Project Category: Electrical

Join our presentation

About Our Project

The objective of this project is to explore data acquisition and automation methodologies through the Cloud by utilizing IoT and LTE technologies that are easier to access while still maintaining the required level of security.

Presently, ExxonMobil manages this data manually and inefficiently through SharePoint spreadsheets, which may get outdated quickly, especially with a large quantity of data. Another problem is the difficulty to retrieve the actual data, since it may be scattered across multiple databases and applications, resulting in unnecessary wasted time, filling forms and in meetings, just to access this data. Our project solves all these issues while maintaining security, reliability, and feasibility.

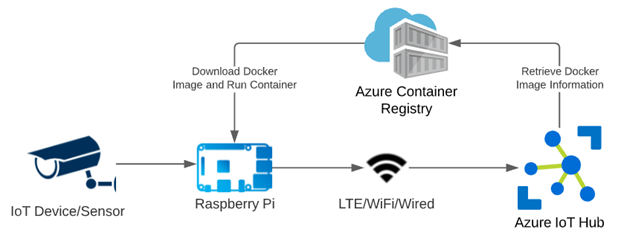

This project consists of hardware and software components. The hardware component includes a Raspberry Pi acting as an IoT edge device along with a SIM card to provide LTE access. All edge devices are collectively managed through Azure IoT Hub. These components together are responsible for secure data acquisition.

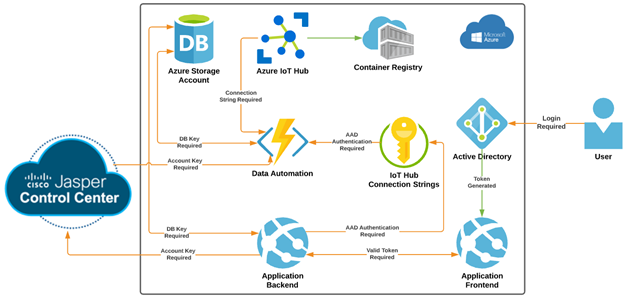

The software component is responsible for amalgamating data from 3rd party interfaces, securing data and keeping it up-to-date, and quickly allowing users to navigate through data and diagnose problems through a web interface. The software solution is hosted on Microsoft Azure.

This project is targeted towards ExxonMobil users. A user-friendly web application has been created to allow users to view and manage data related to sensors, IoT devices, SIM card, and associated IoT Hubs.

Design Details

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

Our project was designed for a particular issue that is faced not only by ExxonMobil but by many different companies in the world. The problem of collecting and storing data from different devices can be quite challenging to any industry present in the market right now especially nowadays with the increasing demand for the Internet of Things (IoT). Our design does a great job of solving this issue by utilizing Cloud resources. Our project makes retrieval, monitoring and further analysis of the data from hundreds and thousands devices fast and easy to the end-user by making the whole process automated and user-independent. We truly believe that our design is an innovative and creative solution for the practical challenges faced nowadays.

WHAT MAKES OUR DESIGN INNOVATIVE

With the relatively new widespread use of IoT devices many companies may run into the issue of scattered information, much like how ExxonMobil was handling their IoT and Edge devices before. Our project implements a whole host of features when it comes to viewing, editing, and managing edge and IoT devices, all without having to navigate what seems like endless Excel spreadsheets and contacting every employer that has any sort of link to an IoT device. Our project aims to take all of ExxonMobil’s IoT devices spread across a large list of IoT Hubs, and have them located in one convenient location where all the necessary edits, and modifications can be made, allowing for increased efficiency, and ultimately an increase in productivity.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

- Our platform consolidates all data fields that concern ExxonMobil’s IoT Devices. The fields currently provided by our platform are the IoT Hubs & Devices data, SIM & Sensor data as well as the running status of Docker Containers. It is important to note that these data fields may originate from different third party sources such as Jasper for our SIM Card data. By amalgamating the data we save the user time from undergoing tedious processes to gain access to said data.

- Additionally, our platform is designed in a way that put user experience at the forefront. Instead of squinting through monotonous Excel sheets, the website provides the data in a manner that is easily understood. Also, since all the data fields are very interrelated, we provided the user the functionality to easily and intuitively route to all data that is closely related to the data they are currently viewing. This way, the user can finally have a grasp of the entire scope of the data they are viewing.

- Lastly, our platform provides very robust diagnostics which allow the user to quickly pinpoint any possible issues even from the front page. The columns in each of our pages were chosen to reflect what diagnostics a user is most commonly looking for. For data that is more specific we have provided a details card listing every diagnostic field a user might need.

HOW WE VALIDATED OUR DESIGN SOLUTION

Our design solution was primarily validated by answering the following three questions:

- Does the solution created satisfy the constraints set by ExxonMobil?

ExxonMobil requires extreme privacy and safety for all data. Maintaining this requirement was our primary concern during the course of this project. we have secured our database to only authorized users and minimized the number of updates an end user could preform. A majority of updates occur automatically based on data secured from a third-party software. - Does the solution created solve the challenges ExxonMobil is currently facing?

As mentioned earlier, ExxonMobil faced many challenges when keeping track of devices or monitoring updates. If stakeholders required data it could take up to weeks to get information necessary for diagnosing where the problem was in the data acquisition pipeline. Our solution amalgamates many useful data fragments that when consolidated allow users to save time solving problems and allow for a quick fix. Our solution allows for tracking and managing changes on IoT devices and retrieving useful data to help diagnose issues much faster than was previously possible. - Does the solution have opportunities for further implementation in ExxonMobil?

The proposed solution allows for many enhancements that can be created by ExxonMobil depending on what they may need in the future. Possibilities using IoT Hub for device to device communication and cloud to device communication opens the project to many new applications that can be incorporated. As well, more data can always be retrieved from the third party software’s that we are currently using. As we were able to answer each of the 3 questions above to a high degree, we have confidence in saying that the design solution created is valid.

FEASIBILITY OF OUR DESIGN SOLUTION

The Hardware Design

Our hardware solution implements a simple, powerful and scalable setup. Any device that is capable of running the Azure IoT Edge runtime can be used. For the purpose of the project, a Raspberry Pi was used since it is easy to use and well documented. The Raspberry Pi was connected to a power source, along with a sensor using the built-in GPIO. A SIM card was used to connect to LTE, but the setup is also compatible with WiFi and wired connections. Finally, the Pi was configured to retrieve and run the specified container application from the IoT Hub. This simple setup allows for remote management and application deployment using IoT Hub and the Docker platform, and presents a very flexible solution to a very wide range of purposes, even beyond the scope of this project. This design is constrained by the memory and CPU specifications of the Pi, as well as the number of devices that an IoT Hub can manage. These constraints can be loosened by upgrading the Pi or using more powerful edge devices, as well as upgrading the Azure IoT Hub plan, but this would add more cost.

The Software Design

The software solution of this project follows a microservice architecture. Multiple resources interface with each other in the Cloud, where each resource has a specific purpose. The result is an efficient design that segregates responsibilities, and makes it easy to troubleshoot any issues that arise. The design enforces security by using authentication to access the application along with any associated APIs, along with encrypted environment variables and connection strings. The database (NoSQL) is also secured by only allowing specific resources to access the data. All of this was quite easily obtained due to the nature of each Azure resource. Our data automation resource ensures reliability by refreshing relevant data in the database and keeping it up to date. This can also be managed and modified quite easily and efficiently due to the serverless Azure service. Combined with well commented code and secure APIs, our solution presents a secure, reliable, user-friendly application to ExxonMobil users. The software solution is constrained by the CPU and memory allocated to each Cloud resource, but this can be controlled by upgrading/downgrading resources through Azure at anytime.

Partners and Mentors

We want to thank the many people who helped us with this project. Our academic advisor professor Emily Marasco, our TA Hugo Leite, and the many people at ExxonMobil who guided us through the process with patience and great advice, our consultation with them was invaluable.