Project Category: Chemical

Join our presentation

Please click the zoom link to enter our zoom room.

About Our Project

With the increasing population growth and economic development, the world’s demand for renewable energy has risen. Core Energy has taken on the task to find a way to cleanly produce electricity by utilizing geothermal energy as a renewable source and sequester CO2. Our firm also wants to minimize our environmental footprint at all costs therefore, we will ensure that our process has zero emissions into the atmosphere.

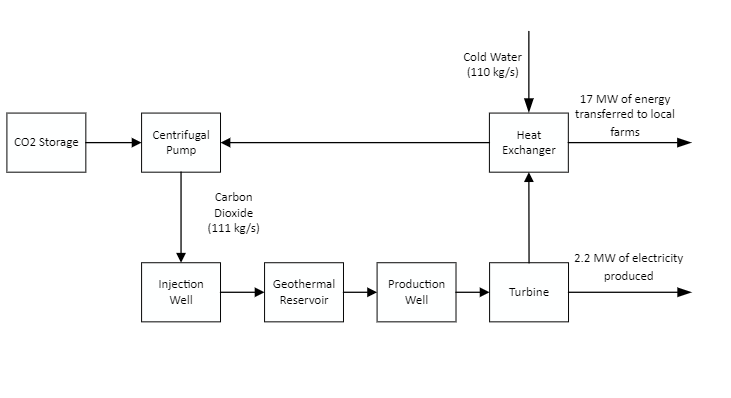

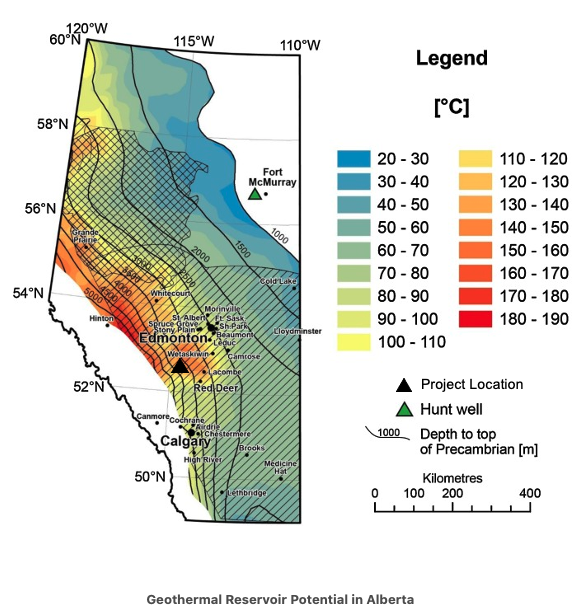

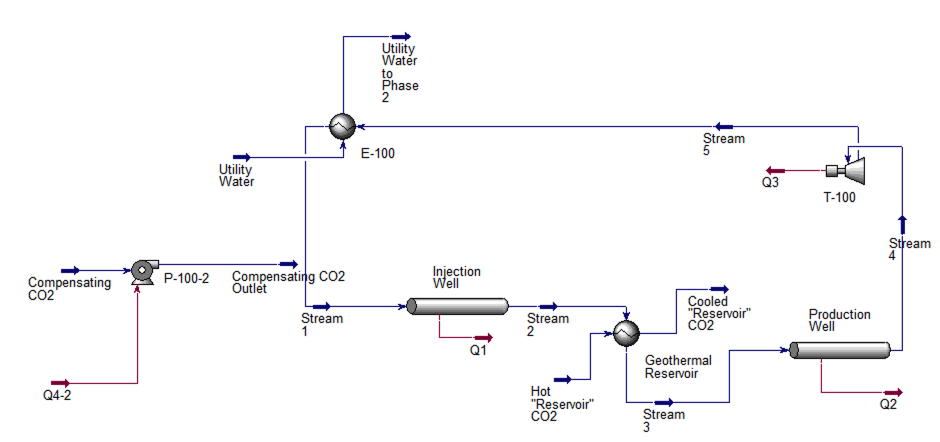

To do so, our company plans to harness the energy from a 120 °C geothermal reservoir at a depth of 5 km in Rocky Mountain House, Alberta. CO2 is the most commonly produced greenhouse gas and methods to capture the compound are the key to reducing climate change. By utilizing supercritical CO2, Core Energy has the potential to produce 2.2 MW of electricity and use the geothermal reservoir as a storage site to sequester 4500 tonnes of CO2 annually.

Core Energy has chosen to tap into the Alberta Carbon Trunkline (ACTL) to obtain 95% pure CO2. By applying government incentives for utilizing abandoned oil and gas wells and a forecasted increase in electricity price, the plant was able to achieve profitability.

Meet our team members

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES?

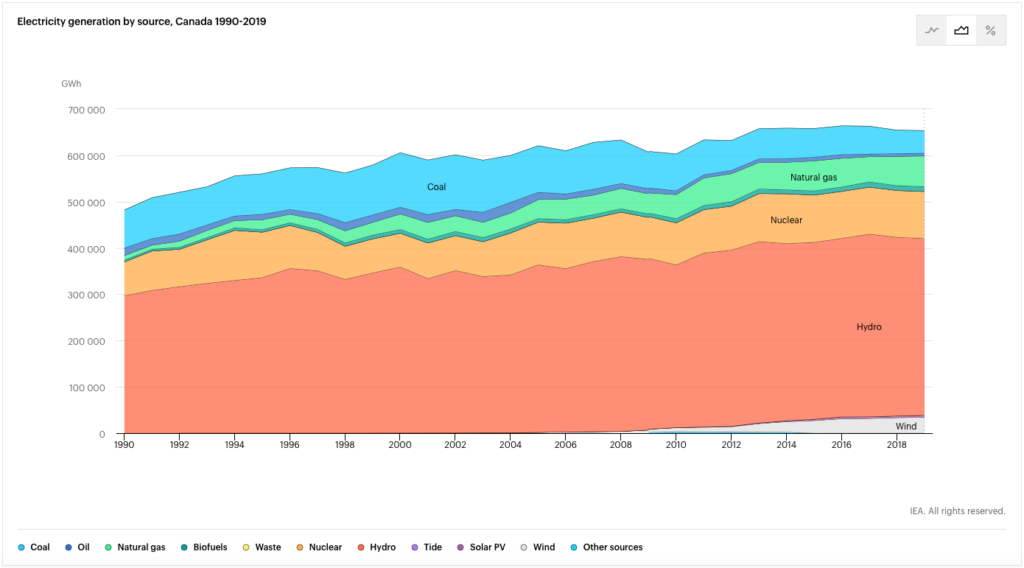

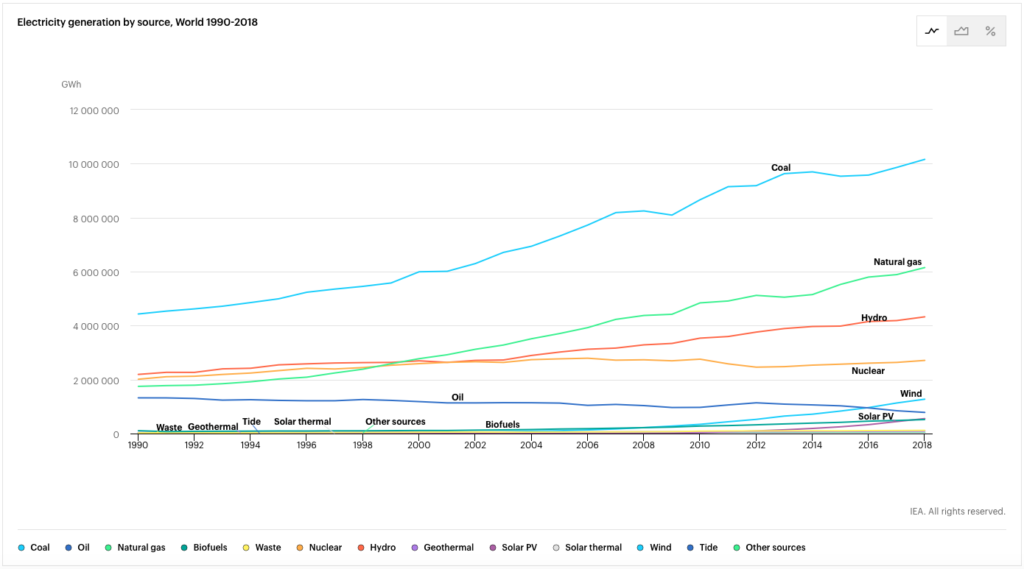

The demand for energy is constantly changing as society progresses. Fossil fuels have provided a convenient and effective source of fuel for many years, but the by-products of burning this fuel have been a complex problem for mankind. Geothermal energy is a potential solution as an alternate source of energy that offers clean, consistent, reliable electric power with no need for grid-scale energy storage, unlike most renewable power alternatives. By utilizing CO2 as the working fluid in our process, there is the potential to sequester CO2 in the reservoir which offers geological storage of this greenhouse gas. Along with energy production, carbon storage provides another source of revenue through carbon credit schemes.

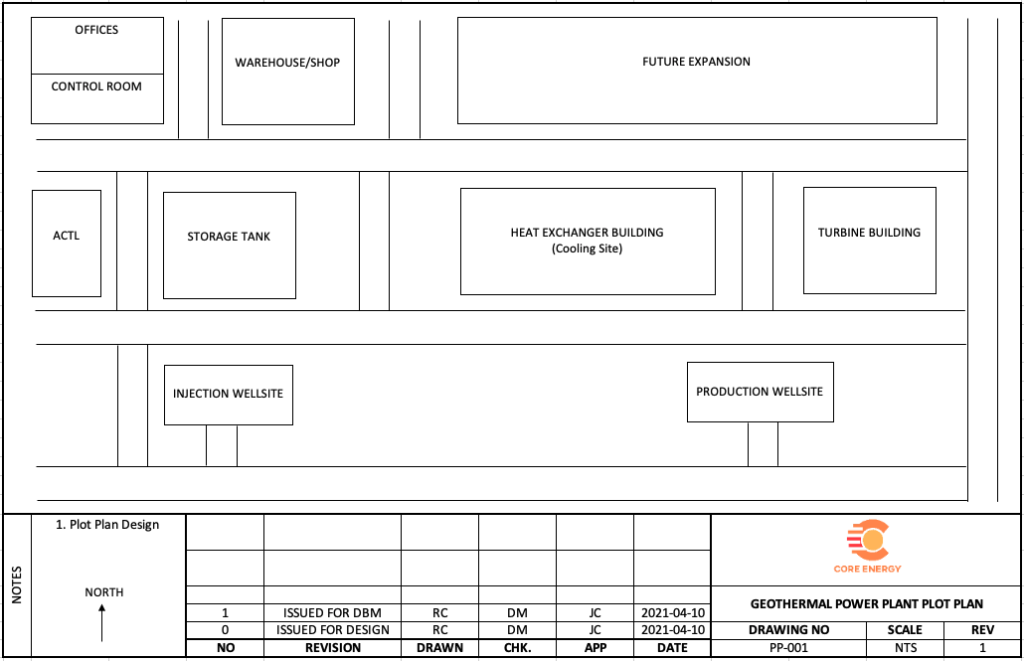

In this process, multiple wells will be required to circulate CO2. Core Energy plans to repurpose abandoned wells to lower capital investment and ensure the environmental impact of the project is minimal.

Reference: S. W. ,T. B. ,G. Z. ,I. M., J. M ,M. U. Hannes Hofmann, “Potential for enhanced geothermal systems in Alberta, Canada,” CrossMark, Edmonton, 2013.

The project location is near Rocky Mountain House, Alberta and our goal is to provide electricity to this area that is off the electrical grid. Core Energy plans to be the sole supplier of electricity for the entire community consistently as geothermal energy is available year-round.

WHAT MAKES OUR DESIGN INNOVATIVE?

Typical Enhanced Geothermal Systems (EGS) use water as their process fluid however, this is an expensive option that uses an already diminishing resource. By pressuring CO2 past its critical point, we can utilize favorable thermodynamic and transport properties to effectively capture heat from the geothermal reservoir. A CO2-based EGS would have a large difference in density between the injection and production well, leading to self-driven high flow rates through the reservoir. This method of passive heat exchange is called a thermosiphon and can circulate the fluid without the need of a mechanical pump.

By fracturing the reservoir, we are increasing the effective flow space for CO2 which subsequently leads to higher thermal extraction. Selecting an area with high permeability was important for this process to ensure enough fluid can flow across the reservoir. To maximize energy production, multiple well pairs will flow across the fractured reservoir.

Currently, there are no active geothermal plants in Alberta. The first large-scale geothermal facility in the province is planned to be completed in 2023 at a cost of $58,00,000. Our design recognizes the opportunity to use a renewable heat source to attract economic investment, diversify the energy sector, and reduce the provinces’ carbon footprint.

Reference: “International Energy Agency,” [Online]. Available: https://www.iea.org/data-and-statistics?country=CANADA&fuel=Electricity%20and%20heat&indicator=ElecGenByFuel. [Accessed 10 April 2021].

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE?

Our geothermal plant can function independently as the power produced from the cycle will be used to power any on-site equipment. No energy storage is required as power produced is designed to meet the town’s energy requirement. Since CO2 reduces pumping requirement and can be used directly in turbomachinery, the energy requirement for the plant is only 565 kW. Utilizing CO2 as the process working fluid also provides Core Energy with two possible sources of revenue. These two options are electricity production and carbon sequestration which can be easily scaled up.

Geothermal energy is a reliable source of energy that can be used all year round regardless of the weather or time of year. The reliability of geothermal power solves some of the main problems that occur with other forms of renewable energy such as wind and solar energy.

HOW WE VALIDATED OUR DESIGN SOLUTION?

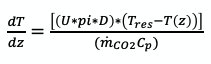

This design solution was first performed through hand calculations and the usage of the ODE solver function in MATLAB. To verify these calculations, each value was compared to literature sources along with the process simulation created in Aspen HYSYS.

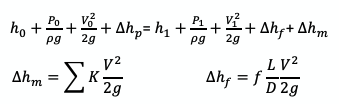

The pressure change across the injection and production well was determined using Bernoulli’s Equation:

Darcy’s law was then used to account for the pressure drop across the reservoir. The permeability was found through literature to be 5.92E-16 m2.

To simulate how the stream temperature would vary across the wells and reservoir, the ODE below was used. For each temperature profile, the overall heat transfer was calculated and then solved in MATLAB.

ECONOMIC FEASIBILITY OF OUR DESIGN SOLUTION

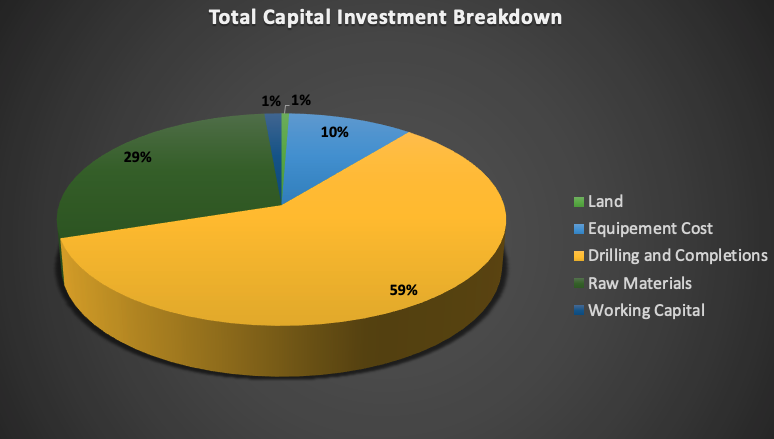

The total capital investment required for this plant design was $45,000,000. The cost is broken down between drilling & completions, equipment costs, land purchase, raw material procurement as well as the working capital.

The feasibility of our design was determined through four major economic indicators; net present value (NPV), internal rate of return (IRR), return on investment (ROI), and payback period. In the economic analysis, the cost of transporting CO2 to Rocky Mountain House, equipment cost, drilling and completions cost were all taken into consideration. Once fully optimized, our design resulted in a NPV of $12,880,000, IRR of 1.33 %, ROI of 29 % and a payback period of 213 years.

ENVIRONMENTAL & SOCIAL IMPACT

CO2 sequestration is an environmentally friendly measure this plant will be contributing to. As the CO2 flows through the reservoir, a fraction of it will continuously leave the loop and dissolve into the reservoir. This provides a potential long-term solution for removing this greenhouse gas.

With the potential of CO2 leaking underground, there is the risk of the fluid mixing with the reservoir brine. This can result in two main problems i.e., mutual dissolution between CO2/water and salt precipitation. To counteract the dissolution, dehydrators may be installed at the surface of the plant to separate the CO2 out from the solution. To monitor the salt precipitation, pressure transducers will be installed at the bottom of the wells and if the pressure decreases this indicates the working fluid is leaking out. Another method to mitigate the salt precipitation issue is to inject fresh water with low salinity into the reservoir.

Since this is a development project, it will result in more jobs for locals and help stimulate the economy. Jobs in various fields such as construction, engineering, operations, and transport will result from this project. The geothermal site can also be easily incorporated into communities without causing any visual disturbance or discomfort. They require a small amount of land area and do not require transportation or combustion of fuel.

Partners and mentors

We want to thank the many people who helped us with this project. Our capstone supervisor Dr. Apostolos Kantzas guided us through the process with great advice and valuable time. We also want to thank Dr. Roman Shor and Dr. Kunal Karan for their invaluable advice in configuring our design.

Our photo gallery

Reference: “International Energy Agency,” [Online]. Available: https://www.iea.org/data-and-statistics?country=WORLD&fuel=Electricity%20and%20heat&indicator=ElecGenByFuel. [Accessed 10 April 2021].