Project Category: Chemical

Clean Energy From Oil Process

About Our Project

The power crisis and electricity shortages due to an uncoordinated rush to carbon-free electricity have caused a significant spike in electricity prices and a concern for future electricity production using clean energy. The emerging industry of geothermal energy is a clean and reliable way to create electricity, but the growth has been slow due to its complications with specific geographic locations.

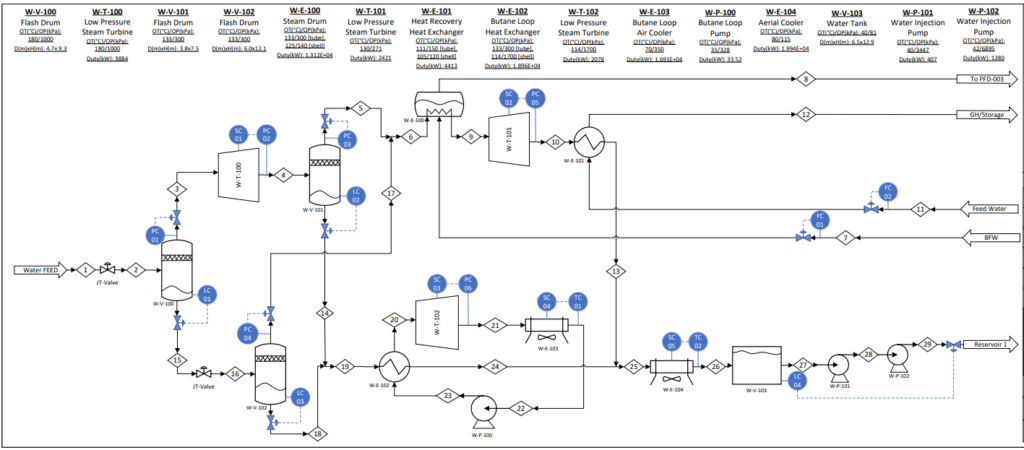

Geogenix was tasked to identify the surface processing units for a novel form of geothermal enthalpy mining to define the best use of electrical generation turbines and separation processes to recover valuable hydrocarbon components as well as CO2 capture for sequestration. Depleted oil wells are retrofitted to create a combustion reaction underground creating high temperatures. Two streams are used to run turbines and create electricity.

The company was able to design major processing units within the plant, including a closed-loop water system, combustion gas system, amine gas treating unit, and lastly an oxygen-enriched air injection plant.

Geogenix Team

Ali Manzoor

Luis Miranda

Gopika Gopika

Tanish Pathak

Steve Jose

Details About Our Design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

Geothermal is a sustainable and renewable way to produce clean energy. Although, low efficiency, high cost and specific geographic locations make it a challenge for geothermal electricity production to be a feasible project. Focusing on renewables, southern Alberta has the highest solar resource and second-highest wind resource. Despite the high energy potential, annual wind capacity efficiency is at 30% and solar capacity efficiency is at 15%. Electricity demand in Alberta is on the rise, from using 73600 GWH in 2011 to 84925 GWh in 2019. Alternative ways to produce more energy without contributing to greenhouse gas emissions need to be addressed.

Turning 30% of the energy content of the leftover oil resources in Alberta into electricity can produce 350 years’ worth of Canada’s total annual direct use of energy. The proposed design by Geogenix can produce 300MW of electricity/day with low GHG emissions. A sudden switch to renewables with low efficiency will hinder day to day operations.

Canada has established targets to transition towards low carbon intensity oil and gas renewable energy system, and Geogenix wants to make sure that the initiative is supported by setting up a clean and efficient way to produce electricity.

WHAT MAKES OUR DESIGN INNOVATIVE

Heat Integration

- Organic Rankine cycle to exploit the heat energy which would otherwise be wasted.

- Remaining heat in process stream after electricity generation are utilized for:

- Heating greenhouse facilities

- Steam for equipment

Carbon Capture

Carbon dioxide is the most important greenhouse gas, and the emissions are mainly a consequence of energy generation sectors. Carbon dioxide stays longer and are in abundance throughout the atmosphere, reason why carbon capture is pivotal. Amine gas sweetening plant is currently the best available technology for carbon capture. There have been thorough studies done on the health, social and environmental impacts of this process.

Wastewater management

The treatment of wastewater is vital for environment and human life. Any wastewater produced during surface operations will be collected safely and then sent to a third-party wastewater treatment plant without interfering with the environment and the sustainability of the plant.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

- The design will aid the rising demand and prices of electricity all over Canada.

- The design achieves substantial electricity production with only minimal emissions. Any CO2 present in the combusted gas product stream, post-electricity production, is sequestered for later EOR value.

- After electricity production, light oil that is collected is sold to refineries, which makes this project feasible.

- The project also surpasses most capital costs such as drilling as Geogenix is utilizing existing mature oil reservoirs that have been discarded by oil companies.

HOW WE VALIDATED OUR DESIGN SOLUTION

VMGSim, a simulation software, was heavily used to simulate the plant to ensure that the suggested design is realistically achievable. Furthermore, rigorous hand calculations were also carried out to confirm the design, including, but not limited to the sizing of equipment, line sizing, efficiency calculations and heat transfer calculations. Literature sources, industrial data, and individuals with decades of industry experience were also consulted for a successful design and operation.

We also utilized Kepner-Tregoe (KT) method in comparing carbon capture technologies to identify the best fit for our project with criteria such as fixed capital cost, energy requirements, process complexity, safety concerns etc.

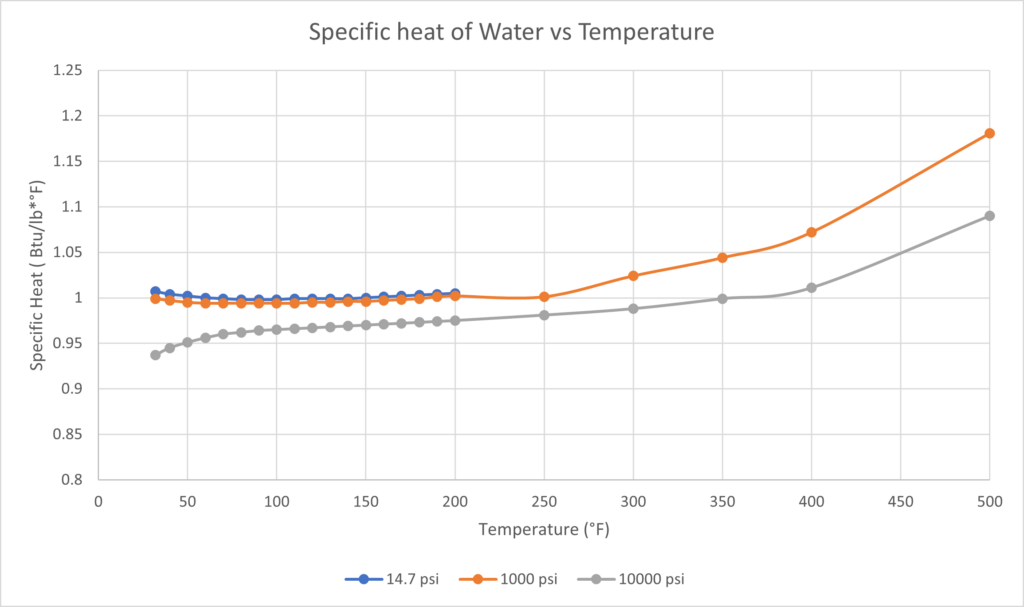

Design pressure and temperature conditions are validated by taking heat capacity of water into account. Heat capacity and enthalpy are strongly related to temperature, high pressure conditions does not produce more work . Thus, pressure conditions can be kept at minimal requirements to operate a turbine, maximizing efficiency and minimizing risk. Chosen pressure condition for the plant are validated using a trial and error process through symmetry and hand calculations.

FEASIBILITY OF OUR DESIGN SOLUTION

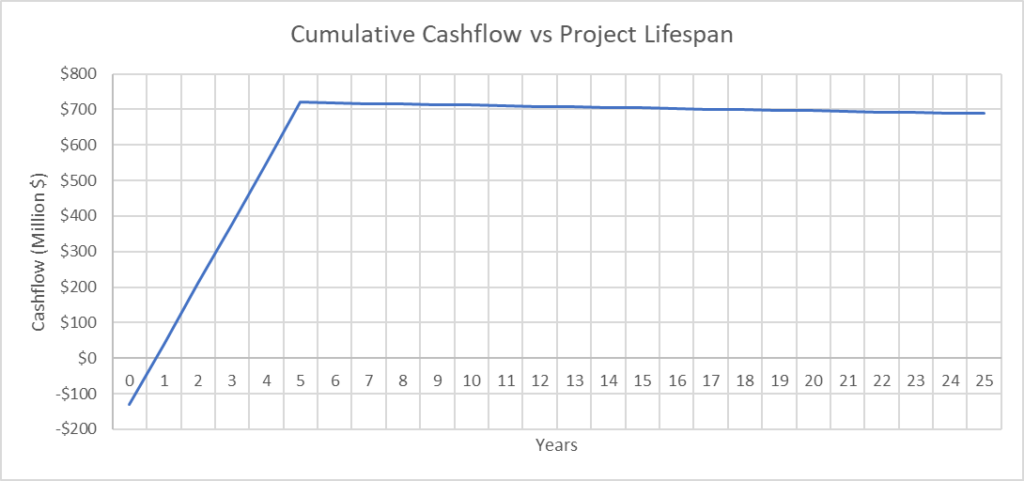

There are important costs to consider when we develop the picture of feasibility including the fixed capital investment, the total capital investment, and the total capital investment, which can be summed up using the following table:

| Fixed Capital Investment | $89,000,000.00 |

| Working Capital Investment | $18,000,000.00 |

| Total Capital Investment | $130,000,000.00 |

An important cost to consider as well is the plant operating costs, which can be summed up using the following table:

| Variable Operating Cost | $4,108,000 |

| Fixed Operating Cost | $7,200,000 |

| Total Operating Costs | $11,308,000 |

With these in mind Geogenix can begin to consider the feasibility for the plant with the final puzzle piece which is the annual revenue from sales. With the price of light oil taken as 80$CAD/bbl and the price of electricity as 85$CAD/MWh, the annual revenue for the first 5 years of operation comes from the light oil which amounts to $250,000,000 and the annual revenue thereafter from electricity amounts to $8,600,000. Geogenix’ plant can now develop its feasibility, as the plant has a payout period of 9 months, the projected revenue can be summed up using the following graph:

With all these considerations, the design solution is very feasible.

Partners and Mentors

We would like to give our heartfelt thanks to Dr. Michael Foley (supervisor) and Dr. Michael Aikman (client) for their immense support and dedication throughout our project and success. We would also like to extend our appreciation to Dr. Hector De la Hoz Siegler for his guidance and encouragement.

Our Photo Gallery

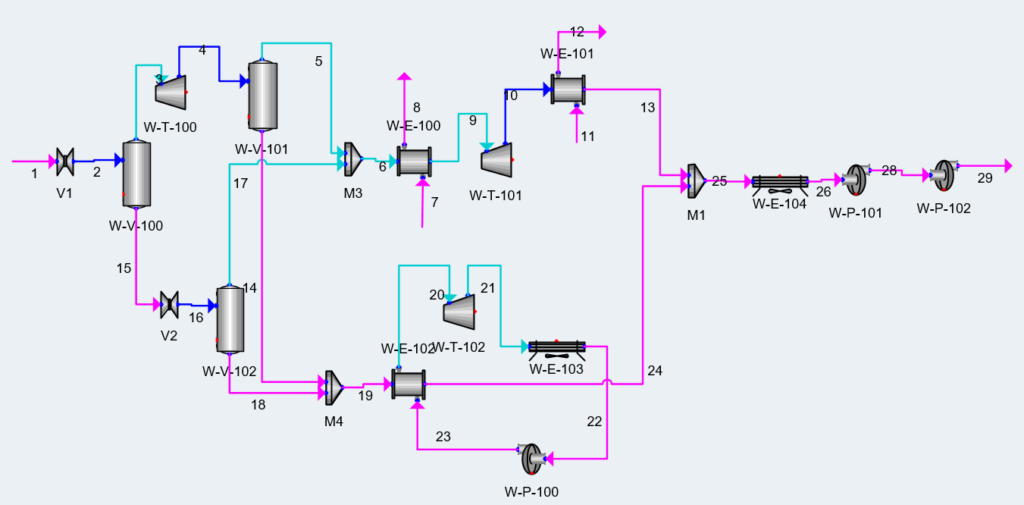

Closed-Loop Water System PFD

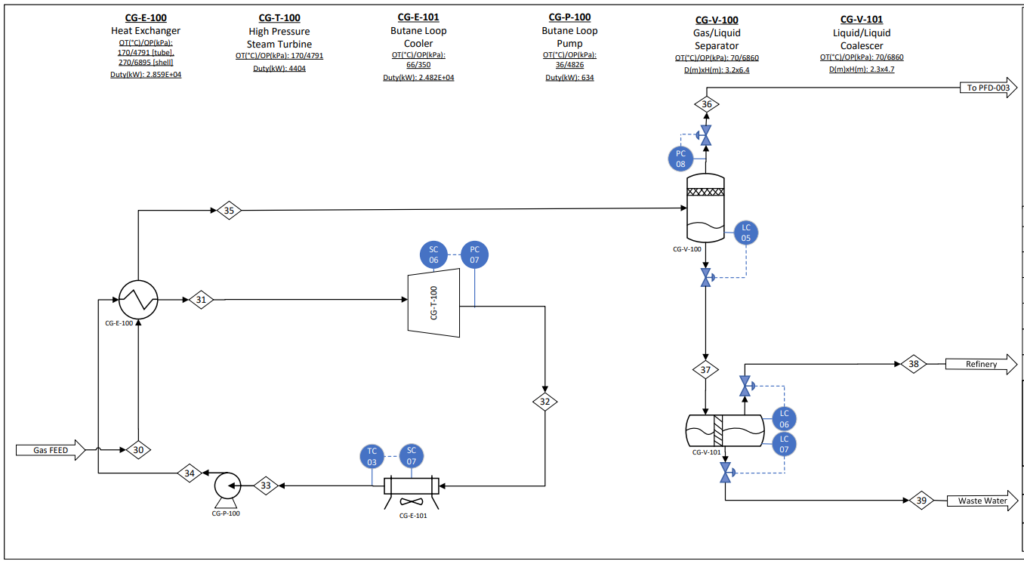

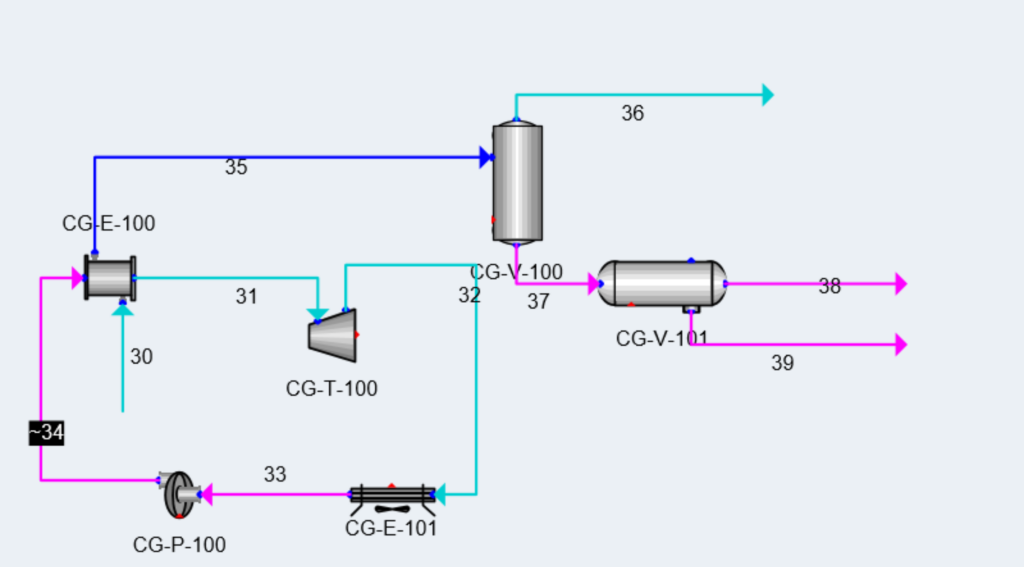

Combusted Gas Unit PFD

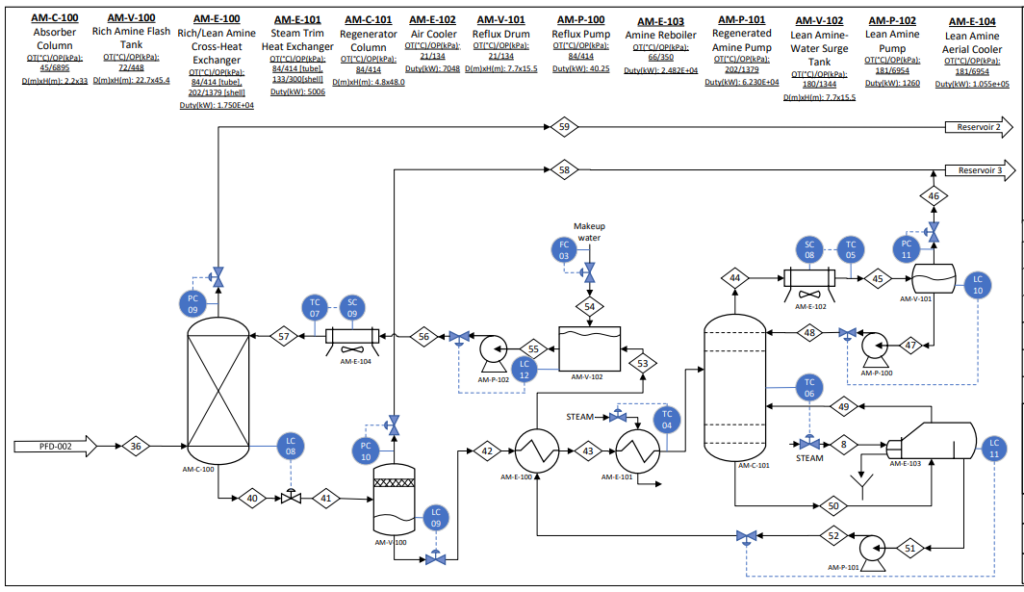

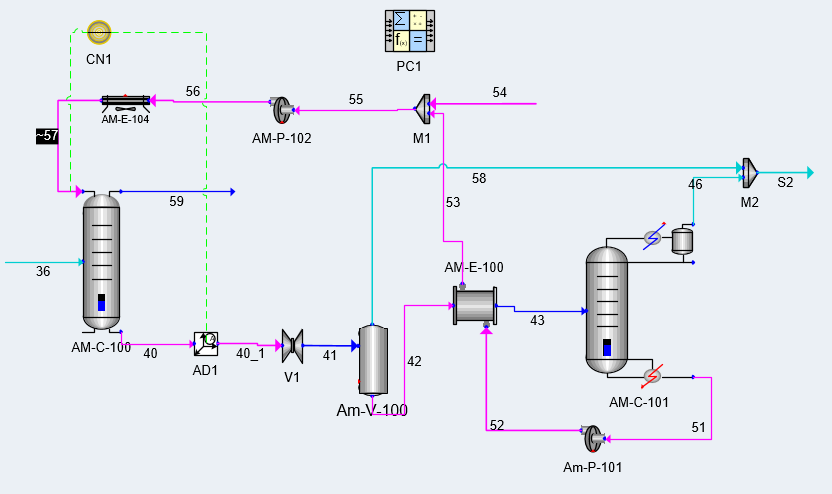

Amine Gas Treating Unit PFD

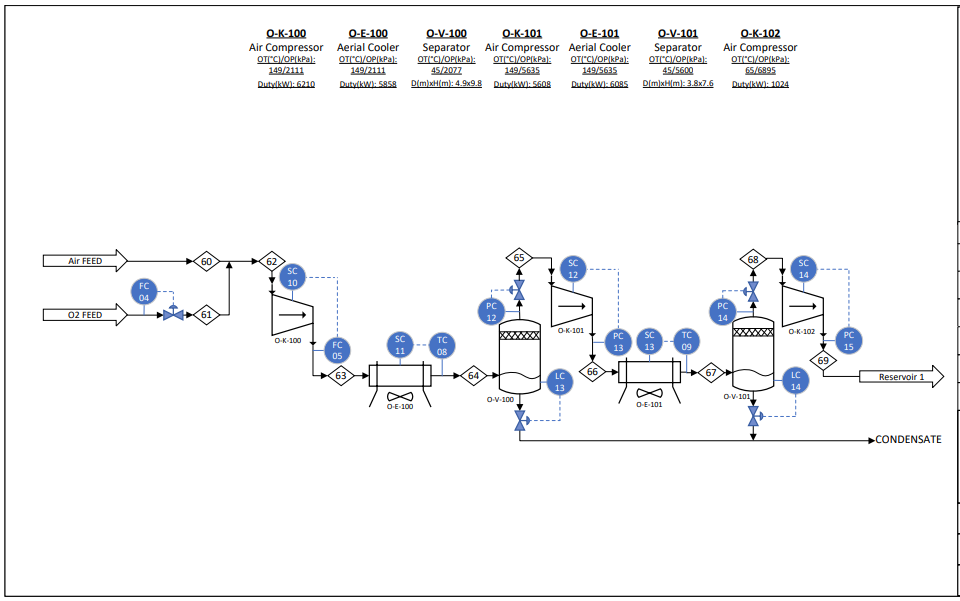

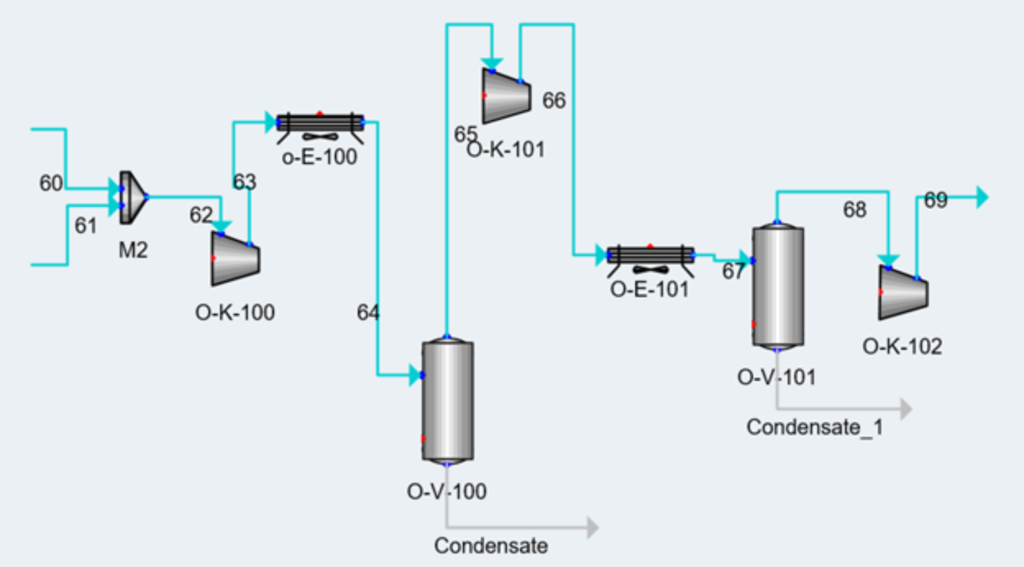

Oxygen-Enriched Air Injection Unit PFD

Closed Loop Water System Simulation

Amine Gas Treating Unit Simulation

Combusted Gas Unit Simulation

Oxygen-Enriched Air Injection Unit Simulation

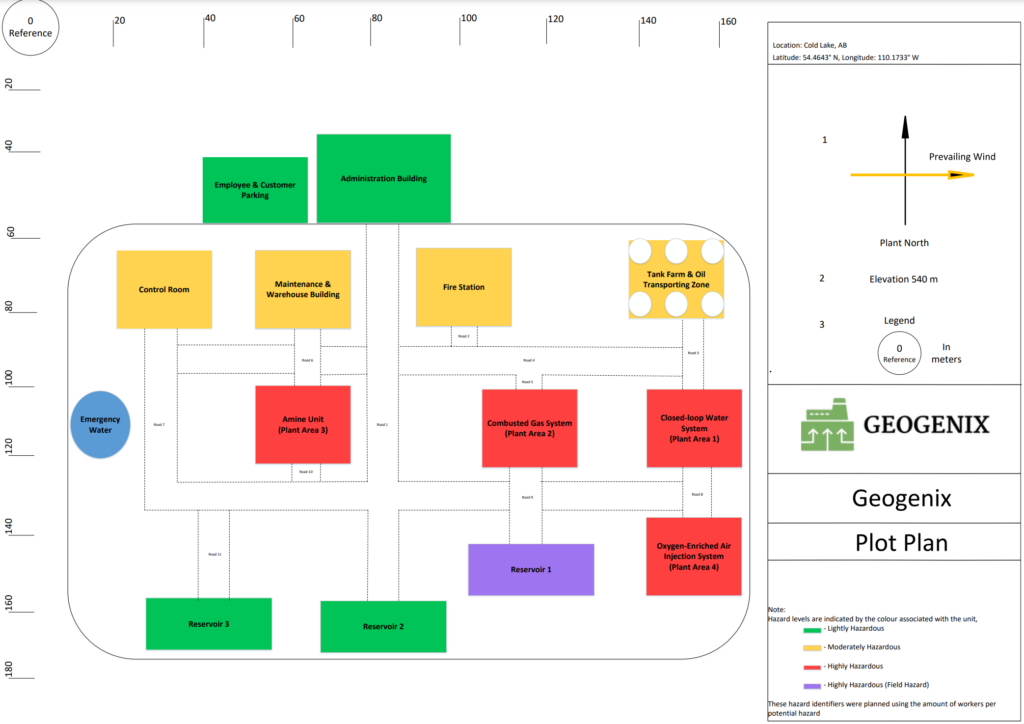

Plot Plan

References

- (6) Aikman, M. Optimization of Surface Integrated Energy and Material Balances: Clean Energy From Oil* Process, 2021.

- Towler, G.; Sinnott, R. Chemical Engineering Design; Academic Press: Oxford [etc.], 2013.

- Sproule. Escalated Forecast; Sproule: Calgary, 2021.

- Alberta Electric System Operator. Historical Pool Price Report; Calgary, 2021.

- Alberta Market Surveillance Administrator. Quarterly Report for Q1 2021; Quarterly Reports; Alberta MSA: Calgary, 2021.

- Song, C.; Liu, Q.; Ji, N.; Deng, S.; Zhao, J.; Li, Y.; Song, Y.; Li, H. Alternative Pathways for Efficient CO2 Capture by Hybrid Processes—a Review. Renewable and Sustainable Energy Reviews 2017, 82, 215–231. [Online].

- [Online]. Available: https://sesinnovation.com/documents/conferencebrochure.pdf (accessed Dec 7, 2021).