Project Category: Entrepreneurial

Join our presentation

https://ucalgary.zoom.us/j/99206858300?pwd=UFFwNUUyS1dEL0Z3bGNKdGZjY3c5QT09

Meeting ID: 992 0685 8300

Passcode: 462082

About our project

Serenity Solutions provides a hands-free knee crutch for patients suffering from a lower leg injury, allowing patients to move about freely without the risk of developing any other medical issues due to traditional crutch designs. Our hands-free crutch will provide comfort to our customers while making it easier for them to use it for extended periods of time. While some crutches exist that can be used with your hands, they require a lot of upper body strength, which is not required for our design. Our main competition will be the hands-free crutch designs but most of them require the excessive use of the hips which is a major cause for osteoarthritis. Our hands-free crutch can be used for longer periods of time and walking up and down the stairs as it mimics a real foot. It also provides better stability and requires less use of your hips hence minimizing the stress on your hips. Our hands-free crutch also offers adjustable leg rest angle which helps improves the blood circulation.

Meet our team members

Project Manager

Details about our design

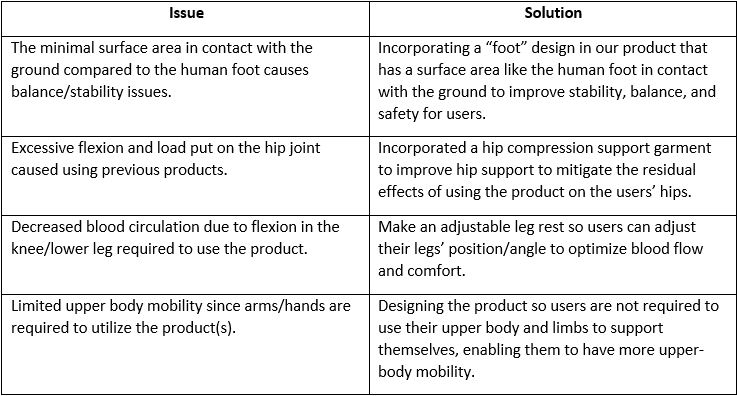

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

The motivation of our product is to address the issues that arise due to the dated designs of the modern-day crutches. Specific issues that arise from traditional underarm/axillary crutches are limited upper body movement because the arms/hands are needed to use them, improper usage can result in the upper arms and body being strained, and can cause nerve damage and crutch paralysis, and limited support because the minimal surface area is in contact with the ground compared to a human foot, which it is attempting to mimic. [1] The forearm crutch does address some of these issues but has some issues of its own, which include being less stable than the axillary crutch, also having a minimal surface area in contact with the ground, and requiring more standing balance and upper-body strength to use them. [1] Alternative products have been developed, such as the iWalk 3.0, which address some of these problems. The iWalk 3.0 is a no-hands crutch that gives users more mobility because of its innovative design. Some issues it has are that the product has been found to cause excessive hip flexion and increase the force and torque on the user’s hip joint. It has been found that both increased hip flexion and increased force in the hip joint have been linked to osteoarthritis diagnosis. [2]

Another problem is that users have found it to be difficult to balance and use the iWalk 3.0, this is likely also due to the limited surface area in contact with the ground by the “foot” of the product, which does not mimic a human foot accurately. Also, the flexion positioning of the lower leg in the leg rest of the iWalk 3.0, has been found to cause decreased blood flow rates in the lower leg [3].

WHAT MAKES OUR DESIGN INNOVATIVE

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

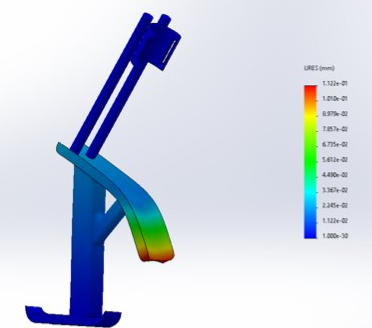

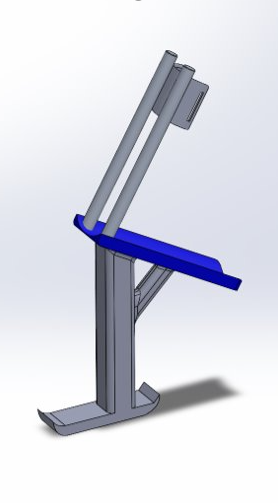

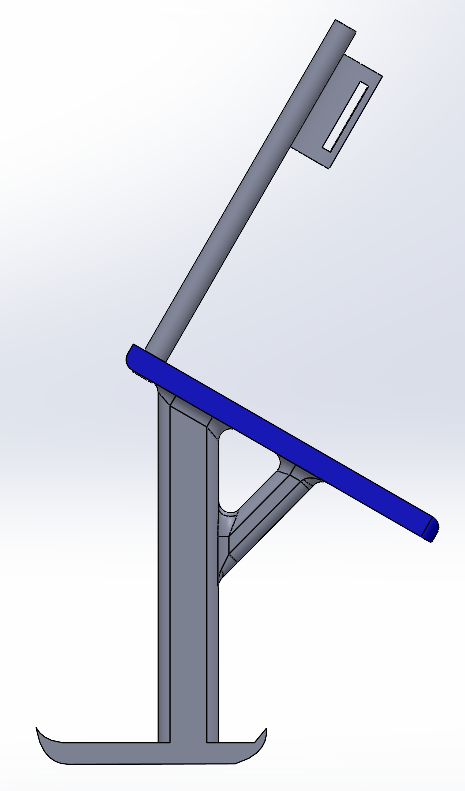

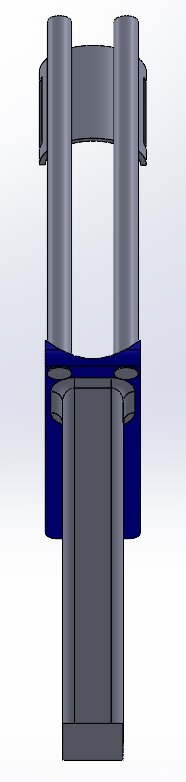

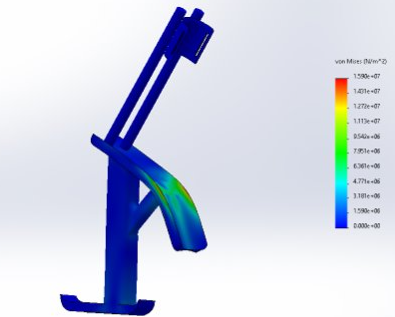

In alignment with our project objective to create a type of crutch that provides long-term comfort while not sacrificing a range of motion, we have created a preliminary design based on thorough research that sufficiently meets our objective. The design is split into four separate components: foot blade, leg rest, leg to thigh connection, and compression garment. We decided to go with an elliptical foot blade to effectively mimic the natural motion of the human foot. We designed a leg rest that can be adjusted to different angles to promote blood circulation within the leg compared to the knee being in full 90-degree flexion. The leg rest is connected to the thigh support and compression garment via aluminum rods. The compression garment provides extra hip support and assists the hip in reducing flexion and the load it’s bearing, which have both been found to be excessive during the use of previous crutch products. In the sections below we will go into further detail on these crutch components.

WALKING BLADE

The foot blade design in our crutch was based on Paralympic athlete running blades. The running blade provides many advantages to amputees and allows them to participate in both casual and professional athletic activities that require extensive use of the lower leg. They are often manufactured using carbon fiber because of their material properties; it is lightweight, very strong, and compresses like a spring. This provides athletes with momentum when the blade is cyclically compressed and uncompressed in athletic movements. Moreover, the foot blade can comfortably withstand sudden deformations and stresses, such as when the athlete lands from a jump.

Biomimicry

Running blades are designed to mimic the hind legs of a Cheetah, one of the fastest land animals in the world [4]. The hind legs of a Cheetah allow them to move incredibly fast by storing potential energy like a spring [5]. Using biomimicry, our foot blade design evolved for a casual user who’s movement regime requires little running and more walking. As previously discussed, carbon fiber is a viable option for weight reduction while maintaining structural rigidity. However, due to its tendency to behave like a bouncy spring (low stiffness, spring constant), there were potential issues using it in scenarios that do not require a sudden burst of energy and hyperactive movement [6]. Upon further research, we discovered that excessive compression could cause issues in the symmetry of the user’s gait, potentially causing a limp. Studies have shown that asymmetric walking gait can expedite the onset of osteoarthritis [7]. As a result, we selected Aluminum 7060 alloy, as this is a commonly used crutch material in alternative crutch products and has shown to be optimal in the use case.

Biomechanics of walking

Another aspect of the running blade design that limits the walking ability of users is that they do not effectively mimic the biomechanics of walking. In the natural biomechanics of walking, the heel strikes the ground first and then the rest of the foot follows the heel [8]. When lifting the foot, the heel is lifted first followed by the rest of the foot. Since the running blade does not have a heel component embedded in its design, walking on them can be viewed similarly to someone attempting to walk on their toes or flat-footed. Running blades also have a minimal surface area in contact with the ground, considering the total width and depth dimensions of one of the best running blades (Flex-Foot Cheetah Extend), which are 7cm and 31.7cm [4]. This does not mean the entire 31.7cm depth is in contact with the ground. Due to its curved design, less than 50% of this depth dimension is in contact with the ground. This results in potential instability due to the average foot width being 10.2 cm and the foot depth/length of the average 10.5 size foot being 26.2cm, for which all 26.2 cm is in contact with the ground when standing [9]. Our design addresses this issue by making the walking blade design have a surface area in contact with the ground that is closer to that of the human foot, and adding an elliptical shape at the leading and trailing edge of the walking blade to better mimic the heel and toe strike motion in the biomechanics of walking.

Rubber Pad Bottom

The bottom of the foot blade will be attached to a grooved soft rubber pad using epoxy instead of glue for durability purposes. The main purpose of the pad will be to increase friction so that the device minimizes slippage. A secondary benefit of using a soft, compressible substance such as rubber is that it will significantly reduce the impulse that is transmitted to the body. As we are increasing the time interval over which the force from the body is applied to the ground, the

impulse (change in momentum) will decrease if that force is held constant. Finding a material that does not become too brittle with changing temperatures was also an important factor in determining our material choice for this pad. We expect this device to be used in both indoor and outdoor environments and a in variety of climates. The more brittle a material becomes, the more susceptible it is to crack and fractures, which is not ideal for the longevity of the product. We have chosen a material that does not have a ductile to brittle transition temperature (DBT) within the expected operating temperature ranges of the product.

LEG REST

Polyactic Acid (PLA)

The leg rest assembly will be 3D printed with PLA filament. We do not expect to see enough forces being applied on this piece to justify going with more heavy-duty material, such as aluminum or plastic. Selecting aluminum would add weight and make the design cumbersome. While, choosing plastic would require a more complex manufacturing process, such as plastic molding. Moreover, PLA has the advantage of being a cheap raw material with high stiffness and the ultimate strength of 65 MPa [10]. The force required to walk is roughly 1.5 times a person’s body weight, which would mean 200 to 300 pounds of force for the average person [11]. So, using PLA is justified due to the match between the small force experienced by the crutch and the material strength.

Memory Foam

The inside of the leg rest will have a layer of memory foam due to its energy absorbent properties and ability to provide pressure relief. From research on the capabilities of composites and memory foam in the automotive industry, it was seen that the addition of memory foam led to a 30-48% reduction in impact force compared to just using a few different composites [12]. So, applying memory foam would make the product more comfortable.

Adjustable Leg Rest

The leg rest has been designed to be adjustable to allow the position of the leg to vary from full 90-degree flexion in the knee to approximately 30-degree flexion. This feature was implemented to optimize blood flow in the leg. Research has shown that when the knee is in 90-degree flexion, venous blood flow in the lower leg extremity suffers [2]. This conclusion was made by researching the effects of using a knee scooter, which requires the knee to be in full flexion.

In a study, the popliteal vein blood flow velocity and venous diameter were measured using duplex ultrasonography for healthy subjects both while having the knee flexion via the knee scooter and while standing. A total of 13 participants were involved in the study, and the following measurements were taken from each of the participants; peak velocity, volumetric flow rate, mean velocity, and vessel diameter. In two measurements, the vessel diameter, and peak velocities were not affected drastically comparing the flexed knee and standing datasets from the studies subjects. The measurements did show that mean velocity decreased when comparing datasets, which were 6.5 cm/s when standing, vs. 3.2 cm/s with the knee in flexion, respectively [2]. The volumetric flow rate was also affected drastically, as it was found to be 227.8 mL/min standing compared to 106.2 mL/min with the flexed knee [2].

The drastic decrease in volumetric blood flow rate for subjects in the knee scooter may cause issues for users. Poor blood circulation has been found to have dangerous effects, including but not limited to skin discoloration, swelling, numbness and tingling, aches and pain, muscle cramps, and even nerve and tissue damage [2]. Since without incorporating the adjustable leg rest, our design would have had our user’s leg in a similar flexed position as the knee scooter, it can be inferred that circulation issues could also arise for the lower leg extremity of our users. Moreover, the adjustable design makes ReWalk more accessible for users with knee problems who cannot bend their knees that far back.

Balance and Stability

Having the knee in a 90-degree flexion would also affect the center of gravity of the user. The center of gravity of a typical standing human is approximately 53% of their height and in the center of their body horizontally [13]. The location is altered by the movement and bending of the body, which can subsequently cause imbalance and an unfortunate fall. When the knee, or lower leg, is in 90-degree flexion, the center of gravity of the user will be affected more drastically compared to when the flexion angle is reduced. When the body is exposed to uneven and untraditional loads, like the load experienced when the leg is in a 90-degree flexion, the body attempts to compensate for this by bending, resulting in an altered center of gravity. Incorporating a design that minimizes the change in the orientation of the user’s body mitigates this risk and provides a more stable, safe user experience.

LEG-TO-THIGH CONNECTION

Both the leg rest and a compression garment will be connected using thin, lightweight aluminum rods and an adjustable plastic thigh support piece. This is done so that more muscles in the body are being utilized in the operation of this crutch as the forces will not be localized to the knee. This connection incorporates the thigh and hips into the motion while providing the thigh with a neutral position to rest and not trigger instability.

COMPRESSION GARMENT

The iWalk 3.0, a competitor hands-free knee crutch, has been found to cause excessive hip flexion and increase the amount of force experienced by the hip joint [1]. To support the hip effectively and mitigate side-effects of using our product, a compression garment has been incorporated that provides extra support in this area.

Studies have shown that the hip flexion angle during the walking gait of someone using the iWalk 3.0 increases by an average of 150.03 ± 8.6° [1]. This results in an alteration in the walking gait of the user, which has been found to potentially contribute to the osteoarthritis diagnosis, as aforementioned. The alteration in the hip flexion angle has been found to increase the force and torque at the hip joint, which can eventually result in patellofemoral pain [1].

To counteract and mitigate these issues, the addition of compression garments, namely one that includes a trochanteric belt, has been found to provide support for the sacroiliac (SI) joint [14]. The SI joint is a pelvic joint that is essential for energy transfer between the lower and upper body and is the inner part of the butterfly-shaped hip joint bone. Hip flexor issues are commonly related to SI joint issues because they are interconnected. Trochanteric belts help minimize the movement of the SI joint. Since the iliopsoas muscles (hip flexors, and the SI joint are directly related, minimizing its movement also subsequently stabilizes the hip flexor muscles and lowers the increased hip flexion angle that arises when using iWalk 3.0. Consequently, the hip will experience a lower load and torque, further decreasing the risk of osteoarthritis for the user.

HOW WE VALIDATED OUR DESIGN SOLUTION

We reached out to pharmacies and physiotherapist offices can also carry our hands-free crutches and sell them to their clients. Such as if someone is going through physiotherapy and is recommended by the Doctor not to put pressure on their foot hence can use our hands-free crutch. Also, it provides better mobility, improved blood circulation, and, less stress on the hips.

We also conducted a survey at the University of Calgary asking the students if they would consider using our crutch. It was found that young athletes suffering from lower leg injuries do not want to use products such as wheelchairs due to the stigma they have behind them, especially at such a young age. They also save the cost of having to purchase more expensive products, such as electric wheelchairs, for an acute injury. Young people also likely need mobility, especially individuals still in University/College, because they must be mobile enough to go from class to class on large campuses while also having to hold things such as textbooks, binders, etc. It was also found that patients aged 20-49 are more likely to use our product.

FEASIBILITY OF OUR DESIGN SOLUTION

We did financial analysis for our product and it found that the cost per unit to develop our hands-free crutch is $2,900. This is based on our current material selection and the price was quoted to us for singular unit production. Using economies of scale, it is safe to assume that the cost per unit would decrease as our variable costs decrease and we have a manufacturer that can produce these at scale, instead of a one-off prototype. According to the website, The Balance, “Manufacturing costs can fall 70% to 90% every time the business doubles its output” [15]. Using the more conservative figure, this would equate to a cost of $870 per unit if we were to make an order for 2 crutches and would continue to fall as it doubles. It is safe to assume that for a production run of 64 units, our total cost will be the cost of materials ordered in bulk, which is $280, and $6.90 for manufacturing costs per unit. This gives us a total cost of production per unit of $286.90 based on an order of 64 units.

We expect to first sell 64 units through product placement in hospitals, local doctors’ clinics where we know some of the doctors, and independent medical device stores within Calgary. With there being 4 major hospitals in the city, we assume we will sell most of our units here as they have the largest number of people compared to other places. The remaining inventory would be distributed through local clinics and medical device stores as there are a lot of locations where we can place our product and the people visiting these smaller venues are more likely to notice our product and be compelled to buy it. There are approximately 20 medical supply stores within the city and 8 clinics where we are familiar with the doctors. Using the property of economies of scale, and the 32 different locations we have within the city to sell this product, a conservative assumption can be made that we will likely be able to sell 2 units per location. A 64-unit initial production run will allow us to sell all our units relatively quickly and raise awareness of our product.

Serenity Solutions would utilize economies of scale to reduce the per-unit cost of goods sold (COGS) and increase the profit margin by 5% after the first year of sale up until 2029. Initially, with a growth rate of 3% per month, Serenity Solutions would hold and sell 64 units’ inventory. However, starting in 2025, the team suspects the growth rate to slightly reduce to 2.5% due to reaching critical mass in terms of market penetration and product popularity. The key information gained from the financial statements was that the team at Serenity Solutions would have to raise $30,000 independently to initiate the venture. Another interesting find was that the R&D cost would continue increasing up until 2029 if Serenity Solutions’Solutions wants to remain competitive in the mobility aid industry. In 2029, $52,873.81 would be spent annually on further developing the product.

The most unexpected find after completing the financial statements and assumptions was that the venture would not be profitable and have a negative net income until the end of 2024. Since the startup would be operating at a loss, there will be no business taxes until the 2025 tax year. Another unexpected finding was that the business would have a return on investment (ROI) of 12.2% per year when analyzing the beginning cash balance in Jan 2024 and ending cash balance in 2029. Despite operating the total OPEX being higher than gross profit until the end of 2024, holding a healthy ROI of 12.2% year-over-year demonstrates the strong potential of the venture.

For the first couple of years, the company will raise equity capital of $37,931.25 to start the business and keep it operating until the venture becomes cash flow positive in 2025. The majority of the capital raised would come from the founders, $30,000 to be exact. The rest would come from local business accelerators and incubators, such as Startup Calgary and ATB Accelerator. Utilizing their network of mentors would result in the venture getting thenecessary guidance and monetary assistance.

Partners and mentors

We want to thank the many people who helped us with this project. Our Entrepreneurial professor Dr. Hamid Zareipour guided and supported us throughout the course. Our academic advisor Dr. Marcelo Epstein invested his valuable time into our project and guided us through technical difficulties. Also, Ashifa Hudani – Technical Advisor, Jose Menjivar – Business Advisor, and Philippa Ngaju – Hunter Hub Advisor, for their patience and guidance to help us achieve our goals.

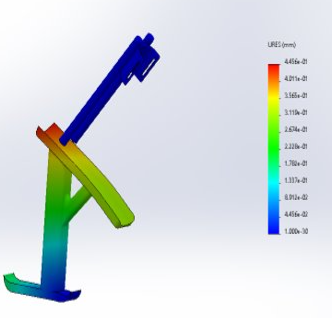

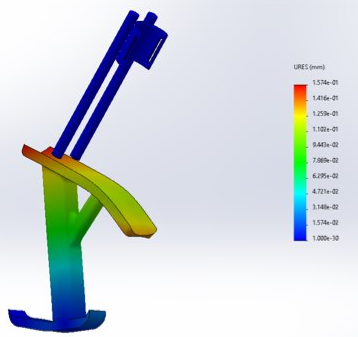

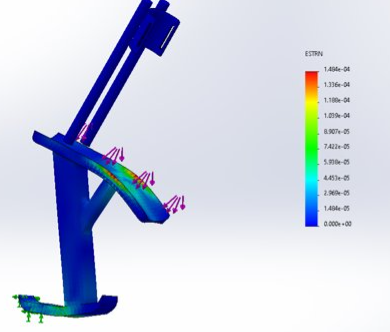

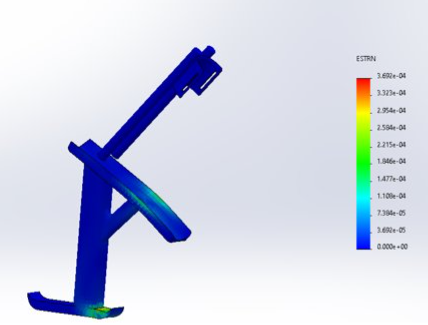

Our photo gallery

References

- “Walking aids,” https://madhavuniversity.edu.in/munew/index.php. [Online]. Available: https://madhavuniversity.edu.in/walking-aids.html. [Accessed: 20-March-2022].

- Champagne, Tyler (2017). The Examination of Hip Joint Kinematics with iWalk in Walking Gait. Undergraduate Review, 13, 65-72. Available at: https://vc.bridgew.edu/undergrad_rev/vol13/iss1/10

- D. J. Ciufo, M.R. Anderson, and J. F. Baumhauer, “Impact of knee scooter flexion position on venous flow rate, “Foot & Ankle International, vol. 40, no. 1, pp. 80-84, 2018.

- C. Hewitt, “FLEX-FOOT CHEETAH XTEND RUNNING BLADE, DESIGNED BEFORE 2000, MANUFACTURED 2013,” cooperhewitt.ord. [Online]. Available: https://www.scientificamerican.com/article/blade-runners-do-high-tech-prostheses-give-runners-an-unfair-advantage/. [Accessed: 24-Jan-2022].

- E.D. Jensen, “What are the functions of the long legs of a cheetah?,” Pets on Mom.com, 19-Nov-2020. [Online]. Available: https://animals.mom.com/functions-long-legs-cheetah-7520.html. [Accessed: 19-Feb-2022].

- L Greenemeier, “Blade Runners: Do high-tech prostheses give runners an unfair advantage?,” Scientific American, 05-Aug-2016. [Online]. Available: https://www.scientificamerican.com/article/blade-runners-do-high-tech-prostheses-give-runners-an-unfair-advantage/. [Accessed: 24-March-2022].

- S. Alharbi, “Gait asymmetry and the risk of knee osteoarthiritis in post-stroke individuals,” dissertation, University of Salford, Manchester, England, 2019.

- “The gait cycle,” Foot Bionics Ltd. [Online]. Available: https://www.footbionics.com/Patients/The+Gait+Cycle.html. [Accessed: 28-Feb-2022].

- A. Jurca, J. Zabkar, and S. Dzeroski, “Analysis of 1.2 million foor scans from North America, Europe and Asia,” Nature Nres, 16-Dev-2019. [Online]. Available: https://www.nature.com/articles/s41598-019-55432-z. [Accessed: 26-Jan-2022].

- “Properties table,” All-In-One 3D Printing Software, 30-May-2019. [Online]. Available: https://www.simplify3d.com/support/materials-guide/properties-table/. [Accessed: 20-Feb-2022].

- L. Hodgkins, “The forces on the body during walking and running,” schoolphysics. [Online]. Available: https://www.schoolphysics.co.uk/age1619/Medical%20physics/text/Walking_/index.html. [Accessed: 20-March-2022].

- A. Pilipovic, P. Ilinči, J. Petruša, and Z. Domitran, “(PDF) influence of polymer composites and memory foam on energy absorption in vehicle application,” ResearchGate, May-2020. [Online]. Available: https://www.researchgate.net/publication/341733045_Influence_of_Polymer_Composites_and_Memory_Foam_on_Energy_Absorption_in_Vehicle_Application. [Accessed: 20-March-2022].

- P. Davidovits, “Center of Gravity,” Center of Gravity – an overview | ScienceDirect Topics, 2019. [Online]. Available: https://www.sciencedirect.com/topics/physics-and-astronomy/center-of-gravity. [Accessed 29-March-2022].

- S.A. Thomas, “Trochanteric belts: Supportive braces for sacroiliac joint …,” Spine Universe, 2017. [Online]. Available: https://www.spineuniverse.com/conditions/sacroiliac-joint-dysfunction/trochanteric-belts-type-spinal-brace. [Accessed: 21-March-2022].

- K. Amadeo and M. Boyle, “What Are Economies of Scale?”, the balance, 2021. [Online]. Available: https://www.thebalance.com/economies-of-scale-3305926. [Accessed: 20- Mar- 2022].