Project Category: Electrical

Join our presentation

Meeting ID: 990 5741 5621

Watch our video

Temperature Controlled Animal Monitor

About our project

Our team has been striving to develop an Animal Monitor and improve ultrasound system that would facilitate preclinical experiments by letting researchers monitor and control vital signs of laboratory animals (like mice).

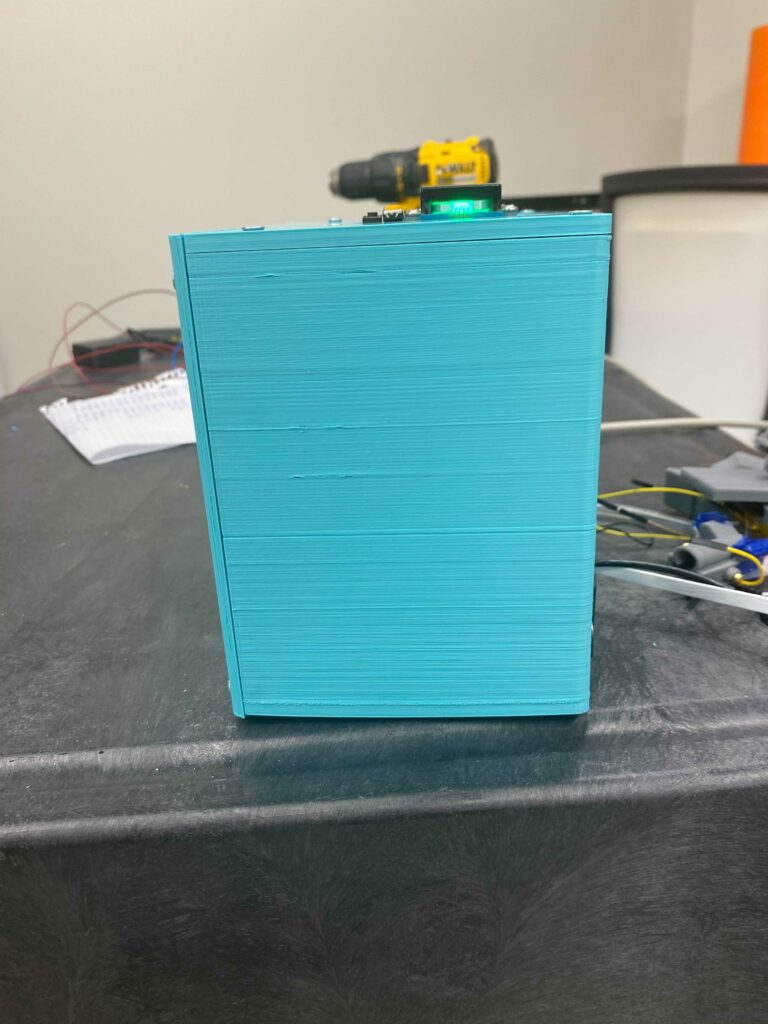

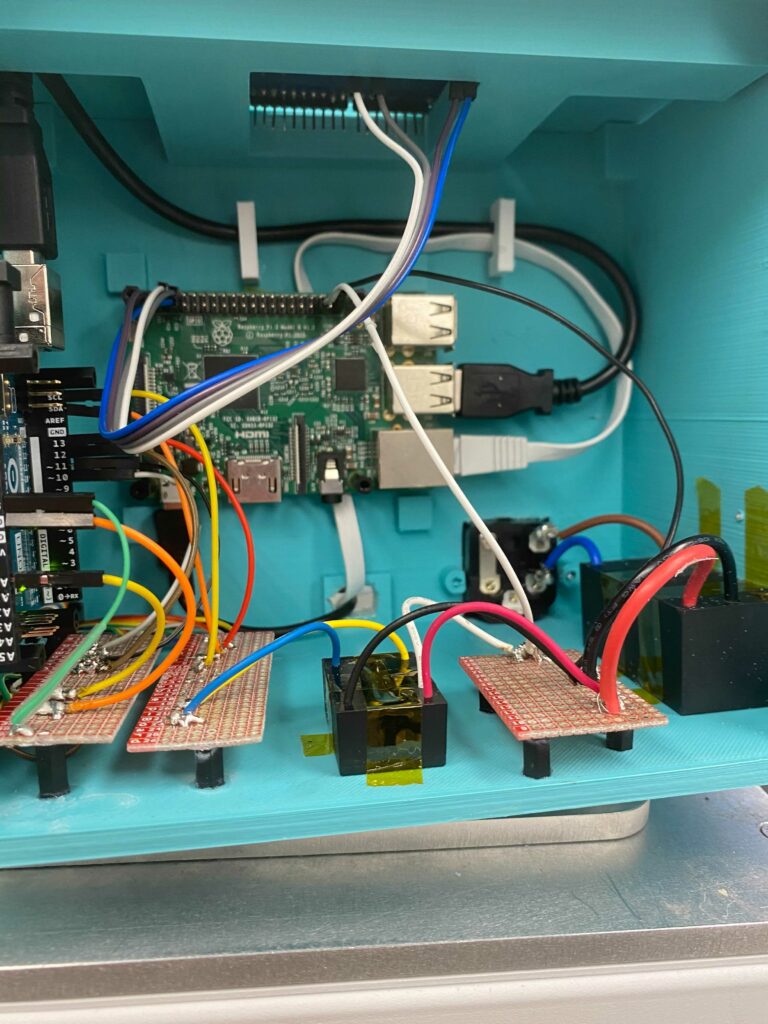

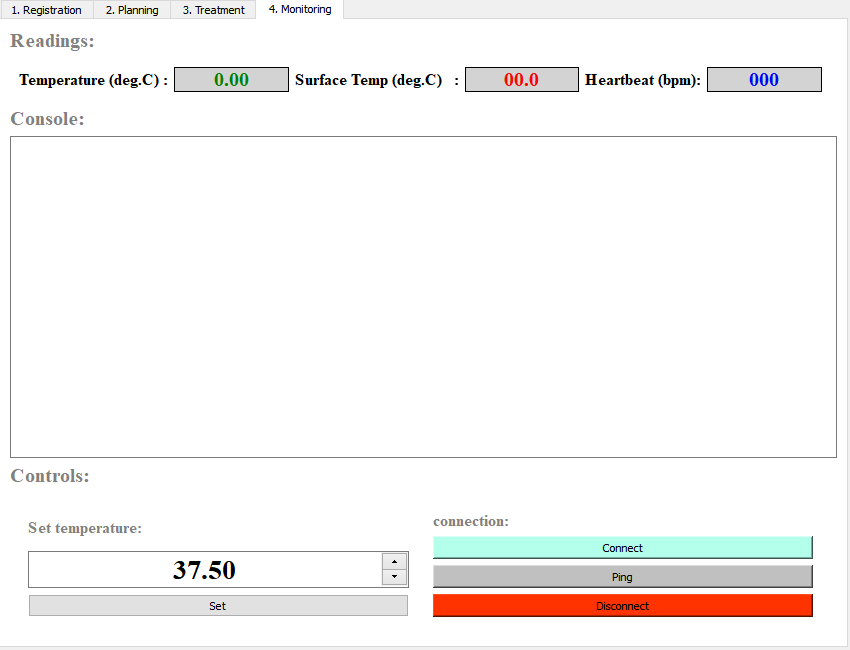

This system is designed to have a bed and anesthesia mask tailored to fit the body of the test subject. They are meant to administer anesthesia to a mouse through the mask, while keeping the animal warm in a comfortably still position. We have also designed an embedded monitoring system using an LCD screen to analyze the animal’s temperature and heartbeat in real time. Researchers will be able to regulate the temperature using buttons on the screen. Our application then will take care of heating or cooling the animal to a desired value. On top of that, our system is adapted to wirelessly dispatch the temperature and heartbeat data to a desktop application. This would allow users to view, graph and save current statistics for further analysis.

Details about our design

Addressing Practical Issues

Our project seeks to make improvements to the RK50, a state-of-the-art ultrasound system used for Blood Brain Barrier Opening and neuromodulation experimentation. Some of the design aspects which should have been improved are:

- The current bed and fixation mechanism can be painful for the animal.

- The use of the rods places a higher risk on the animal waking up during experiments.

- The system ultrasound propagation mechanism gets in the way of collecting experimental data.

- The system has no heating component for mice or ergonomic animal bed design.

- The system has no built-in way to track temperature and heart rate.

Our project seeks to address each of these issues in the following ways:

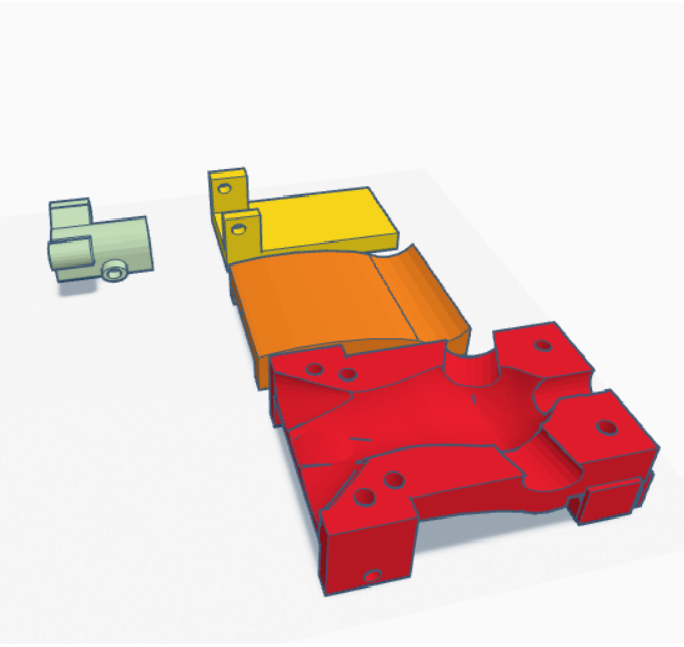

- Design a new animal bed with fixation mechanism, featuring a mask for anesthesia and a source of audio and airpuff stimuli for neuromodulation experiments.

- Develop a heating system on the bed using a PID controller.

- Develop an external water-refillable cone for ultrasound propagation.

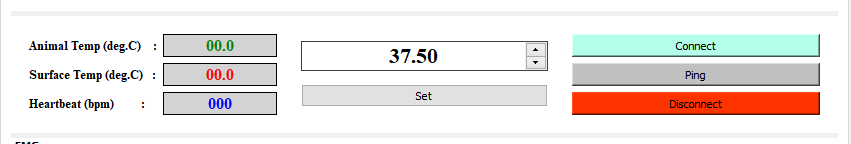

- Update the MORPHEUS application with a new Animal Monitoring Window, This must support communication with a Raspberry Pi to send and receive experimental data via Client/Server.

Design Innovations

- Our design was developed and tested iteratively, meaning we created multiple prototypes, which we tested within the experiments and made a new and improved model after each run. This allowed us to perfect the design of the bed driven by our Experimenter’s feedback.

- Our heating system was built as a control system, which can be easily recalibrated at a later date. This is because we included tools to easily change the heat system parameters and plot its performance against time. This allows for changes to the bed design or electrical circuitry components and then to easily recalibrate the system for precise temperature targeting.

- Our Open source system is also platform-independent, meaning any Ultrasound system or Application can use it and adapt the functionality or build upon it further.

Effective Design Solution

- Our design delivered an experiment-validated comfortable animal bed with an integrated mask for anesthesia delivery, and an external stimuli detached from the bed to allow for easier change in position.

- Our design delivered a heating system for the animal bed that can be controlled through the MORPHEUS application, or through the Raspberry Pi LCD interface to target temperatures within 0.8 °C steady state error.

- Our design delivered an air-tight water-refillable cone for ultrasound propagation to allow for easier video capture of the experiments and streamlined the experimental process.

- Our Software delivered the required updates to the MORPHEUS application including a new Animal Monitoring Window with both a full- and mini-widget for conveniently streaming the sensor data and setting the temperature remotely.

- Our design also features a bonus new calibration and visualization tool to encourage future development on the platform and help future users calibrate the system’s temperature targeting accuracy.

Validating Our Design Solution

Our heating system was validated by comparing the readings of a thermometer with LCD screen values. Our closed-loop control thermocouple is accurate to +/- 0.1 °C. We would run temperature targeting tests between the ranges of 33-39 °C and compare the steady state error between the user set temperature and the mouse’s internal temperature. Our findings were that the steady state error varied between 0.1-0.8 °C depending on the targeted temperature.

Heart rate monitoring was tested against values of other commercially available heart rate monitors. We will compare the heart rate detected by a human sensor with the rate calculated by counting heart beats in a set period. We found our heart rate sensor an accuracy of around +/- 3-4 bpm when compared to other heart rate monitors.

Our bed and mask design was tested in experiments, where the experimenter would later provide feedback for the performance of the design. We would then make the recommended changes and present a new design for the next experiment, and rinse and repeat.

In addition to these testing methods, we used a ‘fly on the wall’ technique during our design iterations to test our solution during real experiments. In this way, we could have experimenters use our design during an experiment and a team member would attentively take notes of any problems or confusion the user experienced. This allowed us to make our system more usable and user-friendly.

Feasibility of Our Design

We also provided our open source code running on our 3 devices: Desktop, Raspberry Pi and Arduino. We included setup manuals and documentation for installation and navigation of the software. This makes it very easy and quick for anyone to use the open source system and integrate it into their own applications. In the very near future we will also be adding our Hardware design documentation and steps for assembly in the open source Animal Monitor GitHub repository.

Our finished product proved effective with an overall cost of between $500-650 when estimating 3D printing costs and electrical component cost. We find this a rather reasonable number for the performance provided by the Animal Monitor and reinforced build quality. We did make efforts to reduce the project cost to a minimum whenever necessary.

Meet our team members

Amine Benaceur

Project Manager

I’m a fourth-year Engineering student at the University of Calgary with a keen interest in solving abstract problems and understanding the inner-workings of computers. I’ve enjoyed the opportunity to use my skills to develop a preclinical focused ultrasound research system at a laboratory in Foothills hospital. Some personal projects I’ve worked on include various Full-stack web applications, Virtual Reality games, a self driving obstacle avoiding race car with camera optimized for speed and multiple other desktop and mobile applications.

Kelvin Krastel

Materials Lead

I am a fourth-year Engineering student at the University of Calgary with an interest in Radio Frequency engineering, and am taking classes on Power Systems. I have experience with 3D modeling and 3D printing and am always looking for new challenges to try to make a design around. I have some experience with Arduino microcontrollers, but it’s not my area of expertise. In the future I’d like to work on Brain-Computer Interfacing and I think this project could provide some valuable insight.

Ryan Ward

Software Lead

I’m a fourth-year Engineering student at the University of Calgary, with interest in various areas including web development and embedded systems. In 2019-2020, I’ve been a part of the Schulich Racing FSAE team, where I’ve gained experience with web development, and hope to work with hardware and virtual reality in the future. Some projects I’ve worked on include a digital clock made with an Arduino Uno, a web application called Aon Feedback, which allows companies to collect anonymous feedback and opinions from employees from various departments, and Schulich Velocity, which is a web application for the Schulich Racing FSAE team.

Farhad Alishov

Software Support

I’m a fourth-year Engineering student at the University of Calgary with a huge passion for learning Programming and Query languages and using them in implementing exciting projects. After two months of working in the Subsea Department for BP, I have also gained experience in analyzing fluid flow in the pipelines. Among personal projects I have an Arduino based Robot that can express emotions after a user’s interaction, and an iOS Application development.

Simran Parmar

Electrical Lead

I am a fourth-year Electrical Engineering student. I finished an internship at McMillan-McGee, where I worked on their power electronics for their heating system. I enjoy working on electrical projects — in my third year I worked on building a grow light that can autonomously adjust its brightness. In my final year I took classes focused on wireless system design.

Usman Zia

Hardware Support

I am a fourth-year Engineering student who is studying Electrical Engineering at the University of Calgary. I recently completed a 12-month internship term with Hydro One, where I was exposed to the telecommunications industry. I am heavily interested in robotics and optics and would like to explore these topics in the future. I am also aiming to join the renewable energy sector, once I graduate. A career in the solar industry is something I am keen to pursue.

Partners and mentors

We want to thank several people who helped us with this project:

Industry Sponsor: Dr. Samuel Pichardo, PhD

Academic Advisor: Dr. Laura Curiel, PhD

System Tester: Jake Hesselink, MSc

System Tester: Dr. Bingbing Chen, PhD

Without their patience, immense contribution and valuable advices, this project would not be possible.

THANK YOU!

Our photo gallery

Top View

Side View

Inner Design

Water-filled Cone

MORPHEUS Application Widgets