Project Category: Electrical & Software

Join our presentation

About our project

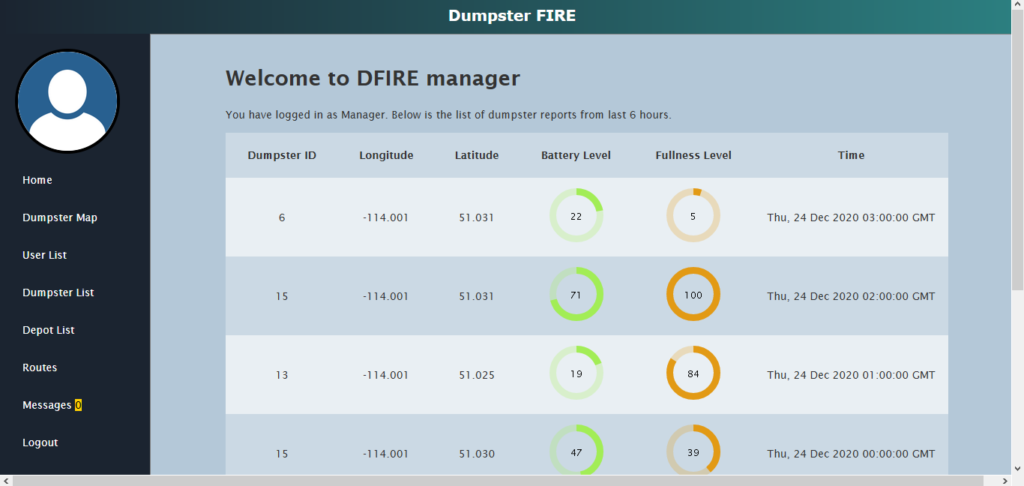

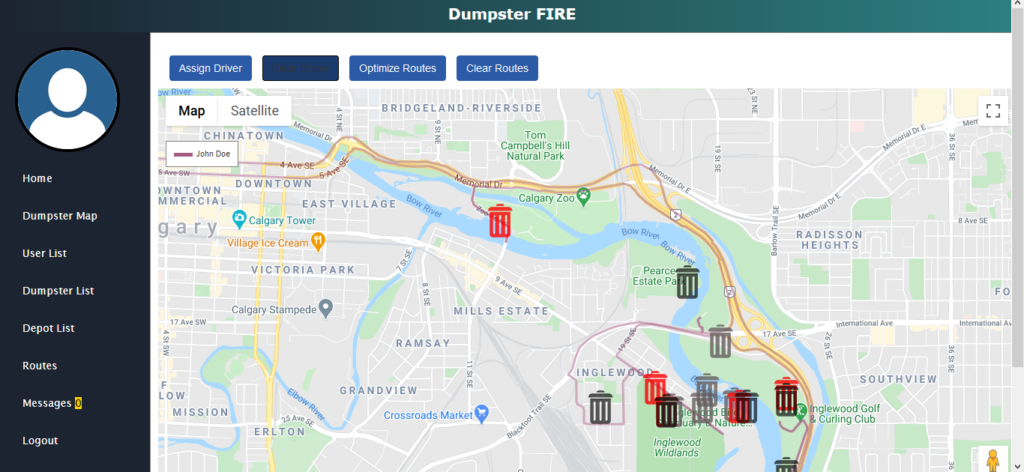

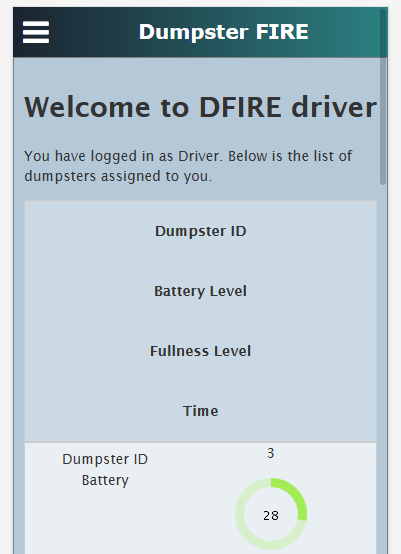

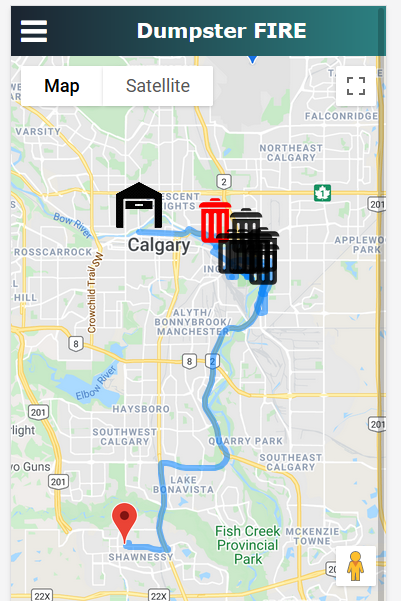

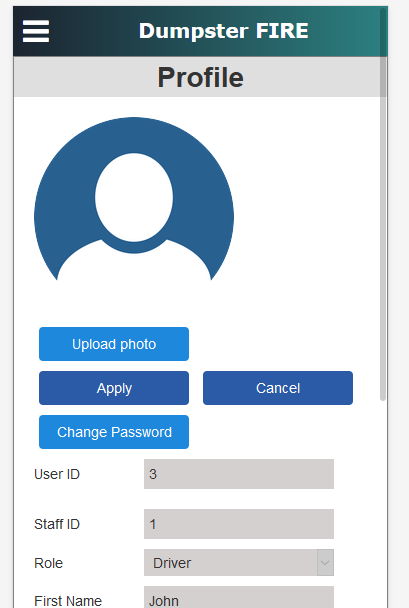

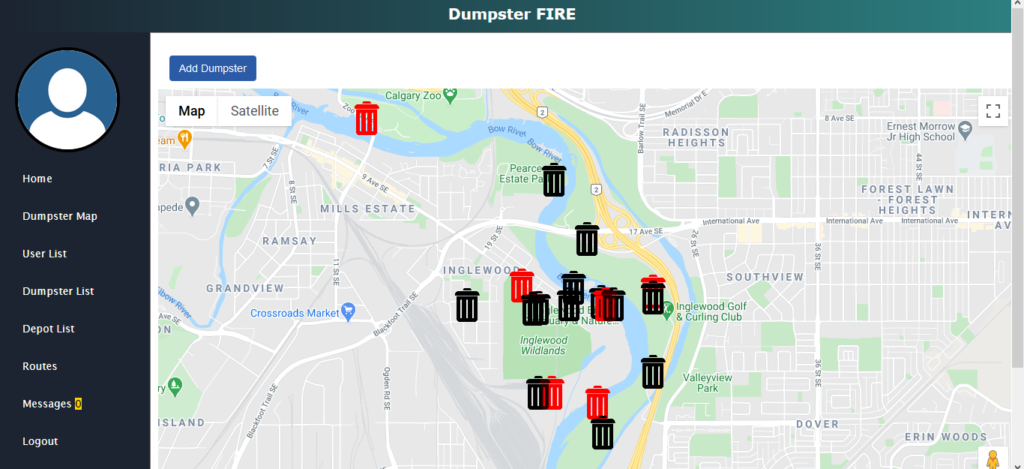

Waste collectors need more information to plan more efficient pickup routes. Every year, fuel, time, and money are wasted emptying dumpsters that are barely full. Other dumpsters are overflowing with trash. While commercial waste level detectors exist, they are not always offered as part of a complete system that offers geospatial location, forecasting, and routing in a secure wireless network independent of existing mobile and internet infrastructure. We have designed a wireless system that can track the fullness level of dumpsters. The system is intended for use by waste management companies. We’ve designed a fullness level sensor that will be mounted to each dumpster. The sensor can use our sponsor’s proprietary MLink wireless modem hardware to relay the fullness and GPS position of each dumpster at a configurable rate to a base station connected to a host PC. The sensors will use off-the-shelf proximity sensors which will be connected to a PCB, micro-controller, an onboard power supply, and the MLink transceiver. The base interface software (hauling company interface) is a web application and that displays the fullness and location of each dumpster as well as the live location of each driver. The driver’s interface is also a web application that displays the dumpster locations, status, and optimized route.

The end goal of our project is to make it easier for haulers to efficiently go to the right pickup location at which point emptying a dumpster is needed while saving businesses money on pickup costs and reducing environmental damage from unneeded CO2 emissions.

Meet our team members

Kazi Ashfaq

Software

Major: Software Engineering, 4th year

Role: Host Software Lead and project manager for September and March

Experience: Embedded software developer for Aurora Wireless Networks

Areas of Interest: Artificial intelligence, Virtual and augmented reality, Network management, Software design

Pitiduwa (Dilshan) Gamage

Software

Major: Software Engineering, 4th year

Role: Host Software Team Member and project manager for December

Experience: Qt GUI Development(KDE)

Areas of interest: Web development, Functional programming, Game development

Jonathan Yee

Software

Major: Software Engineering, 4th year

Role: Host Software Team Member and project manager for February

Past projects: TutorialHub – tutorial website built in Laravel, javascript, and postgresql. Publisher Management System – software management system for a publisher built in Java, and MySQL. ResearchMyProf – academic professionals database website built in HTML, PHP, Javascript and MySQL. Airline Ticket System – built in Java and MySQL

Areas of interest: Software design, machine learning, data science

Sebastien Bernier

Electrical

Major: Electrical Engineering, 5th year

Minor: Energy and Environment

Role: Sensor Lead and project manager for October and April. Primary liaison with industry sponsor (Craig Trask at Aurora Wireless Networks)

Experience: Co-Team Captain with Student Org. for Aerospace Research, Embedded Software Developer for Aurora Wireless Networks (16 month internship), Student Researcher (in power electronics) under Dr. Majid Pahlevani (summer internship)

Areas of interest: 3D printing, aerospace, embedded systems programming, internet-of-things, PCB design, renewable energy

Hani Siddiqui

Electrical

Major: Electrical Engineering, Final year

Role: Sensor Team Member and project manager for January.

Experience: Chair IEEE UofC Student Branch

Past Projects: Automated Lighting Prototype (Arduino)

Areas of Interest: IoT, Software Development, Machine Learning, and Project Controls

Jose Galeano

Electrical

Major: Electrical Engineering, 4th year

Role: Sensor Team Member and project manager for November

Experience: Member of systems team on U of C Solar Car Team

Areas of interest: PCB design, Firmware design, Embedded systems

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

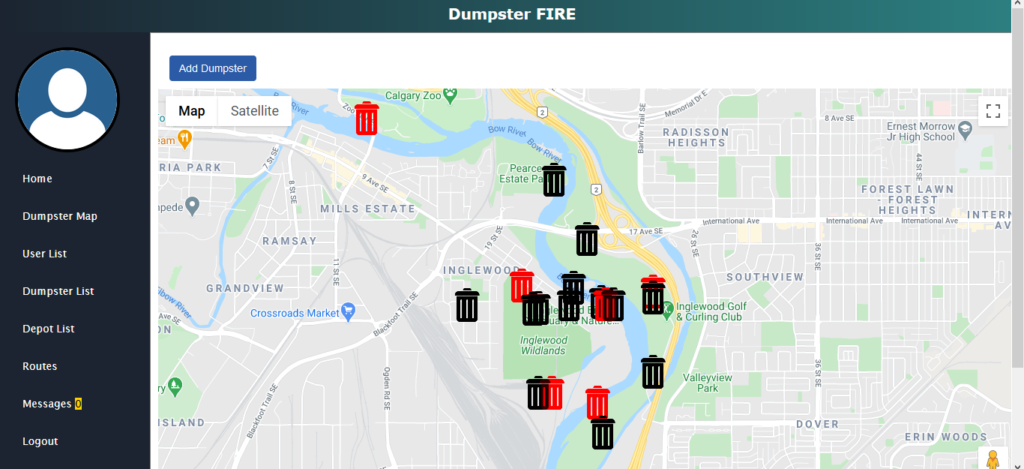

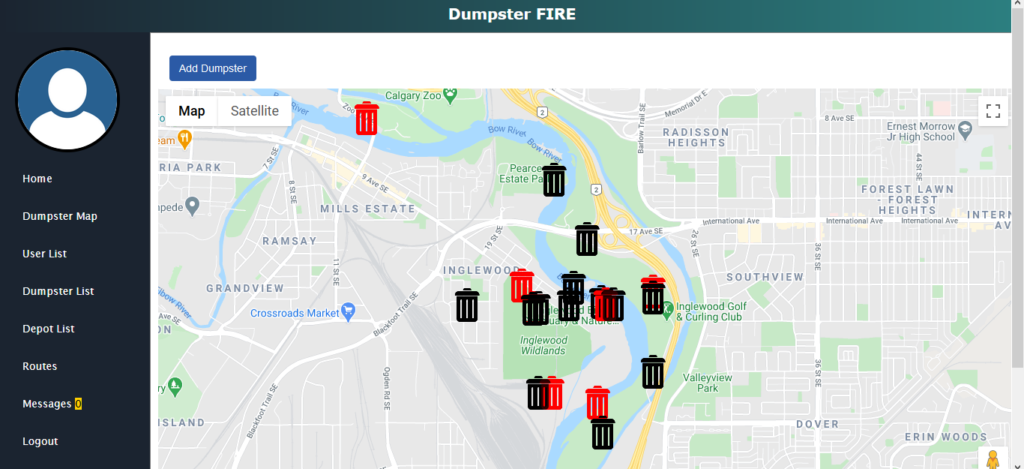

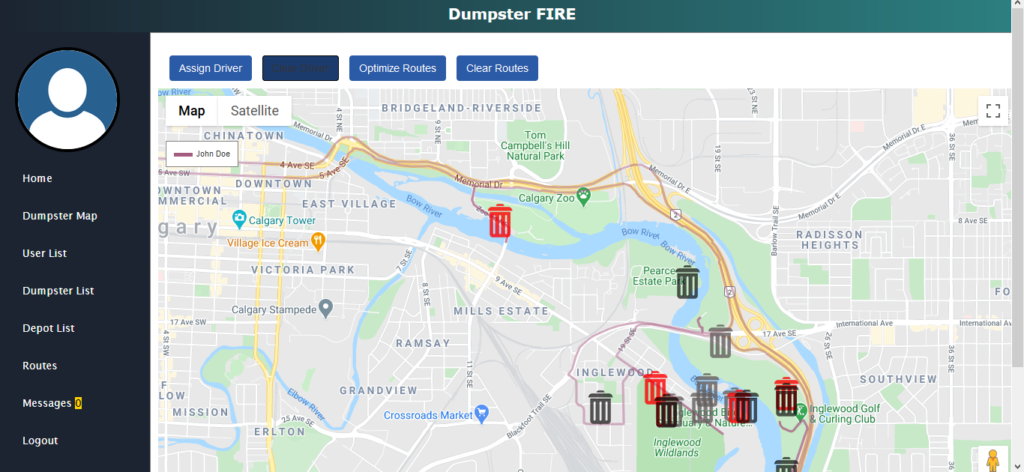

Waste collection is important for keeping our communities clean. Lots of money is spent operating waste collection services. To maximize efficiency creating optimal routes is key. A good route makes sure waste is only collected when it needs to be. A bad route will unnecessarily collect waste and use up more of the waste collectors’ resources. In the long term, it will cost more in fuel, time, and money. Dumpster Fullness Indicator for Routing Expediently (Dumpster FIRE) addresses the issues of bad routes as follows. The DFIRE dumpster sensors are able to measure the fullness level and GPS locations of the dumpsters they are attached to. They report that information wirelessly to a computer dedicated to collecting the dumpster information. That information is now available for our users the waste collection companies. The companies will use our software platform to delegate dumpsters to drivers as routes. When a driver begins work the DFIRE software will tell them which dumpsters need to be collected and also give them the most optimal route. Now waste collection companies will be able to run their pickups at maximum efficiency.

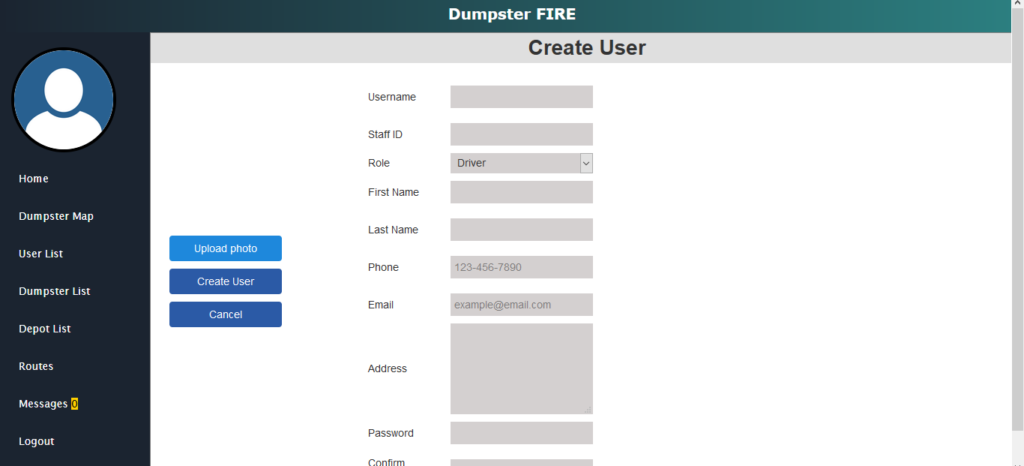

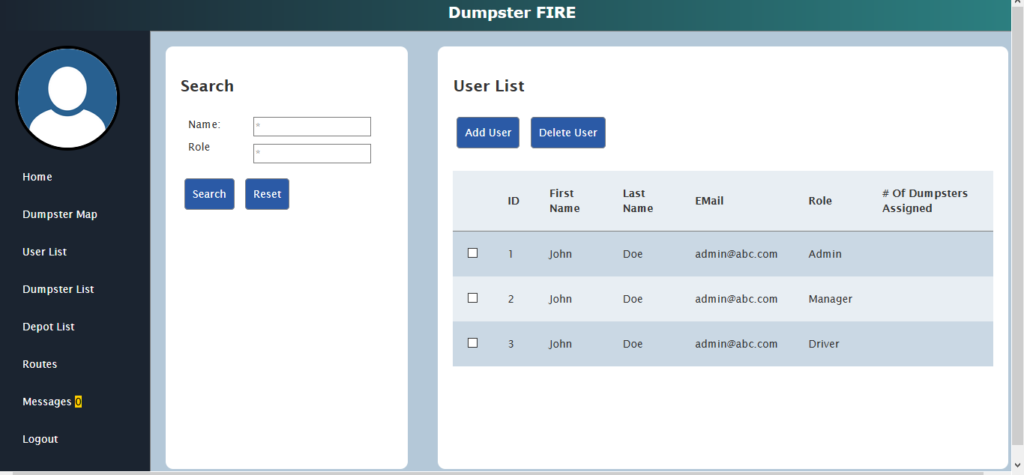

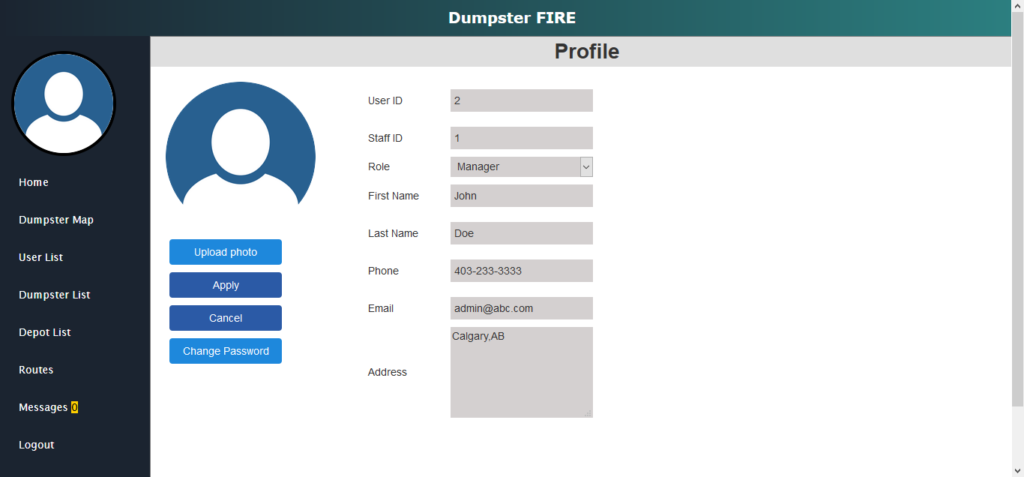

Garbage pickup plays a very important role in keeping our communities clean. Every year, a lot of money, time, and fuel gets wasted due to inefficient routing of dumpster pick up. Furthermore, time gets wasted dealing with dumpster overflows. It is clear that not all dumpsters get filled the same way. In order to solve that problem, we came up with the idea of Dumpster F.I.R.E or Fullness Indicator for Routing Expediently. Dumpster FIRE is a complete system containing multiple endpoints and bases, and a user-friendly web application for the users(admin, manager, and pick up driver). The endpoints will be placed on the dumpsters and by using sensors, and GPS, the endpoints will be able to transmit necessary data (fullness, battery level, location, standard deviation of sensors) to the base using radio communication. The base will be connected with the host computer which will retrieve the data from the endpoints and update the database at every interval (currently set to an hour). The web server will retrieve data from the database on every client call and update the web pages so that the users can be up to date with the dumpster status. We also provide forecasting so that the managers and drivers know when to expect the dumpsters to fill up. An optimized route is provided to the driver so that the driver can save time by picking up only the full dumpsters in the most optimized way. The manager can use the interface to control all the dumpsters, driver routes, and users, and the drivers will be able to handle the dumpsters that are assigned to them. Thus by using our program, the company will be able to plan which dumpsters to pick and when to pick them and the drivers will only pick the full dumpsters in the most optimized way.

WHAT MAKES OUR DESIGN INNOVATIVE

Our design uses a low-power 915MHz ISM-band wireless modem that works completely independent of cell, LTE, or WiFi communication networks. This gives our design superior energy efficiency and therefore improved battery life compared to its competitors. It does not require a special cell or data plan. It is completely secure. And lastly, it is more flexible, as it may be deployed in rural areas or industrial sites without existing wireless communications networks. Our design also includes a fully-featured server, database, and web service application that can be easily set up and maintained by clients, giving them full ownership over their hardware and their data while allowing them to customize it from the source code up to suit their own needs.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

Our design solution is effective because it allows waste collection companies to track drivers and pick-ups in real-time, as well as map out their most optimal routes. This saves time as well as money on gas and maintenance because it ensures that dumpsters are only being picked up when they need to be picked up.

HOW WE VALIDATED OUR DESIGN SOLUTION

We had three parts of our solution to validate: the software interface for users, the dumpsters sensor hardware, and the software that connected the two previous parts. For the software interface, we used unit testing and ad hoc testing to validate the functionality of the system. For the dumpster sensor hardware, we tested the sensor in a garbage bin to ensure we were getting accurate distance measurements from the device. For testing the software that connected the two other parts we used integration testing to confirm they communicated with each other properly.

FEASIBILITY OF OUR DESIGN SOLUTION

In terms of feasibility, our product is suitable in theory for evaluation by industry contacts. Our design architecture is solid and capable of commercialization, however, turning it into a commercial product able to compete with existing waste level sensing solutions would require an additional hardware revision and continual improvements to the software. The enclosure design would benefit from a redesign to make it more compact and weatherproof, incorporating rubber gaskets into the enclosure and substituting waterproof transducers for the existing transducers on the ultrasonic sensors. The microcontroller should be incorporated onto a redesigned PCB board to reduce cost instead of using an existing evaluation board. The firmware would require additional optimizations to save power and handle additional error cases. Lastly, the software suite would benefit from stress-testing with a larger number of sensors, and additional data would allow us to improve fullness forecasting and route optimization, as well as adding quality-of-life features that are provided by our competitors but not by our current solution.

Partners and mentors

We want to thank the many people who helped us with this project. Our electrical engineering professor Dr. Rushi Vyas and TA Thomas Truong were there for support and guidance. Our consultation and collaboration with our sponsors, Aurora Wireless Networks, were invaluable and they guided us through the process with patience and great advice. Big thanks to Tim and Sterben for allowing us to use their 3D printer and for their modeling advice.