Project Category: Chemical

Please join our presentation

About Our Project

A global initiative has begun. In recent years, 18 nations and economies have announced hydrogen roadmaps, outlining their strategies to develop better related technologies and expand its use in sectors that conventionally use fossil fuels. In fact, Canada is among these countries – which include the likes of Germany, Australia, the United States, and the EU. Alberta’s carbon-based resources and established pipeline systems make it key player in Canada’s plan to become a leading supplier of hydrogen and hydrogen-derived products by the year 2040. However, the economic potential of these resources comes at a cost, emitting greenhouses gases to the atmosphere. A major shift in the energy and transportation sectors is upon us, and we must not be left behind! Is there a way to exploit Alberta’s carbon-based resources without the environmental impacts of traditional technologies?

Meet Our Team

Alexia Gendron

Justin Holman

Yu Lin

Is There a Case for Blue Hydrogen in Alberta?

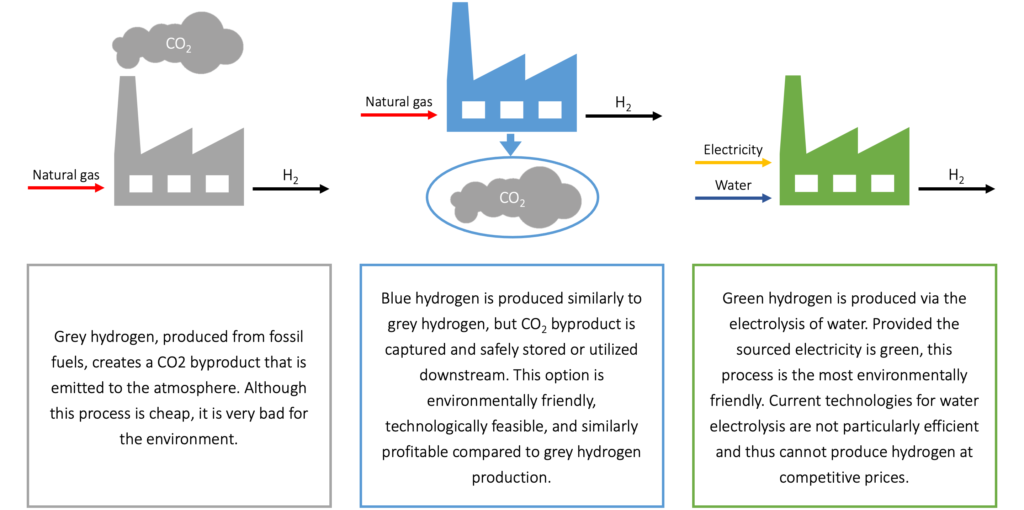

First of All, What Is Blue Hydrogen?

Not all H2 is created equal…

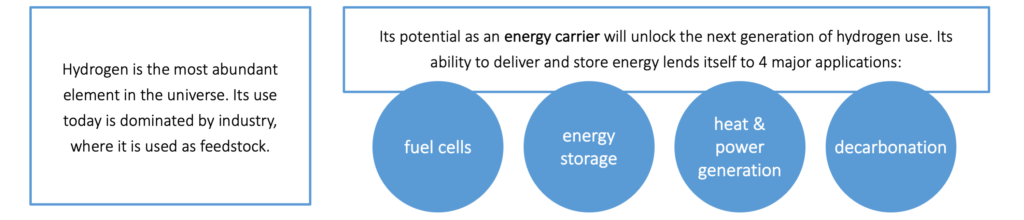

What Makes Hydrogen Important?

The clean and flexible energy carrier that will fuel your future.

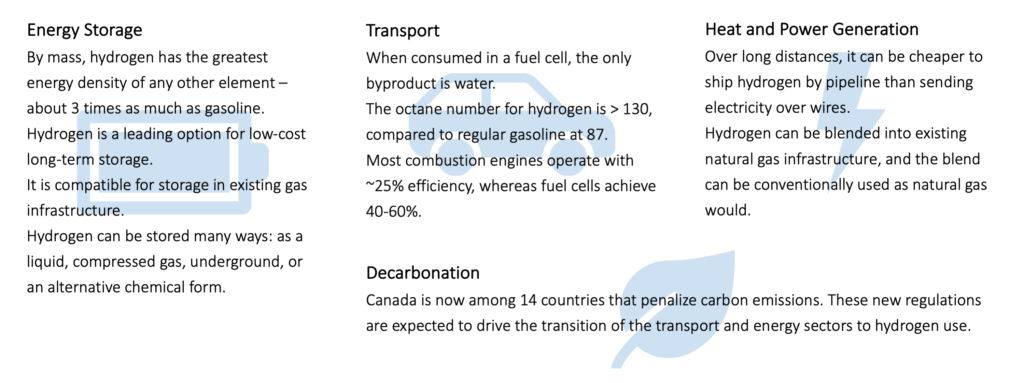

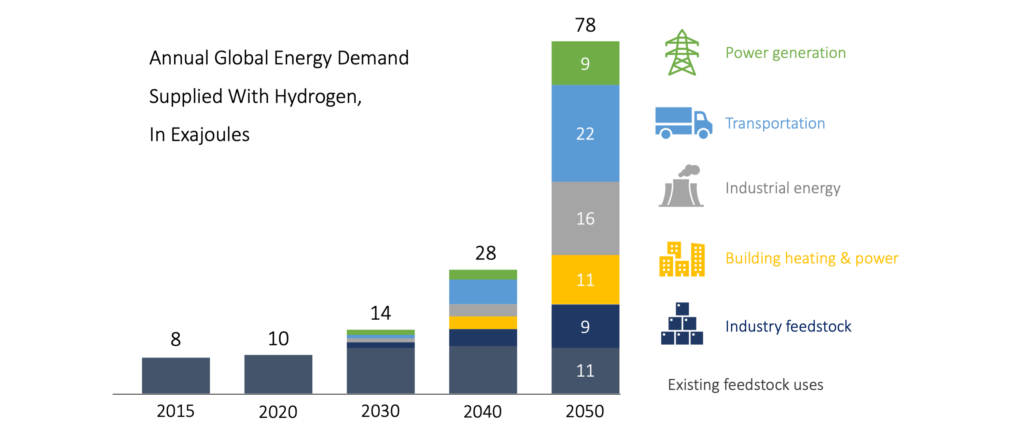

This Is Just the Beginning for Hydrogen

As hydrogen-based technologies develop, its uses and demand are expected to increase.

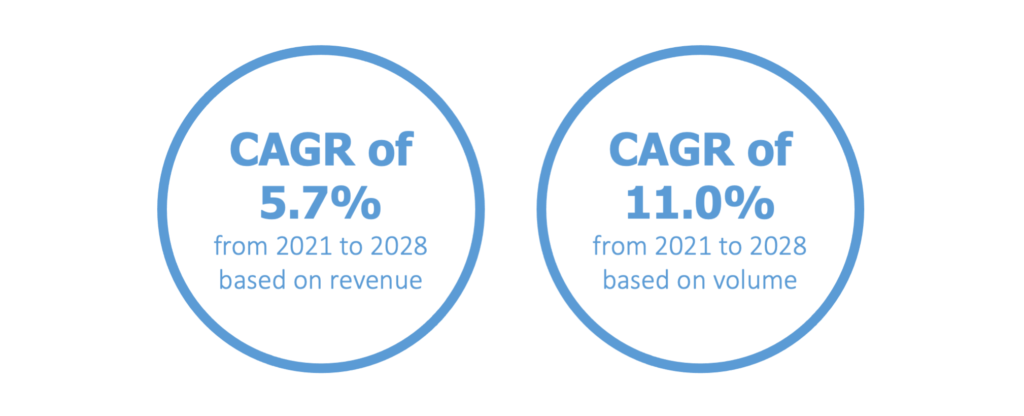

The latest estimates according to Grand View Research (2021, March) forecast tremendous growth for the hydrogen market, which is already worth over USD$120 billion.

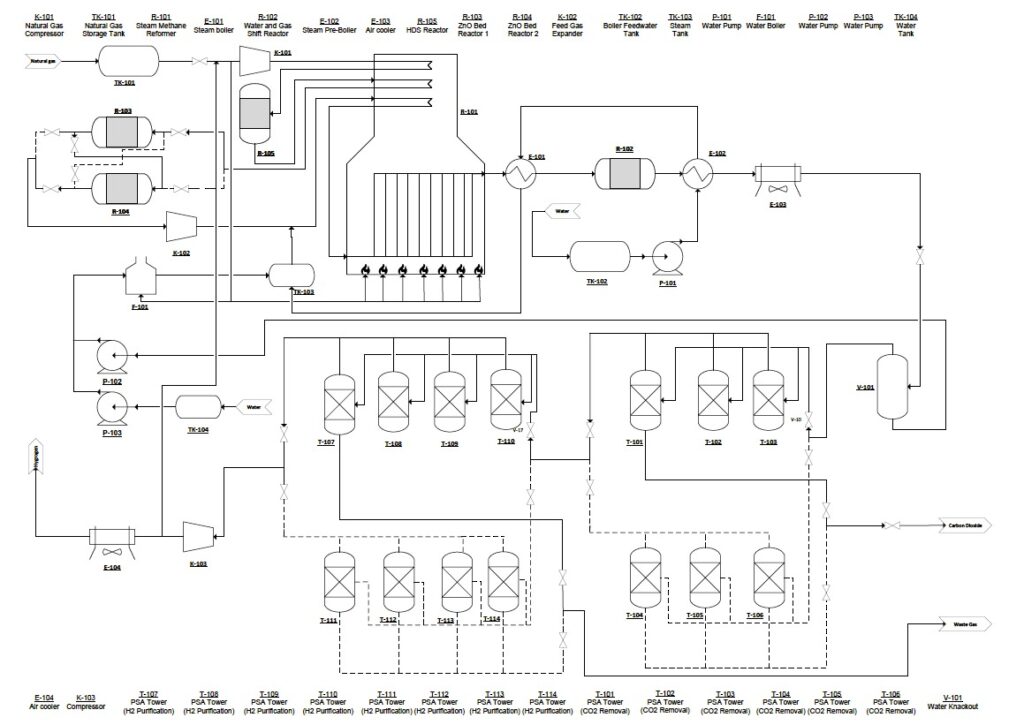

Our Design

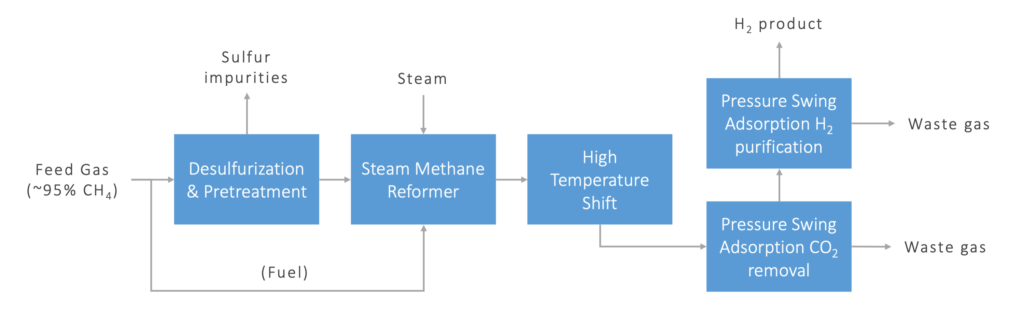

A simple overview of our process is outlined by the block flow diagram below:

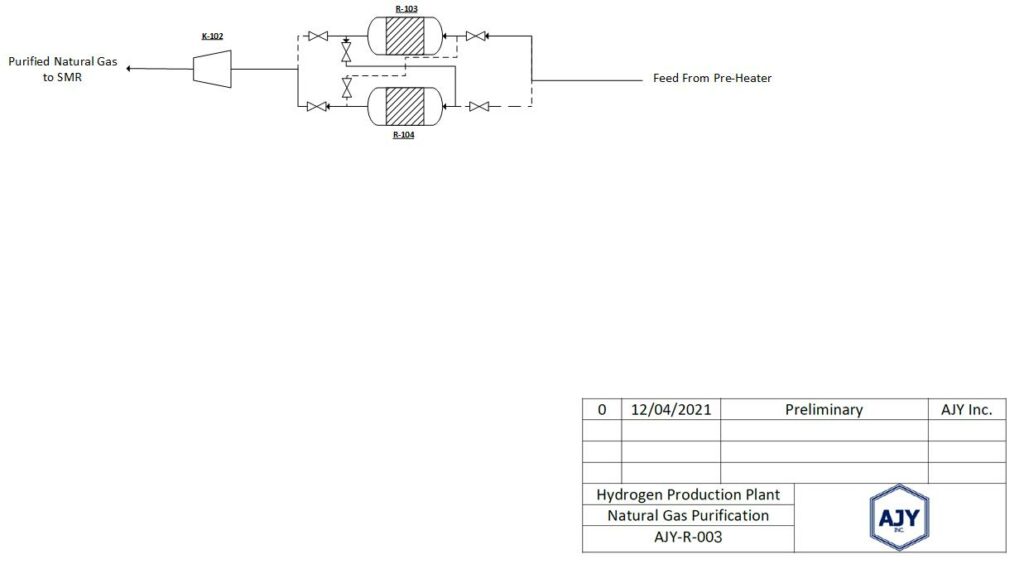

Desulfurization & Pretreatment

In the hydrodesulfurization (HDS) reactor, organic sulfur is converted to H2S. Then, the H2S is removed via adsorption onto zinc oxide beds, which are operated in a lead-lag arrangement. This step is essential to prevent sulfur from poisoning downstream catalysts.

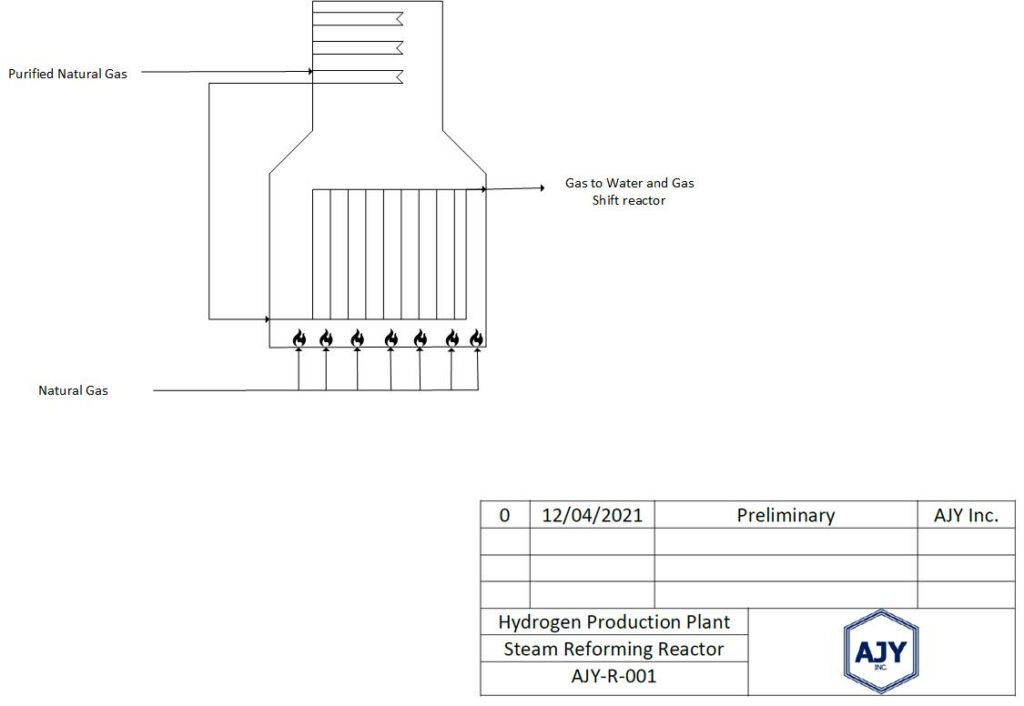

Steam Methane Reformer

Following the removal of sulfur, steam and natural gas are combined and preheated in the convection section of the steam methane reformer (SMR) before entering the Ni/Al2O3 catalyst packed tubes. Burners at the base of the reactor ensure the high temperatures necessary for the conversion of methane to H2, CO, and CO2.

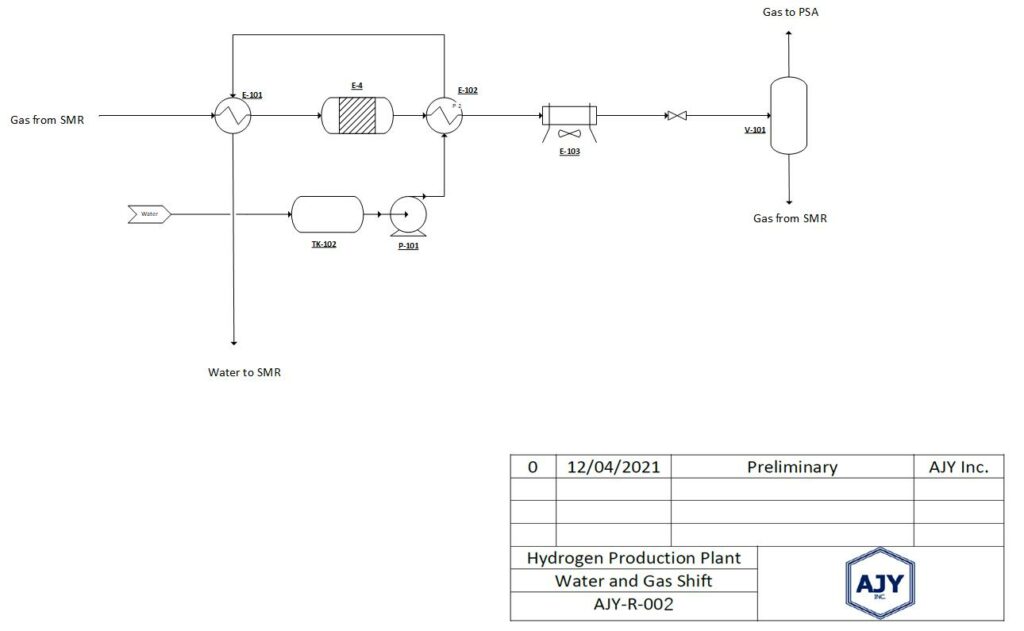

High Temperature Shift

The high temperature shift (HTS) reactor is used to convert steam and CO into water and CO2 by reacting the stream with a Fe3O4/Cr2O3 catalyst. The lower temperature with respect to the reformer is necessary for this reaction, which is thermodynamically favoured at low temperatures.

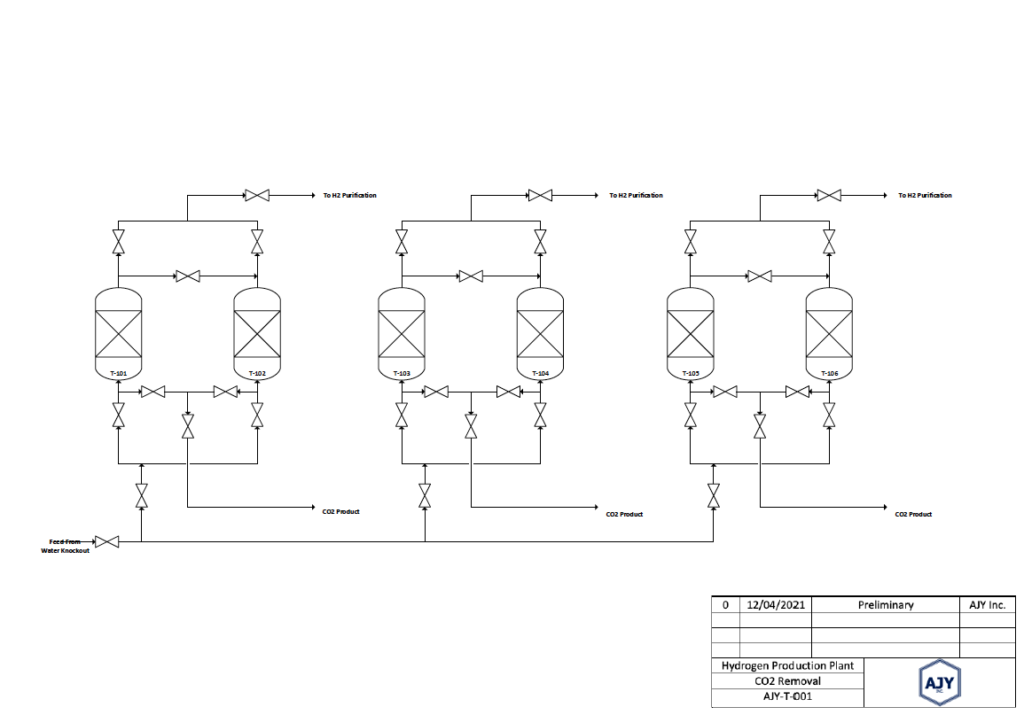

Pressure Swing Adsorption CO2 Removal

In the first round of pressure swing adsorption, silica gel is used to selectively remove carbon dioxide from the process gas. The CO2 product gas is supplied to the Alberta Carbon Trunk Line, where it is used downstream for enhanced oil recovery.

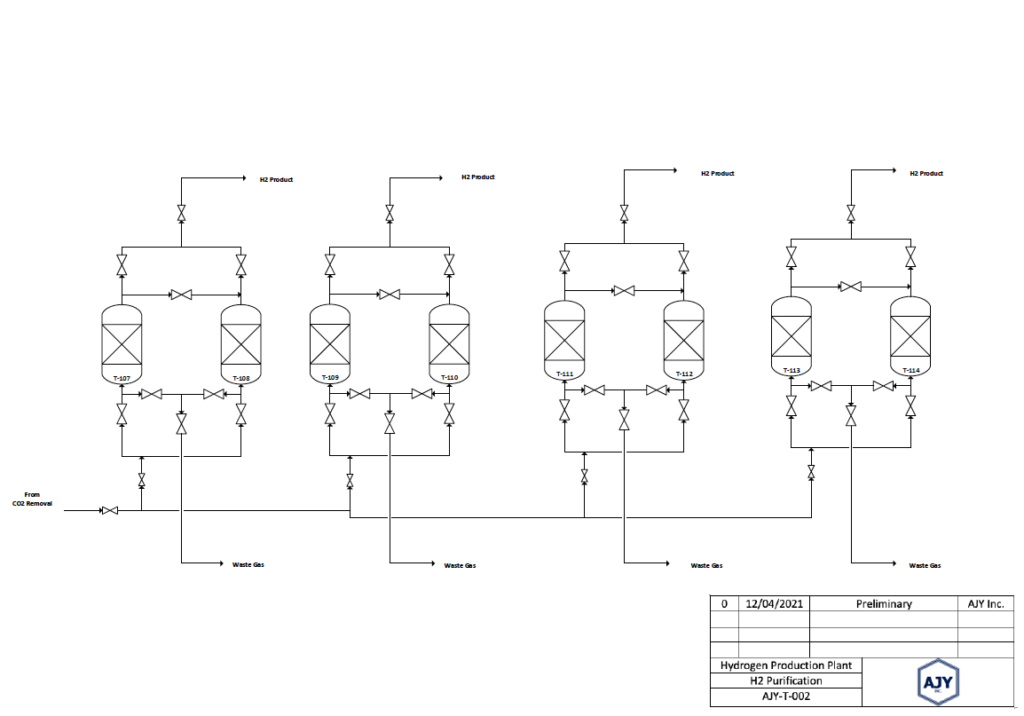

Pressure Swing Adsorption H2 Purification

Following CO2 removal, the light product stream is fed to a second round of adsorption towers. Here, activated carbon is used to separate a hydrogen product from the stream.

Conclusions

Alberta provides the perfect location for such a plant, due to its extensive gas distribution networks and abundant natural gas reserves. By locating in Alberta, our plant benefits from inexpensive feed and accessibility to these pipelines, which would otherwise make the project prohibitively costly if they had to be established.

Until technologies for green hydrogen production have been sufficiently developed, at nearly 3 times the price, their product simply cannot compete with grey production. Blue hydrogen, however, incurs added production costs that are small enough to charge competitively with grey hydrogen while remaining profitable. Therein lies the value of blue hydrogen production as a steppingstone with the ability to achieve profitability using existing technologies while having significantly less impact on the environment.

The technologies we selected for each stage of our process are safe, easily implemented, and inexpensive. Most notably, each of these technologies are well-established, but are not being currently used to realize a carbon capture strategy. When applied in this manner, these technologies have the ability to effectively capture carbon and repurpose it and thus, we believe that it is only a matter of time before policy changes, environmental interests, and economic factors drive the development of this type of plant.

To Our Mentor

A very special thanks goes out to Dr. Karan, who patiently guided us through this project and all of its challenges with his signature warmth and care.