Project Category: Electrical

Join our presentation

Our group will be presenting virtually through Zoom on Tuesday April 5th from 10:00 AM to 12:30 PM.

About our project

Our sponsor, the UVS Robotarium laboratory founded by Dr. Alex Ramirez-Serrano, has been developing a highly maneuverable autonomous underwater vehicle prototype. The vehicle features a set of thrusters with grippers and servos. The most recent hardware version of the vehicle was made available for students to use during the capstone year.

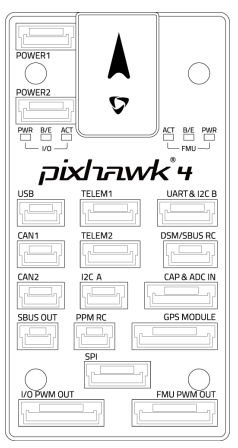

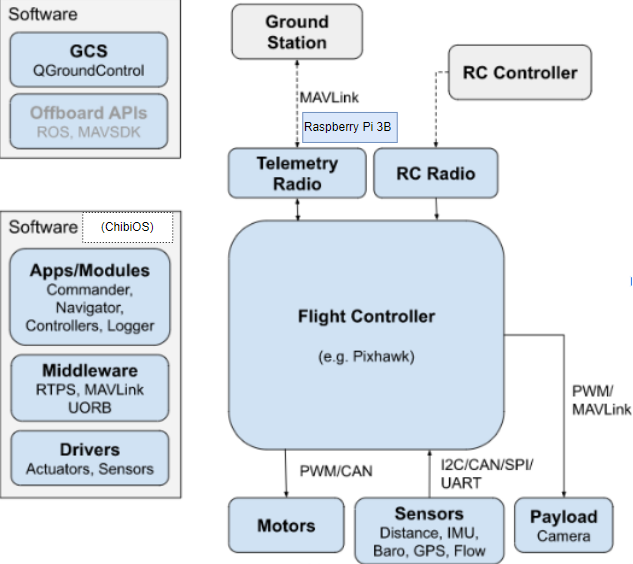

The goal of the present project is to design the electronic and software architecture using a set of commercial off-the-shelf (COTS) components supplied to the team. The system uses an advanced Pixhawk autopilot and its software QGroundControl alongside the MAVLink protocol to achieve coordination between the thrusters, servos and grippers. In addition, our project addresses the possibilities of developing the serial control of the MAVLink protocol with a Pi Connect Lite connection board to operate the motor controllers.

All discoveries in the project were documented for future references.

Meet our team members

Christian is a fourth-year Electrical Engineering student at the University of Calgary. His technical experiences include project management, power systems protection, institutional lighting design and CAD applications. On campus, he was involved with executive roles in the IEEE UCalgary student branch. While attending his studies, he worked on transmission and distribution stations as a protection & control engineering intern at Hydro One.

Darsh is currently in his fourth academic year for his Electrical Engineering degree at the University of Calgary. He is experienced in Arduino research, PCB design, CAD applications, and basic software design. He has been involved with the UC Cricket Association, where he has gained significant leadership experience. Darsh gained engineering internship experience from TC Energy from June 2020 – August 2021.

Muskan is a fourth-year Software Engineering student at the University of Calgary. She has experience in working with databases, front-end and back-end software development using programming languages like Java, C, C++, Python, HTML5, CSS, and JavaScript. She is also experienced in using machine learning and data mining algorithms. She is associated with the Schulich Soundstage as the President in 2021-2022.

Malaika is a fourth-year Electrical Engineering student at the University of Calgary. During her 16-month internship at Seequent, she honed her C++ development skills through a software development role. This experience solidified Malaika’s knowledge of low-level software development, and supplemented her knowledge of firmware development. In addition to her technical experience, Malaika has leadership experience through her time as a Campaign Manager for an Engineers Without Borders’ campaign, (Re)Construct Calgary, where she leads a team in fighting climate change by advocating with the City of Calgary for a bylaw to divert construction waste from the landfills.

Syed is a fourth-year Electrical Engineering student at the University of Calgary. He has some experience with the Arduino microcontroller, circuit design, and some CAD applications. He had developed valuable leadership experience through the Schulich Leadership Program as a Peer Mentor, guiding a first-year international student through the many challenges faced by them during their studies. He also has some experience with soldering miniature components onto a PCB.

Wei Hai (David) He

Wei Hai (David) He is a fourth-year Electrical Engineering student at the University of Calgary. His technical experiences include electrical, SCADA and instrumentation engineering skills in the field. David was working as Certified Engineering Technologist with many Utility, oil and gas engineering projects in the past. He is quite familiar with engineering integration projects, while using some electrical, automation, network communication, SCADA engineering skills to provide and implement engineering solutions.

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

Our design addresses the need of an electronic and software architecture to be implemented into the underwater vehicle prototype developed by the UVS robotarium laboratory. Using a set of components supplied by our sponsor, with the goal of reducing cost, enhancing system integration and creating a user-friendly system that future students can develop on top of.

WHAT MAKES OUR DESIGN INNOVATIVE

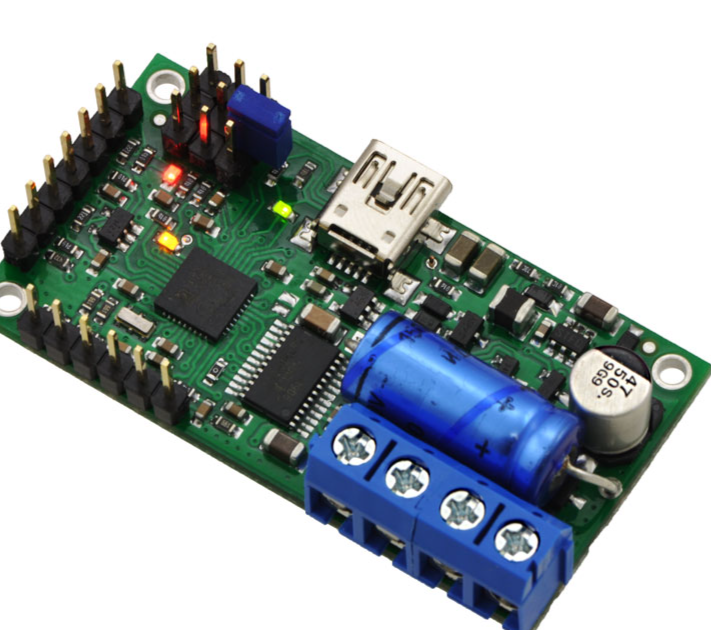

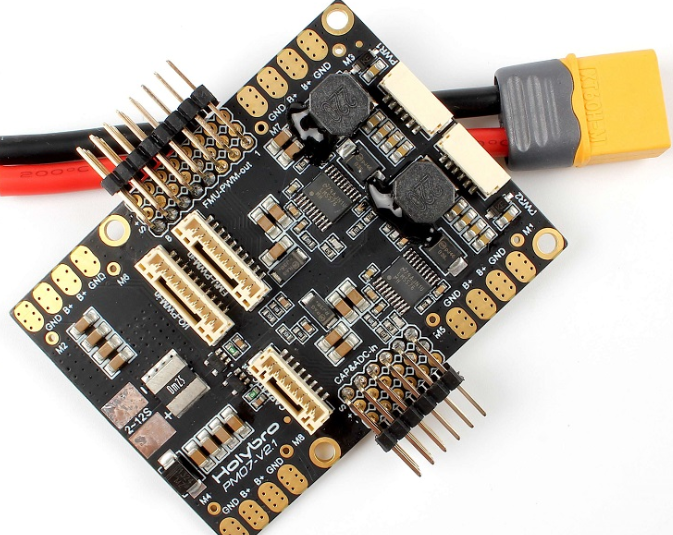

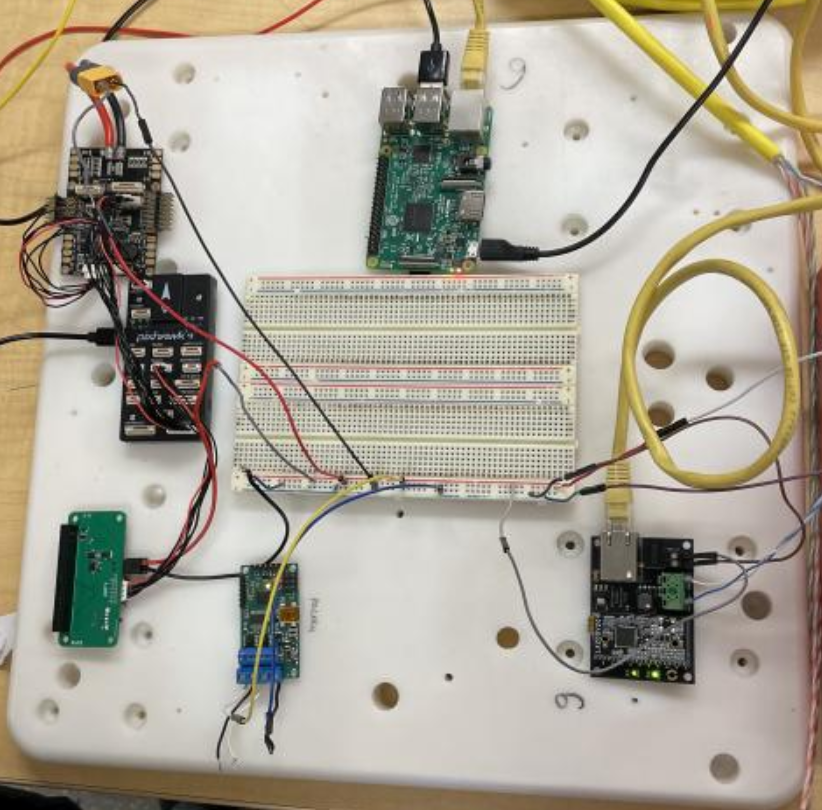

Underwater vehicle project is very special autopilot system integration and application project. It is an automation system using Pixhawk 4 controller ,QGround control software, communicating with the underwater vehicle system through Fathom X Tether Interface and its tether cable. The ground control system using Fathom X tether interface to establish the ethernet network communication with the underwater vehicle. Fathom x tether interface will network connect to Raspberry pi with a Companion software. Then the Raspberry pi connects to Pixhawk 4 using a microUSB port. There a power management board beside Pixhawk 4 to supply the power to some peripherals and pass Pixhawk 4 control signals to end devices, such as Pololu motor controller, thrusters, servos, and grippers. This project design has broad coverage of the integration and application of Pixhawk 4,QGround control system, RaspBerry Pi, Pi Connect serial connection design, thrusters twisted pair serial connection design, Power Management Board PWM signal controls, MAVlink protocol applications. The Open Systems interconnection mode is used to establish, design and test the system connection on different communication and network layers.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

The hardware design establishes an effective and fast communication between the Ground Control Computer and the vehicle where users can interface with the motors, servos, etc. The power management board safely distributes the power requirements of each component.

The design of the software architecture can be easily integrated for future developments of the project. This currently interacts with most of the components in our systems.

HOW WE VALIDATED OUR DESIGN SOLUTION

To validate our design solution, we used a performance evaluation table. To understand the details about the minimum amount of power supply each equipment needed as well as the values that needed to be assigned for the parameters, several trials where conducted. Eventually, we decided to validate our tests in two separate ways:

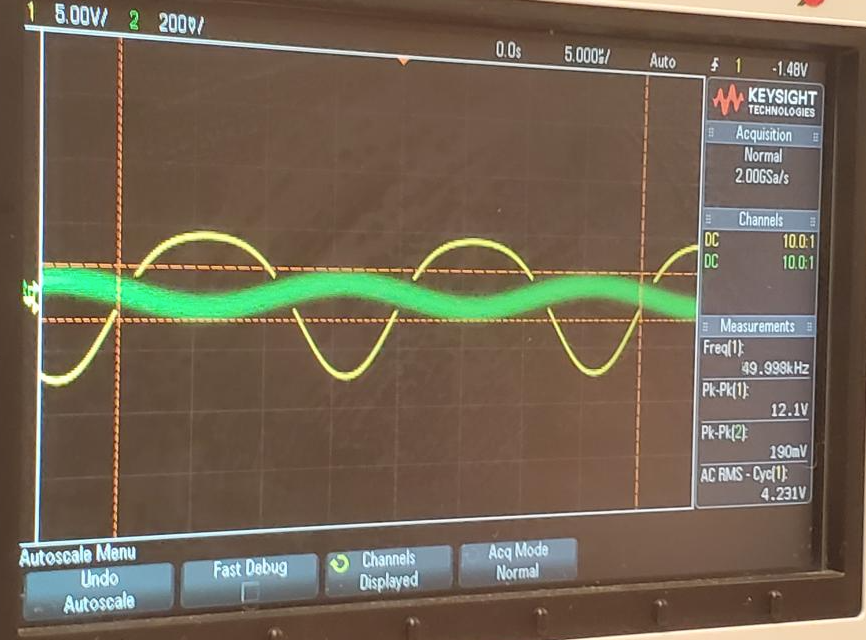

Software: Tests were conducted to confirm that there are communication signals being sent from the ground control station to the underwater vehicle. These tests were mostly unit testing and system testing by specifying different pre-calculated values as arguments for the tests.

Hardware: Tests were conducted using performance evaluation metrics that were discussed by the teammates prior to the tests. The design was considered accepted if each component worked according to the pre-defined tests. If not, the system was modified to give the desired results.

FEASIBILITY OF OUR DESIGN SOLUTION

Throughout the project, we kept an emphasis on system integration. This was due to the end goal of establishing a user friendly interaction between the user and the vehicle. This will also allow the future teams to smoothly reach the end goals of the project.

Our deliverables include:

- A detailed electrical system design layout to power and interface with all the components of the robot including electric motors, sensors, on-board computers, and communication modules. This also includes an electrical user manual describing all electrical circuits and diagrams.

- A complete set of software protocols and libraries to operate the robot from a ground control station via effective Ethernet communication to the vehicle.

We maintained a strict check on the total cost and durability of this robot. Most of the components have come from BlueRobotics. They sell these components for a reasonable price and ensure high quality. Due to this, the chances of water damage in the boards or other components have been reduced and the water drag resistant tether cable ensures smoother traveling for the robot.

Partners and mentors

We want to thank the many people who helped us with this project. Our sponsor Dr. Alex Ramirez-Serrano, academic advisor Dr. John Nielsen and Teaching Assistant Udoka Nwaneto provided us with resources and guidance throughout the process.

Our photo gallery

References

- Serrano, A. R. (2021). Deep-Flight project. University of Calgary, Calgary, Alberta.

- Garcia Rodriguez, J. A. (2020). Control of a Highly Maneuverable Autonomous Underwater Vehicle (Unpublished master’s thesis). University of Calgary, Calgary, AB.

Contact Information

Issues on zoom or inquiries about the project can be directed below