Project Category: Chemical

Join our Zoom Room

Our Zoom Room will be active during the Capstone Design Fair on Tuesday April 13th, 2021 from 10:00am-12:30pm.

Any inquiries outside of the Capstone Design Fair can be directed to us at robert.mcmanus@ucalgary.ca.

About our project

The issue of global medication shortages has been of growing concern over the last decade, and the COVID-19 pandemic has only made this issue more recognizable through the disruption of production and shipping schemes. This issue is especially great in areas of Africa, where medications are very slow to arrive, and often are not of great quality; some even turn out to be fake!

Through the design and implementation of a modular medication manufacturing plant, we will be providing medications to communities in need through the design of a modular medication production plant that can be operated locally. This modular plant will be able to provide a tailored supply to those in need, where and when it is needed, moving forward the mission to provide equity in access to medication for all.

Meet our team members

About our design

The Problem

The issue of global medication shortages has been growing significantly over the last decade and has only been amplified by the production and supply chain challenges caused by the COVID-19 pandemic. This project aims to solve this problem by allowing greater access to medications through a modular, portable, “factory-in-a-box” style medication manufacturing plant that can be arranged to produce a variety of drugs needed in local communities. In doing so, we will increase the access to essential medications for those living without.

The Innovation

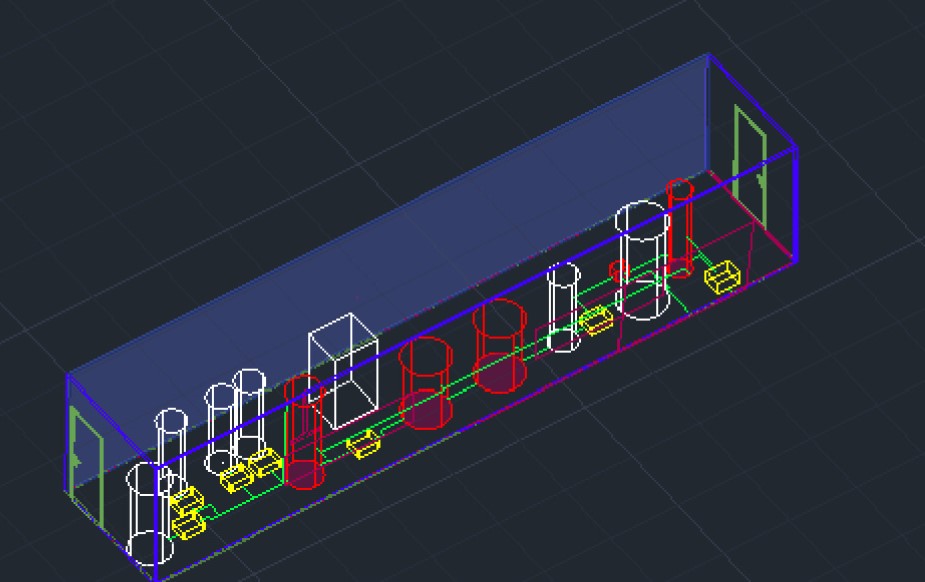

This design is a “factory-in-a-box”, where process modules will be housed in shipping containers. The modularity of this design allows it to be reconfigured such that it can produce multiple medications. The plant will therefore meet the specific needs of its surrounding communities, providing them with essential medications just-in-time, relieving them of their global supply chain struggles by providing what is needed, where it is needed.

How this Solution is Effective

In its portability, this design will help resolve the struggle of medication inaccessibility to many communities in need around the world. By providing the medications that are needed, where they are needed, this modular manufacturing concept will efficiently supply life-altering therapies.

Our Detailed Design

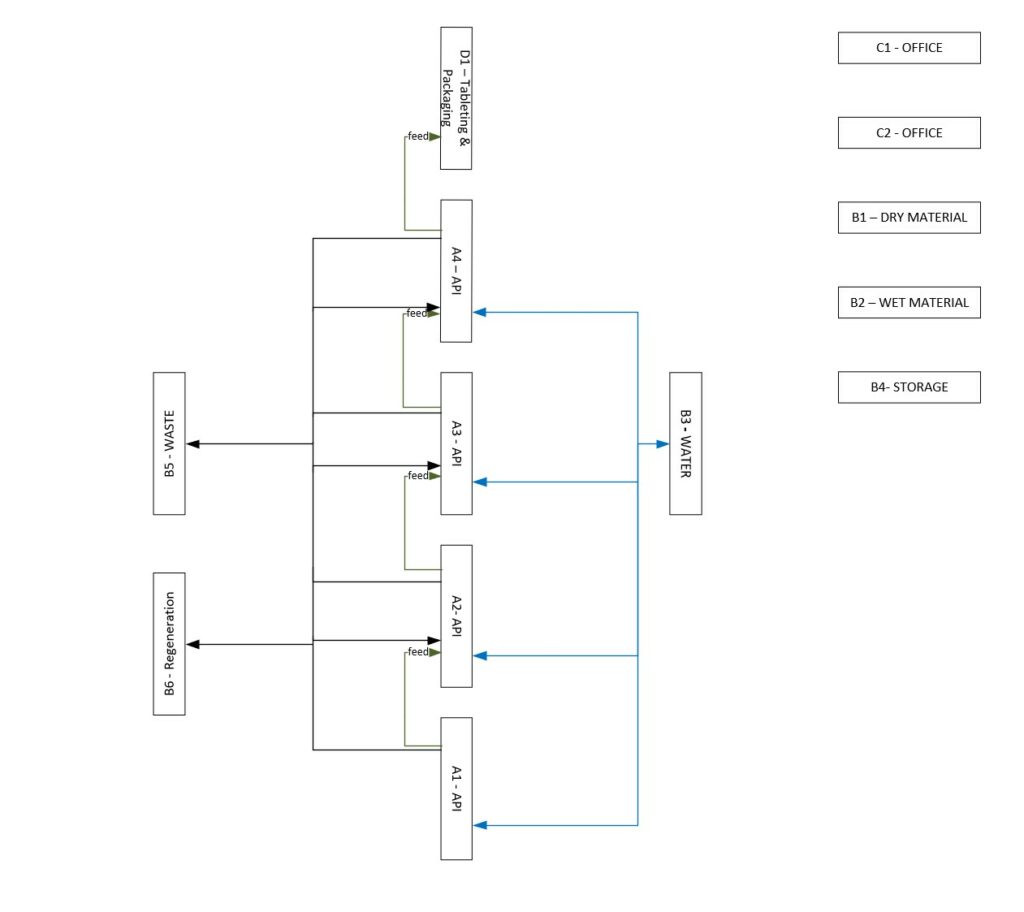

For the purposes of this project, we performed a detailed design of one process module. Our vision for each module is that it will hold one reactor and the required separation units to complete one chemical step in the manufacture of one or more medications. We conducted our case study on the production of pregabalin, a drug which is used to treat a vast array of conditions and is currently listed as in shortage.

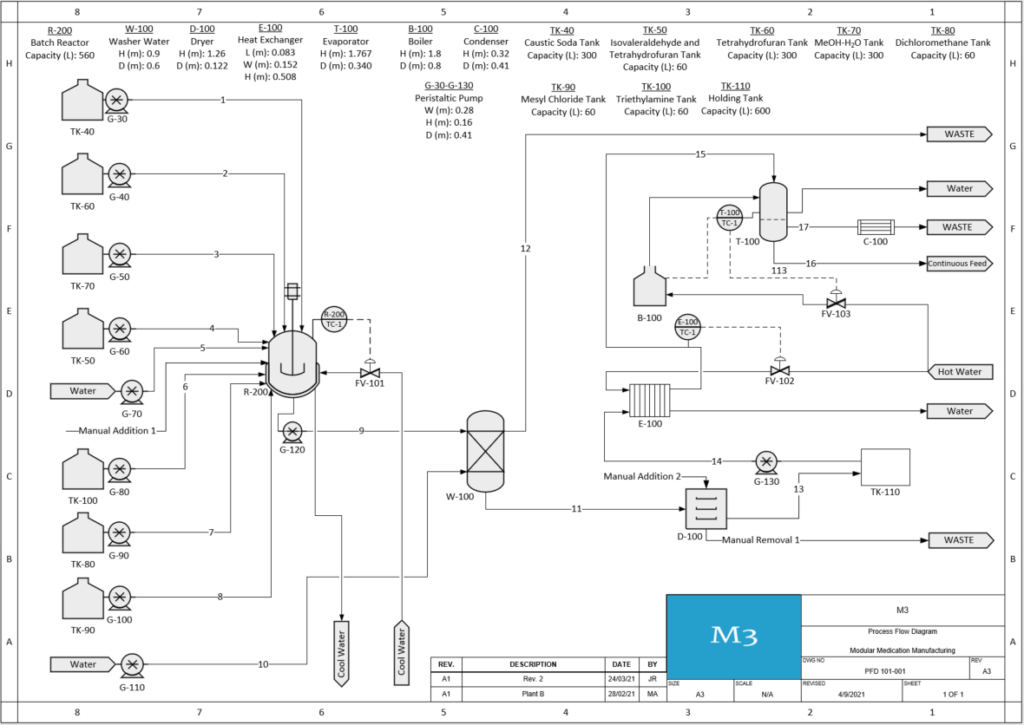

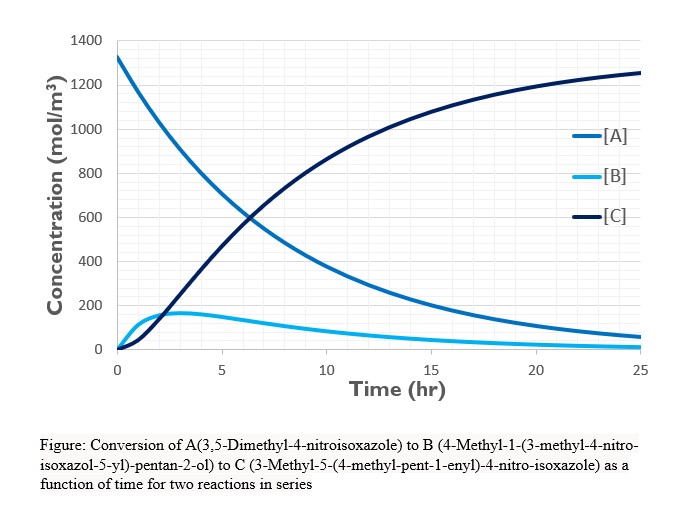

Our detailed design included a reactor, a washer, a chemical dryer, and an evaporator, as well as storage tanks, pumps, and other auxiliary equipment for an intermediate step in the production of pregabalin, where 3,5-Dimethyl-4-nitroisoxazole is converted to 3-Methyl-5-(4-methyl-pent-1-enyl)-4-nitro-isoxazole and then purified.

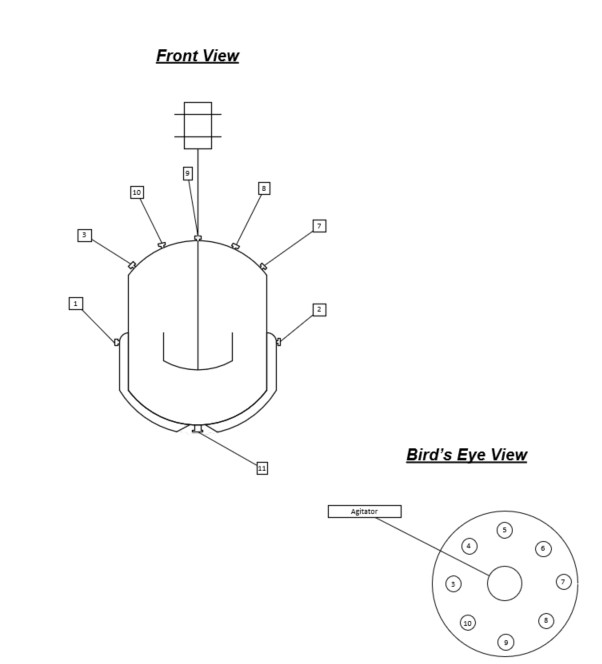

Reactor

The reactor is a stirred batch-type reactor and is the first piece of equipment in the designed module. This reactor has been selected to operate in batches due to the versatility of batch operation, which will allow for a greater number of applications. Given that our plant is modular and set up for the manufacturing of multiple medications, versatility is of the utmost importance. The reactor has a cooling jacket, which can be disconnected from the cooling fluid to a heating fluid, should another reaction require it. The reactor is made of stainless steel, and is the largest piece of process equipment in the module, with a capacity of 550L. This large capacity is used as most pharmaceutical processes take place in very dilute environments with a large number of solvents required. Additional space is also allowed in case any reaction causes frothing within the reactor.

Washer

The washer is the first separation step in the process. It is a 10 stage, continuous, counter-current liquid-liquid extraction column where the aim is to separate inorganic components (primarily mesyl chloride) from the remaining organics in the feed. The feed undergoes a water wash to aid in this separation. The washer is made of stainless steel, operates at 21°C and at atmospheric pressure and is 300L in size, however these operating conditions can be modified to accommodate various processes.

Chemical Dryer

The dryer is a semi-continuous adsorption column and operates in series with the washer. The purpose of the dryer is to remove excess water from the feed using a solid drying agent, magnesium sulfate, prior to the evaporator and heat exchanger. To minimize waste, the waste stream will be further separated and the magnesium sulfate will enter a drying oven at 200°C, where it will be regenerated for reuse in the dryer. The dryer operates with a continuous flow of the feed, but with manual additions and removal of the solid drying agent and wastes. The column has 5 stages, where one stage holds the solid drying agent, operates at 21°C and at atmospheric pressure, and is 15L in size.

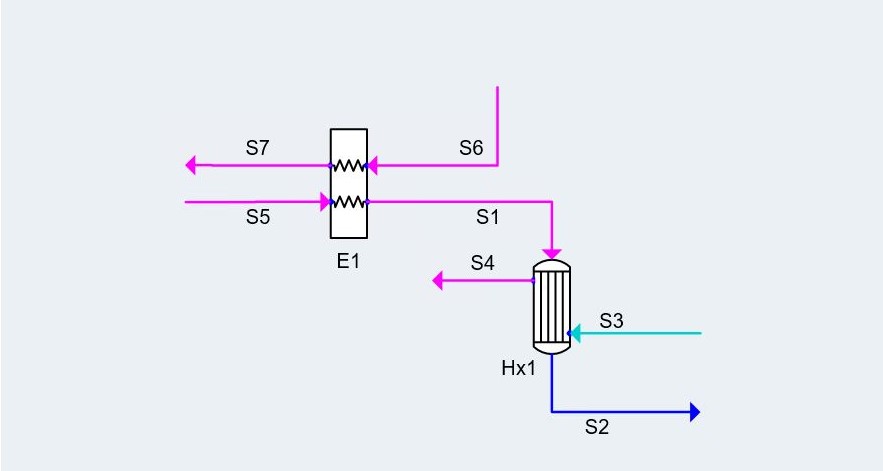

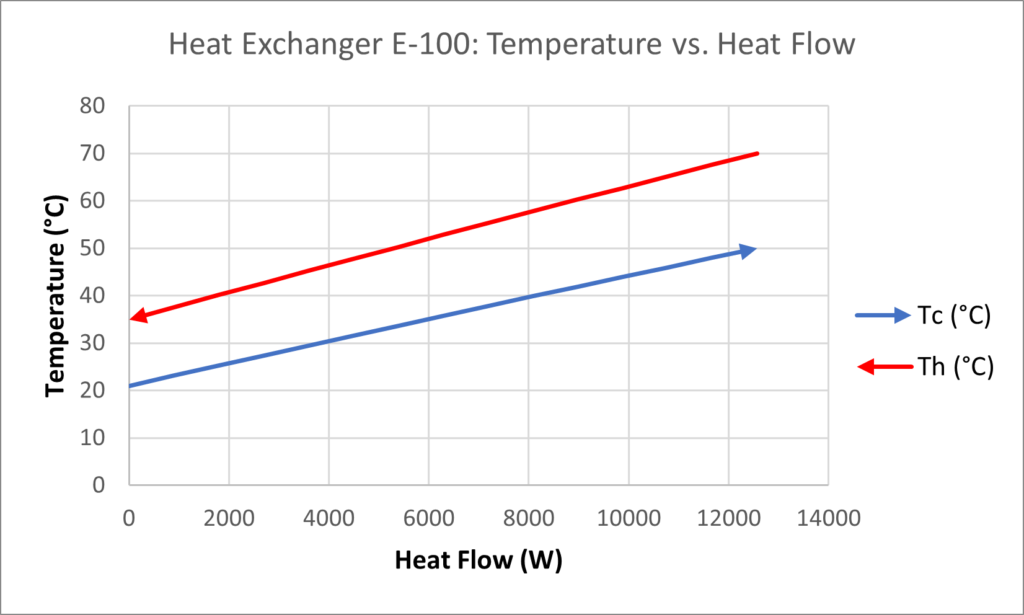

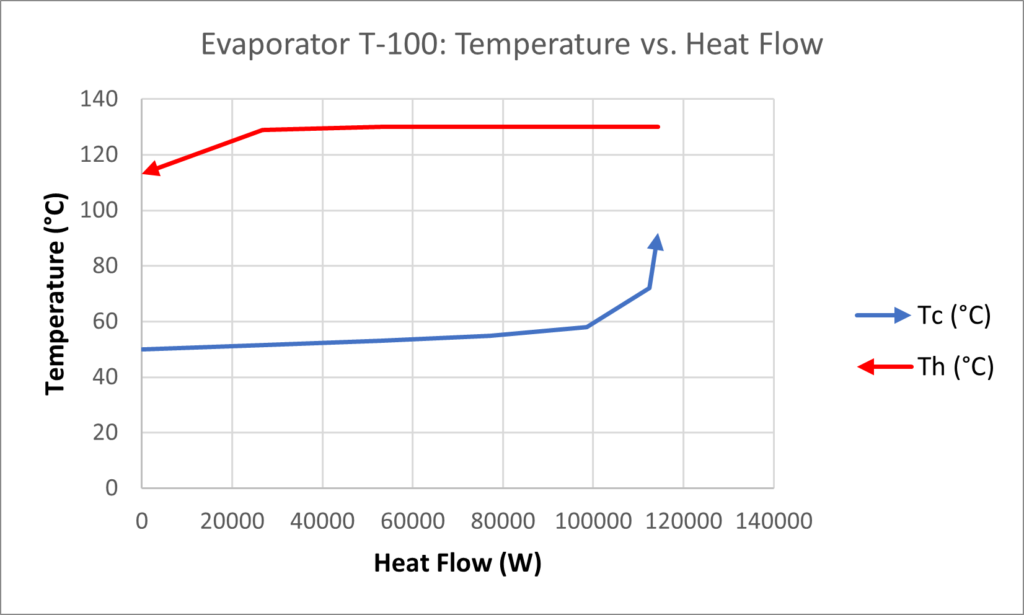

Evaporator and Heat Exchanger

The goal for the design of the evaporator was for it to be able to remove the organic solvents used in the reaction. It was designed to be a falling film evaporator. Floor space available in the container was limited so having a vertical evaporator was beneficial. The feed flows into the evaporator at the top and is distributed across the tube bundle. Saturated steam flows into the shell and the feed is evaporated due to its latent heat. Baffles were included in the design to aid in the distribution of the steam throughout the tube bundle. It is important to note that for this specific step in the production of Pregabalin, the evaporator operates at 55 kPa(g), but the equipment can handle a range of pressures. The shell has a diameter of 340 mm and the tubes are 1.252 m long.

A heat exchanger was added to aid in the success of the evaporator. A plate and frame heat exchanger was selected due to its compact size. Plate and frame heat exchangers have a higher pressure drop than other heat exchangers but due to the smaller flowrates, compared to large scale pharmaceutical production, the pressure drop is still minimum. This heat exchanger will have 15 plates that are 225 mm wide and 733 mm tall.

Pump Selection

Peristaltic pumps were chosen based on their volumetric nature for their ability to accurately and precisely prescribe flowrates and move slurries. Pumps are in between enough equipment pieces to specify flow, but not over specify the material streams.

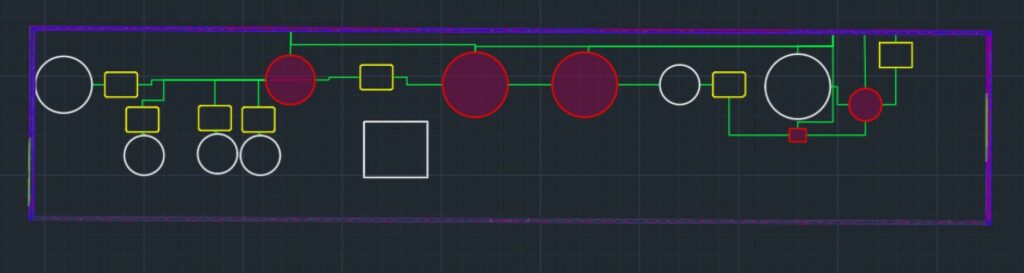

Plant Layout

The modularity of the plant means that both indoor and outdoor climates need to be considered. We chose to insulate all piping with hemp insulation as it is carbon negative and high insulative properties. The plant has been set up so that water and waste is attached to local utilities, and non-flushable waste will be removed every 2 weeks by a contractor. Our water piping will be elevated on 12 ft pipe racks to ensure vehicle access to all modules is still available. All other piping (feed, waste, regeneration) will be on a standard 3.5 feet riser. Since most piping will be made of SEBS, it will be light and easy to install and replace.

Some material storage tanks are housed within the process modules to reduce the amount of piping required, while other larger ones are stored separately and will be pumped into each module as required. Each module will have a control centre for all stream and process controls for that module.

Environmental Considerations

Our plant has no air emissions except in the situation where a electrical outage occurs and natural gas generators are required.

Generally, sound emissions will be will minimal. As each of our modules are lined with hemp insulation, a lot of equipment sound will be absorbed. Noise will be increased during set up and tear down as a result of construction, but not to unacceptable levels.

For waste disposal, it was determined that waste collection will occur every two weeks, as our waste module has a great enough capacity for approximately two batches. Given that the plant is set up such that all modules allow for trucks drive up, we are able to minimize the costs for this process. In order for the waste to be collected, the waste sea can would be drained and vacuumed into a waste truck and taken for treatment.

Economic Data

Based on our calculations, this plant will require an estimated initial total capital investment of $3.5M, and will have estimated annual operating costs of $4.9M. The estimated total annual revenue will be $18M and estimated annual after-tax profits will be $11M. The estimated Net Present Value over 10 years with a 10% rate of return is $187M. It is anticipated that the plant will be profitable after one year and will have a positive opening balance at the start of the second operating year.

Partners and mentors

We extend our heartfelt thanks to our project supervisor, Dr. Michael Kallos, whose guidance and support was instrumental to the success of this project. We would also like to thank Morenike Olaosebikan, founder of Kemet Advanced Manufacturing Inc., whose drive and passion for this project gave us the motivation to put together this inspiring project.

Our photo gallery