Project Category: Entrepreneurial

Join Our Presentation!

Please watch our incredible video below before you hop on over!

About Our Project

You pass through your garage, and everyday you see that one mechanical project you have not started on. It sits and there and rusts, and overtime the bolts holding the piece together will just never let go with the current tools you have. The space is tight, your bulky wrench is no help, you become frustrated.

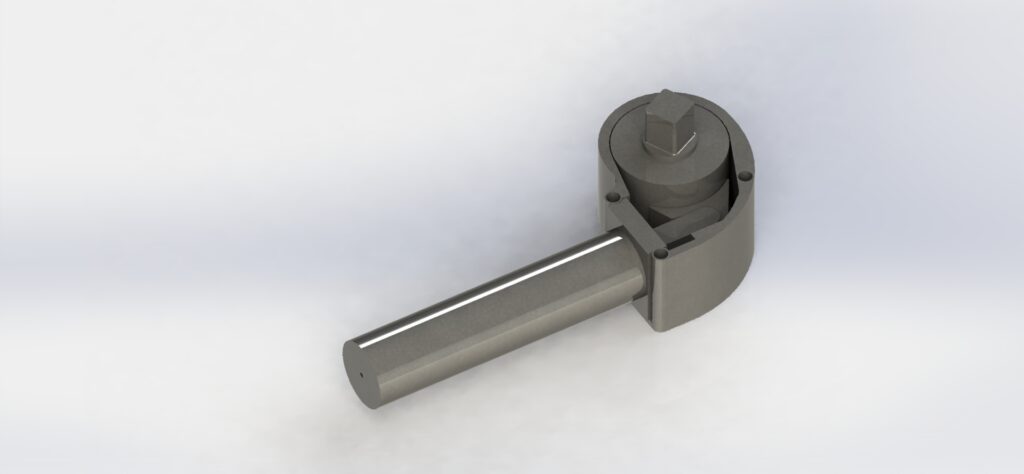

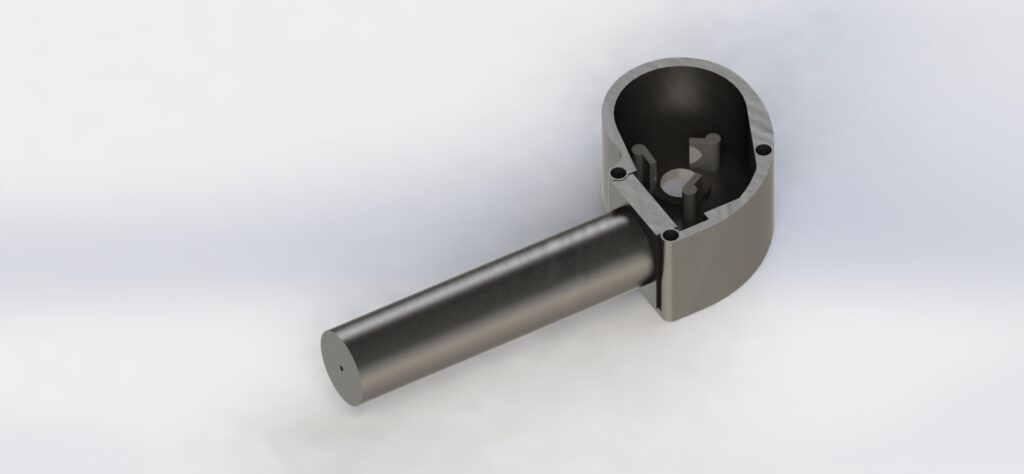

We are the creators of the REVOloosen, a compact and cost-effective manual ratchet with just the right amount of impact needed for frustrated handymen or mechanics to loosen tough bolts. Our tool multiplies the users’ strength, which helps our users take on tougher jobs with ease. While our product works and feels like a normal ratchet, the impact action delivers three times more loosening power.

Well, you may say, why not use a powered version instead? Bulky powered impact wrenches require an expensive external air supply or electricity, but our ratchet with the extra impact can be used in tight spaces and in any environment, without relying on any power!

Safety and reliability are key to us, so come see what we are all about to assist in your upcoming mechanical projects, both safely and effectively.

Meet Our Team!

Jerry Yang – Having been in love with mechanics his whole life, Jerry is now in his final year as a mechanical engineering student. Having worked as a process engineering intern, Jerry developed operational strategies and led cross functional teams in numerous continuous improvement efforts. His extensive operational experience has broadened his interest from the mechanisms of machines to the mechanisms of business and society. Jerry’s passion is to leverage his technical and leadership skills to enable his team to reach its highest potential.

Jamie Lee – Jamie is a mechanical engineering student at the University of Calgary. She has substantial experience in team management and resolving technical roadblocks geared towards engineering. Spending 20 months with a Fortune 100 company as a process engineering intern accelerated her growth and further interest in negotiations with suppliers, technical drawings to improve process flow and steps required to see a project successfully come to fruition.

Tyson Migadel – Tyson is a 4th year mechanical engineering student with a strong interest in fluid mechanics and aerospace. Through his work as a Team Lead with an extracurricular engineering team, he has gained design and leadership experience, which he hopes to apply to new and challenging projects. He successfully completed a 16-month internship with a Calgary-based energy company, which allowed him to further his knowledge regarding project management and methods of improving work efficiency (including automation).

Sam Yun – Sam is a 4th year mechanical engineering student at the University of Calgary with experience in 2D and 3D design, consulting and project management. Upon completing his 12-month work term at a mechanical consulting firm, he gained knowledge and skills to design mechanical systems that meet various design codes, tight time constraints, and clients’ expectations. During his work term, he was also responsible for writing technical reports involving data analysis and simulations, which presented complicated data in an intuitive and graphical manner.

Details About Our Design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

You might have found yourself in a situation where you were in dire need of a ratchet. A flat tire? In the middle of nowhere? No place to hook-up your power tool? What a disaster!

Our design, a form of a ‘ratchet with an impact,’ can not only fit in your pocket, but also does not require any external power sources.

WHAT MAKES OUR DESIGN INNOVATIVE

By ensuring that our ratchet can fit in your jean pocket, its usability is incredible in reaching compact and tight compartments, such as your engine bay.

Our product is 30% the size of a normal ratchet on the current market, yet its size does not deter away from delivering an impressive torque, even without an electrical hook-up.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

Through our impact prototype tests, it was calculated that our tool can output around 150 ft-lb of torque.

This is what we like to call the “sweet spot” for light to medium weight mechanic or DIYers jobs, for about 95% of a car only requires on average 100 ft-lb of loosening torque for things such as a wheel nut.

HOW WE VALIDATED OUR DESIGN SOLUTION

The real question you may ask is, how can you prove that it works?

Over the course of 4 months, our team has designed through SolidWorks, 7 different 3-D printed prototype iterations and 1 impact prototype, thus ultimately leaving us with the final 8th prototype being a combination of 3-D printed and actual metal linkages. This was done to fully understand the technical aspects of this working mechanism, and that all the moving parts were meshing as theoretically planned.

Our first iteration was also strictly the body of the tool. This was done to gauge the real-time sizing of the tool and see if it would really fit into those compact spaces, such as your pocket!

With the continuous research and development of the technical side of this project, our final 7th 3D printed iteration fully confirmed our calculations, into which we can then linearize the relationship to eventually develop our full metal body prototype. With the generous financial support we obtained from the Hunters Hub for Entrepreneurial Thinking, we were able to get funding for our final prototype!

FEASIBILITY OF OUR DESIGN SOLUTION

We want our idea to deliver a high impact, high feasibility solution to our target market. How can we reach this?

To start, we can buy our raw materials in bulk, while maintaining low overhead in terms of storage of inventory. This ensures that we only plan ahead to manufacturing only what we need. By outsourcing our manufacturing and starting off selling our product locally, we can quickly raise brand awareness to eventually go globally.

For the customer, our aim is to sell at a price of around $200, while offering special deals to those who recommend our product to others who are absolutely done with struggling to find the perfect ratchet!

Partners and Mentors

We would like to extend the utmost thanks to the following support team:

- Our incredible on-going support from our Technical Advisors & Business Advisors

- Hunters Hub for providing us the financial assistance to make our prototypes come to life

Our Photo Gallery

Even the simplest tools can empower people to do great things.

– “Biz” Stone