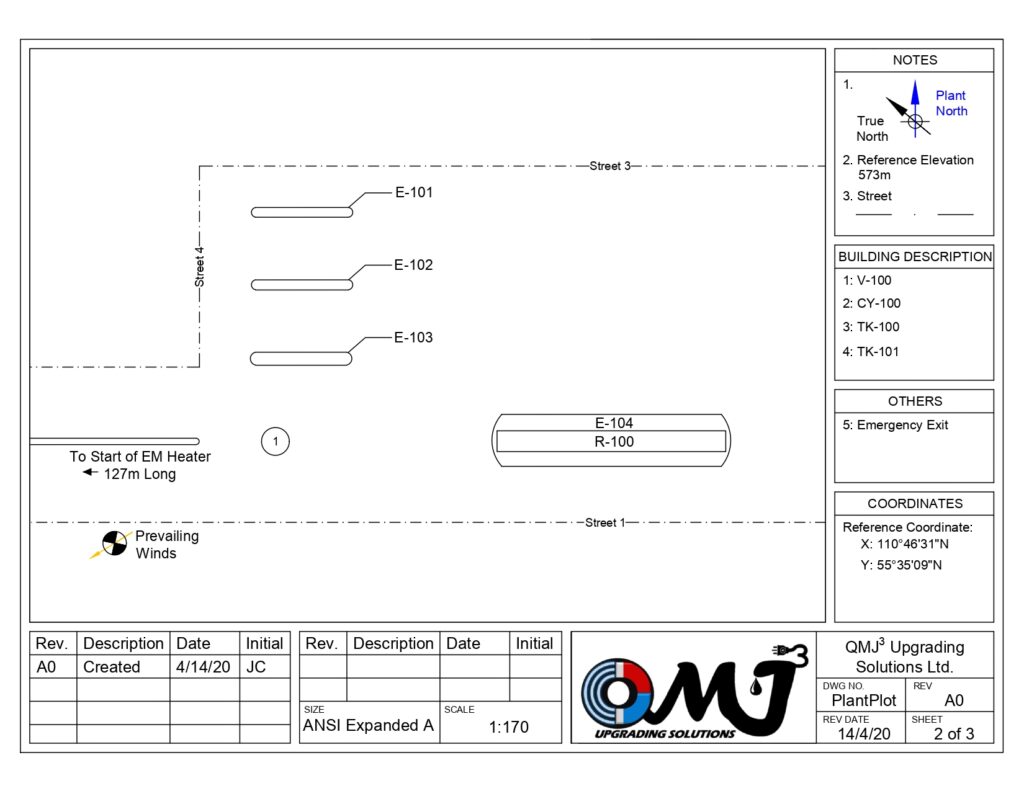

To achieve these goals QMJ3’s process will be located at a Cold Lake pad where diluent is usually added. Our system will instead use electromagnetic radiation to heat the process to desired conditions, allowing the hydrogen addition reaction with methane to occur partially upgrading our bitumen. With this process we set out to evaluate the technical feasibility of our process, design alternatives, plant specifications, safety considerations, economic analysis, simulation models, and much more.

Our Team

The Q

The M

The J1

The J2

The J3

Our Design

ADDRESSING AN INDUSTRY NEED!

Due to Alberta being a land locked province, it relies heavily on pipelines for oil distribution. Using our proposed design, we can upgrade crude oil with less diluent compared to conventional methods. This leads to the pipeline having a higher oil to diluent ratio, effectively increasing the capacity without changing the volume or size of the piping itself.

INNOVATION? WE GOT IT!

The use of electromagnetic radiation as a heat source for our hydro-cracking reaction is a newer approach to a common process. Several companies are starting to explore the uses of electromagnetic radiation, but it is still very new.

Using methane as our hydrogen donor for our hydro-cracking reactions is a novel process which has not been extensively tested at an industrial scale. Our group is hoping that this process can be an effective use for Alberta’s excess natural gas.

WHAT MAKES OUR SOLUTION SO EFFECTIVE?

Our process increases the pipeline capacity. By reducing the need for the addition of diluent to our bitumen we will be increasing bitumen carrying capacity by 40 bbl/day.

At our site there is net zero emissions and the process will reduce emissions produced by upgrading facilities.

The modular setup of our plant allows for a reduced footprint to reduce environmental impact.

BUT IS IT VALID?

As our design is a novel process it would require validation through experimental trials. Due to time and resource constraints these trials were unable to be done. Short of completing these trials, our solution relies on the information we were able to get from published research papers and communication with our mentor.

WHAT WILL IT TAKE TO MAKE OUR DESIGN FEASIBLE?

This project has been completed by making eight major assumptions which would require verification:

- Non-upgraded crude oil represented as C38H56 in material balance

- With the use of the electromagnetic heater, cavitation will occur in the emulsion allowing the for methane-bitumen interface to reach 400C while maintaining a bulk temperature of 235°C.

- Emulsion electromagnetic properties follow those of water when the mixture contains more than 50% water by volume.

- Upgrading characterized by the conversion of C38H56 to C8H18, C12H24, and petroleum coke. Conversion and final weight percent of species set to match from research paper on methanotreating published in 2016 from the University of Calgary’s Department of Chemical and Petroleum Engineering.

- Partially upgraded bitumen assumed to follow viscosity trend developed by De Ghetto and Fitzgerald.

- Assumed 10% of water remains within the bitumen after electromagnetic heating.

- 95% gas and 98% water separation efficiencies in our free-water-knockout (FWKO) with 100% separation of hydrogen-sulfide.

- Plant was assumed to operate 348 days of the year

Remember the use of methanotreating and EM radiation for bitumen upgrading is still a novel process that requires further research and experimentation. As the topic is better understood the feasibility of its implementation will increase.

Recognitions

Thank you Dr. Kantzas

We would like to thank Dr. Apostolos Kantzas for the opportunity to work on this project. You have been a fantastic mentor lending us tremendous amounts of help and guidance along the way.