Project Category: Chemical

Join our presentation

Our Zoom Room will be active during the Capstone Design Fair on Tuesday April 5th, 2022 from 10:00am-12:30pm. There will be at least one person at the booth until the end of the fair.

Any inquiries outside of the Capstone Design Fair can be directed to us at jeremy.ohlhauser1@ucalgary.ca.

About our project

Despite more and more cities adopting greener strategies for the disposal of municipal solid waste (MSW) and the collection of recycling; we still see a trend of increasing accumulation of municipal waste as world population increases. Posing a threat to groundwater and slowly destroying natural habitat with the need for constant expansion. Furthermore, the fossil fuel industry is unpredictable with prices fluctuating regularly depending on world events and land exploitation, which burdens the pockets of everyone.

As such, our project seeks to address both of these issues and their implications by converting unwanted MSW into an alternative fuel source. To accomplish this, waste will be subjected to a chemical process known as pyrolysis, followed by a series of separations, before finally being sold at an incentivized price to heavy oil refineries to be co-processed with petroleum products during their upgrading stages. Meanwhile our project will also return missed recyclables, produce concrete additives, and generate power from waste heat and by products.

a

Meet our team members

Jason Xu

Humza Jamil

Jeremy Ohlhauser

Areeb Sheikh

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

This design uses pyrolysis to convert municipal solid waste to raw bio oil. Bio oil obtained from this process, once upgraded, can be used for a wide variety of applications such as airplane, diesel, and gasoline fuels. The process has a significantly lower environmental footprint when compared to crude oil extraction, MSW disposal, and the impacts associated with landfill runoff.

The production of waste is always guaranteed so there’s never a supply shortage and therefore won’t have fluctuations like seen in the oil and gas market. With every municipal district having at least one landfill, this bio-oils produced from this process don’t need to be shipped out and can be produced directly for the district it will be used in. By pyrolyzing waste, it also reduces the amount of waste in the landfill and heavily reduces the need for expansion which in turn preserves natural wilderness.

WHAT MAKES OUR DESIGN INNOVATIVE

What makes our design innovative is that it uses a feed that is often not considered to have any value and converts it to something that has value in many different fields. Many companies pay large amounts of money to dispose of MSW while we are using it as our main feed source and gaining valuable products from it. Our design also uses some of the byproduct from pyrolysis to meet heating requirements and make our system more efficient overall.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

Our design is extremely effective as its feed supply is reliable, it can be set up anywhere around the world, the reaction is self-sustaining and the heat recovery system supplements energy consumed at steady state. The way our system is designed with the hold up tank and other fail safes allows the process to operate at steady state.

HOW WE VALIDATED OUR DESIGN SOLUTION

Validation was perhaps the most daunting challenge of this project, as much of our project was based on educated assumptions based on literature surveys for attempting to apply results from varying situations to ours. And it is very likely that upon procurement of this process, many parameters will change within a small range.

The biggest factor behind this boils down to the nature of our feedstock and pyrolysis, along with the information available on them. Although the process itself is quite simple – merely heating a substance in an oxygen free environment – the mechanisms and products within pyrolysis are not simple. Especially when applied to a feedstock that varies from day to day. Pyrolysis creates a bewildering amount of distinct chemicals, and as such, work to characterize pyrolysis kinetics generally resorts to predicting relative amounts of solid, liquid, and gaseous phases produced compared to their reaction conditions.

After sifting through Albertan waste reports, and coming up with an average material composition that we would use as a feed, we then did a weighted average of literature kinetics results. These weights were based on the feed each paper studied, and how much of that type of material was present in our feed. Following this, estimates were created for the amount of phases our pyrolysis reaction would produce, heat of reaction, zeroth order mass basis reaction kinetics, and reaction conditions. To determine physical and chemical properties of these phases, a similar undertaking was conducted.

The results of these estimations gave us an excellent starting point to design our process around. However, the parameters we have estimated are extremely sensitive to changes in feedstock and process disruptions that would alter reaction conditions. Nonetheless, should our feedstock’s composition remain constant, and the accuracy of our estimations be true, our team is confident that our design will prove to be valid as a result of closely following engineering principles and thoroughly researching design problems we have not previously encountered.

FEASIBILITY OF OUR DESIGN SOLUTION

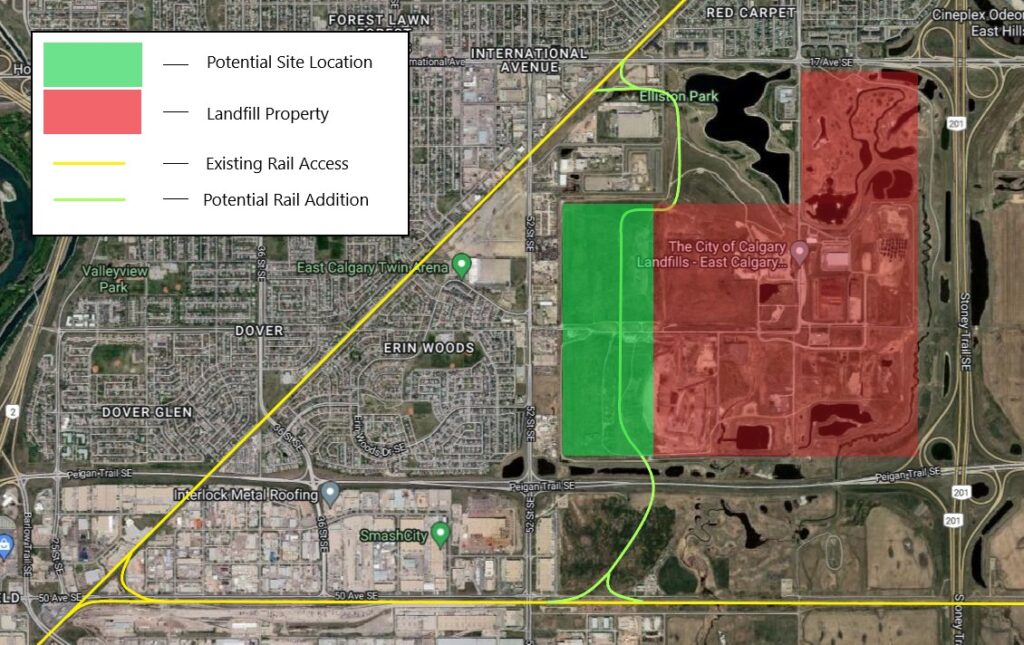

Our project is feasible as it is nearly self-sustaining at steady state and is a process that turns waste into a valuable commodity. It does not require transport of our feed as our chosen site for construction is near a landfill, nor for our products as there is rail access near our site. Additionally our project has a positive net present value and short payback period. And finally, with the world population consistently growing, there will always be an available supply of MSW and the increasing demand for fuel products.

MAJOR PROCESS UNITS

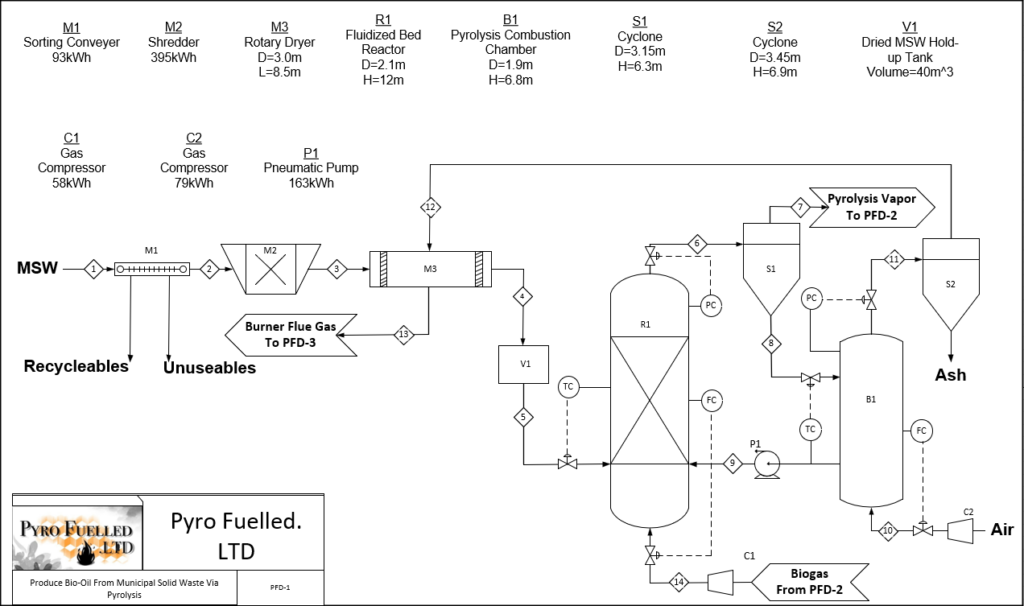

Pre Treatment

Some materials need to be removed from the feed like metals which should be recycled instead. Halogenated materials could cause corrosion while materials that retain large amounts of moisture may not be pyrolyzed well. Therefore, a triad of electromagnets, robotic arms, and workers with pickers will be used to separate undesirables. A shredder is required to increase surface area to volume ratio to assist in faster drying and quicker heat transfer within the pyrolysis reactor as well as reducing the pyrolysis reactor’s size and fluidizing gas requirements. The shredder will be selected to ensure the existing particles have a characteristic dimension of 5mm. With a high moisture content that will hinder the process downstream, our freshly shredded MSW must be dried, and in order to aid in the efficiency of a continuous process a rotary dryer was selected.

Reactor

In order to effectively pyrolyze solid MSW particles in a continuous manner, while allowing nearly instantaneous heat transfer to the MSW, a circulating fluidized bed reactor was chosen to meet the needs of our process. Which also operates in conjunction with a cyclone and burner.

MSW, high temperature sand, and a large volume of recycled syngas enters the bottom of the reactor. The sand then transfers its heat to the MSW while in close contact with it. This provides the heat of reaction necessary for the MSW to pyrolyze, rapidly converting it into a solid char, bio oil vapors, and syngas. Meanwhile the recycled gas fluidizes the solids, blowing everything up and out towards a cyclone. The cyclone diverts vapors and gasses elsewhere in the process, while returning sand and char byproduct to a burner. Here air is injected to completely burn up the char in order to reheat the sand. An auger then brings the freshly reheated sand back to the main reactor, where the above process continuously proceeds.

Separation

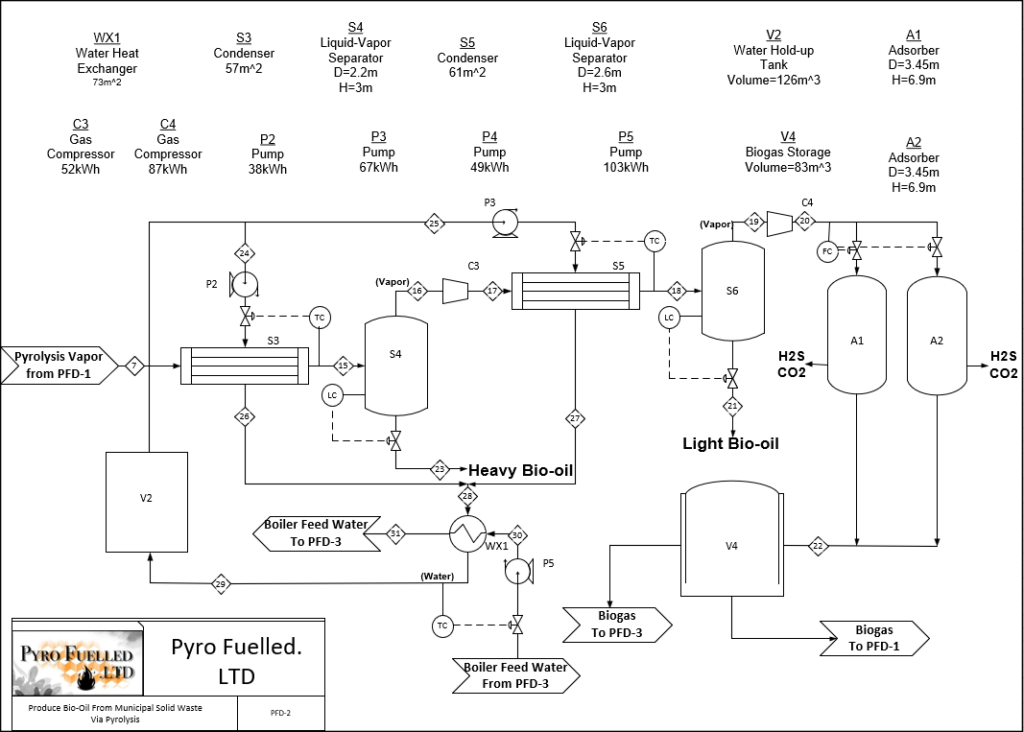

Raw bio oil vapor and syngas fresh from the main reactor and cyclone head to a series of condensers and two phase separators. The first condenser condenses the heaviest fractions of the raw bio oil before a two phase separator diverts the heavy, now liquid, fraction away from the still vaporized light fraction and syngas. The same series of units are used again, however at a different temperature to further separate the lighter fraction of raw bio oil from the remaining syngas. To conclude separations, the syngas proceeds to an adsorber sulfur and carbon dioxide are removed from the syngas using zeolite.

Flue Gas Treatment

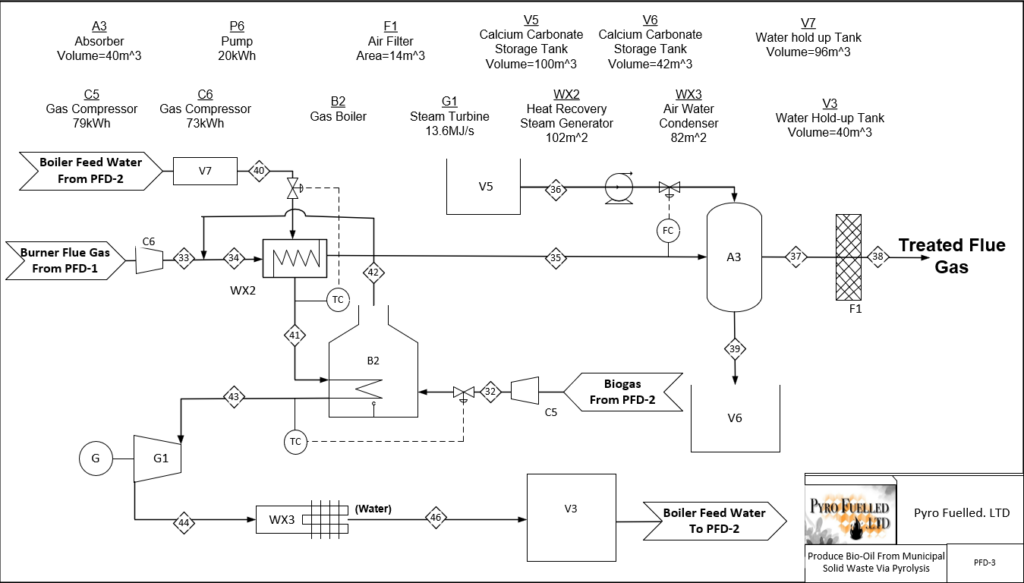

Exhaust gasses from the cooling cyclone and burner are combined to be treated before leaving the system. Since the exhaust gasses contain carbon dioxide and sulfur dioxide, an adsorber with a lime slurry was selected to treat the gas. The flue gas enters the bottom of the adsorber and is bubbled through a slurry running down the adsorber containing calcium hydroxide and water. After leaving the adsorber, the flue gas goes through a filter (particulate collector) to ensure removal of any particulate matter.

Heat Recovery

Our process produces a lot of heat, and in order to maximize our processes efficiency that heat must be recovered. This is accomplished through an isolated thermodynamic work cycle, utilizing a turbine and water as a working fluid. The working fluid first passes through a heat exchanger where coolant exiting the oil condensers flows through in order to be returned to its original temperature. Following this, it then goes to a boiler where combined hot flue gasses from the process pass through, turning the working fluid into a saturated steam, while also bringing the flue gas to an adequate temperature to be scrubbed of its carbon elsewhere. Once saturated, this steam then goes through a burner where excess syngas is burned in order to superheat the steam before being passed through a turbine. Following its pass through a turbine, the steam enters a condenser before restarting its loop. Currently this condenser is an open air heat exchanger, however the efficiency of our heat cycle can be improved by making this condenser the source of heat for a second isolated work cycle, whose working fluid possesses a lower boiling point.

ECONOMIC EVALUATION

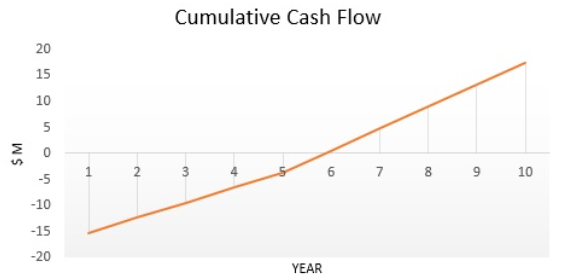

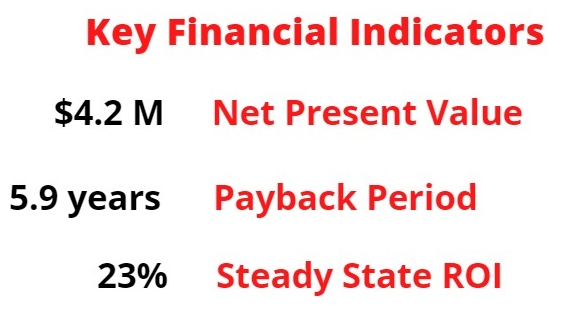

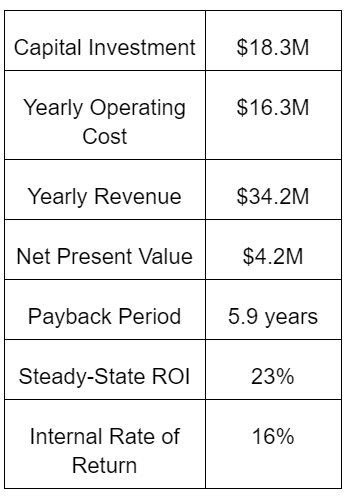

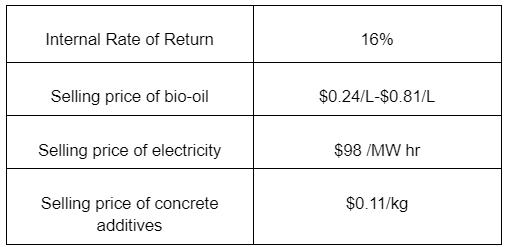

We made several assumptions for our economic evaluation. The discount factor is 10%, the tax rate is 40%, and there is a straight-line depreciation of 20% on equipment for the first 5 years. The lifetime of the project is set to 10 years. The capital investment consists of purchased equipment cost, instrumentation and controls, piping, electrical, construction, and land costs. The yearly operating cost consists of wages for engineering and supervision, utilities, raw materials, rail transport for the bio-oil, and contingency. Yearly revenue is obtained from the sale of bio-oil, the concrete additive, and electricity produced from the turbine. The selling price of bio-oil from fast pyrolysis ranges from $0.240/L to $0.816/L, but the lower end of the range was chosen for a more conservative analysis. The selling price of the concrete additive and electricity was estimated to be $0.11/kg and $93/MW-h respectively. Projecting the cash flow over the lifetime of the project results in a net present value of $4.2 million, a payback period of 5.9 years, and a steady-state ROI of 23%.

Partners and mentors

We would like to thank all those involved in this project as well as numerous researchers who shared their work which we referred to in this project. Finally, we would to thank Dr. Lu, Dr. Siegler and Dr. Foley for helping us ensure this project reached its full potential.

Our photo gallery

References

[1] “Population Clock”, Census.gov, 2021. [Online]. Available: https://www.census.gov/popclock/. [Accessed: 03- Mar- 2022].

[2] “Topic: Waste generation worldwide”, Statista, 2022. [Online]. Available: https://www.statista.com/topics/4983/waste-generation-worldwide/?fbclid=IwAR2-FwzXSTc1V7SnkzvS86uHM6-2I9Fer16Nqn2Hz78BZSYUBhRzciuINgw. [Accessed: 05- Mar- 2022].

[3] “EIA projects nearly 50% increase in world energy usage”, Eia.gov, 2019. [Online]. Available: https://www.eia.gov/todayinenergy/detail.php?id=41433. [Accessed: 05- Mar- 2022].

[4] National Waste Characterization Report. Gatineau, QB: Environment and Climate Change Canada, 2020.

[5] W. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 5th ed. McGraw-Hill Book Company, 1993.

[6] M. Mehboob, “Sizing Of A Rotary Dryer”, Chempds Blogspot, 2019. [Online]. Available: https://chempds.blogspot.com/2019/01/sizing-of-rotary-dryer.html?fbclid=IwAR0dxiTHXYhpDpmTtDF4wq5nZrywNhTT9W4wUP6Hy1ueP9771OPKhgmkLLY. [Accessed: 06- Mar- 2022].

[7] Q. Li, A. Faramarzi, S. Zhang, Y. Wang, X. Hu and M. Gholizadeh, “Progress in catalytic pyrolysis of municipal solid waste”, Energy Conversion and Management, vol. 226, p. 113525, 2020. Available: 10.1016/j.enconman.2020.113525.

[8] S. Nanda and F. Berruti, “A technical review of bioenergy and resource recovery from municipal solid waste”, Journal of Hazardous Materials, vol. 403, p. 123970, 2021. Available: 10.1016/j.jhazmat.2020.123970.

[9] G. Newalkar, K. Iisa, A. D’Amico, C. Sievers and P. Agrawal, “Effect of Temperature, Pressure, and Residence Time on Pyrolysis of Pine in an Entrained Flow Reactor”, Energy & Fuels, vol. 28, no. 8, pp. 5144-5157, 2014. Available: 10.1021/ef5009715.

[10] J. Grace, X. Bi and N. Ellis, Essentials of Fluidization Technology, 1st ed. Wiley, 2020.

[11] A. Ghaemi and A. Behroozi, “Comparison of hydroxide‐based adsorbents of Mg(OH) 2 and Ca(OH) 2 for CO 2 capture: utilization of response surface methodology, kinetic, and isotherm modeling”, Greenhouse Gases: Science and Technology, vol. 10, no. 5, pp. 948-964, 2020. Available: 10.1002/ghg.2015.

[12] A. Gupta, Eeer.org, 2022. [Online]. Available: https://www.eeer.org/upload/eer-2020-438.pdf. [Accessed: 15- Feb- 2022].

[13] Youtube.com, 2022. [Online]. Available: https://www.youtube.com/watch?v=GaJmi_aDkKo. [Accessed: 16- Feb- 2022].

[14] S. Brosillon, Oatao.univ-toulouse.fr, 2022. [Online]. Available: https://oatao.univ-toulouse.fr/23281/1/Brosillon_23281.pdf. [Accessed: 13- Feb- 2022].

[15] Exxonmobilchemical.com, 2022. [Online]. Available: https://www.exxonmobilchemical.com/en/catalysts-and-technology-licensing/emrd?utm_source=google&utm_medium=cpc&utm_campaign=cl_emrd_none&ds_k=hydrotreating&gclid=CjwKCAiAjoeRBhAJEiwAYY3nDHe9t-pUjMFxY1EgV2MMqBHlUCVo-BDdWqOw9Hqw_dMqhTFz7cWJDxoC3RoQAvD_BwE&gclsrc=aw.ds. [Accessed: 08- Mar- 2022].

[16] S3-us-west-2.amazonaws.com, 2022. [Online]. Available: https://s3-us-west-2.amazonaws.com/prd-wret/assets/palladium/production/mineral-pubs/zeolites/zeolmyb02.pdf. [Accessed: 08- Mar- 2022].

[17] “The Average Size of Parking Spaces in Canada — Parking Industry”, Parking Industry, 2022. [Online]. Available: https://www.parkingindustry.ca/construction-maintenance/the-average-size-of-parking-spaces-in-canada. [Accessed: 06- Mar- 2022].

[18] “For Sale: Lot 4 70527 Range Road 224, Rural Greenview No. 16, M.D. Of, Alberta – More on POINT2HOMES.com”, Point2homes.com, 2022. [Online]. Available: https://www.point2homes.com/CA/Vacant-Land-For-Sale/AB/Lot-4-70527-Range-Road-224/118379970.html. [Accessed: 06- Mar- 2022].

[19] Glassdoor.ca, 2022. [Online]. Available: https://www.glassdoor.ca/Salaries/alberta-process-engineer-salary-SRCH_IL.0,7_IS4074_KO8,24.htm. [Accessed: 06- Mar- 2022].

[20] Glassdoor.ca, 2022. [Online]. Available: https://www.glassdoor.ca/Salaries/calgary-senior-process-engineer-salary-SRCH_IL.0,7_IM970_KO8,31.htm. [Accessed: 06- Mar- 2022].

[21] “Pipeline crunch sending crude to markets—by truck: op-ed”, Fraser Institute, 2022. [Online]. Available: https://www.fraserinstitute.org/article/pipeline-crunch-sending-crude-to-markets-by-truck#:~:text=On%20the%20economic%20side%2C%20the,times%20more%20expensive%20than%20pipelines. [Accessed: 06- Mar- 2022].

[22] Frontiers in Energy Research, 2022. [Online]. Available: https://www.frontiersin.org/articles/10.3389/fenrg.2021.770355/full. [Accessed: 06- Mar- 2022].

[23] P. Badger, “Techno-economic analysis: Preliminary assessment of pyrolysis oil production costs and material energy balance associated with a transportable fast pyrolysis system :: BioResources”, Bioresources.cnr.ncsu.edu, 2011. [Online]. Available: https://bioresources.cnr.ncsu.edu/resources/techno-economic-analysis-preliminary-assessment-of-pyrolysis-oil-production-costs-and-material-energy-balance-associated-with-a-transportable-fast-pyrolysis-system/#:~:text=of%20product%20yield.-,The%20cost%20for%20the%20bio%2Doil%20from%20fast%20pyrolysis%20was,ton%20or%20%2450%2Fdry%20ton. [Accessed: 06- Mar- 2022].

[24] “Calcium Hydroxide, China Calcium Hydroxide Selling, Selling Calcium Hydroxide, Tianjin Xinxin Biotechnology Research and Development Center”, Sunsirs.com, 2022. [Online]. Available: http://www.sunsirs.com/m/page/commodity-exchange-detail/commodity-exchange-detail-63.html. [Accessed: 06- Mar- 2022].

[25] “Supply High Quality Wholesale Price White Calcite Powder Food Grade Caco3 Calcium Carbonate Powder – Buy Calcium Carbonate Powder With Factory Price,Caco3 Calcium Carbonate Powder,White Calcite Powder Product on Alibaba.com”, Alibaba.com, 2022. [Online].Available: https://www.alibaba.com/product-detail/Price-Calcite-Calcium-Carbonate-Carbonate-Supply_1600279822662.html?spm=a2700.7724857.normal_offer.d_title.1c1442174JtsNJ&s=p. [Accessed: 06- Mar- 2022].

[26] P. Evans, “$2 per litre for gasoline is here — and experts say it may stick around | CBCNews”,CBC,2022.[Online].Available: https://www.cbc.ca/news/business/gas-prices-friday-1.6371492. [Accessed: 06- Mar- 2022].

[27] CNBC,2022.[Online].Available: https://www.cnbc.com/2021/06/09/tc-energy-terminates-keystone-xl-pipeline-project.html. [Accessed: 07- Mar- 2022].