Project Category: Electrical

Join our presentation

About our project

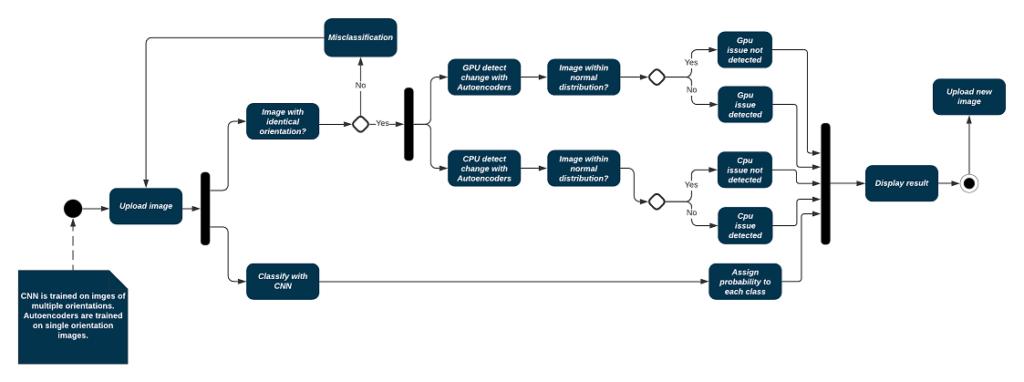

The purpose of this project is to develop a machine learning algorithm that can detect temperature abnormalities within infrared images of electrical equipment, and display the results to the user via a user interface.

The software is able to successfully analyze both situations where failure cases have been previously observed, and cases where a failure has never been seen by the model. In addition, the model is capable of differentiating between failure of different pieces of equipment depicted within the image.

Our Industry Sponsor, AltaLink, aims to use this software to monitor critical HVDC equipment such that technicians can detect and remedy malfunction before it causes system failure, helping to keep the lights on for Albertans. Our co-sponsor, FLIR, has loaned the team an infrared camera such that large and unique datasets can be built and tested on the software.

Meet our team members

Jennifer Hunchak

Project Manager

I am currently completing the fourth and final year of my degree in Electrical Engineering, and will be graduating in April 2021. Prior to my degree, I completed the Engineering Design and Drafting Technology diploma program at SAIT, and worked as a Piping Designer at a Calgary EPCM specializing in natural gas processing plants. I have completed summer internships in software development and oil & gas field operations, as well as in power transmission. After graduation, I will be entering the Alberta power industry as an EIT.

Fadi Katto

Machine Learning Lead

I am a fourth year undergraduate Electrical Engineering student. Prior to my degree, I worked in a mixture of job fields including tax preparation and construction. During the previous four years working on projects in school, I developed technical skills and interest in CAD, PCB design, and machine learning. My interests lie in machine learning and the power industry, and I am currently seeking employment as an EIT in either of those fields after my graduation this April 2021.

Harjot Bhandal

GUI Lead

I am a student currently in the fourth year of Electrical Engineering, and returning to the program after previously completing a degree in the Oil and Gas Engineering program. After previously completing a program I worked as a program coordinator and exploration engineer to scout reservoirs for procurement. Since entering the Electrical program I have completed software development contracts and after graduation I hope to pursue a career in either software development or the power industry.

Lirui Yu

Technical Architect

I am a fourth-year student currently completing my Bachelor of Science degree in Electrical Engineering. I am an electronics enthusiast and enjoy spending my spare time in the hobbyist community and seeking those projects that allow me to convert theories into practice. I have completed several projects in the area of digital filters, analog circuits and control systems. I enjoy the process of learning and anticipate pursuing a master’s degree in solid-state electronics or deep learning after graduation.

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

The HVDC valve halls, owned and operated by AltaLink, are critical to providing safe and reliable power to all Albertans.

By having this machine learning software, AltaLink will be able to take the guesswork out of determining whether or not their equipment is malfunctioning. An infrared image can be fed into our pre-trained models, and immediately convey system issues by locating the cause of the failure within the image.

By providing rapid and accurate results, this project helps keep the lights on for Albertans.

WHAT MAKES OUR DESIGN INNOVATIVE

In the most realistic scenarios, a dataset of electrical equipment won’t contain images showing what it looks like when it’s failing. We monitor the equipment because we want to detect and prevent failure before it occurs.

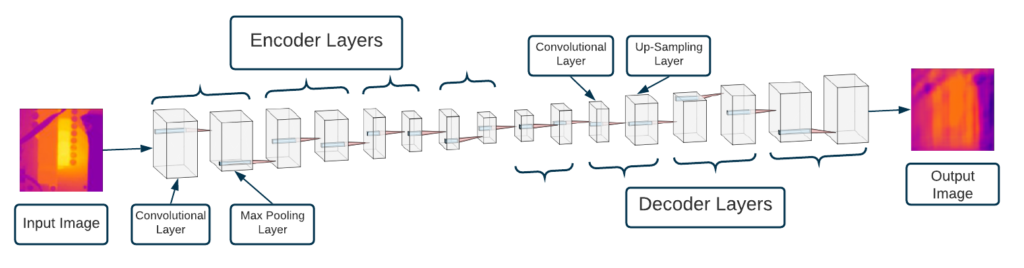

This software is able to detect temperature abnormalities within an infrared image even when the model has only been trained on a dataset depicting normal operating conditions.

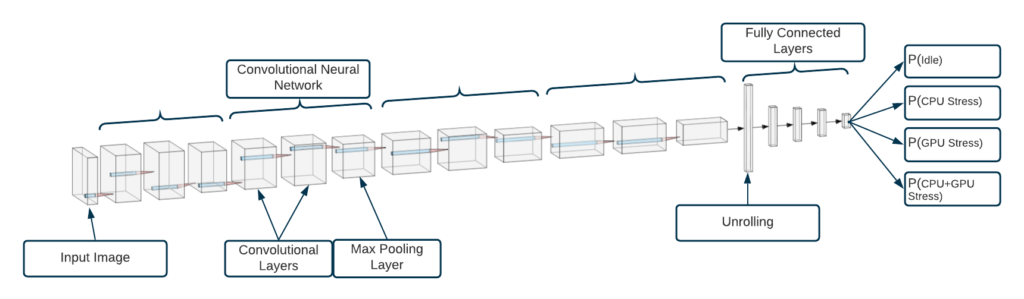

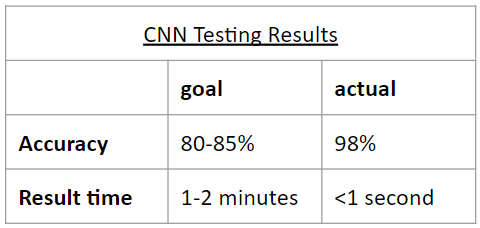

Our CNN model works for when the dataset does contain failure cases:

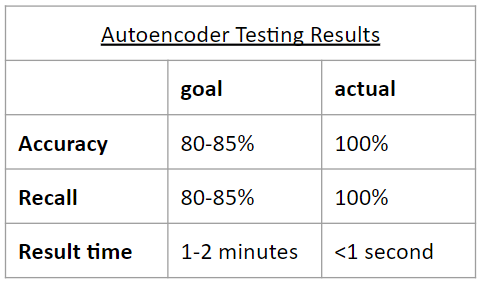

Our autoencoder model works for when the dataset does not contain failure cases:

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

Our project solution delivers results fast.

When monitoring equipment, an image can easily be loaded into the GUI for testing. Since the models are pre-trained, the results of test can be displayed instantly, indicating any temperature abnormalities for individual pieces of equipment.

HOW WE VALIDATED OUR DESIGN SOLUTION

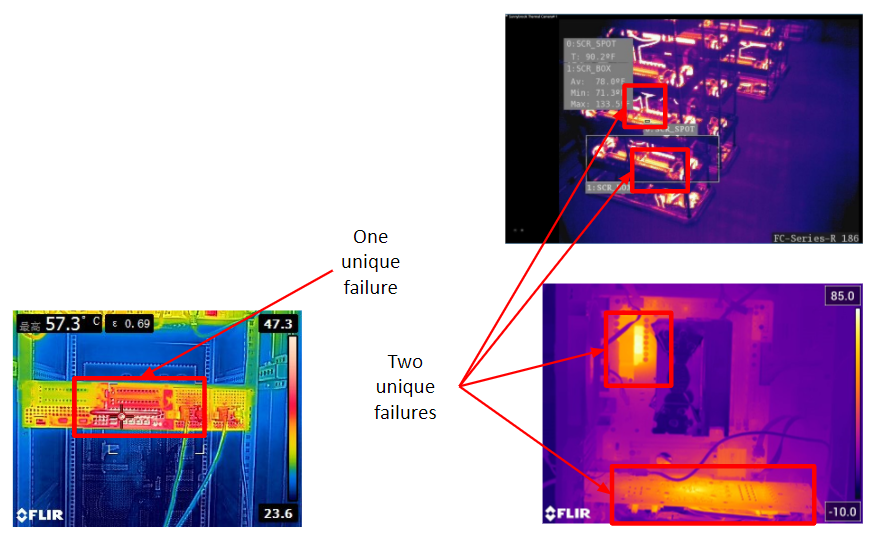

The HVDC valve hall could fail for different reasons; there could be a cooling system blockage, or one of the thyristor modules could malfunction. Our solution needed to be able to separate the different types of failures and indicate which was occurring.

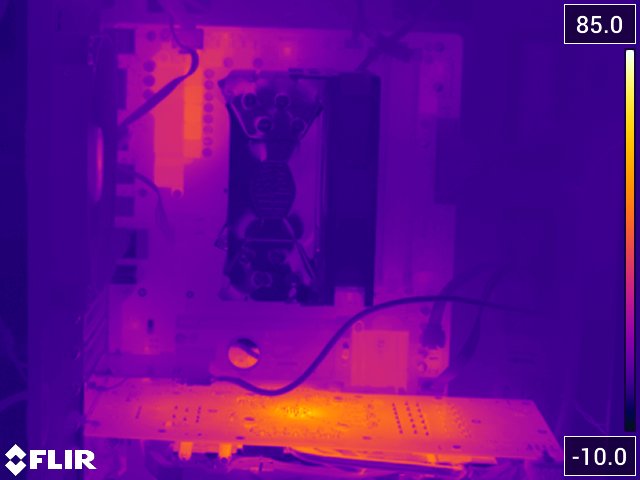

To simulate these two possible failures, we set an infrared camera onto a PC, taking images of normal operating conditions, CPU under stress, GPU under stress, and both CPU and GPU under stress. Our model is able to differentiate between the two separate stresses, indicating which failure is occurring and display that result to the user with a confidence measure.

FEASIBILITY OF OUR DESIGN SOLUTION

The FLIR E95 camera makes building a useful dataset easy.

The camera can be set up on a tripod to take a continuous stream of thousands of images. Once collected, our team can take the dataset and use it to train the model and load it into the GUI.

Partners and mentors

We would like to thank our industry sponsor AltaLink for engaging us in such an interesting and challenging project. Our mentor Colin Clark provided invaluable guidance to our team throughout the year, and our Capstone Coordinator Asher Waqar helped us stay organized.

We would also like to thank Travis Wiens, from our industry co-sponsor FLIR, who provided our team with an infrared camera and made it possible for us to test the limits of our models.

We would like to thank our academic advisor, Dr. Henry Leung, who helped us to understand machine learning principles and how we could use it to solve our problem.

Lastly, we would like to thank our assigned Teaching Assistant, Tariq Al Shoura. His dedication to ensuring we were meeting our goals is so appreciated.

Our photo gallery