Lithium-ion batteries (LiB) have made portable electronics ubiquitous, and they are about to do the same for electric vehicles. That success story is setting the world on track to generate a multimillion-metric-ton heap of used LiB that could end up in the trash.

Opportunities always coexist with challenges. It’s time to take the bull by the horns and get serious about recycling Li-ion batteries.

Liang An, Metals recycling Specialist – Hong Kong Polytechnic UNIVERISITY (2020)

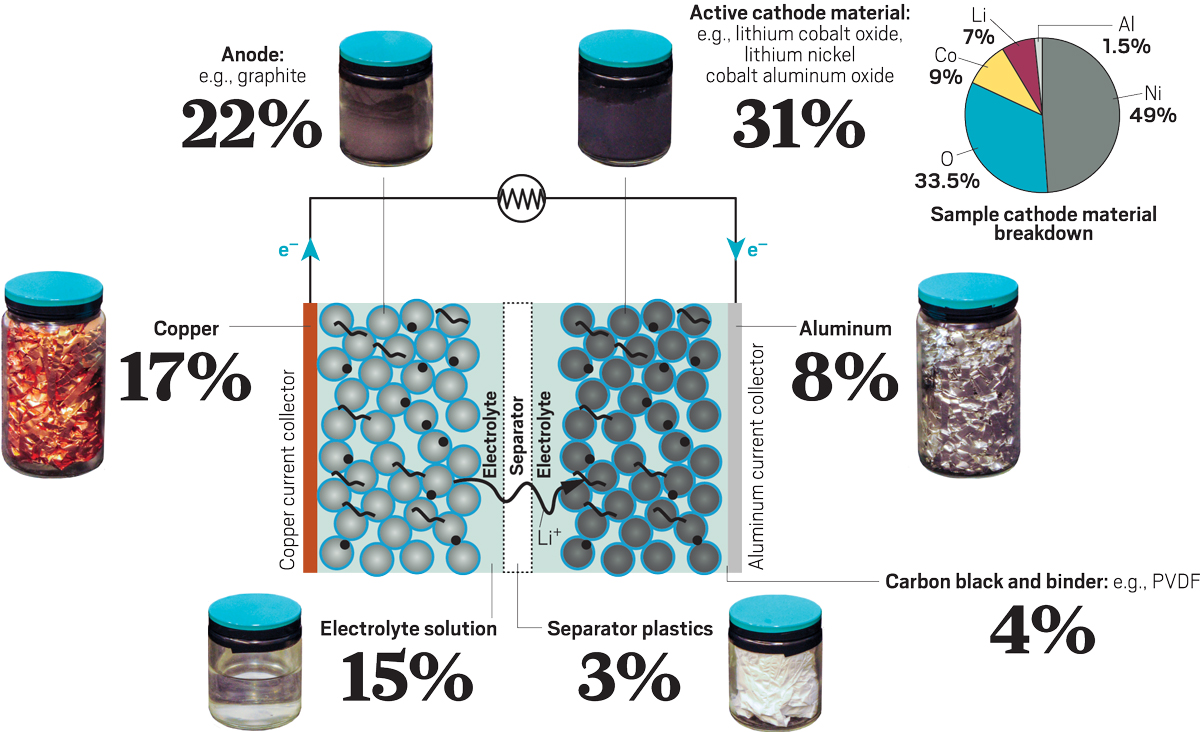

The increasing prevalence of consumer electronics has also been accompanied by the increasing electrification of transportation, the lack in lithium extraction infrastructure, and significant environmental risks associated with battery disposal. This all suggests that LiB recycling will become increasingly required. To address these issues, LiFE Inc. has developed a recycling process that recovers the high concentrations of cobalt and lithium from used batteries.

Our process is based on hydrometallurgy, which extracts metals through a series of acidic and alkaline conditions, intaking 4,500 tonnes of lithium cobalt (LiCoO2) battery waste per year sourcing from consumer electronics in Canada. The batteries are valuable and recyclable, but because of technical, economic, and other factors, less than 5% are recycled today. LiFE Inc.’s mission was to overcome these challenges and pave a prosperous path for recycling.

Design Details

ADDRESSING PRACTICAL ISSUES

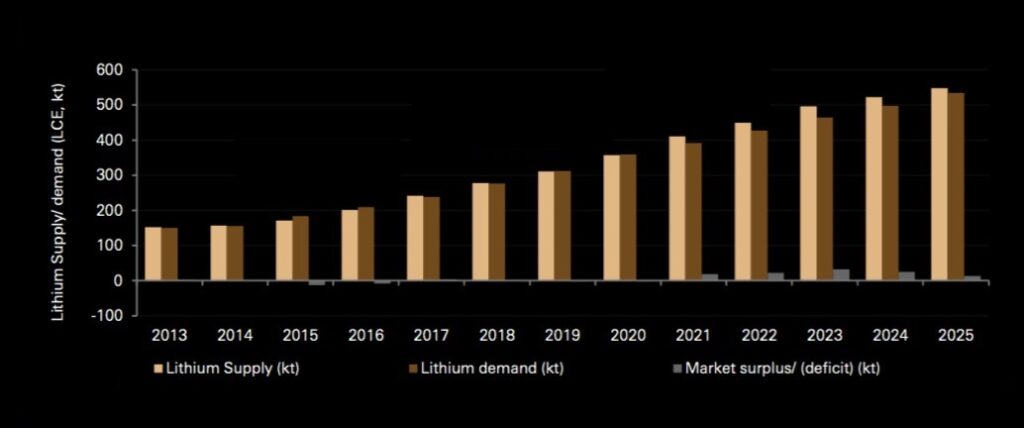

- Current Supply Methods are Falling Short: Lithium is currently supplied by ore or brine extraction, but extraction infrastructure for these methods is simply not developed enough yet to meet the projected lithium demands. However, recycling of used batteries can provide a solution!

- Lithium Shouldn’t be in our Landfills: If current trends for handling these spent batteries hold, most of those batteries may end up in landfills even though Li-ion batteries are proven as recyclable. Cobalt and other metals found in batteries can readily leak from the casing of buried batteries and contaminate soil and groundwater, threatening ecosystems and human health.

- Supporting Circular Economies: The materials recovered could be used to make new batteries, lowering manufacturing costs. Currently, these materials account for more than half of a battery’s cost, particularly the cobalt in the cathode which possesses a current market price of $30,000 per metric ton.

DEVELOPING INNOVATIVE DESIGN

- Hydrometallurgical Design: A series of acidic and basic reactions is used to effectively leach lithium and cobalt into high-value products. This process does not require high-temperature melting-and-extraction, or smelting, resulting in a safer, cleaner process.

- High Product Recovery: We have developed a process that recovers our high-value cobalt tetroxide (Co3O4) and lithium carbonate (Li2CO3) products both recovered around 95% which means our design restores value of battery materials for manufactures to produce more batteries.

- Diversity Accepted! A variety of LiCoO2 battery structures can be fed into the process feedstock. The proposed battery pretreatment stages have capacity to handle the variety of sizes and shapes of batteries that are currently in our waste stream. Each battery cell contains a cathode, anode, separator, and electrolyte – and we can safely and effectively process them all.

AN EFFECTIVE & PROSPEROUS SOLUTION

Our hydrometallurgical design provides the first of few large scale economical recycling solutions. Unlike most battery recycling operations which often run near 1,500°C and burn away lithium, aluminum and other metals, our process operates under 100°C and ambient pressure. This is how we offer a less energy-intensive alternative and lower capital costs.

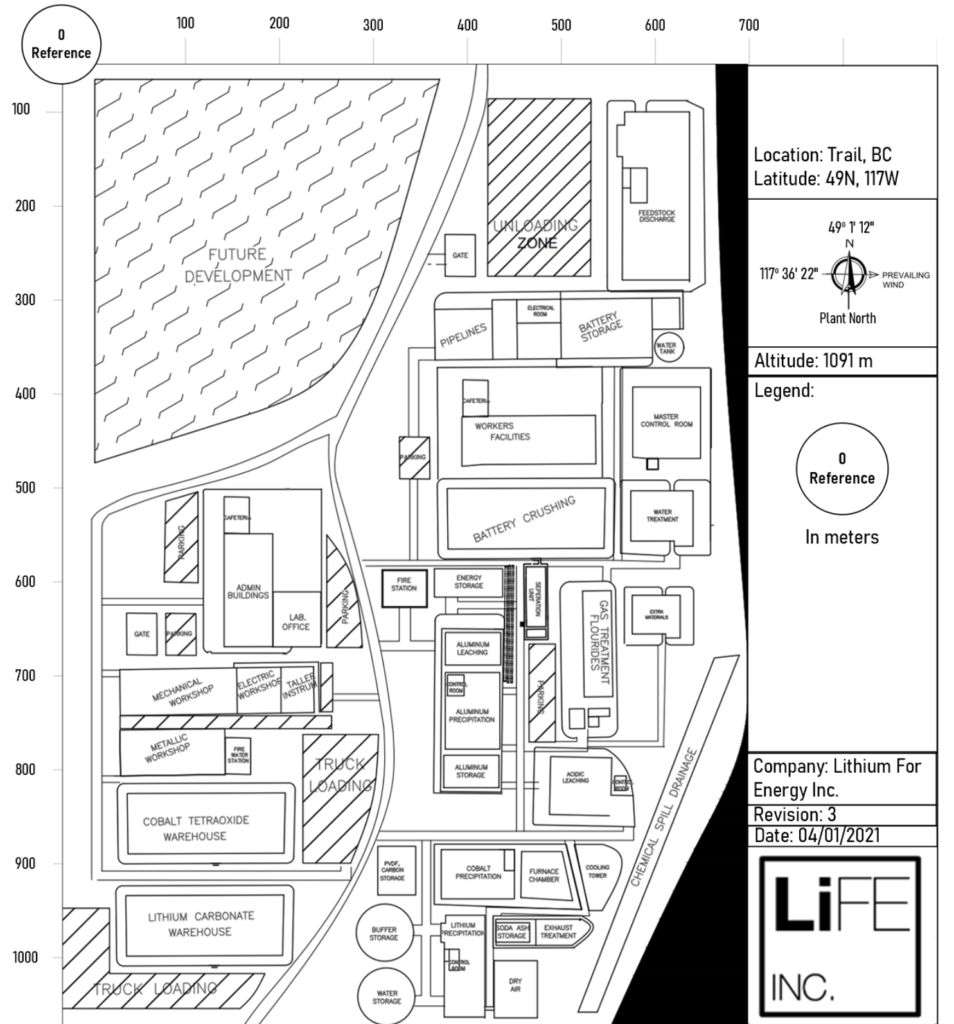

Our plant is located in Trail, BC where we can have our feedstock transportation costs conveniently subsidized and located at the hub of materials recycling in Canada.

DESIGN VALIDATION

Validation of the proposed design was conducted using AspenPLUS modelling with the electrolyte Non-Random Two Liquid (e–NRTL) property package. We also consulted outstanding novel research in the battery recycling industry to develop the LiFE Inc. solution. We invite you to view some current industry leaders in battery recycling and management that inspired our business model.

PROJECT FEASIBILITY

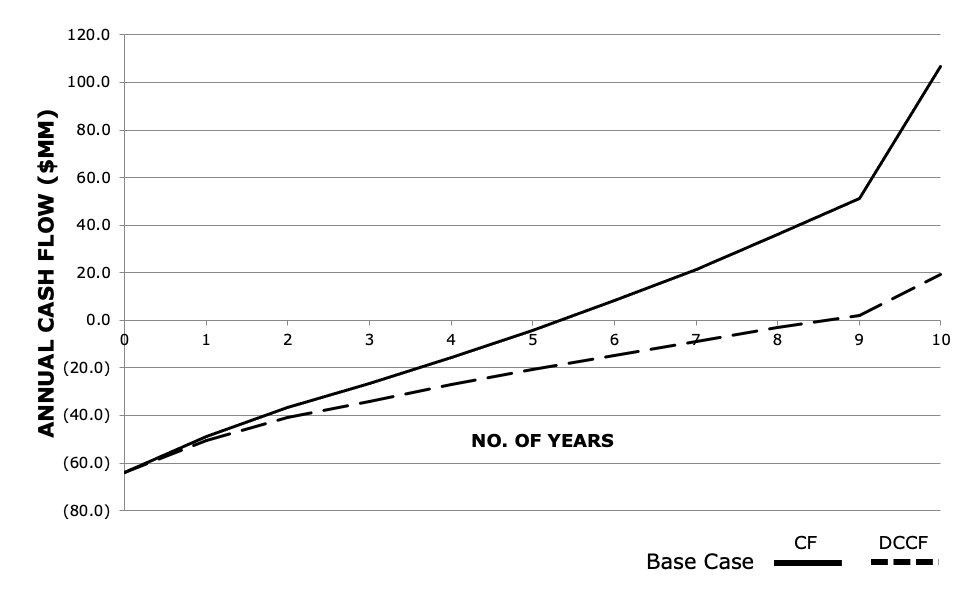

The global lithium demand has carved out an opportunistic market to establish our competitive outlook. Our process has demonstrated recycling can be competitive and profitable, with economic indicators as:

- Net Present Value: $19.3 MM

- Internal Rate of Return: 12.4%

- Project Lifespan: 10 years

Media Gallery

Plant Location

Plant location nearby Trail, BC. Map: Google Images, 2021.

Plot Plan

Proposed plot plan for 300-acre recycling facility.

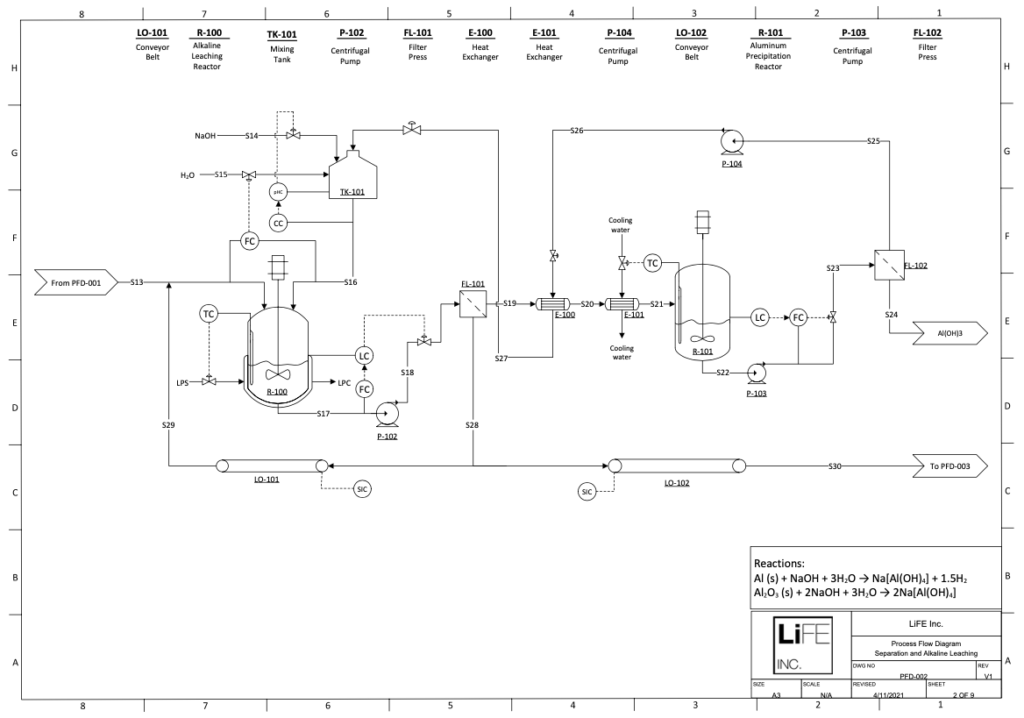

Sample PFD

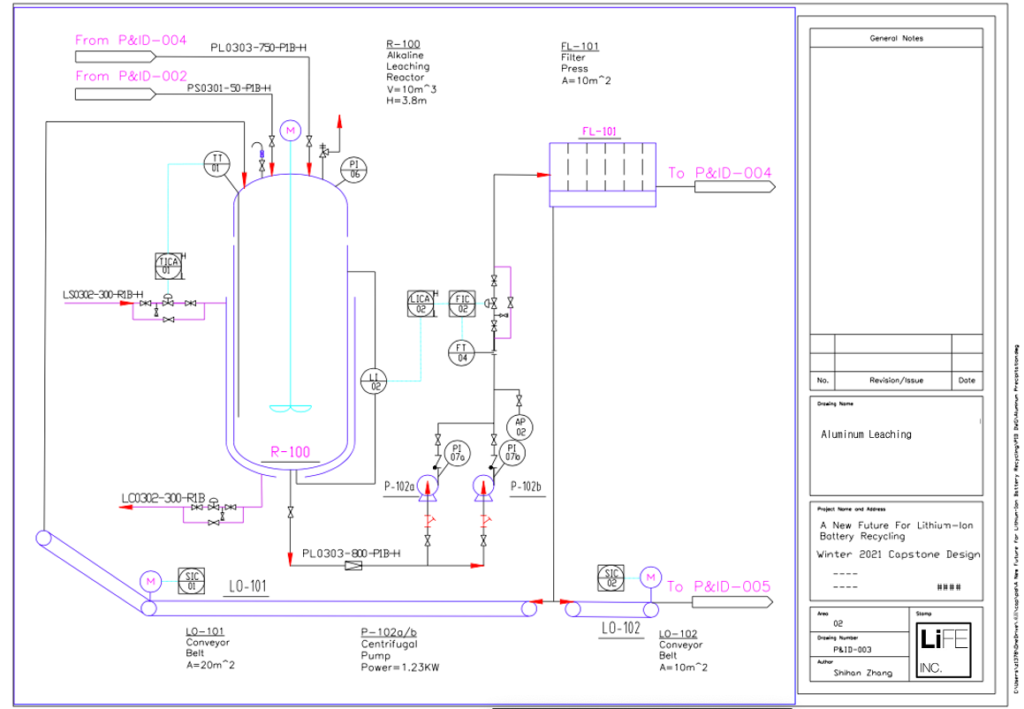

Sample P&ID

To Our Mentors

We want to thank Dr. Kunal Karan for inserting energy into our project, and guiding us through the chemical design process with patience and great advice. We would also like to thank Dr. Hector De la Hoz Siegler and Dr. Mike Foley for helping shape our project through their invaluable feedback.