Project Category: Electrical

Join our presentation

About our project

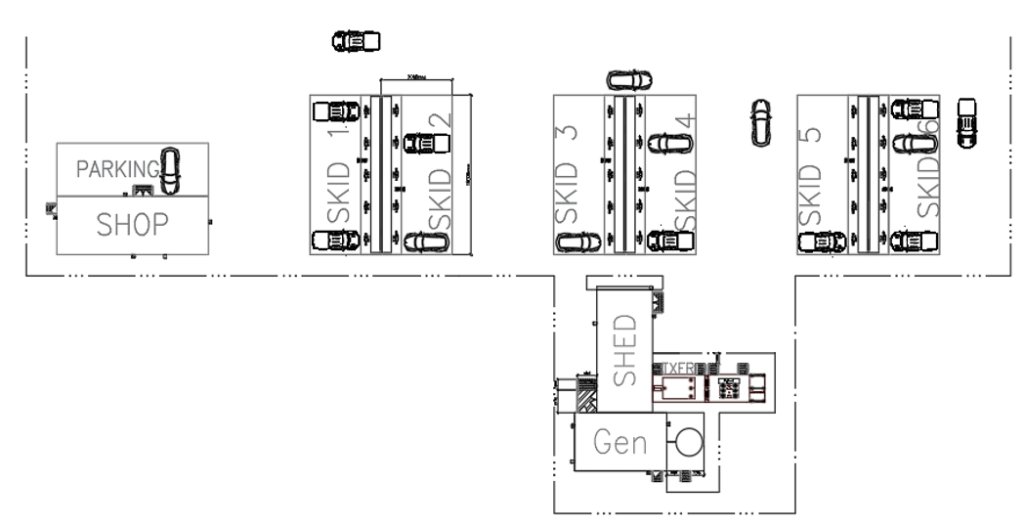

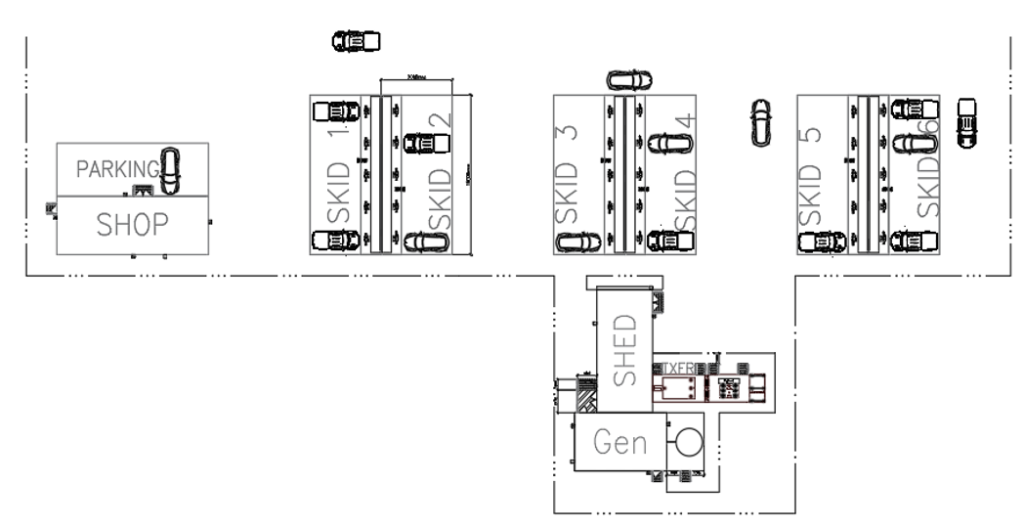

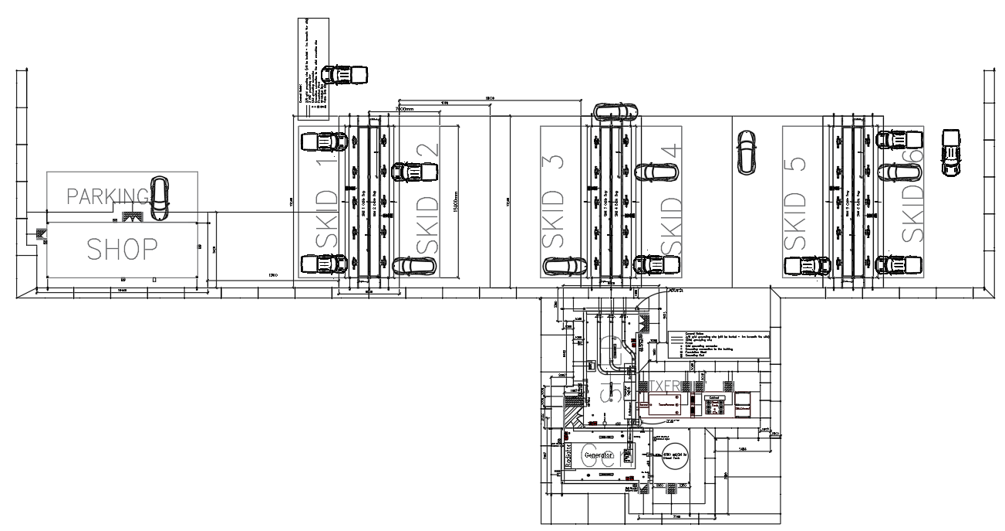

Our project tackles the issue at hand with limited driving ranges for electrical vehicles in Alberta. We designed the project to be mounted on skids to allow for easy transport of and relocation of the site to provide electrical charging infrastructure as needed.

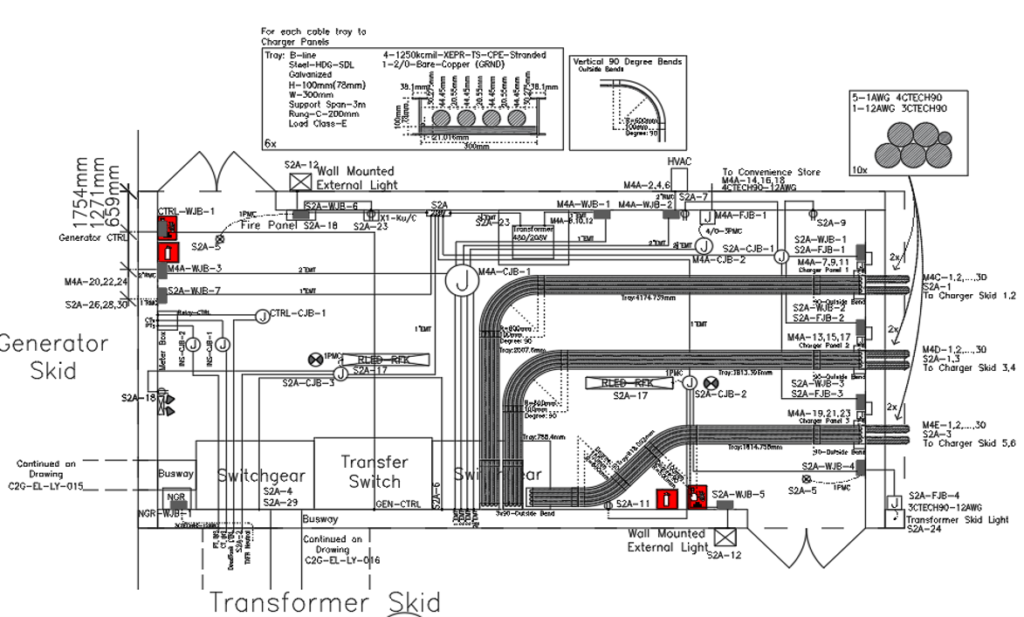

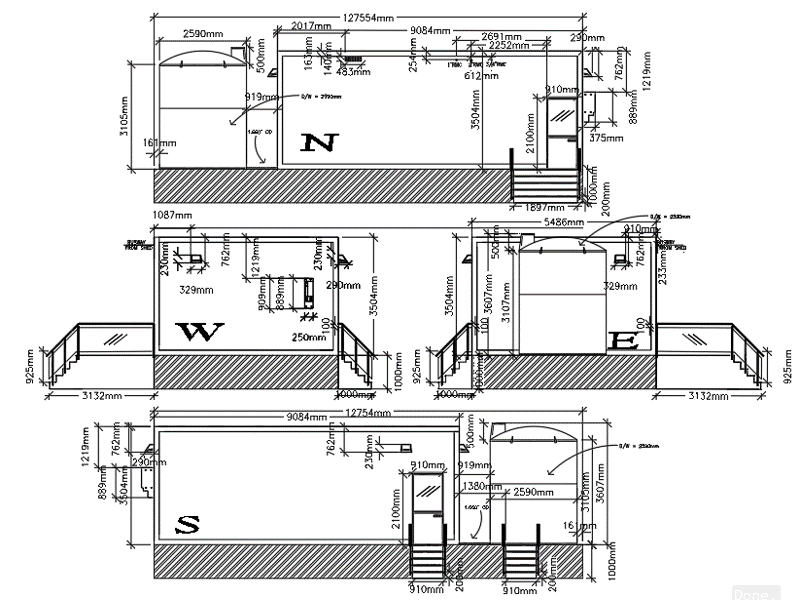

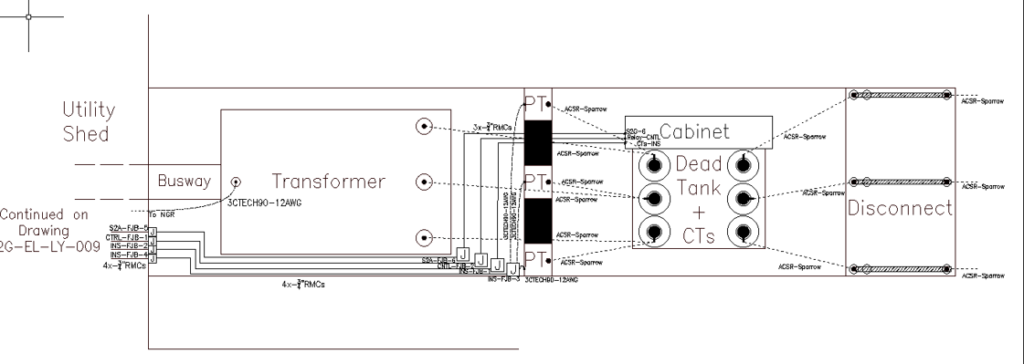

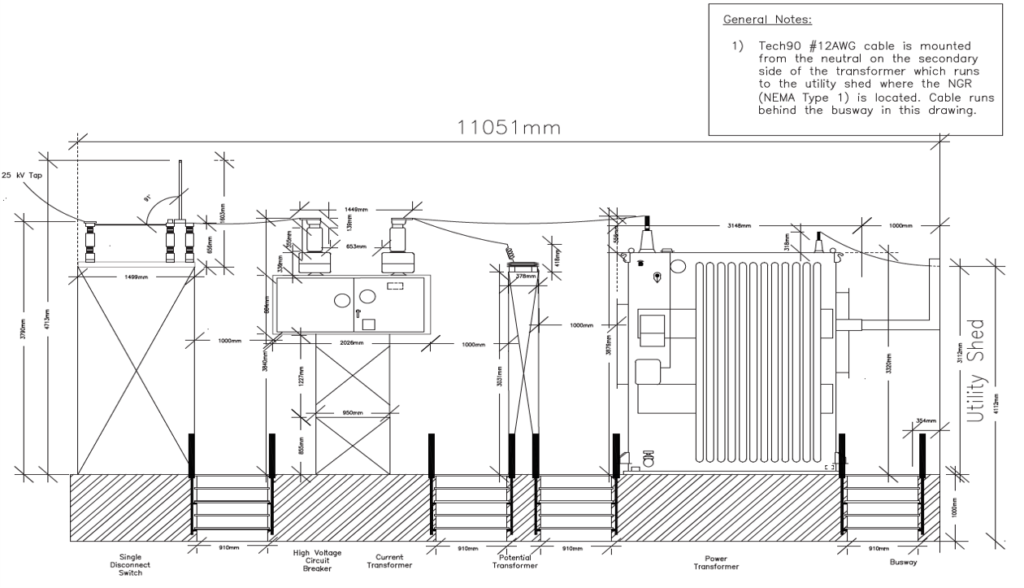

We designed a skid mounted electric vehicle charging station akin to a mobile gas station. We have 20 chargers mounded on skids, 5 chargers per skid, with an option for an additional 10 chargers to bring the total to 30 chargers. The project includes a convenience store, that is also skid mounted, so attendants and customers can shop while their vehicles are charging. These skids are supplied by the utility building skid which contains our switchgear unit. The switchgear unit is connected to a substation (transformer) skid and our 24 hour backup diesel generator. The generator is contained in its own skid mounted building. All of these skids are easily transported on public roadways and only a 25kV dead-end structure is required for an electrical hook up.

Estimated Direct Costs: $3,450,000

Meet our team members

Kejni Cobaj:

Kejni Cobaj has great interest in working with distribution systems and applying his knowledge to substation, generator and transformer design. He worked with Plan Group for a 12-month internship where he was exposed to reviewing and marking up Single Line Diagrams. Kejni also has been exposed to working with layout drawings for distribution panels, panel boards, transformers, generators, splitters, switchgear, lighting, substation and elevation. In addition, Kejni has knowledge with and used Tables 44, 45 and D16 of the CEC in order to correctly size mechanical motor loads for feeder breakers. Kejni is interested to learn and use ETAP’s software which will help him continue to grow his skills as an engineer.

Daniel Floyd:

Daniel Floyd has both project management and design related experience in the energy industry and academia. He formerly worked as a Summer Research Assistant at the university and assisted PhD candidates with performing experiments relating to motors and generators. He also worked for Husky Energy as a Project Manager in their Pipeline Division, as well as METSCO Energy Solutions, a consulting company in Calgary, performing asset condition analysis, statistical modeling, and developing maintenance plans for electrical transmission and distribution systems. Daniel has a passion for sustainable and accessible energy systems and electric vehicles and would like to see the support infrastructure for electric vehicles improved in North America so they become a more viable option in the long run.

Kenneth Gabriel:

Kenneth Gabriel has prior knowledge and experience with power networks and energy systems. As part of his schooling, Kenneth has excelled in courses relating to electric power generation, transmission, and distribution, including steady state model of generators, transformers and transmission lines, three phase systems, per unit analysis, power flow analysis and transmission line parameters. He is currently taking the Electrical Power Systems in Commercial Buildings and Power System Protection courses. During his internship, Kenneth worked on preventative/predictive maintenance of multiple substations, motors, generators, and transformers on draglines. He also used AutoCAD to create and update blueprints of electrical layouts of draglines, substations, and HVAC systems in the building.

Hamdi Gato:

Hamdi Gato has worked in Hydro One for 16 months as a transmission and distribution settlement analyst intern where his line of work included setting up meter data, create totalization tables for customer setup in the grid, calculate transmission and radial line losses by analyzing SLD’s, LTOD’s, SSLA’s and other technical documents, implement aggregations of multi-metered and large scaled customers, as well as working with distributed generator, net-metered, load displacement, LDC, as well as end-use customer setups. Hamdi also worked with customer meter queries and other issues related to a customer’s connection.

Jeffrey Layton:

Jeffrey Layton is taking a double major in electrical engineering and computer science. He specializes in computer engineering with an added concentration of computer graphics. During the summer break between semester he has worked as an electrician which brought valuable information to the team with regards to cabling. He completed a 12-month internship at Husky Midstream as a co-op student for the pipeline projects management team. In his free time, he is a professional dance teacher and dances with his dance crew.

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

Our project tackles the issue at hand with limited driving ranges for electrical vehicles in Alberta. Currently, there are sometimes hundreds of kilometers between charging stations, a distance that many electric vehicles are incapable of travelling on a single charge. Our design of modular and portable charging stations will be capable of bridging the gaps in the existing infrastructure to allow for more widespread feasible use of electric vehicles.

WHAT MAKES OUR DESIGN INNOVATIVE

Our design is innovative as we have fit all the required components of the electric vehicle charging station onto skids. This includes the utility building, generator building, our entire substation, a convenience store and level 3 chargers. These units can be moved from location to location based on demand to increase usability and affordability.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

We know our design to be effective because it is capable of being deployed anywhere within the province of Alberta to fill the gaps in the existing electrical infrastructure. It also has sufficient capacity to meet current demand and capacity for expansion as the demand increases over the coming years.

HOW WE VALIDATED OUR DESIGN SOLUTION

We validated our design by completing engineering studies throughout the project. We completed the following studies:

- Load Flow

- Short Circuit

- Lighting Study

- Area Class Report

- Protection and Coordination Study

- Arc Flash

- Voltage Drop

- Grounding and Soil Resistivity

- Sizing Calculations

All of the studies performed showed that our design is valid and correct.

FEASIBILITY OF OUR DESIGN SOLUTION

Our design is economically feasible and has a reasonable payback period. The total estimated cost of the project is $3,4500,000. If we assume a 10% loss of energy due to realistic efficiencies in equipment, choose to sell electricity to customers at a 25% markup from wholesale market prices, and assume that we have an annual operating cost of $100,000 including employee salaries and maintenance costs, the project will have a payback period of 9 years, after which all income will be profit.

Partners and mentors

We want to thank the many people who helped us with this project.

- Our Sponsor, Trevor Dring, who helped us through problems we were facing.

- Our Technical Advisor, Seyed Pouyan (Yani) Jazayeri, who helped verify our design and help provide access to technical software.

- Our TA, Hugo Leite, who helped give us administrative and project management guidance.

Our photo gallery

More drawing can be found in the video or the Zoom meeting, both of which are linked above.