Aggregated Battery Energy Storage System (BESS)

Project Category : Electrical

2022 Electrical & Software Engineering Capstone Design Fair Winners

The Batt Boys

Discover an innovative energy storage investment powering a reliable transition from fossil fuels to renewables.

Join our presentation in person at Booth 17 during the 2022 Engineering Capstone Design Fair! April 5th from 10:00 a.m. to 12:30 p.m.

Brought to You By:

About Our Project

The Aggregated Battery Energy Storage System (BESS)

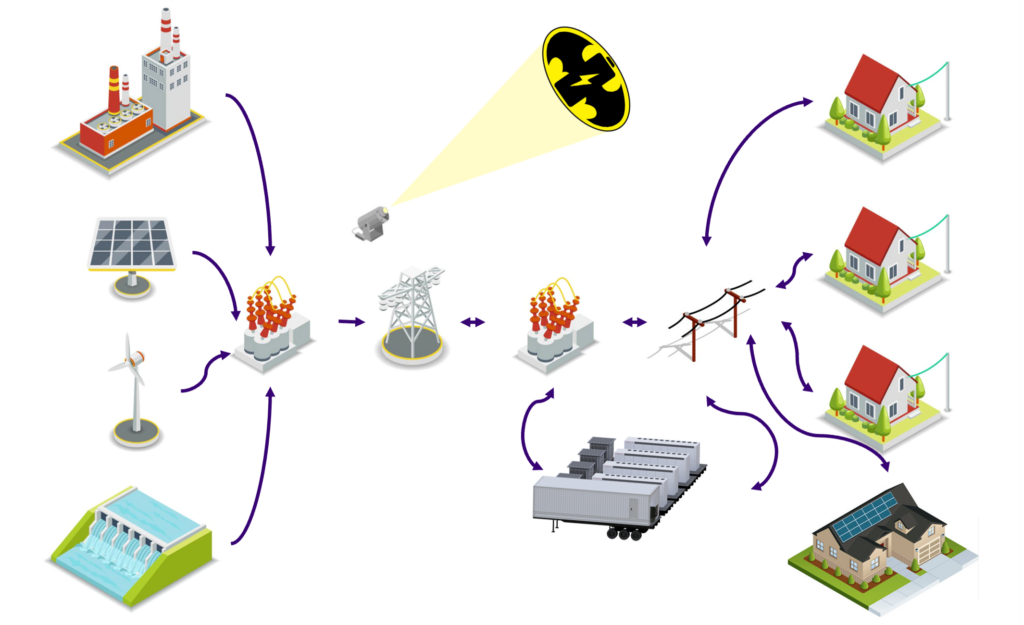

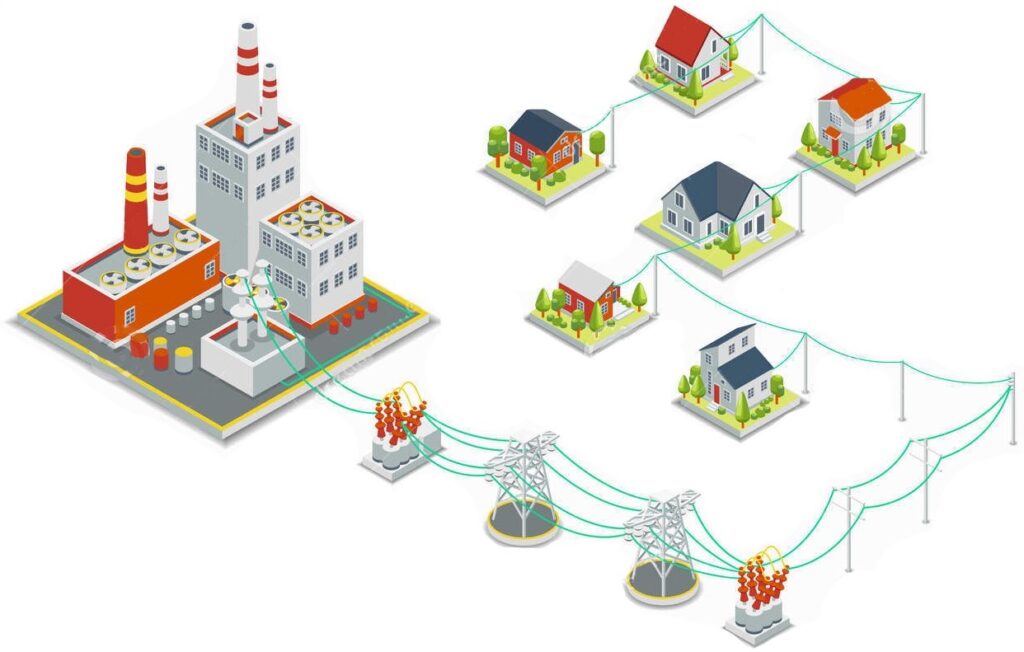

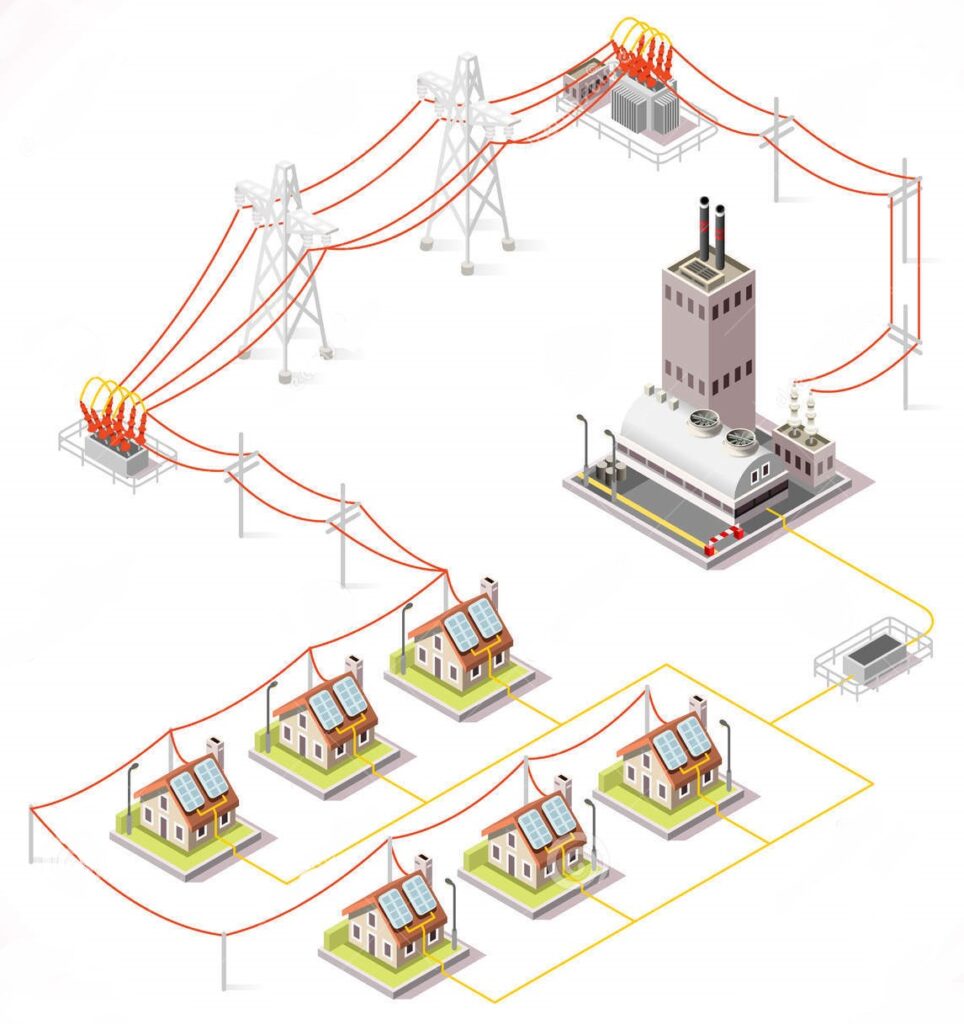

The electricity powering this webpage was generated via water, gas, wind, or some other form of energy, potentially hundreds of kilometers away, only fractions of a second ago. Electrical grids are considered some of the single largest systems in existence, and they operate with almost zero slack. This means that engineers must design a grid which must be reliable and stable while balancing increasing energy loads using aging infrastructure.

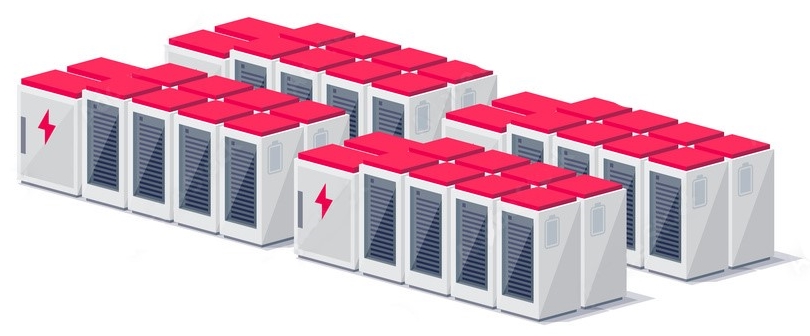

This is where our BESS facility comes in. The BESS facility is an all-in-one modular transportable utility-scale battery facility which can deliver much needed grid support in any area faster than any of our competitors. Featuring patented Tesla Megapack technology, the BESS facility can act as both a generator and a load and will be used to alleviate substation feeder overloads. Our design also pairs well with renewable energy sources such as wind and solar. Storing the electrical energy generated when the wind blows or the sun shines and saving it for later use is something the current grid is unprepared for. Our innovative BESS facility provides a modular solution to store energy for when it’s needed the most.

Enfinite provides reliable, sustainable energy solutions with the aim of creating a balanced future. Enfinite’s energy storage investments are supporting a reliable transition from fossil fuels to renewables.

Applications of Utility Scale Battery Systems

Grid Support

The BESS facility will be ready at any time with its standby charge to protect against unpredictable usage patterns. During normal operation, the BESS facility will charge during times of low demand and discharge during times of high demand. Our BESS facility is optimized to reduce grid feeder overloads by discharging during times of high energy usage.

Renewables

The time frame for renewable energy generation and consumer energy usage almost never aligns. The BESS facility can bridge this gap, storing excess renewable energy for later use. Large scale battery facilities will be essential in the world’s transition to net-zero solutions. The BESS facility makes renewable energy more viable and reliable.

Consumers

Residential solar has become increasingly popular throughout the last decade. The BESS facility can store energy for whole communities operating on residential renewables. Certain transmission line and substation upgrade fees can be alleviated by the implementation of a BESS facility. A community BESS facility aims to be a profitable investment for the long term.

Meet Our Team

“Nathan can cook, clean and is amazing at web design? Sign me up!”

Joshua Valiquette

Project Coordinator“Nathan has made me a better man physically, mentally and spiritually. Thank you Nathan”

Lukas Morrison

Technical Lead“I highly regret not joining the Batt Boys, they clearly have a superior solution and deserve to win the capstone design fair. I will be following their career very closely in the future.”

Aidan Johnson

Client“Working with Nathan throughout this project has been one of the most incredible and eye-opening experiences of my life. I am Adam Kucharski.”

Adam Kuchraski

Technical Lead“I love Nathan ⭐⭐⭐⭐⭐”

Justin Nguyen

Documentation Lead“I would do Capstone all over again if it meant being able to work with The Batt Boys. They are loving, kind, and respectful – everything you want from a top tier engineering team. “

Sami Ismail

ClientOur Design

The problem and our solution

Coal Fired and Natural Gas

Changing energy use patterns, aging power grid components, and increasing electrical load due to advances in technology are a few reasons existing power distribution networks are experiencing an increasing burden. With the rapid growth of renewable energy production, strained electrical grids have become increasingly volatile and unsustainable.

Our team researched and designed a Battery Energy Storage Systems (BESS) to provide a cost-effective and modular solution to complement existing infrastructure. Using our innovative design, the need to upgrade current power distribution networks can be circumvented. Our project provides documentation consisting of complete drawings detailing the facility design, a feasibility study to prove the validity of the system, a bill of materials, a statistical analysis of overload support, a 3D CAD model, and an economic breakdown of the facility.

A complete Front End Engineering Design (FEED) study was used in the creation of business cases on the implementation of this facility for power distributors within Alberta.

A BESS facility can complement any type of grid

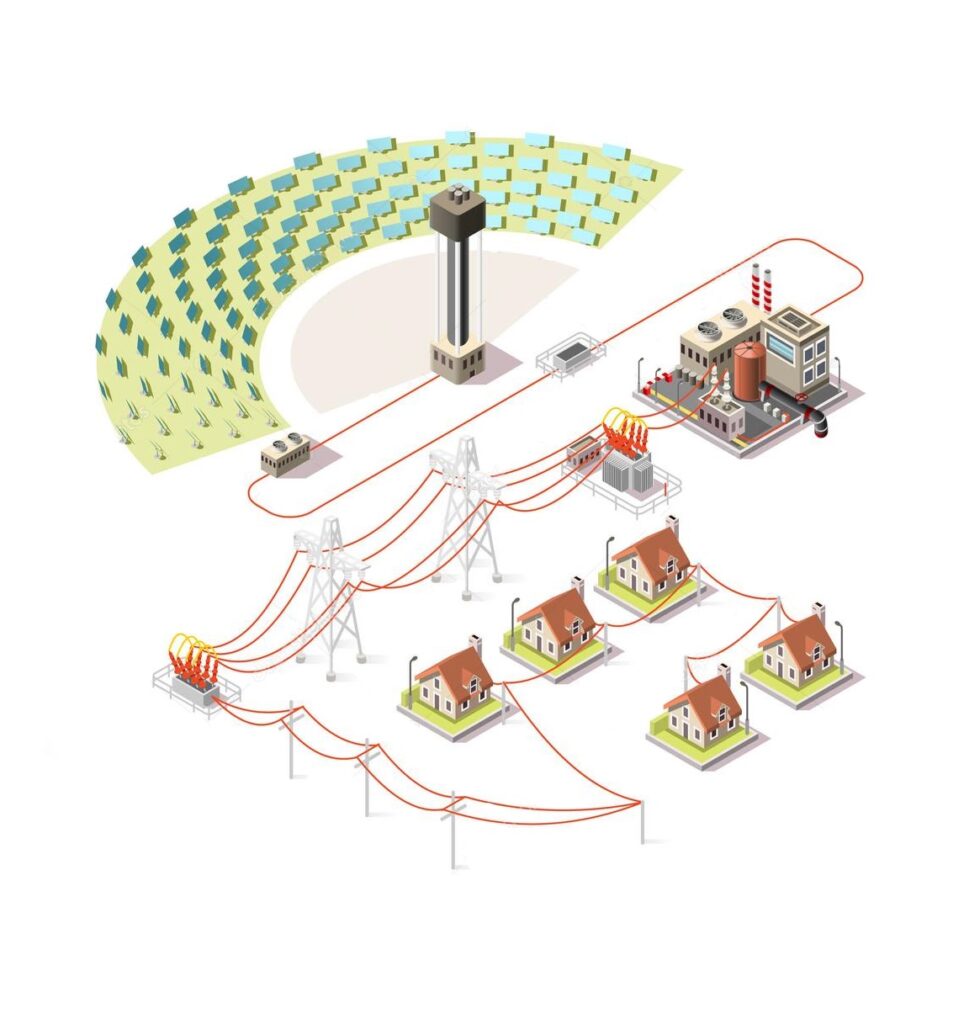

Large Scale Solar

If you didn’t know, solar energy doesn’t work at night (crazy right?). Pairing a BESS facility with solar energy allows for more reliable and consistent net-zero energy production. During the day the BESS facility charges and as the sun sets, the BESS begins to discharge for use throughout the grid.

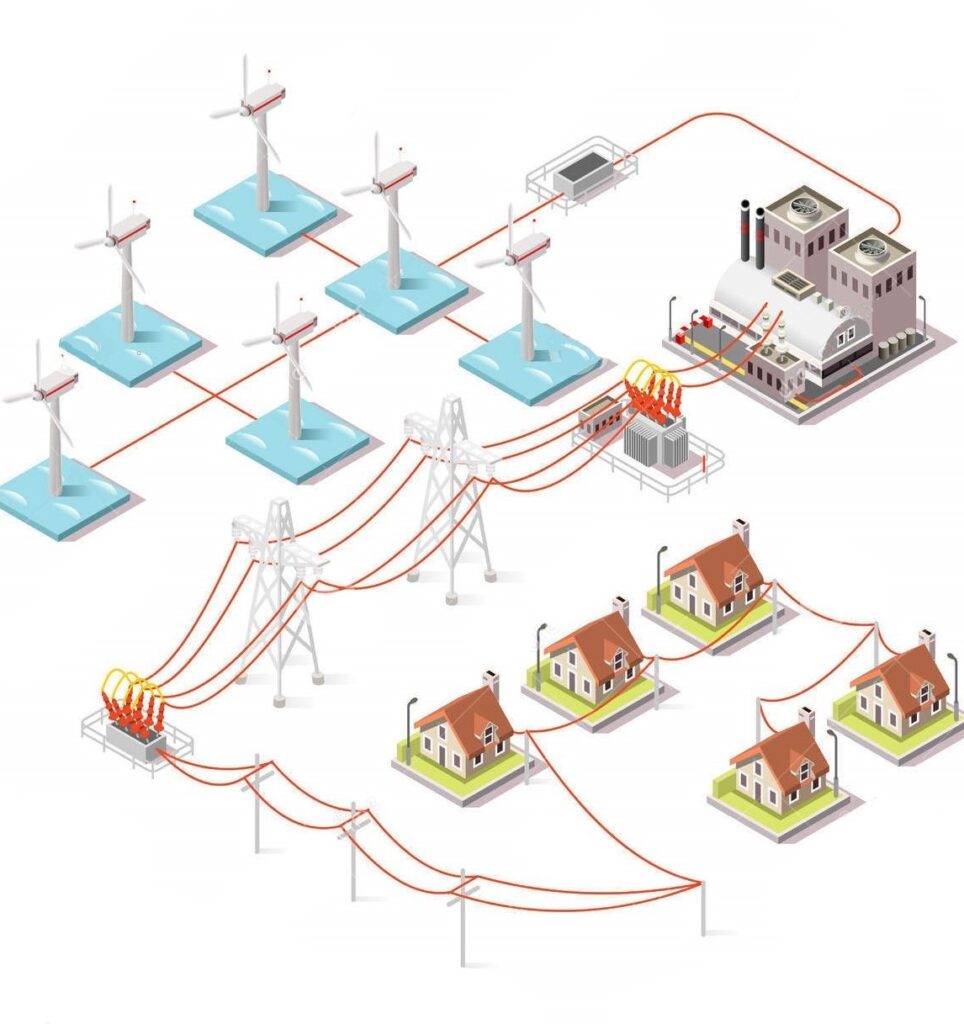

Large Scale Wind

Wind energy suffers from intermittency, which is a disruption caused by the inconsistency of the wind itself. The BESS facility would be used to reduce the unpredictability of wind energy. The BESS would store the energy produced when the wind is blowing for usage when the wind dies down.

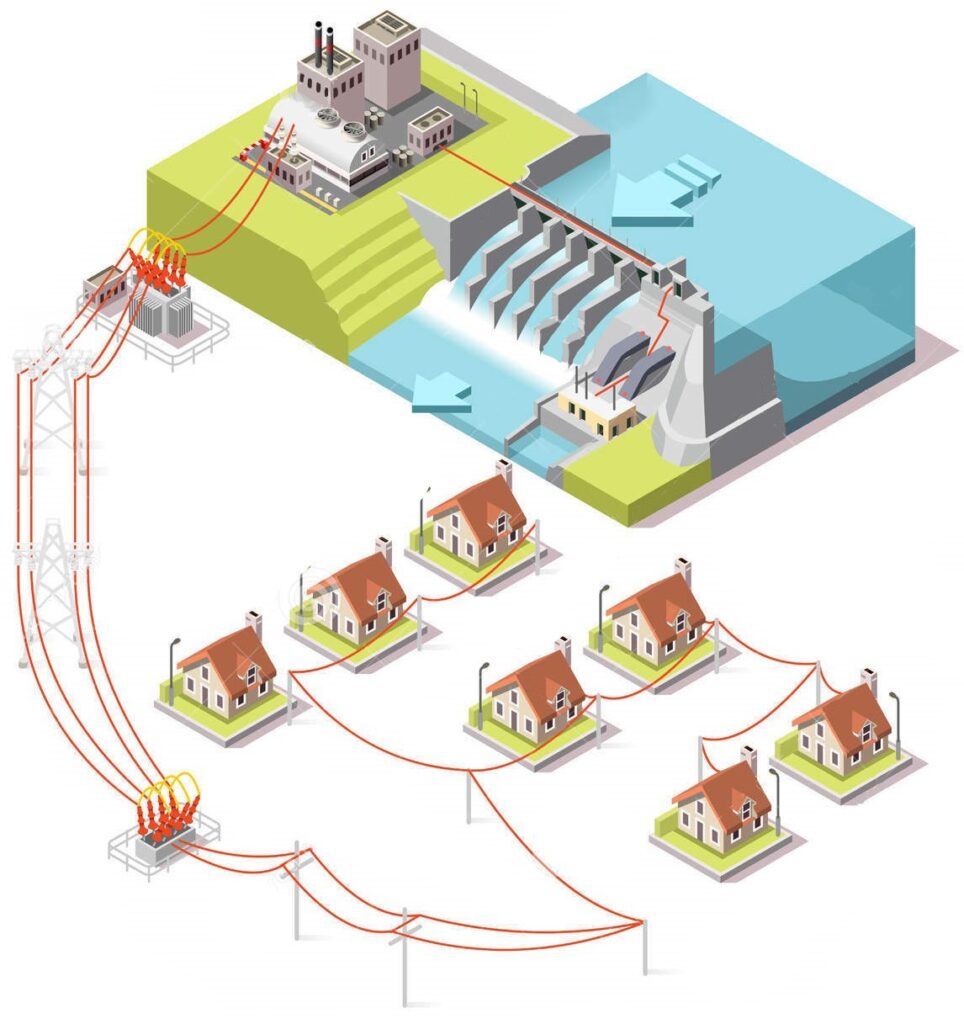

Large Scale Hydro

While hydro energy is considered one of the most reliable and consistent energy sources, there are still ways a BESS facility could be implemented. A BESS facility could provide essential backup energy to the station services during outage events as well as maintaining reliability in times of drought.

What makes our design solution innovative and effective?

Grid-scale batteries are a relatively new concept in the Canadian electrical sector, however, with the ongoing transition to net-zero electrical grids there is an increasing demand for sustainable energy storage.

Traditional methods for combating intermittent demand on the power grid include firing up peaker plants, which are short run-time fossil fuel generation facilities. Our facility essentially replaces the need for peaker plants in electrical grids. As energy demand ramps up, the BESS facility can discharge almost instantaneously to provide additional load support. Compared to peaker plants, which are notoriously inefficient at low heat rates, the BESS facility provides a fast and efficient solution for variable energy demands.

An additional factor driving the need for energy storage is the increasing penetration of renewable energy generation in the market. As renewable energy production grows, the applicability of the BESS facilities grows as well.

Residential Solar

Combatting grid overloads is a key area which sets the BESS apart from its peers. Traditionally, to prevent overloads, utilities will perform load transfers to ensure critical areas are not left without power. This would include adding temporary feeder ties or temporary generators in the short term. The long term solution would be to construct new feeders or reorganize loads – a costly and time consuming task. The BESS facility provides overload support while maintaining flexibility and adaptability to the grid. On top of these features, the quick setup and installation time ensures no one goes without power for extended periods of time.

How we validated our design solution

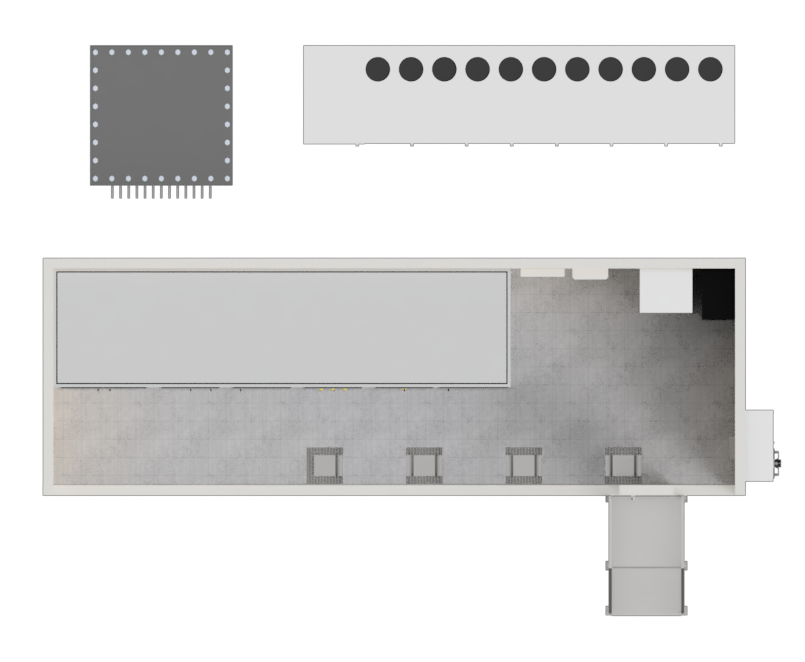

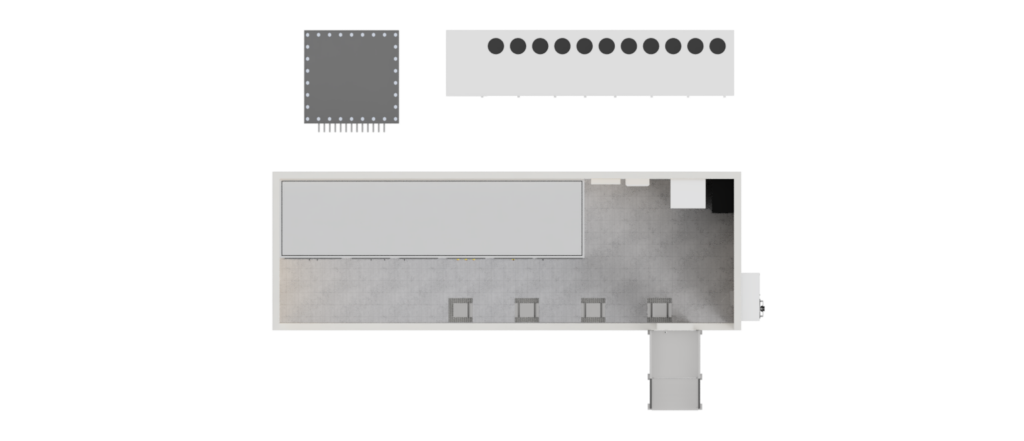

A comprehensive, to-scale 3D representation of the BESS facility and all relevant components was created in Autodesk Fusion 360. This model serves the purpose of design validation by ensuring component sizing, facility layout, and transportation requirements. The total facility dimensions were derived from the model, yielding size requirements for different battery aggregation configurations. The inferences made from the 3D model were used to make important design considerations, such as the deployment location of the facility. In addition to all this, the 3D CAD model provides a tangible aspect, bringing a concept one step closer to a reality.

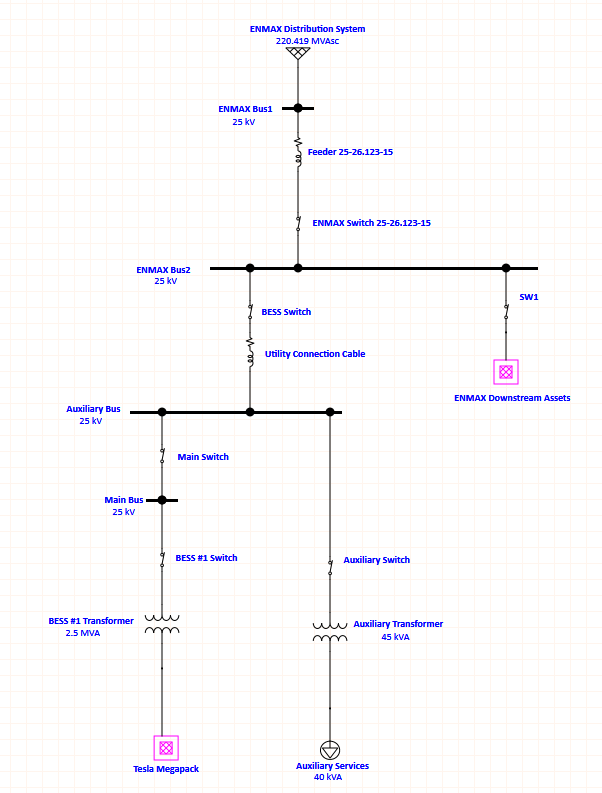

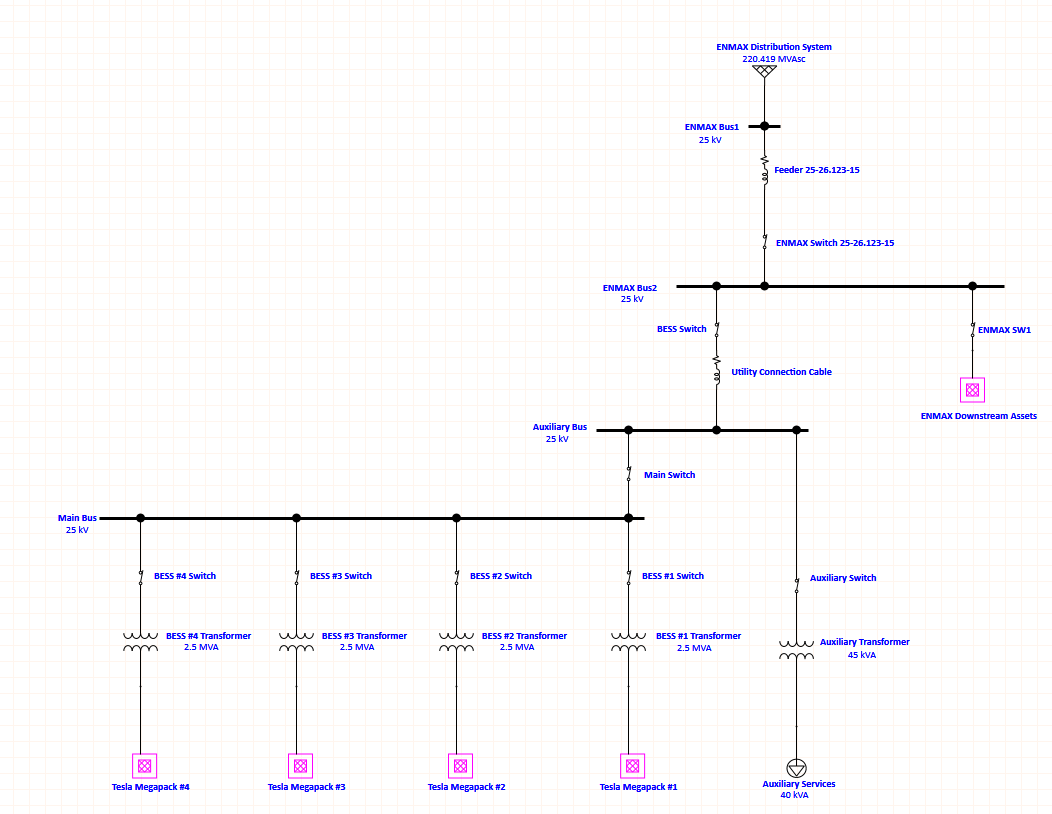

A feasibility study was conducted that looked at the BESS’s ability to perform as required, and to do so safely. The study was completed using an overloaded distribution line, or feeder, in the community of Auburn Bay, Calgary. All information regarding this application was provided by ENMAX.

The Power System was modeled in ETAP, an electrical modeling and simulation software program. Power Flow studies were completed to demonstrate the BESS’s ability to handle an overload. Additionally, Short Circuit Tests were performed to determine protective ratings for electrical equipment, and for protective device coordination.

Feasibility of our design solution

Environmental considerations

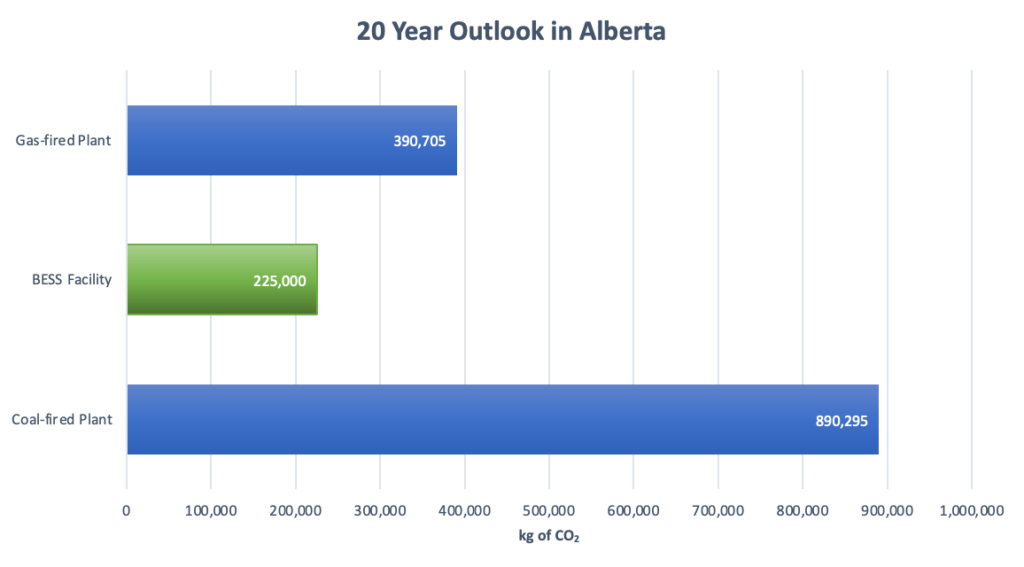

Implementation of the BESS facility would be used to reduce Greenhouse Gas (GHG) emissions for existing grid infrastructure. The largest amount of GHG emitted occurs during the initial manufacturing phase of the Tesla Megapacks but it must be noted that future improvements in the space will greatly reduce emissions. Battery manufacturing includes the mining, refining, and processing of materials, such as lithium, nickel, cobalt and aluminum. Tesla Megapack batteries from the Gigafactory in Nevada are estimated to emit around 60 kg of CO2-eq/kWh.

The BESS facility also pairs very well with net-zero generation sources. It has the ability to smooth out renewable generation while maintaining a low carbon footprint. Overall, a BESS facility can lead to GHG emission savings of at least 20% paired with a photovoltaic (PV) system. Adding a BESS facility to your grid is a great way to encourage and promote renewable energy sources in your power mix.

Economic analysis

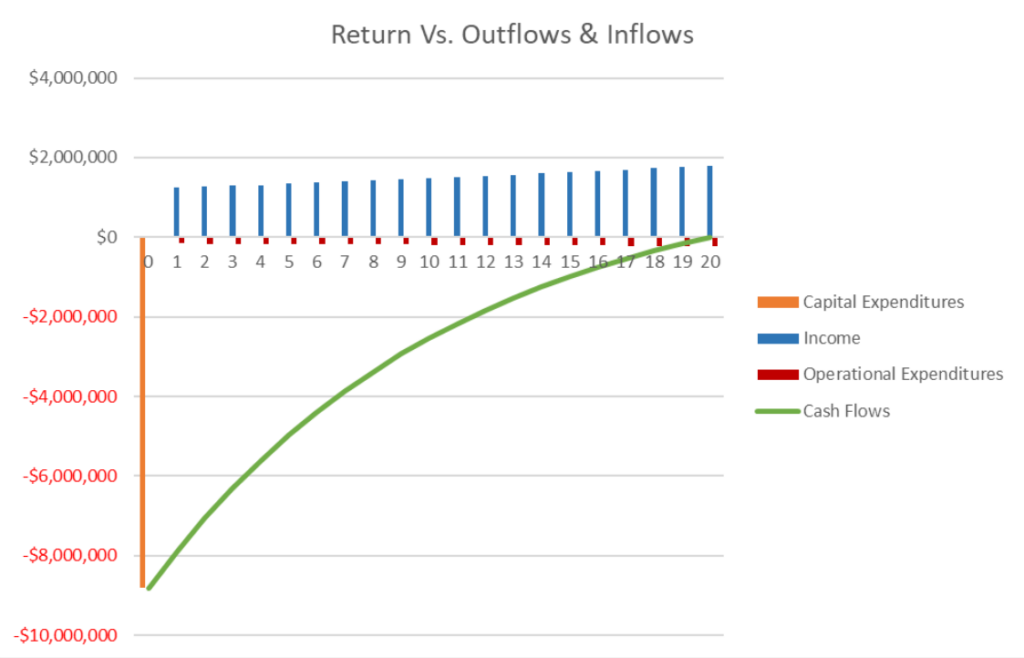

To determine the economics of the project, we first collected all the total capital expenditures for the project. This included the material cost and the labor cost of manufacturing, building and installing the facility. The largest portion of this cost was, of course, the Tesla Megapack batteries. Next we needed the estimated operation expenditures or the OPEX costs. This includes the maintenance cost of the batteries as per the Tesla website, the maintenance of the electrical equipment, and an overhead cost. Some costs that we made note of but did not include as this is an unknown variable dependent on a site to site basis is the potential for site prep such as civil works and interconnection costs, or the cost to relocate the facility.

Impact of our solution on the grid

Modern electrical grids are plagued by the combined variable demand of millions of consumers every day. Electricity has become ubiquitous in our society and consumers expect reliable service to consistently power their lights, TVs, air conditioning, or computers when they wake up in the morning, or get home in the evening. This demand volatility is difficult to predict and sometimes there is not enough energy to go around. The BESS facility can eliminate this issue by providing reliable energy to the grid to get through times of high demand. The system does not add any additional load to the grid, instead it draws at times of low energy demand.

The BESS facility can regulate the grid for safety and efficiency; it will maintain power draw within operating limits, preventing overloading and outages to keep the lights on for all.

Partners and Sponsors

We want to thank the many people who have helped out or provided guidance during this project. Throughout the life span of our capstone, the team has received a great deal of support and assistance from talented people across the industry. The backing we received was extremely valuable and allowed us to complete a project that makes the Batt Boys name proud.

Enfinite

Jason White – P.Eng.

COO – Enfinite

Amin Kassam – P.Eng.

Facilities Engineer – Enfinite

Azim Vira

Technical Consultant

University of Calgary – Schulich School of Engineering

Seyed Pouyan (Yani) Jazayeri – Academic Advisor

Senior Instructor – Department of Electrical and Software Engineering

Hamidreza Zareipour – Course Coordinator

Professor – Department of Electrical and Software Engineering

Udoka Nwaneto – Technical Advisor

Graduate Teaching Assistant – Department of Electrical and Software Engineering

Enmax Power Corporation

Freddy Gatta

Distribution System Development Engineer – Enmax Power Corporation

Suleman Osman – P.Eng., PMP

Distribution System Development Engineer – Enmax Power Corporation

The City of Medicine Hat

Mustafa N Hassan – P.Eng., PMP

Engineering Superintendent – Medicine Hat Power & Water

Sabre Instrument Services Ltd.

Trevor Vaughan

Trevor McInnis

Jacob Wollenberg – T.T RSE

Photo Gallery

The Batt Boys

Facility Model

Drawing Set

ETAP Testing

Feasibility Analysis

Please note: many of our photos and documents contain sensitive, proprietary information and cannot be shared on our website. If you are curious, come visit us in person and we can go into more detail about our project!

“Yesterday is history,

– 🐢 Master oogway

tomorrow is a mystery,

and today is a gift…

that is why they call it the present”

Image Accreditation:

Megapack facility photos and videos provided by Tesla, Inc.

Isometric vectors provided by Freepik

All rights reserved by The Batt Boys ©, 2022

Great website Nathan!