Project Category: Entrepreneurial

Join our presentation

About our project

We are developing a cost effective product to address problems with the onset of COVID-19, specifically targeting masks. There are environmental concerns of too many masks used a single time and thrown away. Developing a viable product to ensure safe sanitization of masks will allow for re-use without needing to wash the mask which can be cumbersome. Having a product to sanitize masks will also promote further hygiene practices because of easy accessibility leading to environmental and health benefits.

Ultraviolet-C (UV-C) is effective at inactivating COVID-19 and we are utilizing LED technology as the means to provide the sterilization of masks. To safely house the UV-C light, we developed a mechanical enclosure and designed electronic circuitry to control the time of UV-C exposure to the mask for effective sanitization.

Cost: $49.99 CAD + GST.

Meet our team members

Sardar Faizan Hanif

Electrical Engineering

Project Manager

Varinder Singh

Electrical Engineering

Documentation Lead

Mohammad Nabeel Uddin

Electrical Engineering

Testing Lead

Vagelis Markakis

Electrical Engineering

Business Lead

Shahzaib Ather

Mechanical Engineering

Mechanical Lead

Andrew Calvin Currie

Electrical Engineering

Technical Lead

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

With the onset of COVID-19 we saw a lot of environmental issues that come with mask usage and disposal. Like plastic, masks do not readily decompose and require proper disposal. If reusability is extended, the waste will be heavily reduced benefiting the environment as well as reduction in buying costs. After researching in this niche market, we found that there are UV related products however few were dedicated to sanitizing materials such as masks, lacked portability and were quite expensive.

Based on the research results we approached the product development to be portable, easy to use and cost effective.

WHAT MAKES OUR DESIGN INNOVATIVE

During the research phase of the project, we noticed quite a lot of UV related products simply state their use case and do not provide documentation that the product can sterilize materials. Using published journal articles, we have taken the next step in verifying the specific calculated requirements of using UV-C to effectively sanitize a mask. For example, using the surface area of a mask, we determined how much energy must be delivered by the LEDs to sanitize the mask and what kind of usage we can provide using current batteries.

Most products in the market are not portable and that is our second selling point in term of innovation. Our product can provide 400+ cycles of sanitization before needing another recharge and that is possible because of integrating a battery system within the electrical design.

We believe our design is innovative in taking the existing technology and making it safer and easy to use in this new emerging market of sanitizing products.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

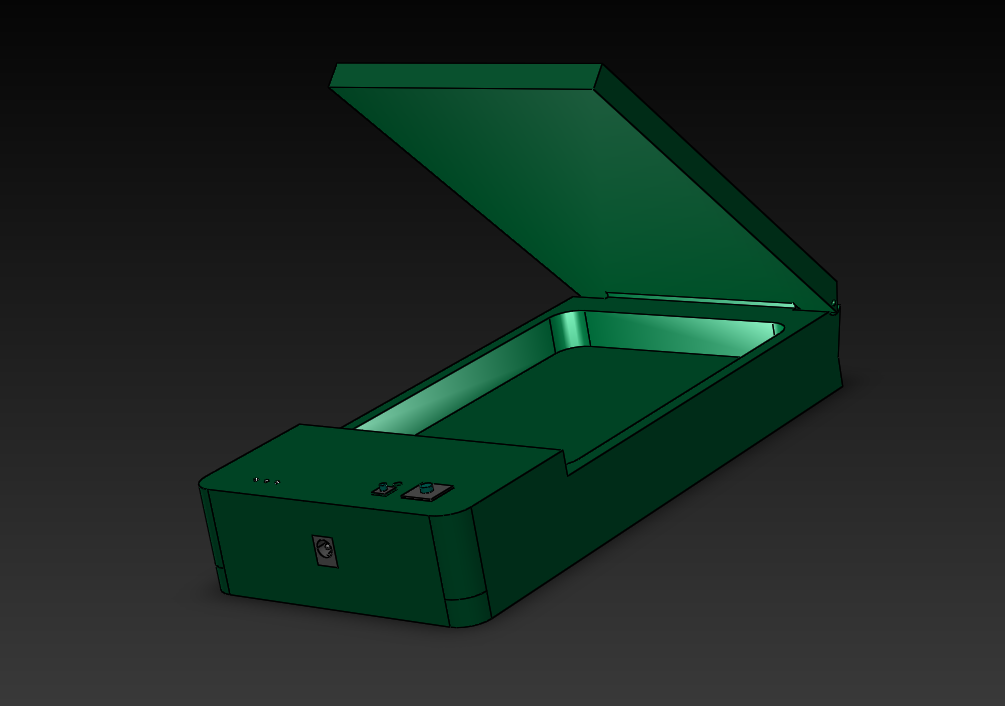

Focusing on the shortcomings of current products in the UV market, we targeted to add functionalities to our product that will make our design solution effective. These functionalities include safety, ease of use, portability and most importantly sanitization effectivity. While other products do not safely contain the UV light and repeated use can cause skin damage, our product uses a hinge style top to completely close off. We also implemented an automatic 20 second cycle which will effectively sanitize a mask and second layer of safety using contacts on the lid which will disrupt power to LEDs if the device is open mid-operation.

Using only a button to activate the cycle and another button to power the device, we kept the ease of use in focus and made the device portable by integrating Lithium batteries. Having a product with these key features will promote use of sanitization and curb environmental waste of masks as well as promote healthy hygiene practices. Portability, ease of operability and safety provides a niche advantage to our product development to make our design solution effective.

HOW WE VALIDATED OUR DESIGN SOLUTION

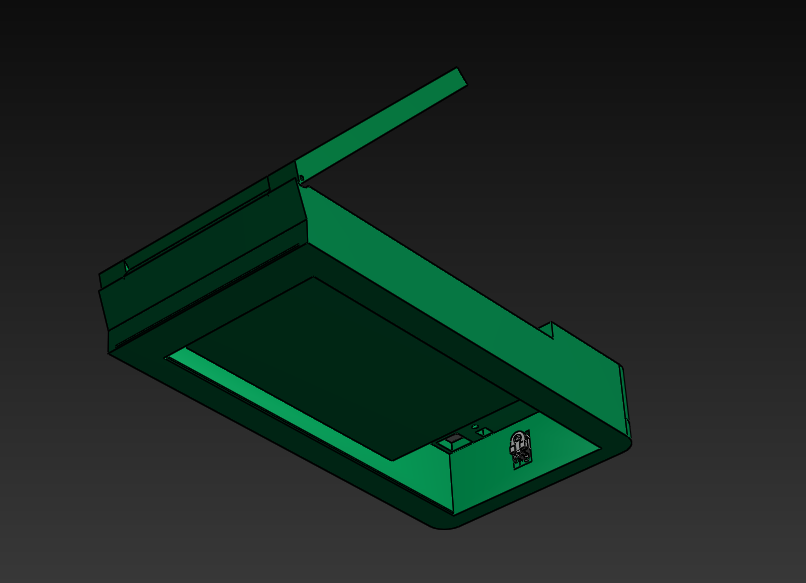

To validate our design as we developed the product, we reached out to the public with surveys on functionality, usability and pricing. Along with the surveys we got great feedback from TAs and our advisor on how to improve the functionality while reducing the cost of the product. First part of the project was to develop an enclosure that can house UV-C light which was validated using Solidworks CAD software and further solidified using 3D printing.

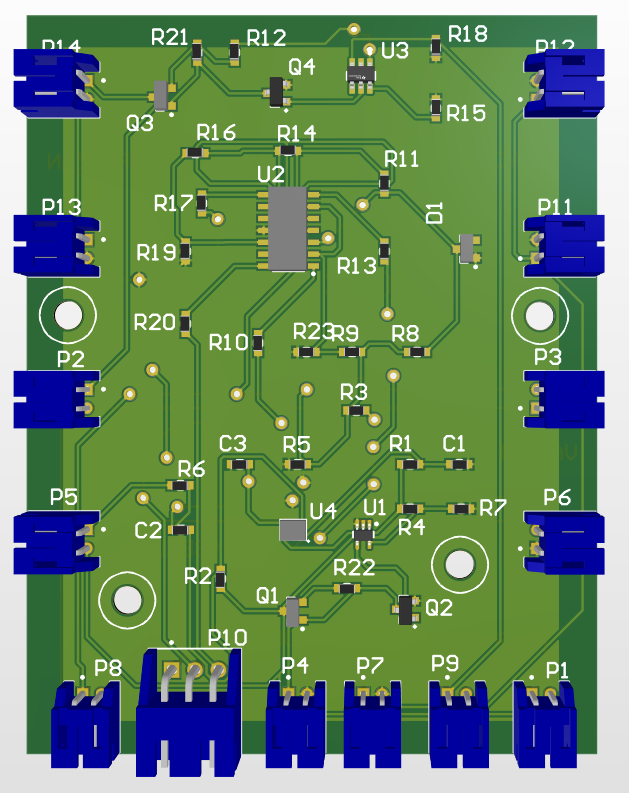

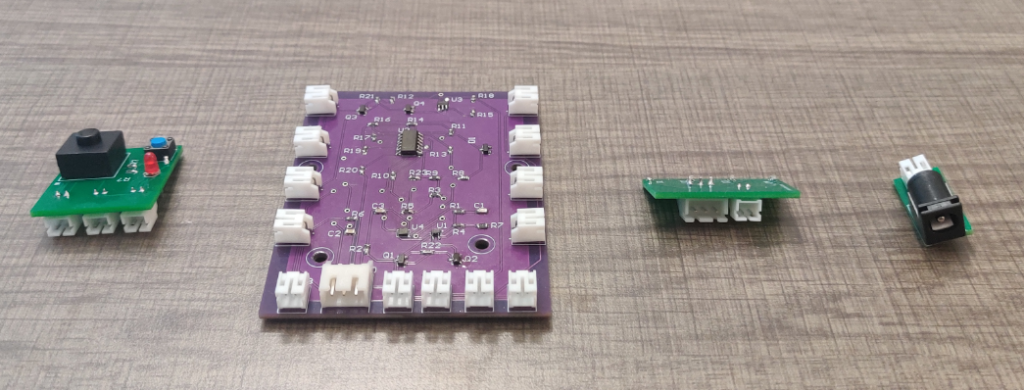

Secondly, we designed the electrical boards using Altium and tested the various functionalities in a lab setting. For example, we verified the desired on-off function, battery level indication, on-time of the UV-C LEDs and various electrical protections.

Research backed information was used to calculate that 20 seconds of exposure is enough to sanitize a mask, and our device is configured to deliver the energy requirements in that time frame.

FEASIBILITY OF OUR DESIGN SOLUTION

As the public continually becomes more aware of benefits of masks and sanitizing, products related to these areas will become prevalent. Within this growing market, our product feasibility is high as seen from feedback as well from manufacturing standpoint. We have shown development with CAD models, 3D prints and electrical designs which can easily be transferred with economies of scale into a cost-effective product.

Partners and mentors

Special Acknowledgements

Adviser: Mohamed Balla Elamien

Technical TA: Udoka Nwaneto

Business TA: Jose Menjivar

Professor: Hamidreza Zareipour

Grad Assistant: Anton Vykhodtsev

Organizations: Maker-Space

Our photo gallery

3D CAD Model

CAD Model Bottom

PCB from left to right: Control buttons; main board to control timing and on/off of LEDs as well as charge batteries; Battery level indicators; charging port