PlasmaTech Fuels Ltd.

Meet our team

- Dr. Hua Song – Project Supervisor

- Damola Korodele

- George Imevbore

- Lauren Van Horne

- Muhammad Harris Akbar

Join our virtual booth

Live from 10 AM till 12:30 PM on Tuesday April 13.

About our project

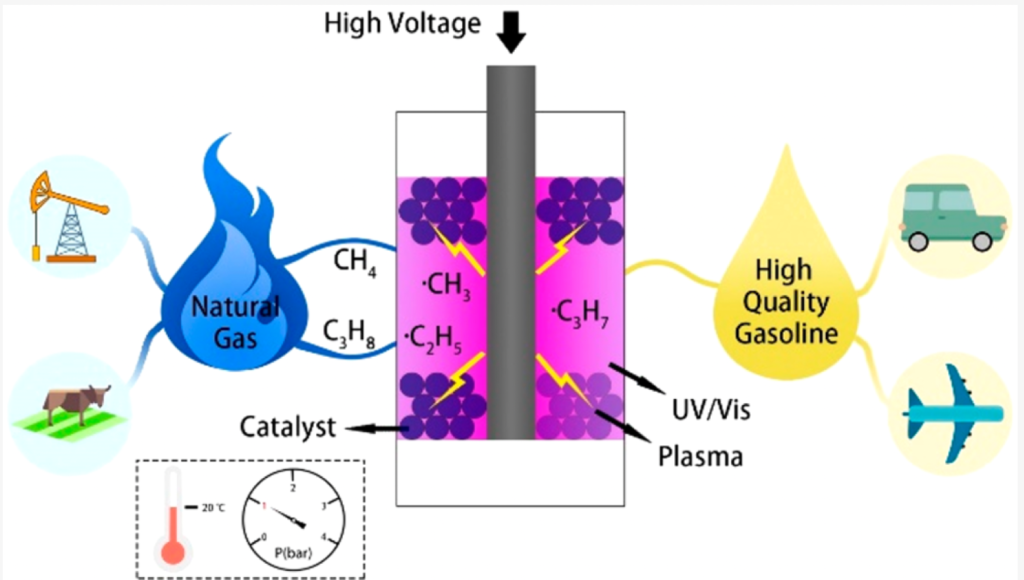

Can natural gas be part of a low-carbon future? Very much so. Natural gas – the cleanest burning fossil fuel – can be converted to higher-value liquid fuels that would alternatively be produced from crude oil with a higher carbon footprint. With innovative processes like nonthermal plasma-assisted photocatalysis, natural gas can be efficiently converted into higher-value liquid fuels at ambient conditions, unlike the conventional methods that require very high temperatures. The non-thermal plasma is generated by electricity, which can be produced from renewable sources such as wind and solar. By this sustainable approach, natural gas can be part of the low-carbon future with an increased economic value for investors as a liquid fuel.

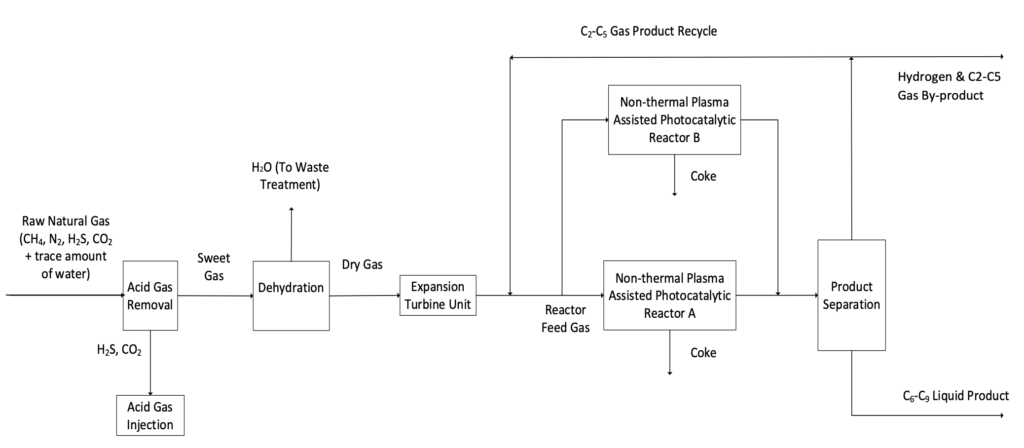

As part of our capstone project, we designed an integrated process to convert a raw natural gas feed of 40 MMSCFD into 6500 bbl/d of liquid fuel abundant with C6-C9 paraffins. Our process comprises pre-treatment of natural gas with amine to remove the acid gases and glycol for dehydration. The acid gases are disposed of into an injection well by using acid gas compressors. The treated gas then undergoes the plasma-assisted photocatalytic conversion in the reactor to yield C6-C9 liquid product along with C2-C5 gas by-product and minimal coke deposition.

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

- Natural gas is an abundant but underutilized resource in Alberta. Non-thermal plasma technology will increase the utilization of Alberta’s natural gas resources and stimulate the struggling economy with a high return on investment.

- The gas conversion process operates at ambient temperature and pressure, making it a more sustainable alternative compared to traditional methods that require very high temperatures.

- Minimum gas emissions into the atmosphere.

WHAT MAKES OUR DESIGN INNOVATIVE

- Unlike the traditional methods that require multiple steps to transform natural gas, the non-thermal plasma is a one-step approach with a simple process design.

- Non-thermal plasma is generated by electricity and can be powered on/off easily, making it a viable choice for intermittent sources of electricity like wind and solar.

- Natural gas conversion is thermodynamically unfavourable at low temperatures. However, with non-thermal plasma this reaction can be effectively stimulated at near room temperature.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

- The process achieves high product yield and purity with fewer units of operation, minimal coke formation, and less energy consumption.

- Inherently safer design with process risks carefully analyzed and mitigated.

- The process incorporates energy integration to minimize external utility loads, resulting in economic savings and lower environmental impact.

HOW WE VALIDATED OUR DESIGN SOLUTION

- The process simulation performed on VMG Symmetry was validated by hand calculations based on the literature.

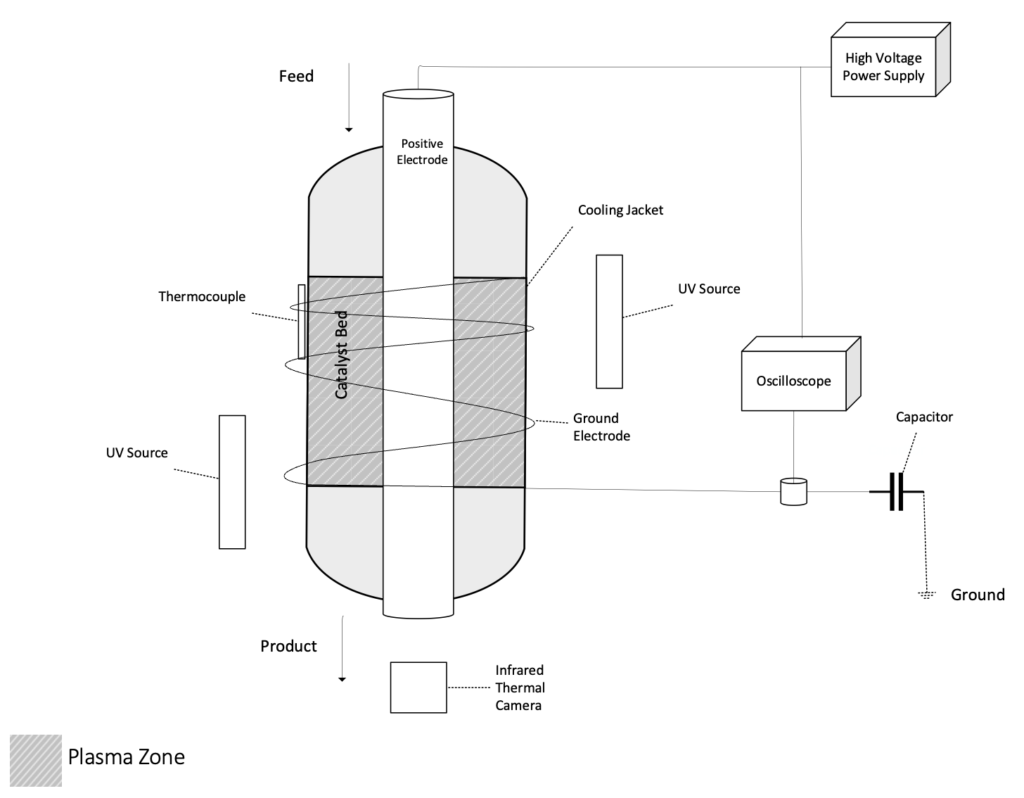

- The nonthermal plasma-assisted photocatalysis results from the simulation were crosschecked with the experimental results provided by our supervisor.

- The design of our process was consistently improved based on the feedback from our supervisor and consultation from an industry expert.

FEASIBILITY OF OUR DESIGN SOLUTION

- Based on our economic analysis, the project has yearly profits of approximately 56M after the third year, indicating that it is economically feasible.

- The unit operations selected for natural gas pre-treatment are common industry processes with the required equipment readily available.

- Owing to the high energy efficiency of the reactor, the power required to generate non-thermal plasma was deemed feasible.

Partners and mentors

We want to thank our project supervisor Dr. Hua Song, the Ph.D. Candidate Shijun Meng and the course instructors Dr. Siegler and Dr. Foley for their guidance throughout the project. We sincerely appreciate the feedback provided by various professors who attended our presentations. And, we are very grateful for the consultation with Mr. Rein Saar from Equinox Engineering.

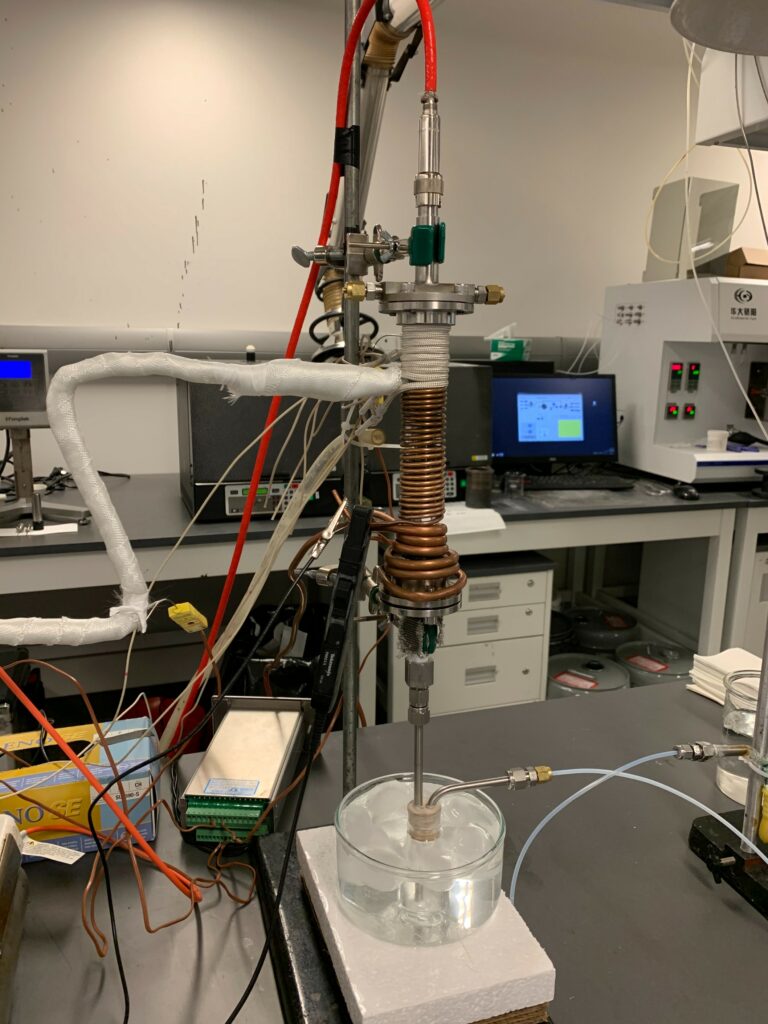

Our photo gallery