Project Category: Geomatics

Join Our Presentation on Tuesday, April 5th

Atrium CNRL Complex (Schulich School of Engineering) at our in-person booth!

About our project

Pipelines carry pressurized natural gas or oil long distances to meet the everyday demand of consumers. However, they come with their own risks. Structural failure of the pipe would lead to large quantities of oil or gas contaminating the surrounding region. Pipeline companies need to ensure that they build and operate the pipeline based on the risk it poses to the surrounding environment.

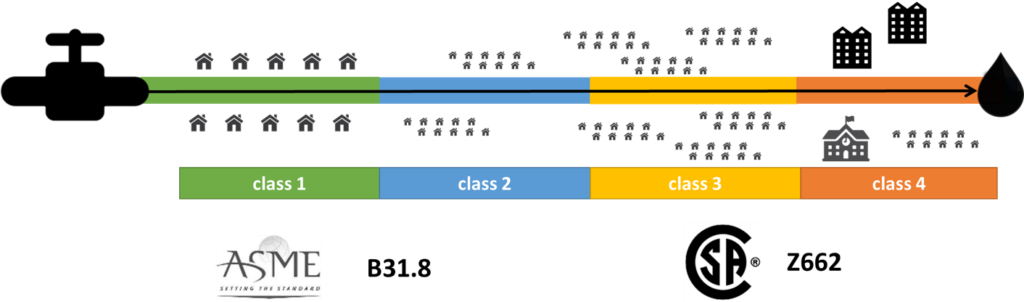

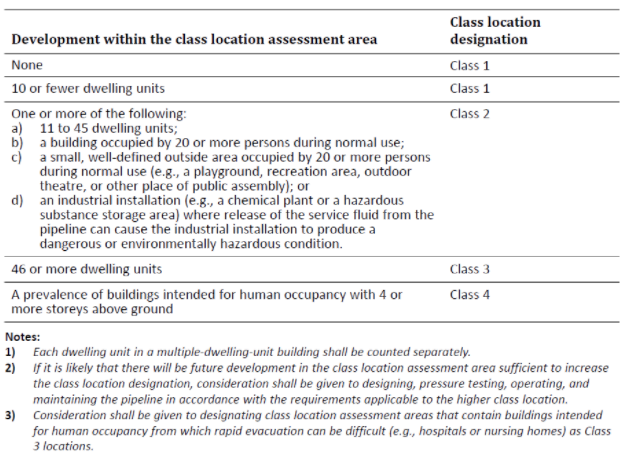

To determine how the pipeline should be built and operated, oil and gas transporters need to conduct a class location assessment. The Canadian Energy Regulator refers to class location as an area around a transmission line that is “classified according to density and factors such as environmental sensitivity”. All companies that are regulated by the Canadian Energy Regulator must have a clear understanding of their current pipeline class location. Changes to population and the environment have to be tracked during the operational life of the pipeline. If the class location does change for a pipe segment, they will need to create a plan on how to continue to operate the line safely based on the new class designation.

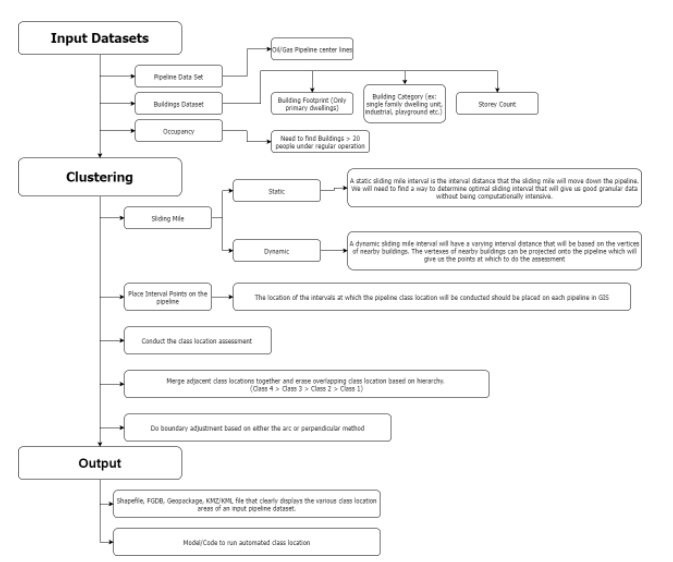

Because this is a location-based analysis, it is a problem that could be solved using Geospatial Information Systems (GIS). To accomplish this, We have used GIS to maintain and analyze the pipeline data as well as the data of the surrounding environment. This was the purpose of this project, to build a process that would take an input of spatial data and conduct the class location assessment.

Meet our team members

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

Class location is a risk assessment done on oil and gas lines across Canada. The main purpose is to determine the risk of a containment breach on the adjacent environment, property, and population. It is also used to determine how the environment, property, and population can cause a containment breach. Class location assessments are used to design or adjust the safe operating conditions of the pipeline such as the pipeline wall thickness, operating pressure, and depth of cover.

WHAT MAKES OUR DESIGN INNOVATIVE

When researching class location assessment, we found that the industry does not have a standard method or procedure for conducting class location. It can vary, from some firms choosing to do it by hand, to others who have automated systems built into their own pipeline risk assessment system. There is also no standard method on how to do class location; however, the most common method that can be found online is an assessment that is conducted at a static interval along the pipe, which we would call this method the static model.

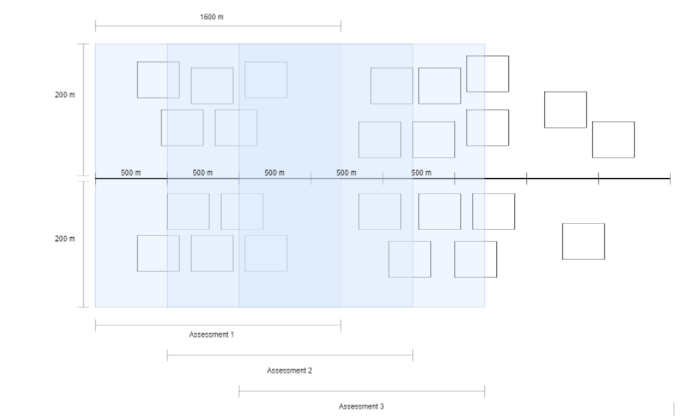

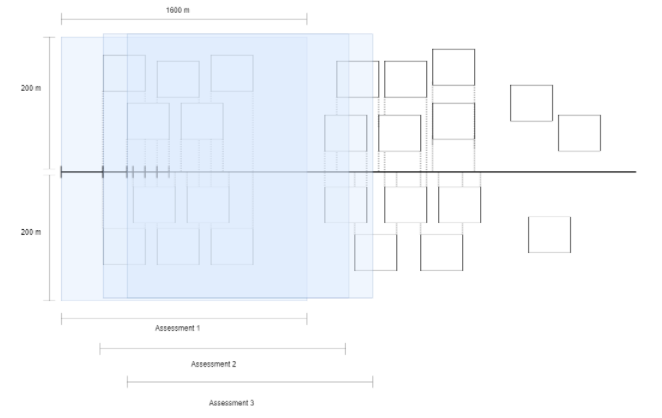

In the static model, as we can see below, we took an assessment area and shifted it by a given static interval. In this assessment area, we have done the clustering process, which is where we took the occupancy and building metadata of all the buildings that fell inside the assessment area to calculate the class location of that section of the pipe. After we were done with the first assessment area, we then shifted it by the chosen interval and then did the class location assessment in the new area. We continued this until we have reached the end of the pipe.

WHAT MAKES OUR DESIGN EFFECTIVE

To ensure all of the objectives of the project were met, a concrete set of requirements was needed to be defined:

- – An automated process of conducting the class location assessment is the most important requirement of the design. A user is able to input pipeline, buildings, and structure data and output the class location assessment.

- – The design is able to work with different forms of input geospatial data such as Feature Classes and/or Shapefiles.

- – The design is being able to work with different geometries for buildings.

- – The design is able to work with geospatial datasets that are in multiple different spatial reference systems such as North American Datum 1983 (NAD83) or World Geodetic System 1984 (WGS84).

- – The design is able to take in parameters such as the spatial reference system of the output, the length and width of the assessment area, and their units such as meters or feet.

- – The design is also being able to work with large datasets.

HOW WE VALIDATED OUR DESIGN SOLUTION

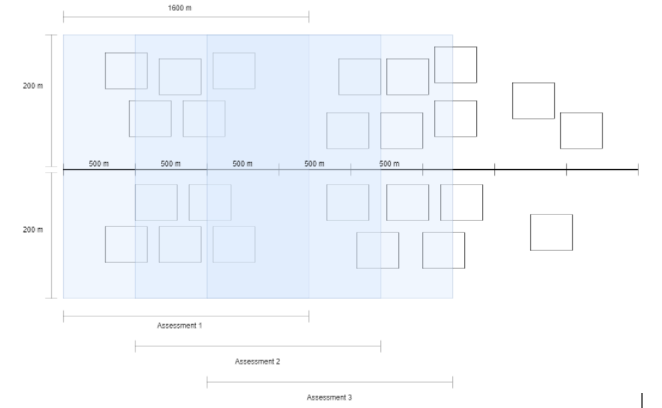

The biggest question that engineers have to answer when doing a class location assessment using the static model is what interval to choose. When researching how the intervals are chosen, we were told that it is subjective and it is up to the discretion of the person doing the assessment. This can be seen as the inefficiency of the static model and something we can improve upon.

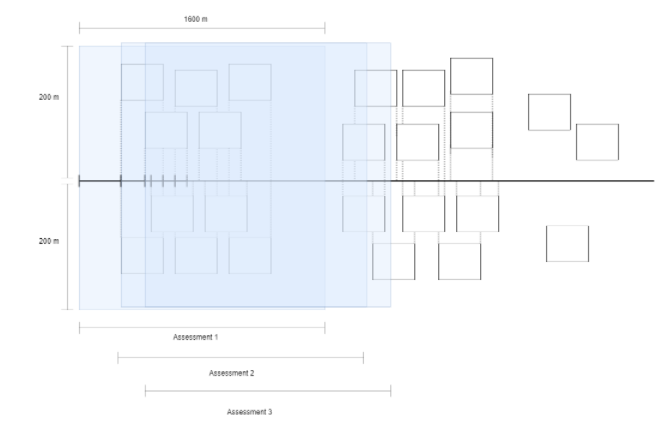

Therefore, we proposed to do the assessment using what we would then call a dynamic model. The dynamic model, shown below, takes the vertices of the buildings nearby a pipeline and projects them onto the pipeline. It then does the assessment at each of these points on the line. Because this model would conduct the assessment based on the buildings in the surrounding area, we would get assessment intervals that would reflect the environment.

FEASIBILITY OF OUR DESIGN SOLUTION

The class location assessment for this project was conducted using ESRI tools, with added help from ArcOnline, QGIS, and FME as needed. To make this an automated assessment we decided to build it in Arc Model Builder.

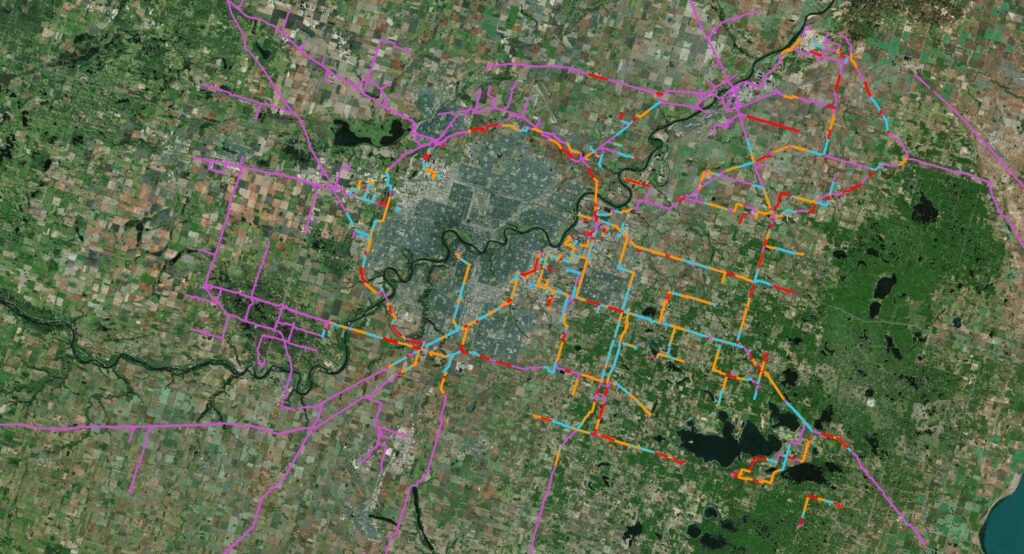

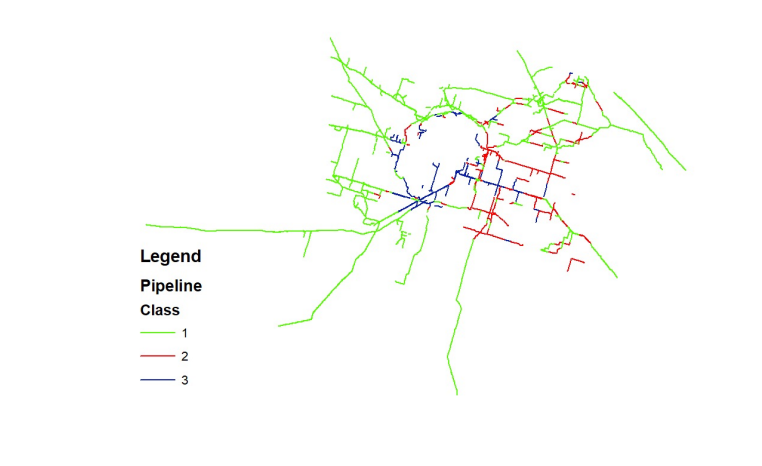

The output for this project is either a Shapefile, FGDB, Geopackage, or KMZ/KML file that shows the class location assessment of the entire transmission system; as well as the model/code for the entire process.

Partners and mentors

We would want to express our gratitude to everyone who assisted us with this project. Shirley Chan, our adviser from Stantec, went above and beyond in leading us through every phase of our project. Her thoughtful suggestions have helped lead this group and our project to success. We would like to also thank Dr. Micheal J. Collins for all of his help along the way as we learned more about project planning. We learned a lot from this assignment, which was an altogether new experience for us.

Our photo gallery

References

- Canada Pipeline Maps & Facts. CAPP. (2021, August 31). Retrieved March 30, 2022, from https://www.capp.ca/explore/oil-and-natural-gas-pipelines/.

- CSA Group. CAN/CSA-Z662-15 Oil and gas pipeline systems, 2015 edition, SKU: 2423368

- Government of Canada, C. E. R. (2021, February 12). Backgrounder: What is a Class Location? CER. Retrieved March 31, 2022, from https://www.cer-rec.gc.ca/en/applications-hearings/submit-applications-documents/filing-manuals/archive/2017gd-e-cnslttn/backgrounder-what-is-class-location.html.

- ProductPage-HCA. (n.d.). Retrieved April 3, 2022, from https://www.looknorthservices.com/pipeline-ccl.html.

- South Dakota Public Utilities. (n.d.). Determining class location. Retrieved March 30, 2022, from https://puc.sd.gov/commission/PSOT/Presentation/classlocations.pdf.