Project Category: Chemical

Our Project

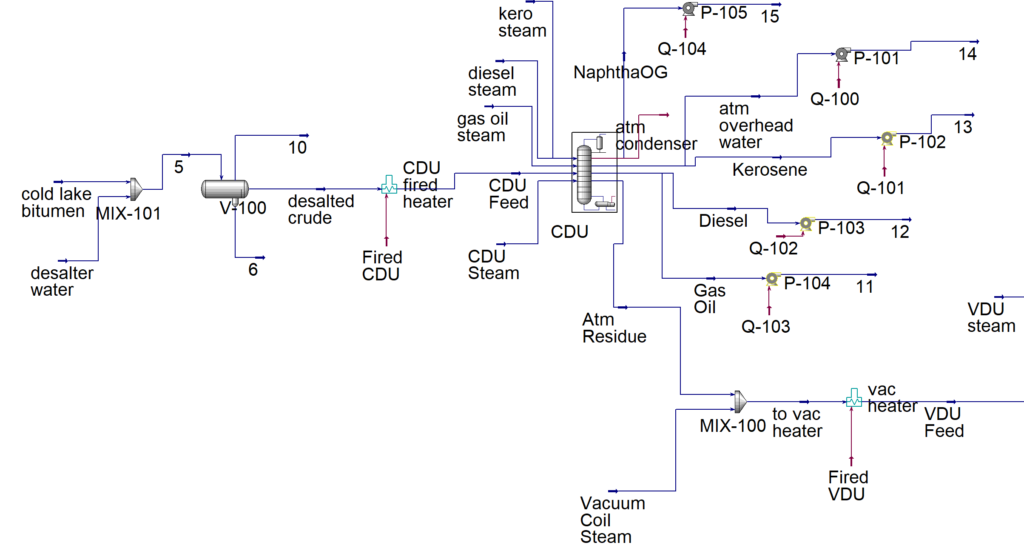

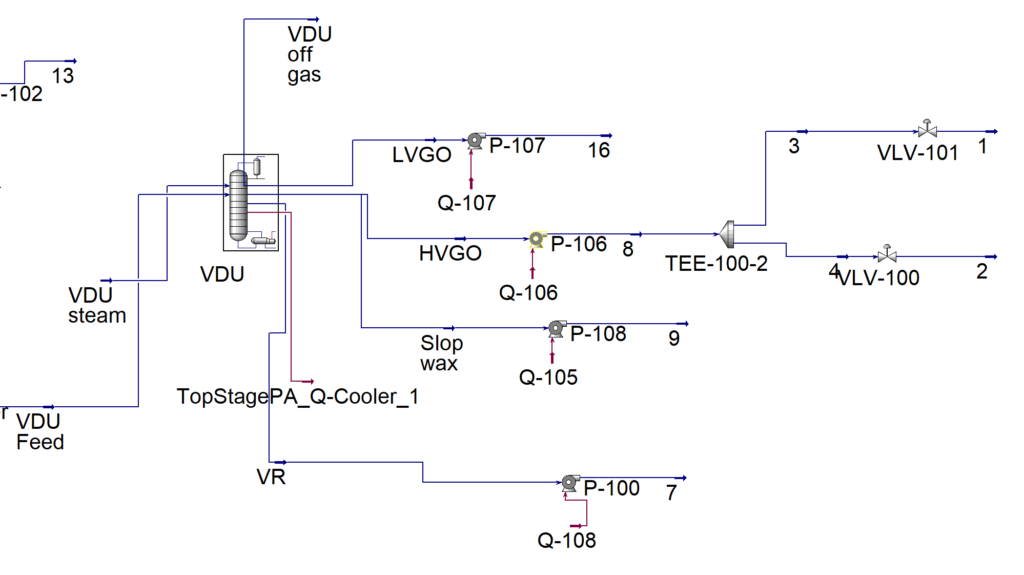

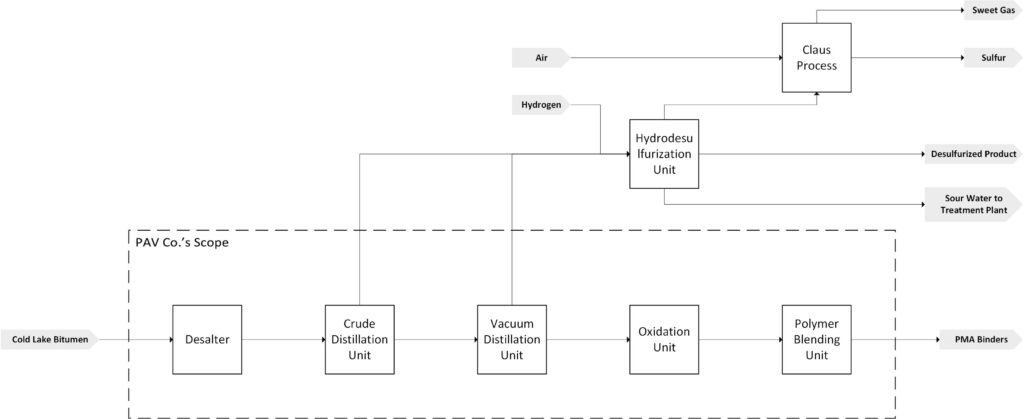

PAV Co. takes the role of a primary refinery that specializes in the production of polymer modified asphalt binders. It takes specifically Styrene-Butadiene-Styrene (SBS) and mixes it with treated vacuum residue to create our up to spec binder ready for Albertan roadways. The aim of our design is to explore and develop binders for roadways that are less susceptible to cracking and structural failure, especially given the cold climates of Alberta. The introduction of a polymer has been investigated, and found to be the key to establishing longevity and healthier roadways for larger ranges of thermal, and mechanical stresses.

We aim to produce 5000 tonnes per day of high-quality polymer-modified asphalt binder (3% SBS by mass). Our design also produces co-products such as gas oil, kerosene, and diesel. which also contributes to the overall feasibility of the plant. These by-products are sold to a nearby plant for further secondary upgrading. The main product (Polymer Modified Asphalt Binder) is sold to asphalt vendors.

Meet Our Team

Ahmed Abouahmed

Gibran Hnidi

Mohamed El Ansary

Mohammed Ali

Mohanad Sayed

Details About Our Design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

The most common issue in road design is rutting (permanent deformation) and cracking due to extreme cold temperatures, especially in cold areas like Alberta. Our product is designed to withstand extreme cold temperatures and high traffic loads making it more resistant to permanent deformation, rutting and cracking. This allows for long lasting roads that require less frequent maintenance with lower costs.

WHAT MAKES OUR DESIGN INNOVATIVE

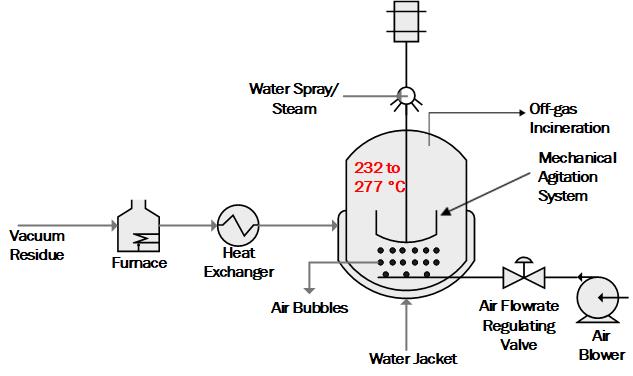

What makes our design innovative is the addition of the oxidizing unit. Typically refineries do not include the oxidation unit. However, since PAV Co is producing polymer modified asphalt binder, the pre-preparation of the binder is important to bring some of its properties closer to the specification required prior to polymer mixing. Within the oxidizer, vacuum residue is air blown at high temperatures of 200℃ – 275℃. Dehydrogenation and polymerization are involved in the exothermic air blowing reaction. In principle, the oxygen in the air reacts with the hydrogen in the asphalt (a hydrocarbon) to produce water vapour. This leaves unsaturation for cross-linking. The blown asphalt thus has more and stronger molecular interactions than the original bitumen and is, therefore, more cohesive. Blowing causes the softening point to increase and the penetration to decrease. This means that blowing reduces the temperature susceptibility of bitumen. This makes for better and more durable asphalt for paving roads.

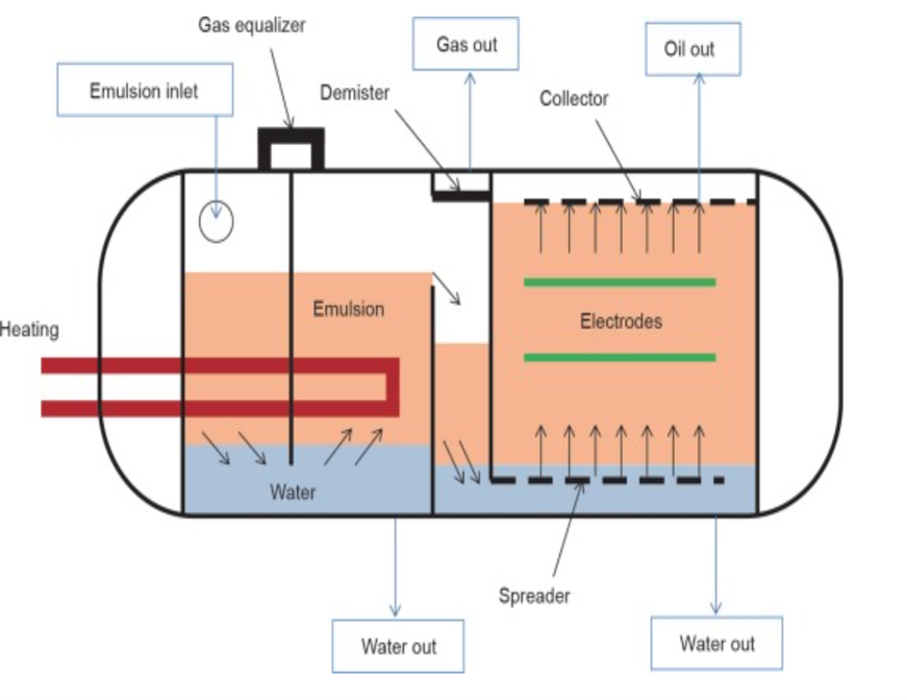

Another innovation would be the addition of the desalter unit. What makes this unit particularly innovative is its electrostatic properties that furthers the separation of water-oil emulsions. This unit excels in separating solids and large emulsion droplets via gravity, however inducing an electric field allows for further coalescence of more stable emulsion droplets improving water-oil separation allowing for a more pure crude oil downstream for processing. This beats the typical gravity settling techniques as the electric field allows for a purer crude with less solids, salts, and water. The removal of contaminants also ensures that our asphalt binder maintains its high quality for road pavement.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

The purpose of production of PMA (Polymer Modified Asphalt Binder) is to adjust the mechanical and rheological properties of unmodified asphalt binder via the addition of SBS polymer. The process allows for higher quality roads that can withstand extreme temperature variations and increased traffic loads.

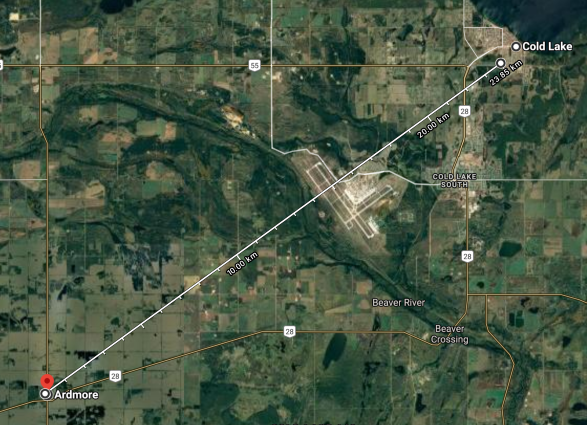

Another effective approach was the plant location to be selected as Ardmore, Alberta, Canada near their field of production, in order to minimize the pipeline transportation costs.

The distance between Cold Lake and Ardmore, our desired plant location, is about 24 km

HOW WE VALIDATED OUR DESIGN SOLUTION

- The Husky Endowed Research Chair in Bituminous Materials at the University of Calgary has been Canada’s top centre of asphalt research for over 25 years. Over the course of our project we have been consulting Dr. Martin Jasso, the chair and head of research of Husky’s Bituminous Materials research program. Dr. Jasso provided us with constructive advice on process unit selection, unit design specifications as well as operating conditions. Our design solution validation was mainly based on Dr. Jasso’s research papers as well as other published literature.

- Furthermore, we’ve taken into consideration alternative designs used in asphalt production facilities overseas. We consulted ENPPI, an EPC company, which engineered, procured, and constructed a project for an asphalt production plant located in Suez, Egypt.

- Lastly, we validated our design by modelling our process on Aspen HYSYS using the Peng-Robinson thermodynamic package.

FEASIBILITY OF OUR DESIGN SOLUTION

From the profitability analysis conducted, we concluded that PAV Co.’s design is economically feasible and our product is viable.

Shown below is our profitability analysis and sensitivity analysis, respectively.

| Profitability Analysis | |

| Parameter | Value |

| Capital Costs, CAPEX | $91,000,000 |

| Operational Costs, OPEX | $170,000,000 |

| Net Present Value, NPV | $4,700,000 |

| Discounted Rate of Return | 43.00% |

| Discounted Payback Period | 1.50 years |

| Annual Cost of Manufacturing | $170,000,000 |

Partners and Mentors

We would like to first thank our supervisor, Dr. Maen Husein. His guidance, motivation, and expertise were matched by no other. His advice and feedback were very constructive and helped shape us into more engineer-minded individuals. We appreciate the availability to our groups needs; always present for any question or concern we had.

We thank Dr. Hector De la Hoz Siegler for his work ethic in coordinating the entire capstone course. We appreciate the help we have been given through emails, zoom meetings, and for his informative lectures which have been a great help in our capstone project.

We would also like to thank the Chair and Head of Research of Husky’s Bituminous Materials Research Program, Dr. Martin Jasso for his excellent consultation and mentorship through the beginning phases of our project.

Our Photo Gallery

Photo courtesy of, F. Rossi, S. Colombo, S. Pierucci, E. Ranzi, F. Manenti, “Upstream Operations in the Oil Industry: Rigorous Modeling of an Electrostatic Coalescer”.

Photo courtesy of: www.eurobitume.eu