Join our Presentation

About our project

DAC Attack focuses on the physical design of modular sorbent matrices, not the entire DAC process.

Increasing the efficiency of the sorbent unit will significantly impact pilot plants’ overall performance and affordability, hence our limited scope.

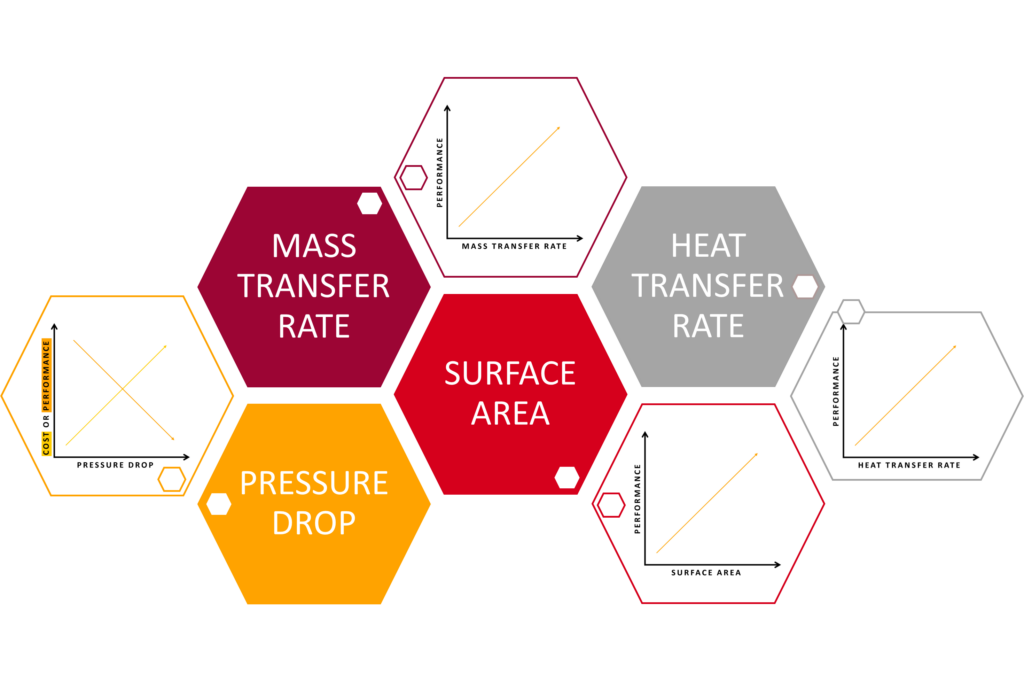

In order to objectively rank different design options, we have determined four Key Performance Indicators (KPIs). These KPIs provide insight into how physical changes in the matrix will impact the performance and cost of the DAC unit

KEY PERFORMANCE INDICATORS

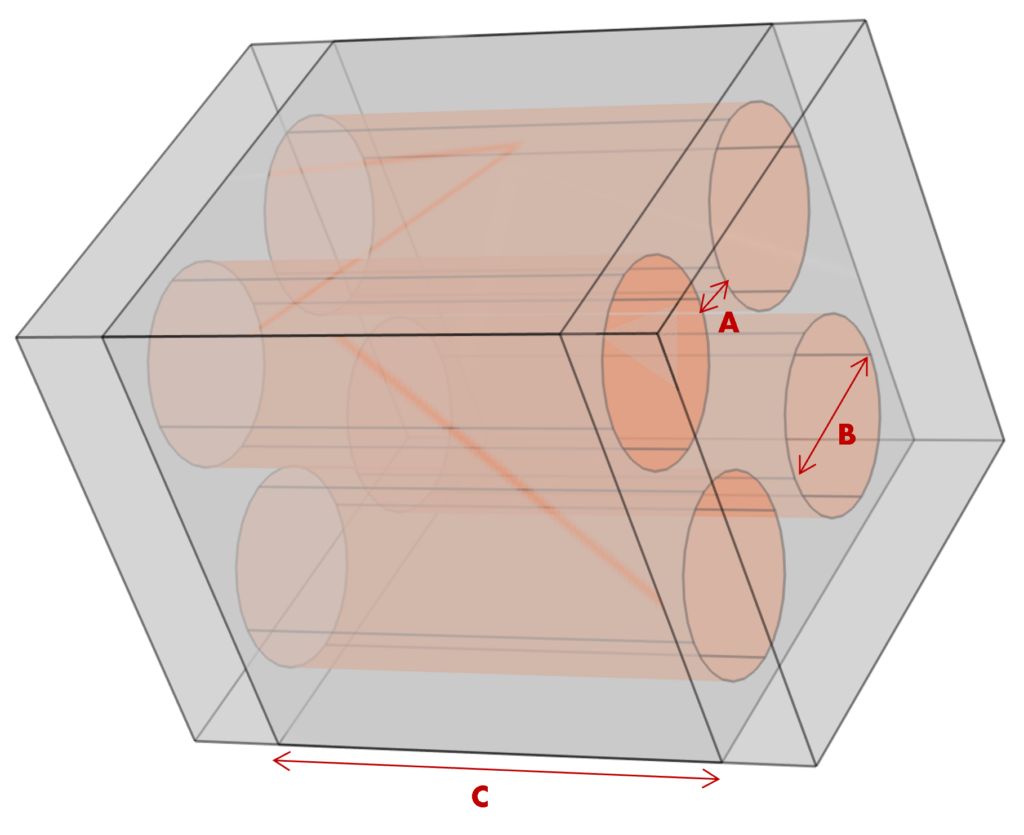

DETAILS ABOUT OUR DESIGN

Project Drivers

Global warming

DAC is an attractive investment opportunity for entities looking to implement negative emission technologies

Models

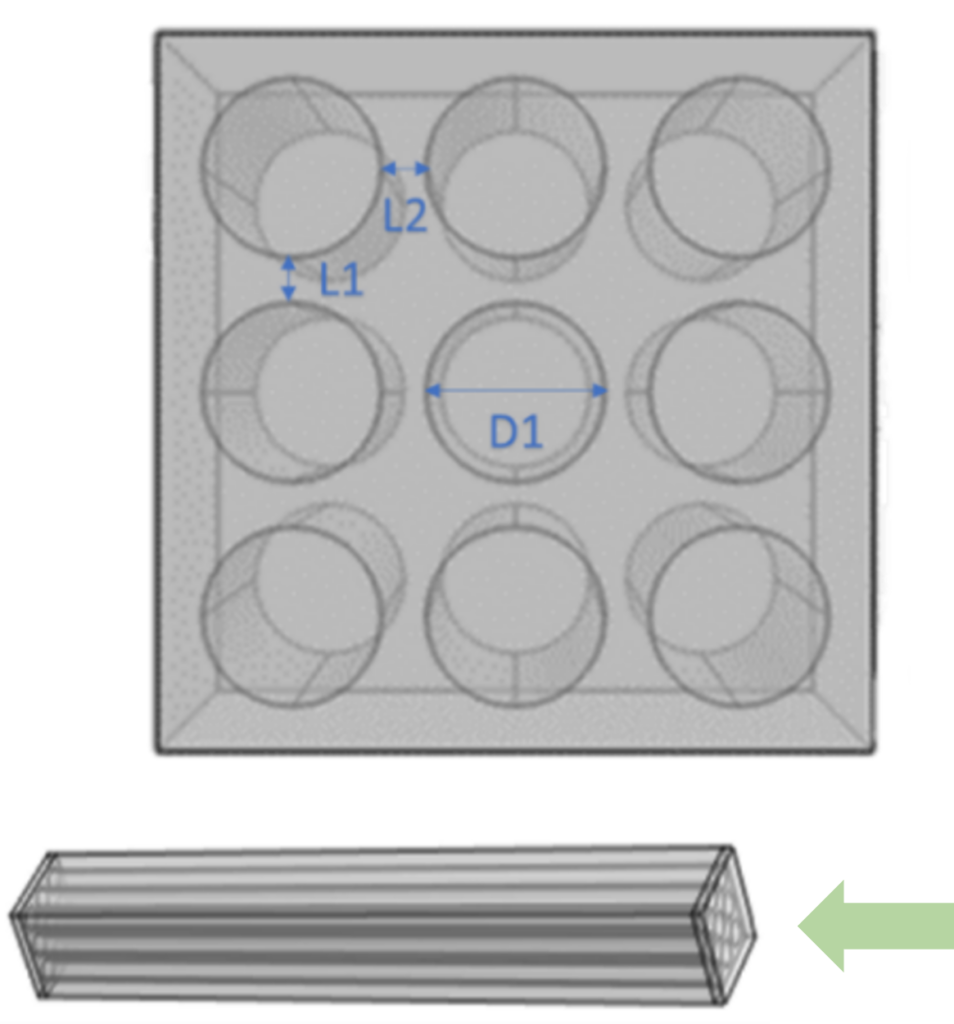

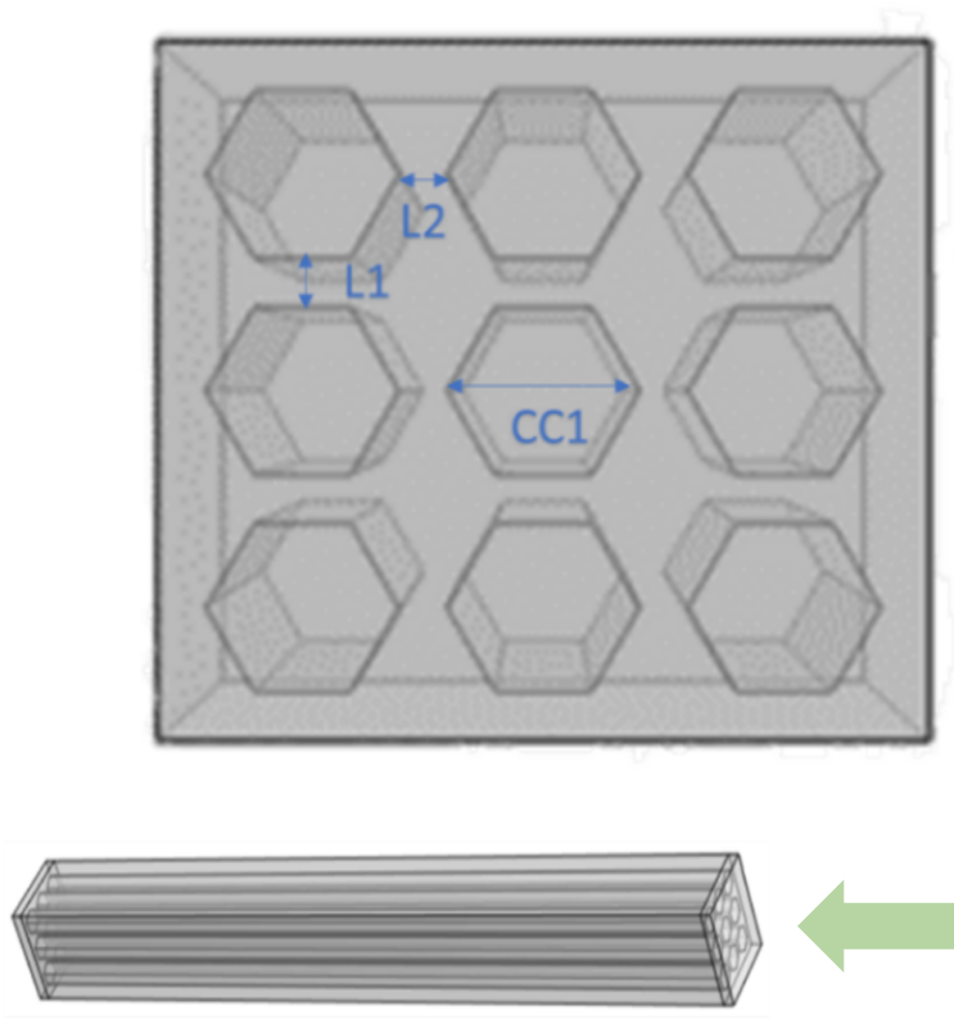

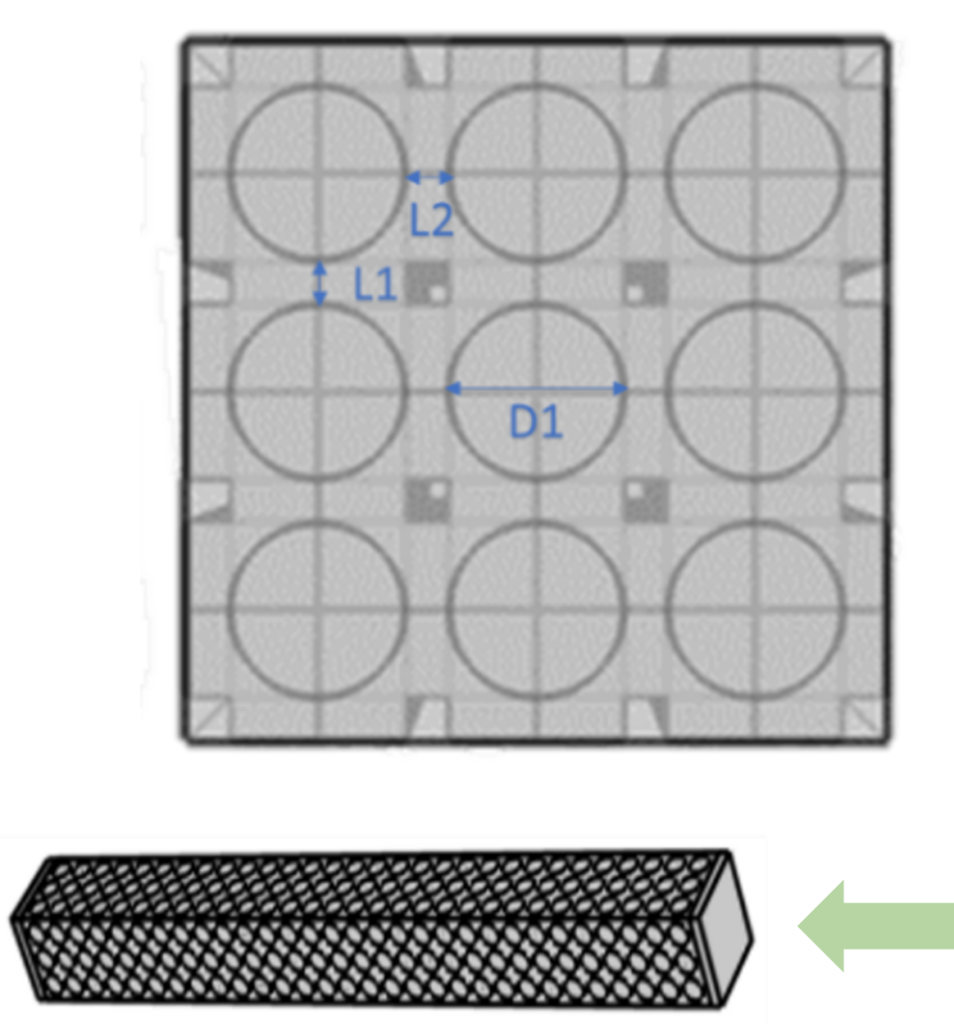

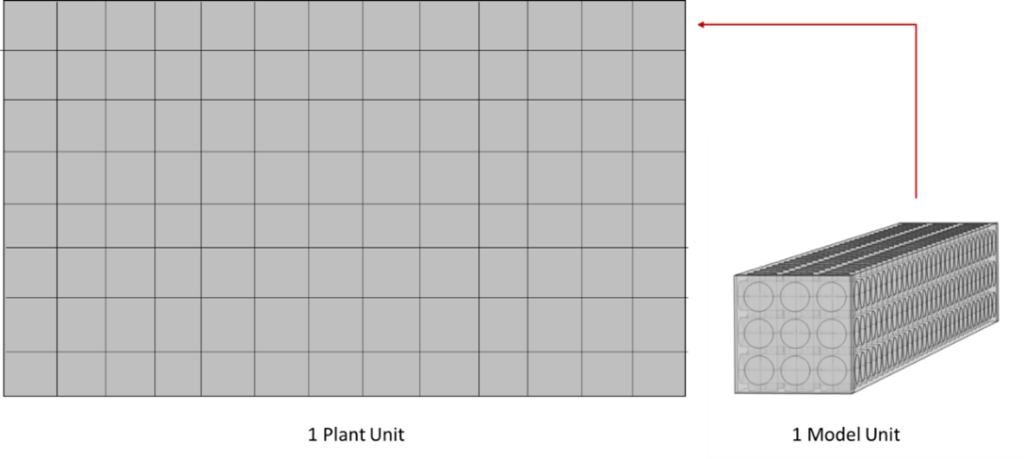

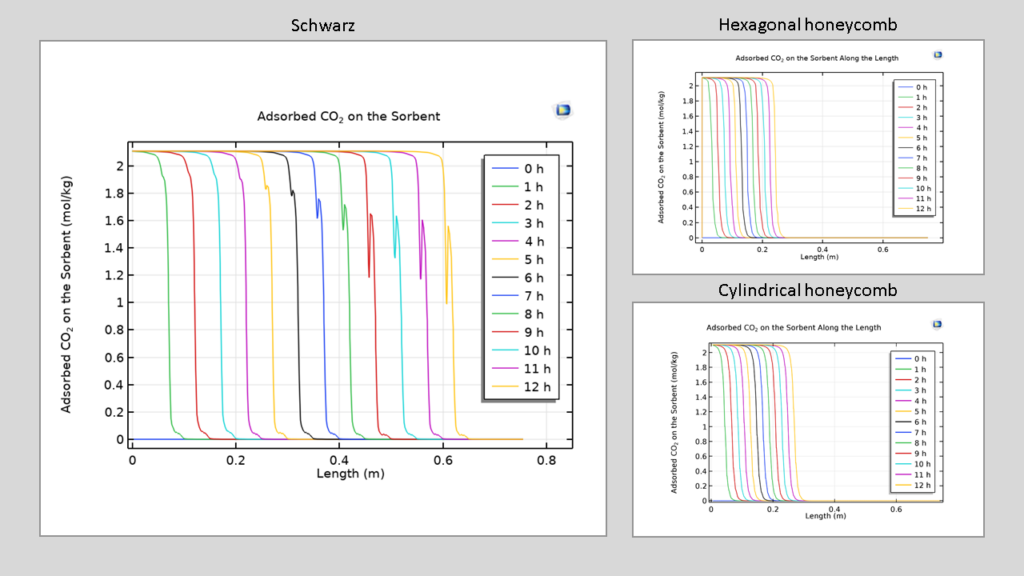

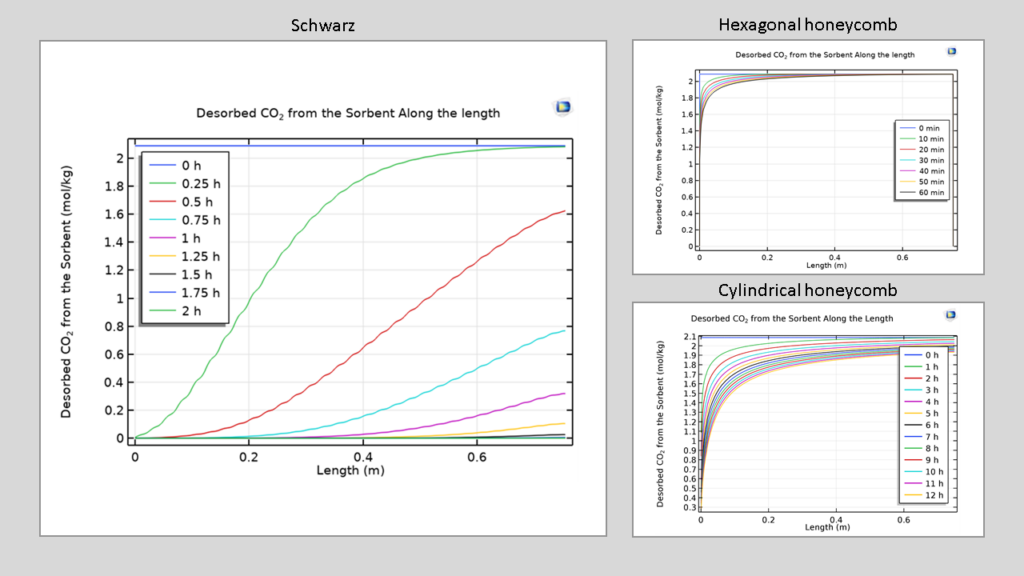

Various designed geometries were tested and ranked, based on our KPIs. Some examples include the Cylindrical Honeycomb, Hexagonal Honeycomb and Schwarz matrix

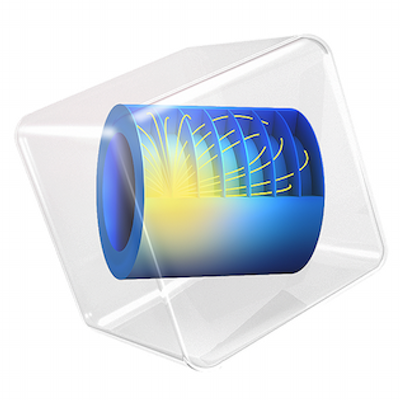

Modelling Software

COMSOL Multiphysics.

This simulation software allows the user to combine multiple physics phenomena to recreate real-world problems, such as the airflow through a sorbent matrix

Economics

Our plant design was based in Iceland, as low-carbon power sources are required for the feasibility of DAC plants. The economic evaluation focused solely on the effects of the sorbent design on the net income of a potential client, such as Climeworks.

PARTNERS AND MENTORS

We want to thank the many people who helped us with this project. Our chemical engineering professor and program coordinator Dr. Hector De La Hoz Siegler, and our direct supervisor Dr. Anne Benneker, along with all the other professors who offered constructive feedback throughout the past year.

GALLERY

Meet the DAC Attack Team