Project Category: Entrepreneurial

Join our presentation

If buttons do not redirect you please see bottom of page for links.

About our project

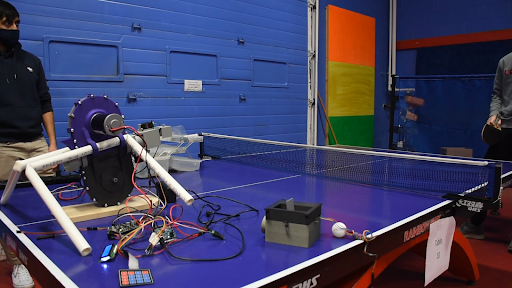

Our goal at Heightened Sense Solutions is to provide innovative solutions for the next generation of pro-athletes. The combination of technology and sports has been there for some time, but our company strives to make it even better by creating iterative models with better economical options to facilitate players from all spectrums. PingPongPal, the first product of the company, is a Table Tennis ball launcher with dynamic difficulty adjustment options for professional table tennis players seeking economical and convenient self-improvement devices to increase their daily training time. PingPongPal delivers combos, variable velocity and trajectory options that will serve as the most effective tool for table tennis players to refine their strokes thus allowing them to master their game.

The cost: $700.00, including GST.

Meet our team members

David Yu

Project Manager

David Yu is a 5th year Mechanical Engineering Student with a minor in Mechatronics. He has gained valuable Project coordination skills when he was interning at Pembina Pipeline Corporation as a Projects Intern and gained a keen eye for safety through his training of H2S, First Aid and working as an RO for the UCFA. His interests range from badminton to tennis, hiking to climbing, and archery to firearms. He looks to further his knowledge and experiences in project management and CAD designing after graduation.

Carlos Rendon

Electrical Lead

Carlos Rendon is a 5th year Electrical Engineering student with consulting experience at IDOM in Bilbao, Spain and Norden Energy in Calgary he has experience working on various types of projects. He gained valuable experience in electrical system design in buildings along with substation design. He looks to add to his experience by continuing to work in power upon graduating.

Yixuan Gao

Mechanical Lead/Ping-pong SME

Yixuan Gao is currently a 5th year Mechanical Engineering Student, and the major mechanical designer on PingPongPal. He recently completed an internship at CoolIT Systems in Calgary. He gained valuable experience in CAD designing, mechanical system simulation and product testing. In addition, he is a formal professional Ping-pong player. He has a great interest in combining his designing and sports experience to create more interesting products.

Zhe Han

Mechanical Lead/Ping-pong SME

Zhe Han is currently a 4th year Engineering Student, Majoring in Mechanical Engineering combined with Environmental and Energy Specialization; He recently completed a four-month summer job at Atco Gas. He gained valuable experience from various types of renewable projects. Formal professional Ping pong player. Interests in Sports, Mechanical Designing; with skills and experiences such as data sorting in Excel and CAD design.

Cristopher Joseph

Business Lead/Entrepreneurial SME

From humble beginnings to building an entertainment business (Big Fun Canada Entertainment Inc.) to 6 figures and securing contracts with the likes of The Calgary Flames, The Calgary Stampeders, Red Bull, etc.; Cristopher has become an expert in entrepreneurship and client relations. When he is not working, you can find him in the mountains, creating music, exercising, or having an incredible night out with friends. Now pursuing his mechanical engineering degree to pair with his business acumen, Cristopher thrives to create a lasting impact on his city.

Muhammad Saud Gaziani

Business Lead

Muhammad Saud Gaziani is a 4th year Mechanical Engineering student and Business Lead at Heightened Sense Solutions. He gained valuable business experience while managing bookstore franchises in Pakistan and also, recently worked as a Junior Design Engineer for Quantum Designs & Technologies Inc in Edmonton. He thrives to combine his diverse expertise, gained during past few years, to start his own business ventures in the future.

Details about our design

HOW OUR INNOVATIVE DESIGN ADDRESSES PRACTICAL ISSUES

From discussions with our sponsor and consulting our in-house ping-pong SME’s we have derived that the current mechanical practicing solutions that are available on the market are either inadequate for more professional players or too expensive for most people to own. Our solution was to increase the capabilities and improve on the shortfalls of current market designs by increasing the motor effective power while balancing the motor operating ranges to allow for the system to operate for extended periods of time without fail or requiring cooldown.

From our prototype, we were able to achieve ball velocities that no other market solution is capable of doing; in our prototype testing, we were able to achieve a velocity of 87km/hr. Being that we were able to achieve that with a prototype where some of the manufacturing procedures were not fully developed, means that our product when ready for distribution will be more than capable of achieving the velocity goal of over 100kph.

Having the design stemming from current market solutions will bring manufacturing costs down which in turn will reduce the retail price; based on the opinions of those we consulted, the AI bio-mechanical solutions are useful concepts to further our scientific development as a species but as a practice tool is too cumbersome and financially overkill.

Furthermore, our design adds an underappreciated aspect to it, which is the implementation of customizable combo settings, allowing full immersion into the training sessions by allowing the player to target specific weak points and to push the player’s dynamic limits.

Finally, our design also adds the ability to connect the feeding mechanism to a ping-pong back netting, allowing nearly infinite recycling of balls, allowing the player/user to practice without having to refill a reservoir for extended periods of time.

HOW WE VALIDATED OUR DESIGN SOLUTION

Under heavy collaboration with our sponsor Yongjun Duan, former coach of the Canadian national table tennis team, we established user-accepted milestones. These milestones included high-speed shots, targeting, combo sequences, and a high feed rate.

For the high-speed shot, we investigated the fastest shots in the world. The current fastest smash is held at 112km/hr. For the scope of this course, we set a target of 100km/hr with a lower tolerance of 10%, which yields a minimum of 90km/hr. Our fastest shot is estimated to have hit 87km/hr.

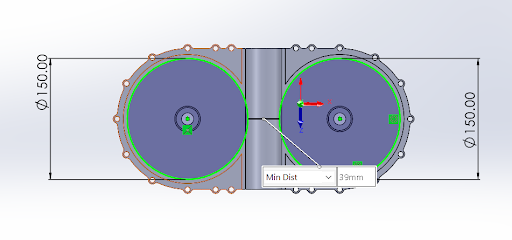

For targeting, we sought out to divide the far half of the opposite table into 9 quadrants. We aimed to hit the center of each target section within a circular area of 15cm which is approximately 3 ping pong balls in diameter. In addition to accuracy, consistency is also vital, thus we established a measure of success in which 10 consecutive balls would have to land within the 15cm tolerance at each of the 9 targets. Unfortunately, due to breakage during our initial tests and demo with our sponsor, we were unable to validate this.

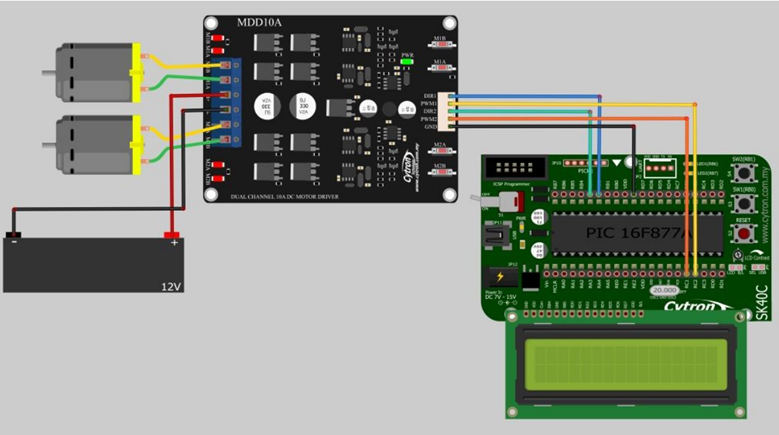

For combo sequences, the main goal was to create code that could handle multiple combo inputs. This would allow players to fully customize their sequences to simulate real game scenarios and target transitional weakness. Currently, our code can handle 4 combo sequences with 64 different parameter configurations.

For the feed rate, we investigated that the average time between moves is 1.2 seconds which is equivalent to a shooting rate of 50 balls per minute. Through our four-finned hopper design and a stepper motor, we were able to achieve a feed rate of up to 60 balls per minute. At higher feed rates the motor would begin to jitter and balls would start to get stuck but at 60 balls per minute, the hopper feeds constantly and without major strain.

FEASIBILITY OF OUR DESIGN SOLUTION

With our current design, we are able to provide the customization and power of a mid-tier competitor ($1500-$3000) at a cost of an entry-level ping pong ball launcher ($600-$800). The current selling price of our solution is $700. This due to the straightforward design and standard components. This benefits us in the manufacturing price as well. Even utilizing 3D printing our production times could be as low as 10 hours per unit when utilizing multiple printers. Currently, we are looking for options to manufacture in China as a large majority of our target customer base is in China. This would reduce manufacturing and shipping costs, reduce manufacturing time, improve material options and improve product integration/consistency as outsourcing to a proper manufacturing company will give us access to more modern and intricate methods of manufacturing. Outsourcing the production will also provide more freedom to our owners allowing them to focus on expansion into other sports markets such as tennis.

Based on our current financial forecasts, we will be cash flow positive within 2 years after the full production begins and will be a 6-figure company within 4 years even with a raised estimated production cost.

Partners and mentors

We want to thank the many people who helped us with this project. Our Mechanical engineering professor Jeff Pieper supported our project with his extensive knowledge and experience in Mechatronics and our field testing coupled with consultations with YongJun Duan were very insightful.

Our photo gallery

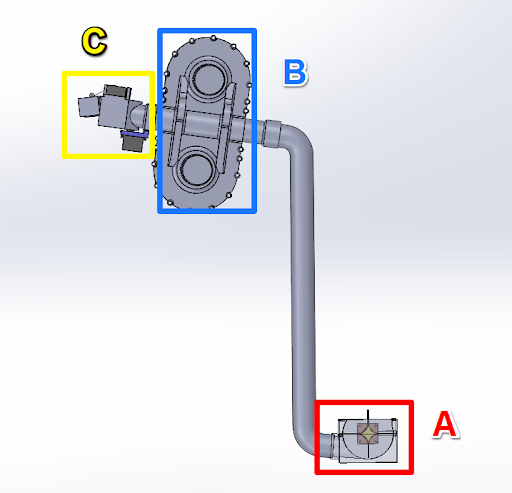

Overall Conceptual Layout

Flywheel housing CAD design

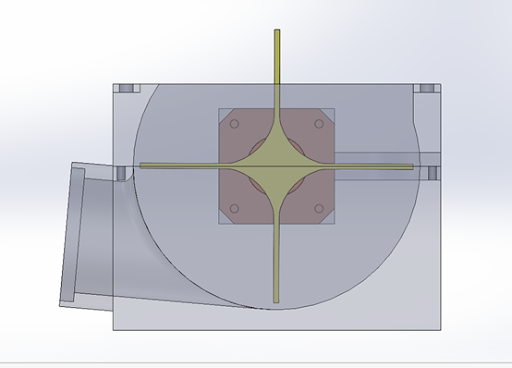

X-ray CAD side view

Conceptual motor control

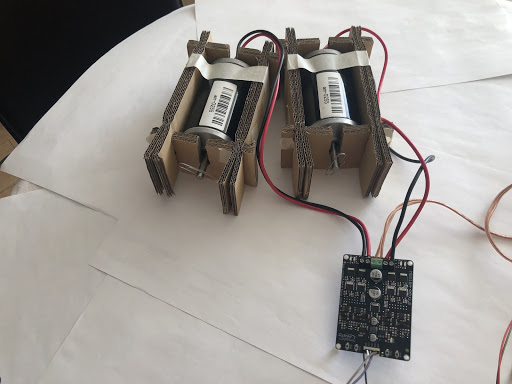

Drive motor test runs

Fly wheel attached to side panel

Interior of feed motor

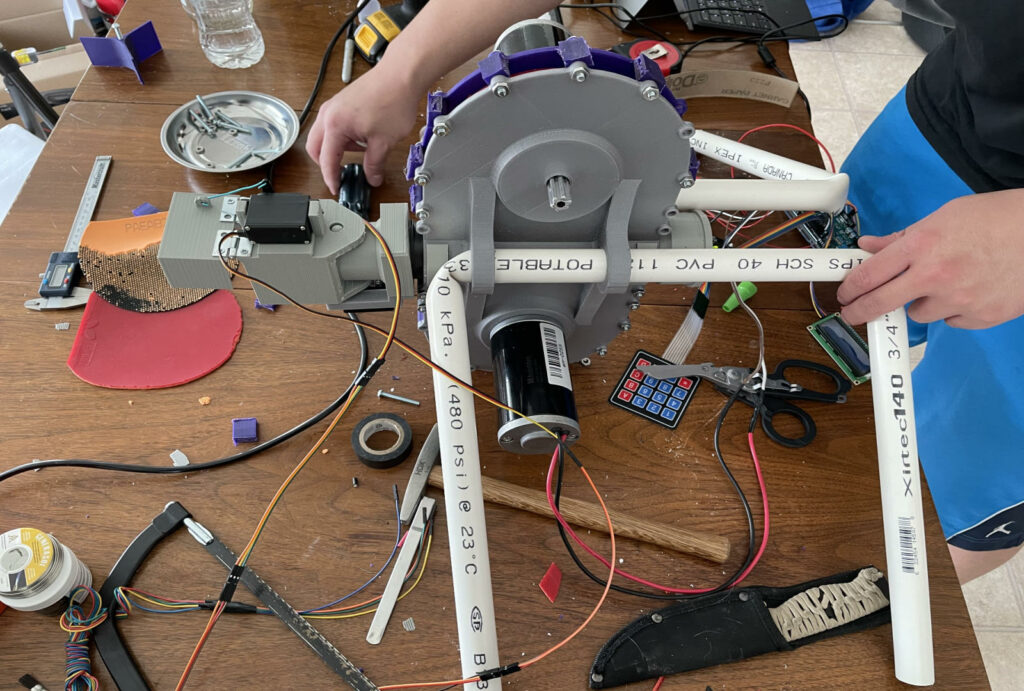

Overall Feeding Mechanism

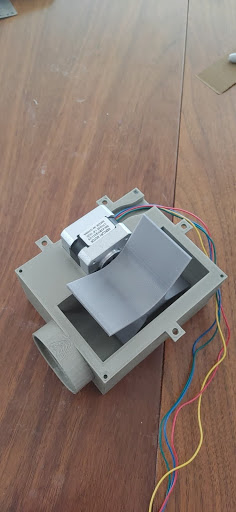

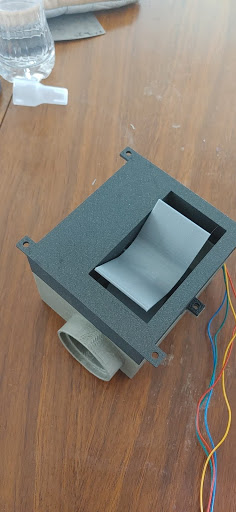

Fully Built Nozzle 1

Fully Built Nozzle 2

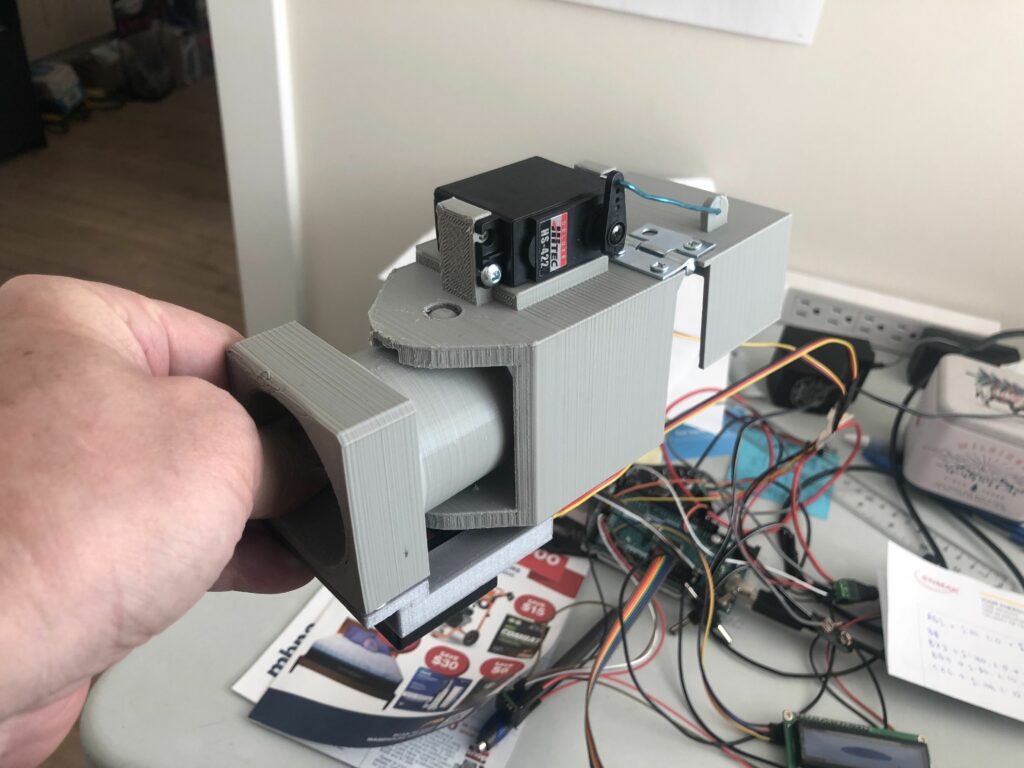

Assembled Shooting Mechanism

Overall System

Setup for Testing

Links in case buttons do not redirect you:

Zoom: https://ucalgary.zoom.us/j/4204451132

Video: https://youtu.be/9TZeQtoL9PQ