Project Category: Geomatics

Join our presentation

About our Project

Deformation monitoring is an important process in the assessment of possible movement in a structure or in the detection of movement that jeopardizes a structure’s stability. It is of great importance for the geomatics engineer to be able to report back their findings with confidence, as decisions regarding the state of the structure and any mitigation undertaken are based on these results.

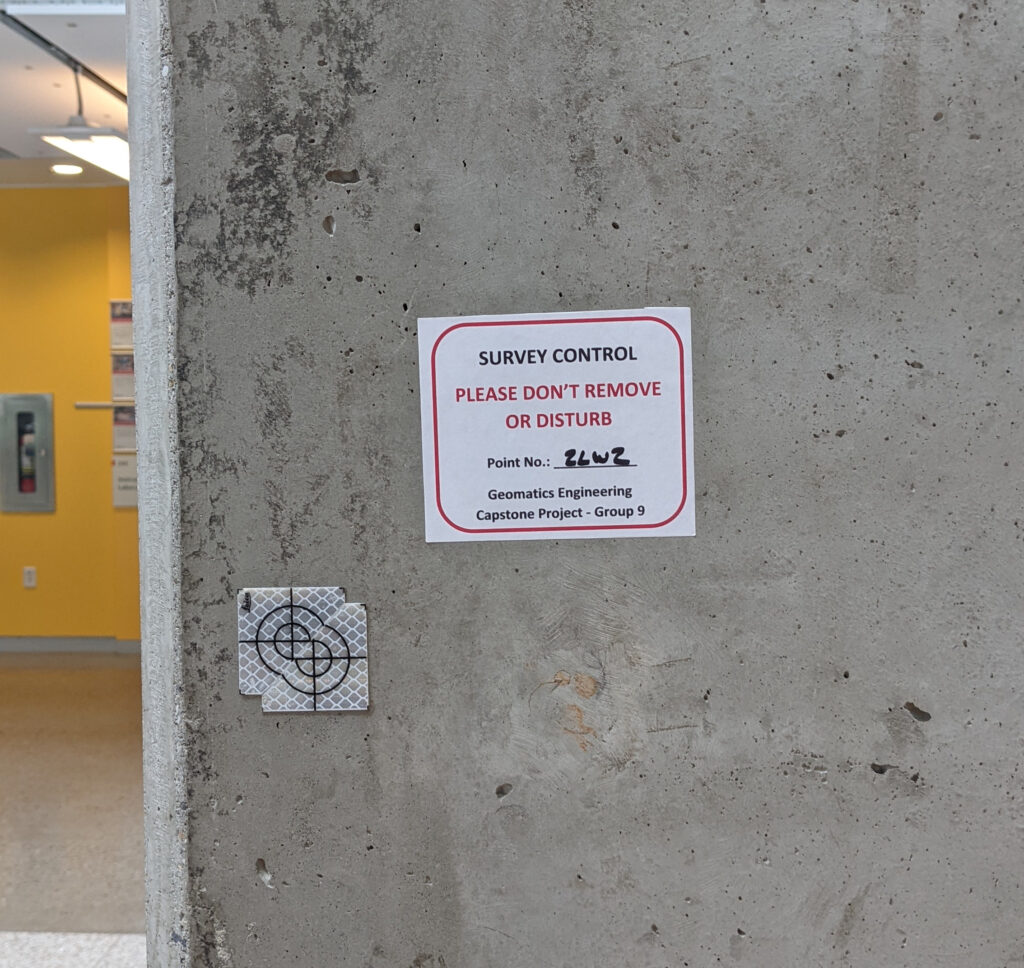

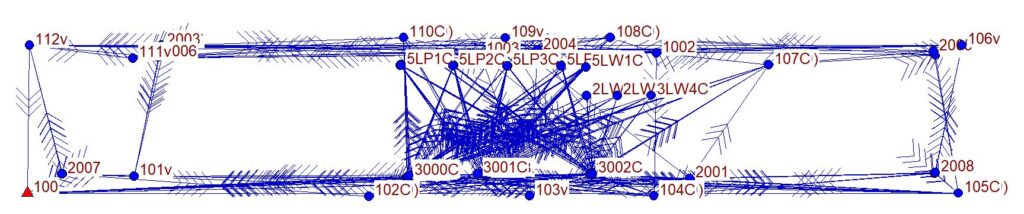

The objective of this project is the assessment of various technology solutions to best determine the presence of deformation in a building face. The goal set out at the beginning of the project was to observe sub-centimeter movement of the face with confidence. Control and target networks were designed for repeatable results and to have adequate geometry to be reliable for deformation surveys. This involved pre-analysis, error propagation, and provisional measurements to determine which types of equipment, or combination thereof, are suitable to meet the accuracy requirements. The client requested bi-monthly technical reports highlighting the results of the various measurement epochs from the deformation monitoring surveys. We should note that it is not, however, within the scope of the project to report the actual magnitude of the deformation of the selected building face, as the motion will be simulated by the group by a known value and processed to evaluate if the returns accurately reflect the simulated movement. Each epoch of observations underwent confidence testing and error analysis to assess the validity and quality of the observations. All results and findings were summarized in short action technical reports describing the state of the building at the time of observation and also compared results from epoch to epoch.

The building face selected for the project is the northern interior concrete structure of the EEEL building on the University of Calgary Campus.

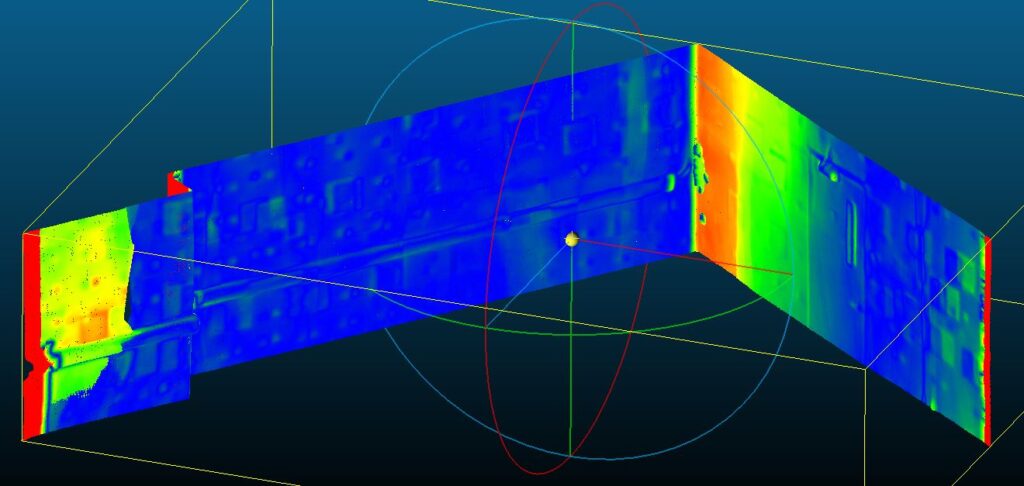

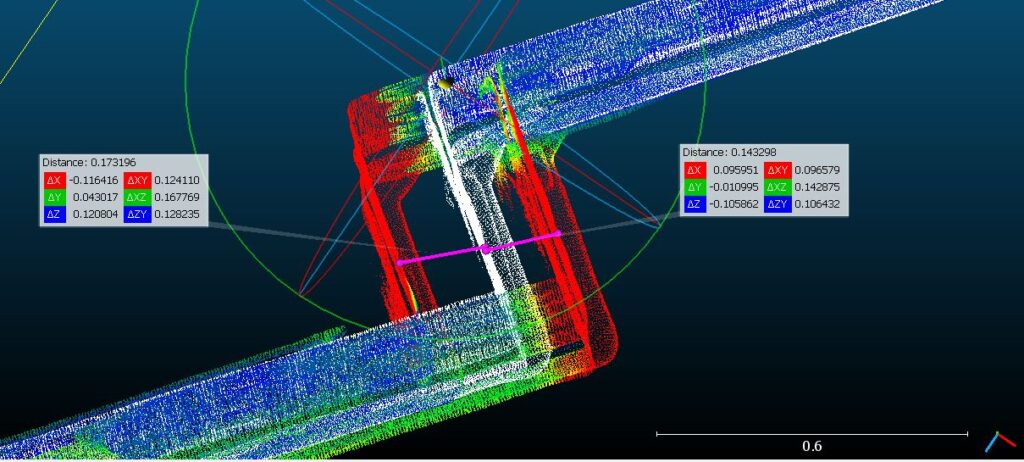

Primary technology used was Leica TS30 0.5” Total Station, secondary technology used was iPhone 13 Pro Lidar sensor.

Meet the Team

| Jeff Turgeon | Evan Kemp | Renaud Veniere | Lucas Tombrowski |

|---|---|---|---|

Project Manager + Field Assistant | Technical Lead + Party Chief | Communications Lead + Field Assistant | Lead Editor + Field Assistant + R&D Lead |

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

- Assesses validity of specific technologies to perform deformation monitoring and detection of sub-centimeter movement.

- Provides insight to the planning requirements and pre-analysis for a long-term deformation monitoring campaign.

- Provides insight to methodology for deformation monitoring surveys.

- Bi-monthly reports emphasize clear and concise communication with the client regarding results of measurement epochs.

WHAT MAKES OUR DESIGN INNOVATIVE

- Selection of interior building face to reduce environmental factors.

- Performing extensive pre-analysis calculations ahead of fieldwork.

- Assessment of iPhone 13 Pro Lidar sensor as potential affordable, hand-held platform for deformation monitoring.

- Creation of custom reflective sticker targets for the purpose of simulating deformation.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

- Conducting monitoring campaign in similar fashion to industry.

- Experienced team members with instruments, processing software and field work methodology.

- Controlled environment provided by interior building face.

- Simulated deformation targets have known offsets and can be compared between nominal measurements and observed process results.

- iPhone 13 Pro Lidar sensor is compatible with 3rd party apps to collect 3D scanning data and be processed in publicly accessible software like CloudCompare.

HOW WE VALIDATED OUR DESIGN SOLUTION

- Total station was calibrated at a baseline. (supports validity of survey and results)

- Divided field work into control establishment, deformation target establishment (epoch 0), network validation (epoch A), deformation survey (epoch B), and retracement survey (epoch C).

- Attempted iPhone camera calibration despite resorting only to Lidar scans and not 3D reconstruction from photogrammetry.

- Tested capabilities of iPhone in calibration lab as proof of concept before deciding whether or not to adapt to full-scale.

FEASIBILITY OF OUR DESIGN SOLUTION

- The Leica TS30 0.5” Total Station was more than sufficient for achieving sub-centimeter deformation detection.

- Through statistical analysis, we are able to detect deformation of at least 5 mm in magnitude at a 95% confidence level.

- The iPhone was range limited and unsuitable for the distances required of the full-scale project.

- The results from the iPhone were inconsistent in laboratory testing, giving scalar and alignment issues.

Partners and Mentors

We want to thank the many people who helped us with this project.

Our project would not have been possible without the assistance and advice from those included below:

Advisor

Kate Cairns – McElhanney Land Surveys Ltd.

Consultations

Matt Sakatch, Dr. Derek Lichti, Kent Jones, Jeff Sinclair, Emily Wyatt – University of Calgary

Mark Budgen, Rob Tupper, Brad Cooper – Monashee Surveying and Geomatics

Aaron Shufletoski – Underhill Geomatics Ltd.

Axel Ebeling – McElhanney Land Surveys Ltd.

Equipment and Logistics

Survey equipment provided by University of Calgary Geomatics Engineering Survey Store

Lance Hummel – Leica Data Collector provided by SAIT

Geoff Banham – Access to Calgary EDM Calibration Baseline

Apple iPhone 13 Pro provided by McElhanney Land Surveys Ltd.

Our photo gallery

References

- CloudCompare [Software], Version: 2.11.3 (Anoia)

- MicroSurvey Star*NET [Software], Version: 9.2.6.556 (NicroSurvey Software Inc. 2019)

- TPS1200+/TS30/TM30 Technical Reference Manual, Version: 7.1 (Leica Geosystems)