Project Category: Civil

Join our presentation

Click zoom link above to meet team members and ask questions

About our project

The current Jaipur bridge had two major reasons that eventually led to its planned replacement. The first reason was the increased rate of deterioration of the structure from salt-laden moisture. This affected the overall structural integrity of the bridge. City officials have announced the immediate action of closing the bridge in 2019 after failing to meet safety requirements through an annual inspection. The second motivating factor for a bridge replacement was that the current bridge did not follow updated standards for bridge and bank elevation based on flood mitigation improvements in the Eau Claire area. The 2013 flood in Calgary initiated mitigation projects in the Eau Claire area with one being the initiation of the Riverwalk promenade upgrade to meet current standards. As the banks were being improved, the current Jaipur bridge also needed an upgrade to meet the 100-year flood elevation.

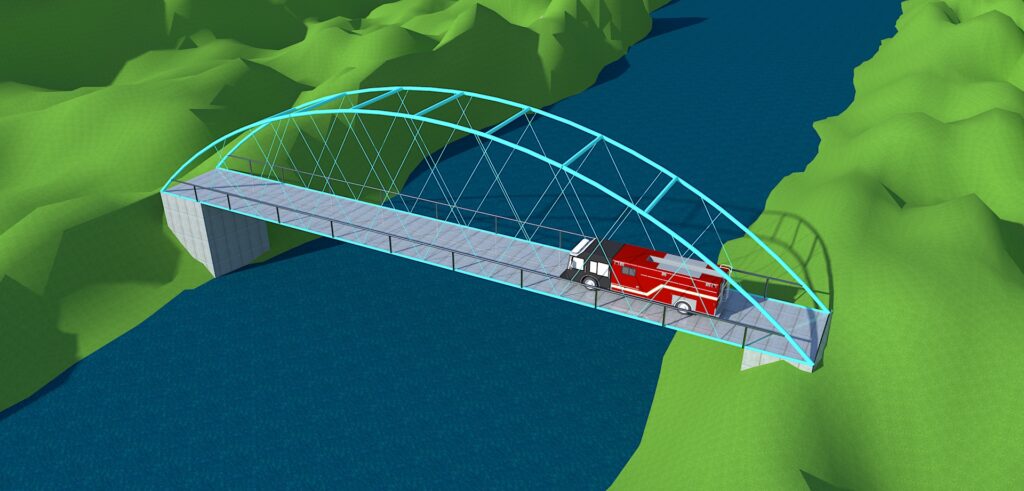

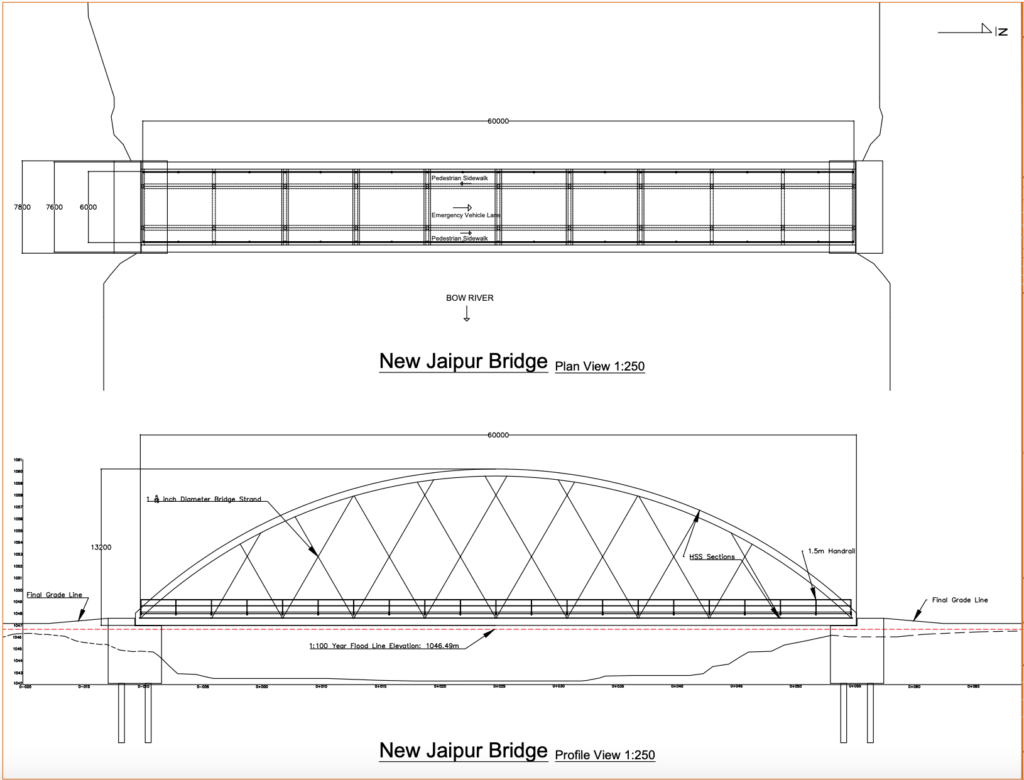

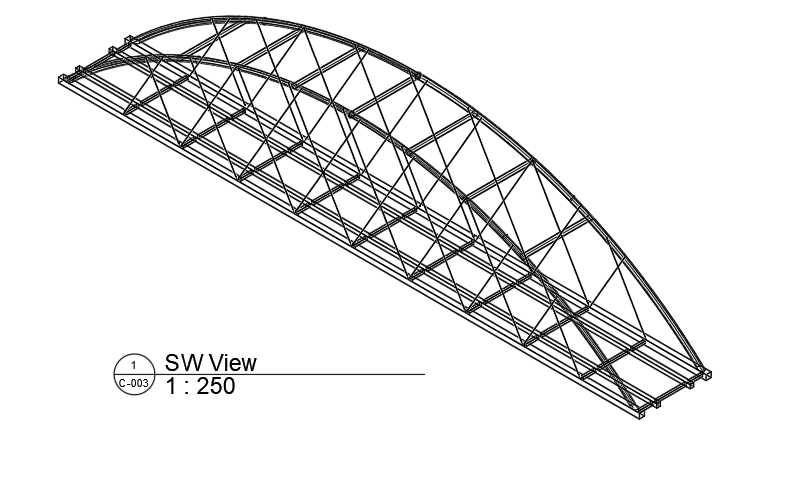

The Bridge we present today is a tied-arch bridge that has a 60 meter open span. The bridge we designed was created with respect to Calgary’s sister city relationship with Jaipur, India. The two cities were twinned in 1973 because of common interests in industries like engineering and manufacturing. We incorporated Jaipur’s innovative engineering spirit into our design through designing an efficient pedestrian bridge uniquely for pedestrian and emergency vehicle access. The choice of a tied arch bridge will create a more pleasant view for the Calgary Skyline and tie in with the Eau Claire Promenade project.

Meet our Team Members

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

To prevent the types of risks stated above, the new Jaipur Bridge will be built based on a 100-year flood + 300mm requirement and which will improve its overall flood resiliency. The additional criteria of the project will involve the bridge’s capability in accommodating emergency vehicles that need to access Prince’s Island Park. To meet this criteria our group was required to design a bridge that can withstand vehicle and pedestrian loads. In addition, The City of Calgary required the new design to limit the environmental impact in the area. With these constraints, our solution was to design a bridge that did not require piers to be installed in the river and as such reducing the environmental disturbance in the area. To address this change and still design a bridge that safely resists moving vehicular loads on a 60 meter span, our group decided on a tied-arch bridge structure after a cost-benefit analysis. With our design, additional public issues were addressed such as increased area under the bridge for winter activities such as skating.

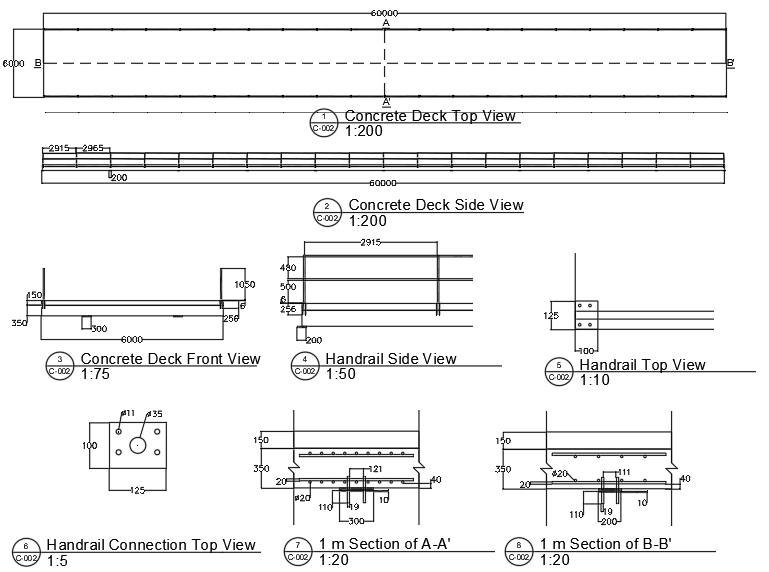

The installation of our bridge design will also have a positive impact for the pedestrians from its increased width. The current width of the bridge is only 4 meters, which made it difficult for pedestrians to stop and enjoy views from the bridge. To address this issue, our design increased the width to 6 meters allowing more room for pedestrians to stop and not disrupt the traffic of other pedestrians using the bridge.

WHAT MAKES OUR DESIGN INNOVATIVE

Our bridge design is a unique solution differing from typical designs of beam span bridges with river piers seen in several locations in Calgary. Once constructed, our tied-arch bridge will be the only pedestrian bridge in downtown Calgary with emergency vehicle access. In addition, the new design provides an aesthetic appeal to one of the major landmarks in Calgary and tie in well with the new Eau Claire Promenade upgrade.

In accordance with Eau Claire being a spot of high population density and traffic, the tied-arch structure will be on display for many to observe the innovative aesthetics and engineering required to provide a safe mode of travel from downtown Calgary to surrounding areas. The new Jaipur Bridge will not only be a main mode of travel in the city but provide an increased resiliency to future flooding in the region. Adjusting our design to have a width of 6 meters was another innovative strategy that allows for better traffic flow on the bridge.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

The tied-arch bridge design is an effective strategy to address all the concerns and constraints of the area. Additionally, the bridge will have a lower maintenance cost in the future with an absence of river piers that can corrode and deteriorate over time. The design decreases the bridge’s physical and noise impact to the surrounding environment, which includes fish habitats and close proximity to residential areas. Furthermore, the design includes several aspects that will become advantageous with increasing weather aberrations from climate change.

HOW WE VALIDATED OUR DESIGN SOLUTION

Superstructure Design:

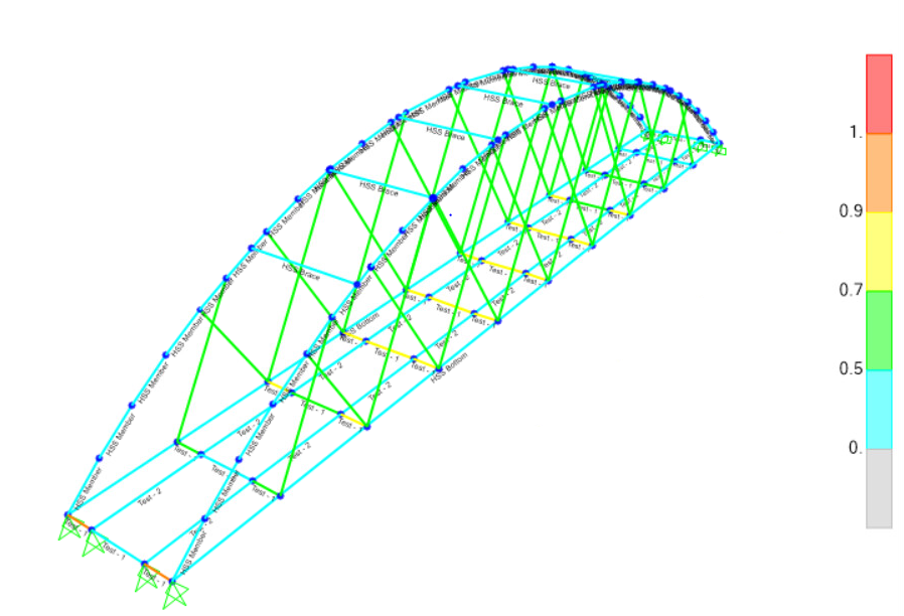

As an engineer, it is crucial to meet industry standards to maintain the integrity of the design and provide the clients with a competitive design that can transcend our increasing societal needs. To achieve this, we used three distinct design codes provided by CSA. The main code that determined most of our design was the “Canadian Highway Bridge Design Handbook.” This showed us the unique structural requirements for designing a bridge that will satisfy Canadian-wide standards. After we determined the general design, each component of the bridge was further analyzed using more specific codes. The steel arch and other steel members were pre-sized using the “Canadian Steel Design Handbook.” Also, the concrete members were pre-sized using the “Canadian Concrete Design Handbook.” As a result, we were able to produce a hand-calculated design that could be further optimized using SAP2000 structural software program.

During the pre-sizing stage and developing a detailed design for the tied-arch design, there were notable alternative methods that we considered. The two main design processes that needed alternative approaches were the design of the deck slab and floor beams. The pre sizing method of design where various members are tested until they can fit with the design criteria was chosen as it is the most efficient and reliable method of Civil Engineering Design. In Civil Engineering the various members of the structure must be tested to withstand all possible load combinations. The pre sizing method of design allows Structural Engineers to refine their design by sizing down members to cut down costs while also meeting code guidelines.

The deck slab design required an unconventional method of analysis due to the lack of depth in our design courses. From discussing with the industry advisors, we were recommended to use the yield line analysis for determining our deck design geometry. But we did not have any similar examples or experiences in designing a deck using the advised method. So, we separated our deck into two distinct parts to accommodate for all the loads being applied and used the direct design method we learned in our design course. After the analysis, we shared our results with the advisors, and they were satisfied with the approach we took which aided us to move onto the next step of the design.

The floor beams were initially assumed to be a rigid frame, but as we gained more experience during our design process, we produced an alternative that would better fit our purpose. This alternative was to have a floating slab with only one fixed support in the middle. This way the concrete slab would not go into tension when the steel bottom chord did. The final part of our design was to design our welded connections for the bottom chord, hangers, and arch (all made up of HSS sections).

Geotechnical Design:

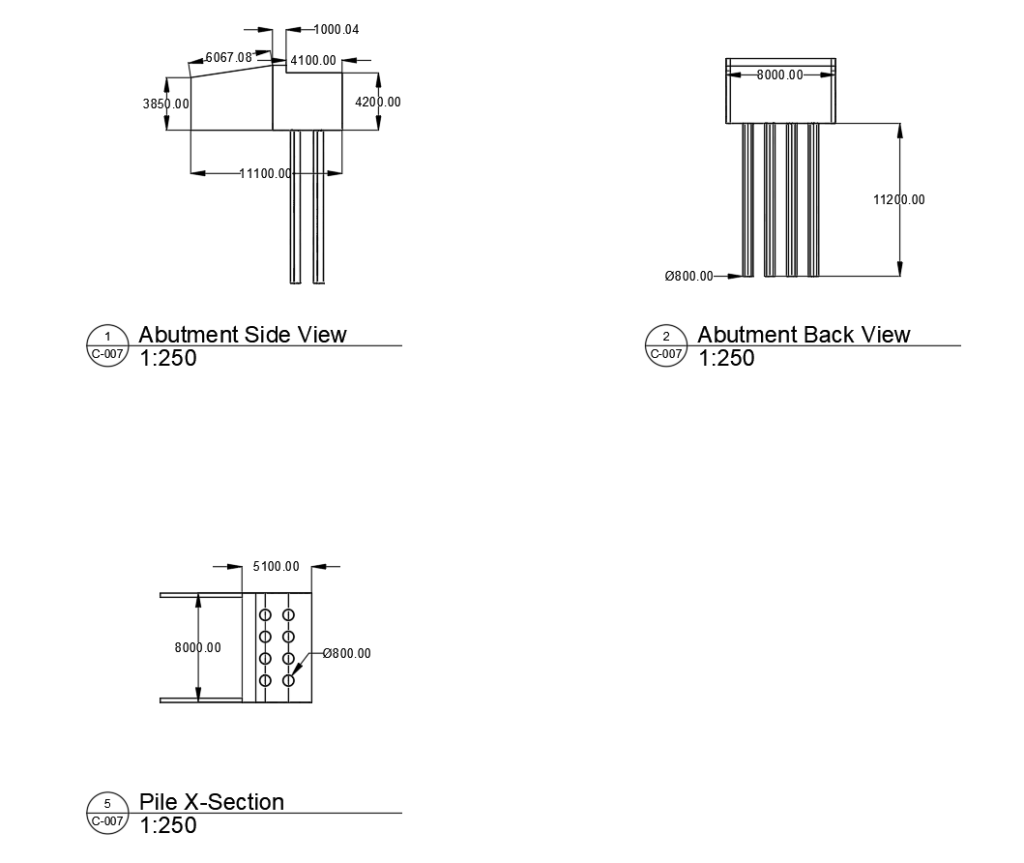

During our initial sizing stages for piling specifically, we referred to ENCI 523 course notes. We found this extremely effective in designing our piles since the design considerations and equations we were taught in class directly apply to the design solution needed for our project. More specifically taking ESA & TSA design calculations into consideration, we were able to achieve a final pile layout with a combined safety factor over 2.0. For the abutment and wingwall section of our design, we used AASHTO LRFD Bridge Design Specifications codes provided by the U.S. Department of Transportation. Due to our lack of exposure for sizing and reinforcing these members, our team felt like following the U.S Department of Transportation design guidelines was a suitable solution for the purpose of our project. Using these design codes, we were able to design a safe and stable foundation composed of a steel reinforced concrete abutment and a steel reinforced concrete wingwall. These components of foundations were calculated through excel using the formulae and steps from the codes mentioned above.

FEASIBILITY OF OUR DESIGN SOLUTION

Feasibility of our design was addressed by the factors of constructibility, sustainability, and maintenance. The constructibility of our design is a less invasive operation as piers will not be drilled into the river bed. The main superstructure will include HSS sections and cables where most fabrication will be done in shop. with the absence of piers, our design will decrease its impact on the surrounding environment, which includes a fish habitat. Additionally, the maintenance of structures within water bodies is difficult due to the changing environment under the water and requires more repairs from corrosion damage. This maintenance will be reduced with a tied-arch structure design.

Partners and Mentors

We want to thank our academic and industry advisors Dr. Rafaat El-Hacha, Peter Phillips, and Hothifa Rojob from Parsons for their invaluable advice and consulting they provided during the bridge design process.

Our Photo Gallery

[1] City of Calgary Image of Jaipur Bridge: https://www.calgary.ca/transportation/ti/pedestrian-bridges/jaipur-bridge-project.html