Project Category: Mechanical

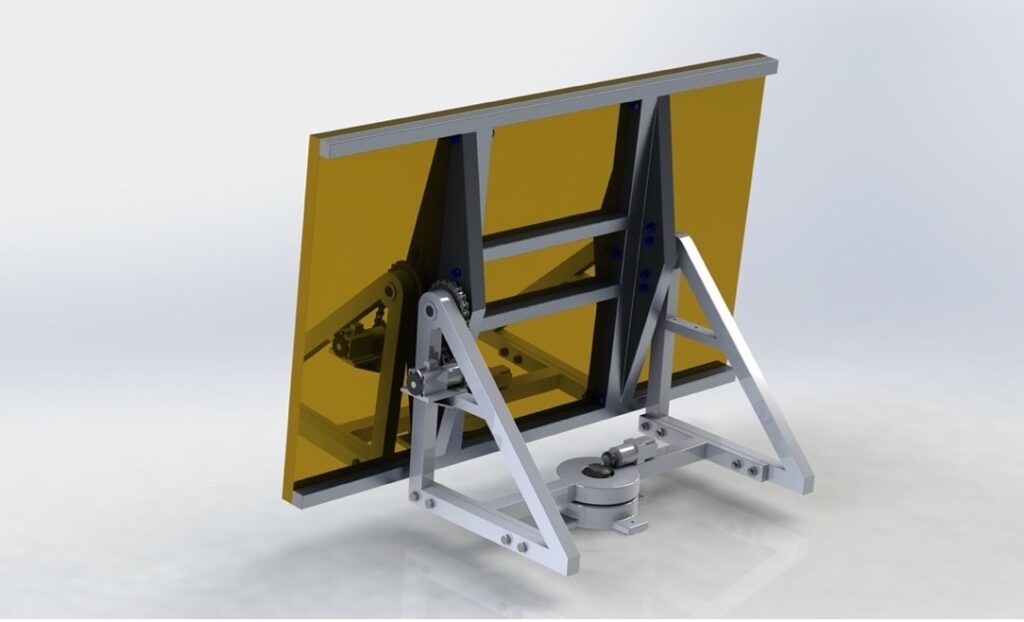

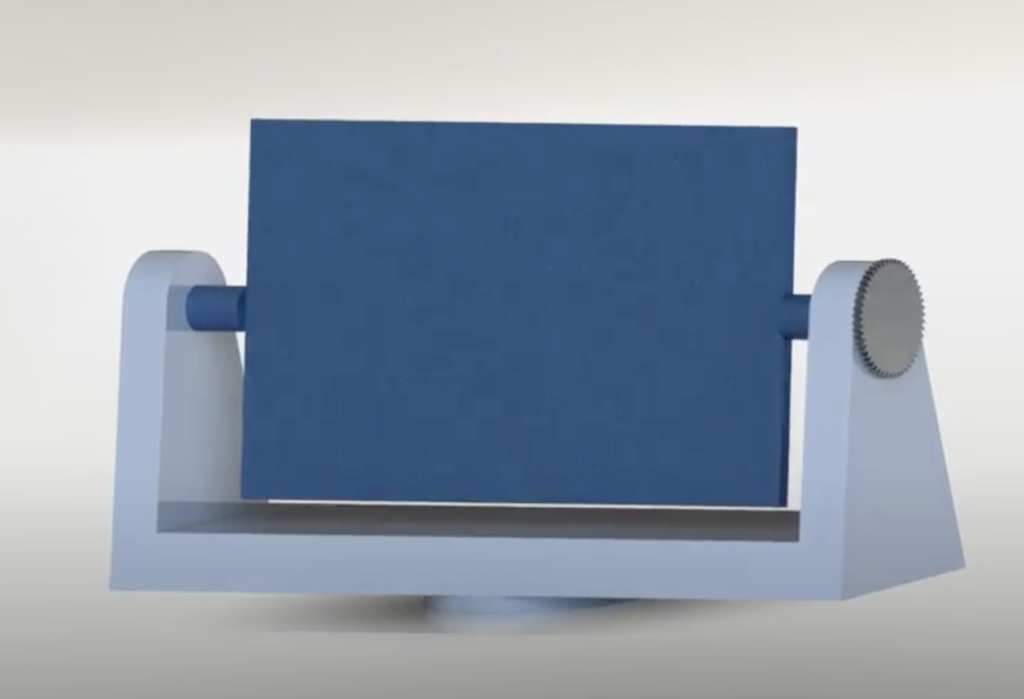

Final Design (CAD Model)

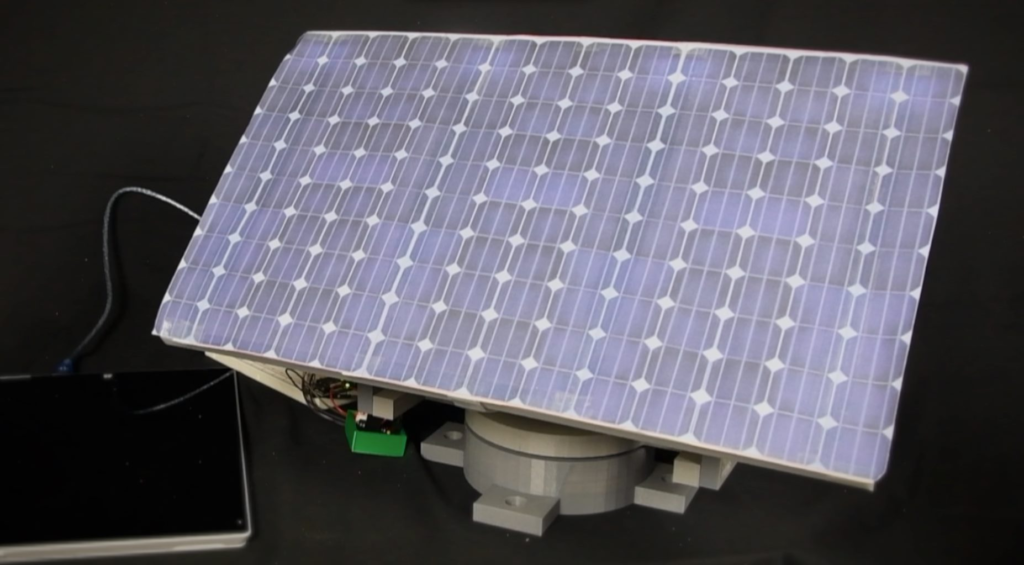

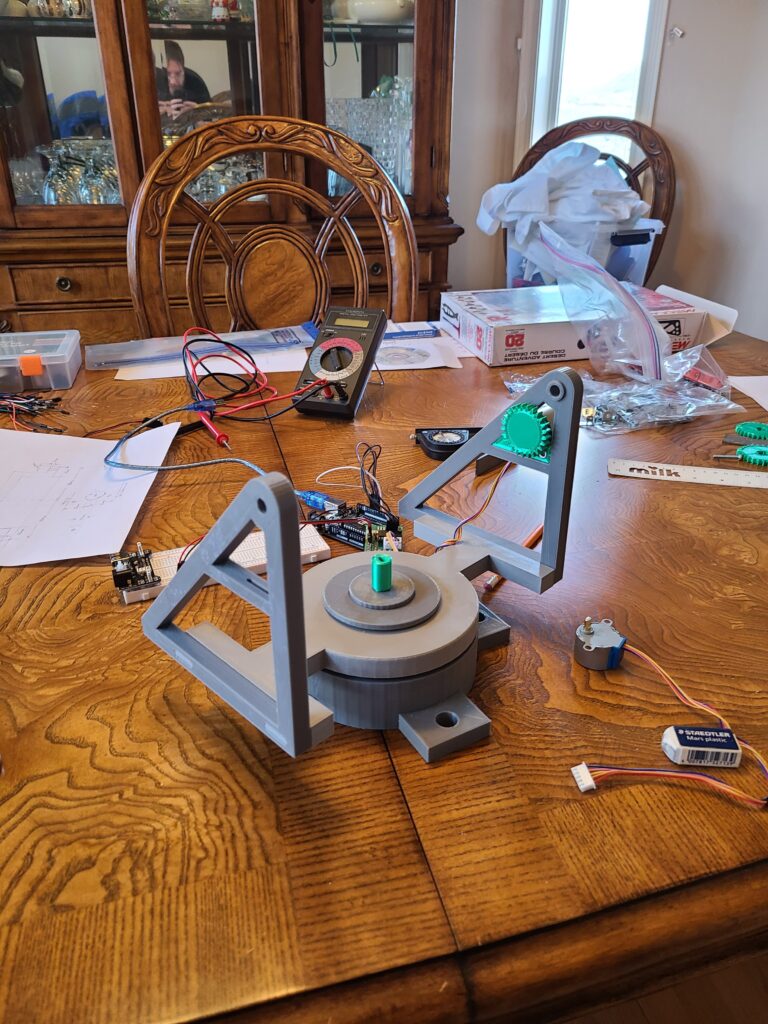

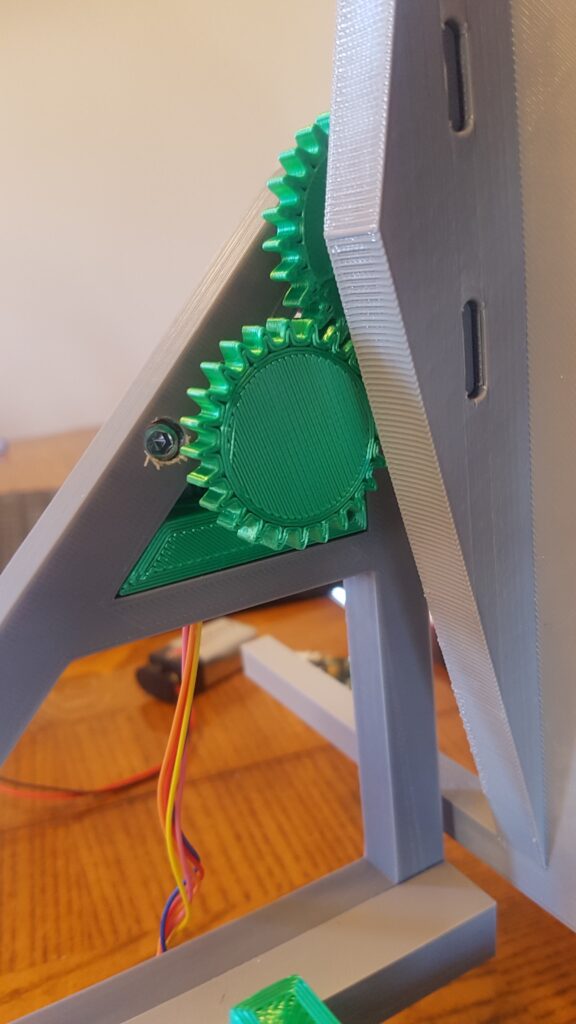

Prototype Design (3D-printed)

Join our presentation:

About our project

Renewable energy provides almost 20% of Canada’s total primary energy supply, and solar photovoltaic energy is the fastest-growing electricity source industry in Canada. With the ongoing transition towards renewable energy, we have created an innovative mount for an industrial solar panel that can be used on solar farms and other wide-scale applications.

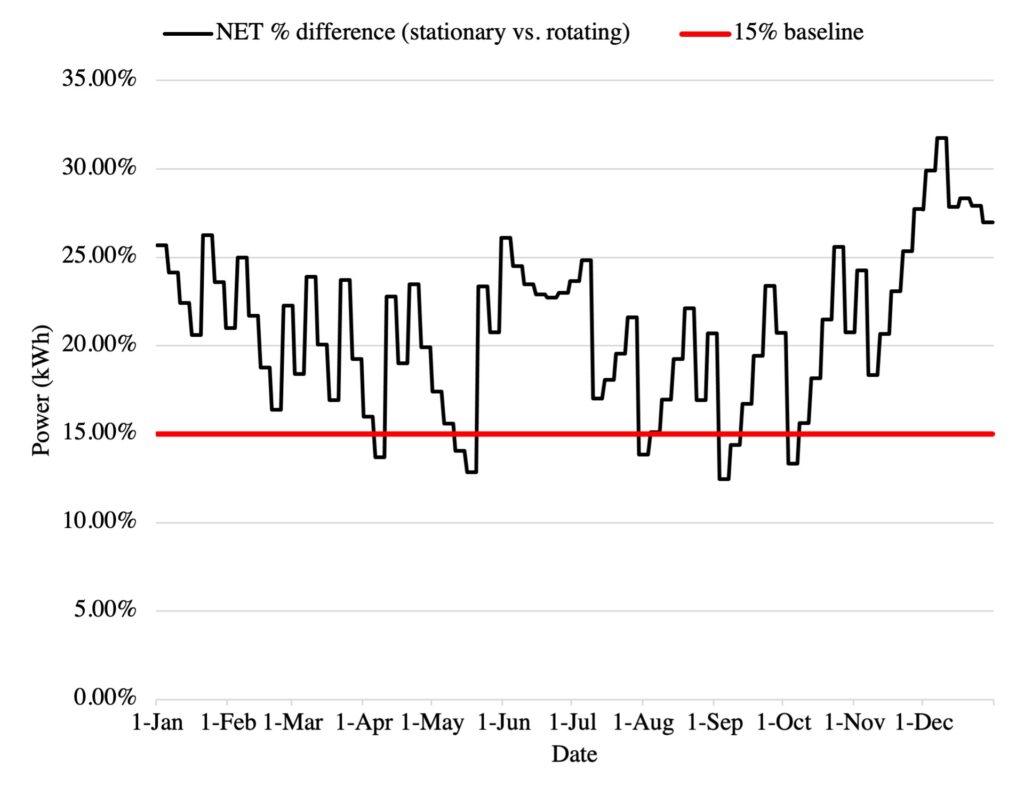

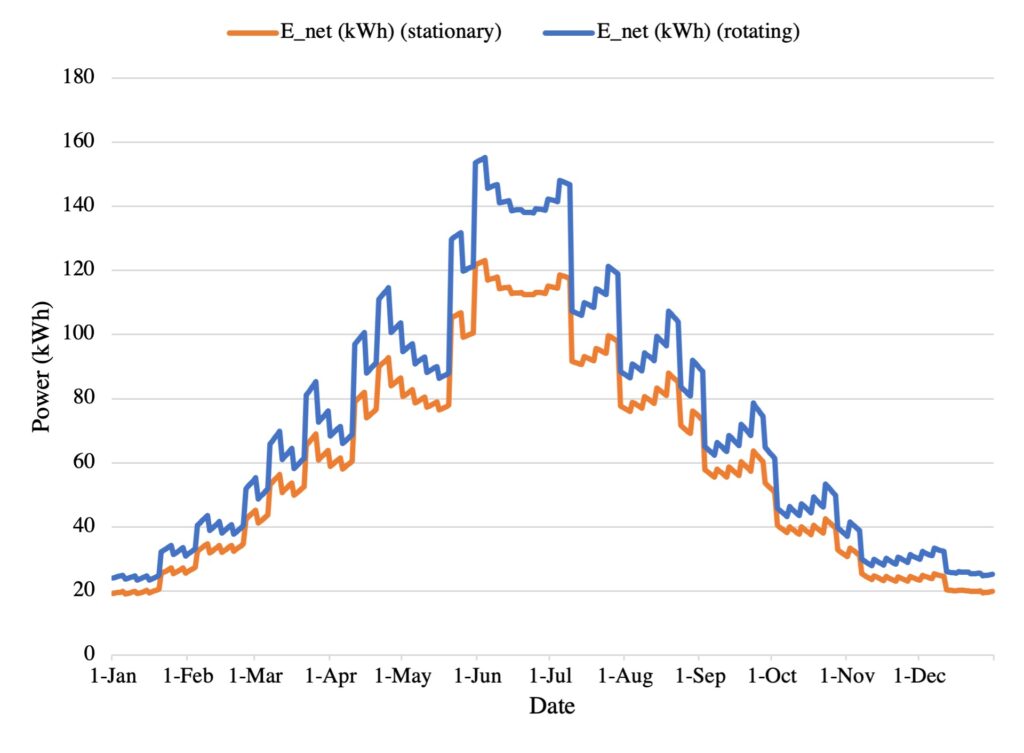

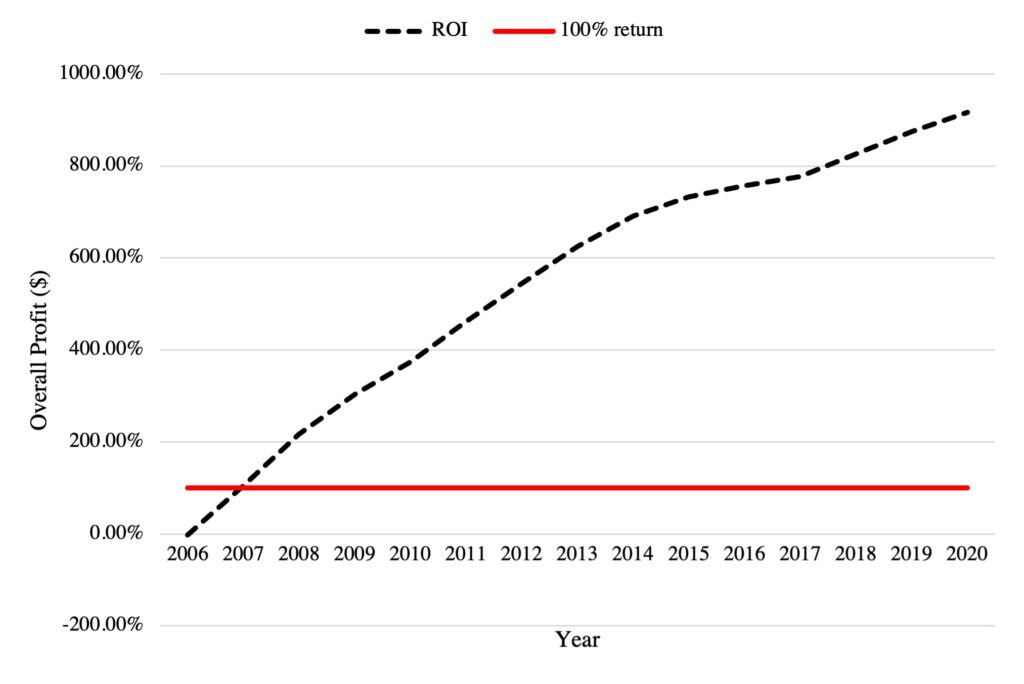

This mount rotates in response to the sun along two axes and increases the net annual energy production of this industrial panel by 15-30% (in comparison to a stationary panel). It is also economically feasible and has the capacity to make up to (and possibly more than) $25,000 over 15 years.

Meet our team members

Jose Pedreanez

Dylan Anderson

Ayomide Bamgbose

Bradley Gow

Project Advisors

Course Instructors: Dr. Simon Li / Min-hyung Lee

Supervisor: Dr. Ahmad Ghasemloonia

Project Sponsor

Shell: Shell Experiential Energy Learning (SEEL) Program

Funding: ~$1000

Details about our design

Will rotating a solar panel in response to the sun’s position increase its net annual energy production?

Design Problem / Rotating solar panel design

Design Specifications

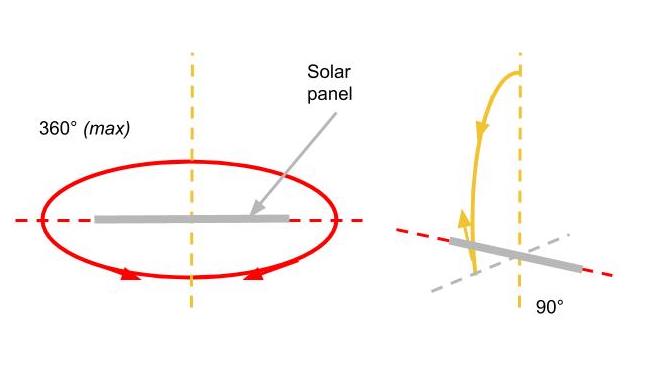

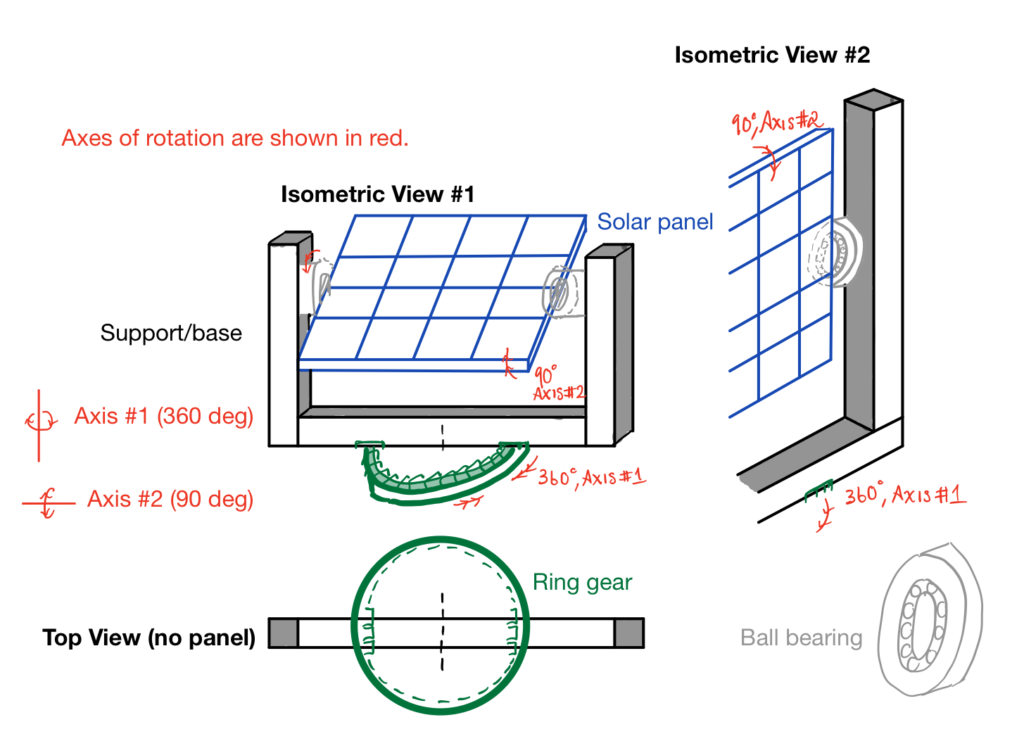

Axis 1 (360° rotation at 0.570 RPM)

Axis 2 (90° rotation at 0.964 RPM)

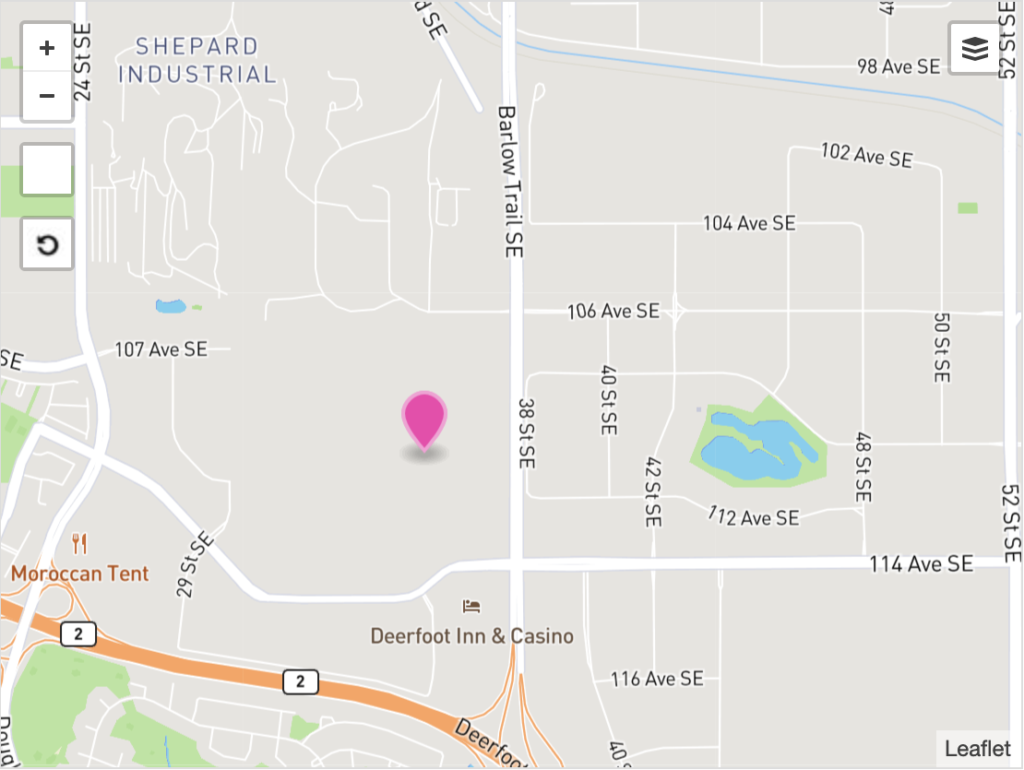

Proposed Panel Location

Selected Panel: Canadian 310W 60-cell Solar Panel

Latitude: 50.96°, Longitude: -113.99°

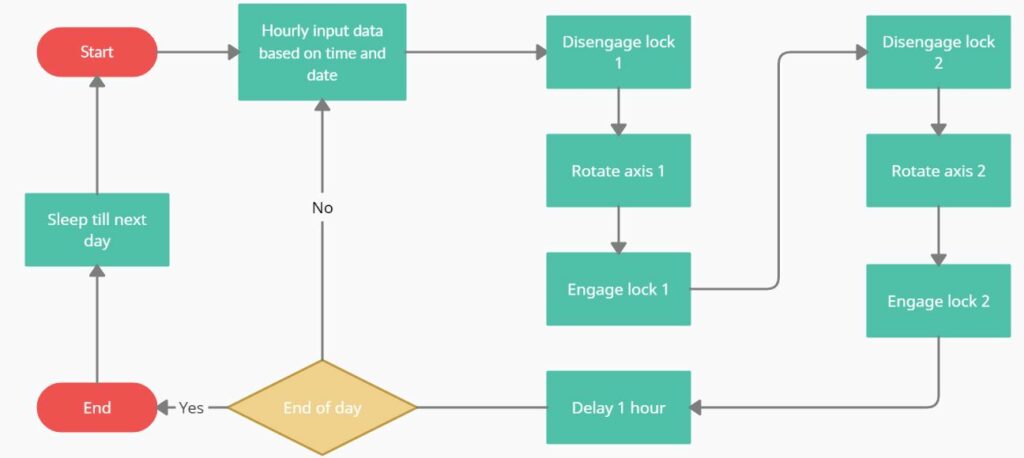

Control System Design

General control system block diagram

The control system (implemented with the ARDUINO Elegoo UNO R3) is used to control the motion of the solar panel along each axis. It takes in geographical solar data from 2020 as an input. Lock 1 and 2 correspond to Axis 1 and 2, respectively.

Control system code [SAMPLE]

A sample of the code used for a given day in the year (C programming language)

////////// Set up global data //////////

// Times: 9,10,11,12,13,14,15,16

int azimuths_axis1[8] = {0,145,155,170,185,200,215,0};

int altitudes_axis2[8] = {0,10,15,15,15,15,10,0};

// startTime, endTime, activeTime, sleepTime

int times[4] = {10,16,6,8};

// Set up time/day variables (times/days)

int currentTime, currentDay, startTime, sleepTime;

int count = 0; // initial value

// Set up axis variables

int axis1Angle, axis2Angle;

////////// Start the process //////////

void start(){

printf("Setting up today's parameters!\n");

// set global variables

currentDay = 0;

printf("%s%d \n", "Current day: ", currentDay);

printf("%s%d \n", "Count: ", count);

currentTime = times[0];

printf("%s%d \n", "Current time: ", currentTime);

sleepTime = times[3];

printf("%s%d \n", "Sleep time: ", sleepTime);

startTime = times[0];

printf("%s%d \n", "Start time: ", startTime);

// Run the code for the day

printf("\nStarting a new day!\n");

while(endOfDay(currentTime) == 0){ // while NOT at end of the day

// run locking + unlocking sequences

lockUnlock(1);

lockUnlock(2);

// delay for one hour (updates the current time)

delay();

// Update current time!

printf("%s%d \n", "Current time is now: ", currentTime);

}

printf("(Day has ended). \n\n");

sleep(currentDay);

}Mechanism Design & Prototyping

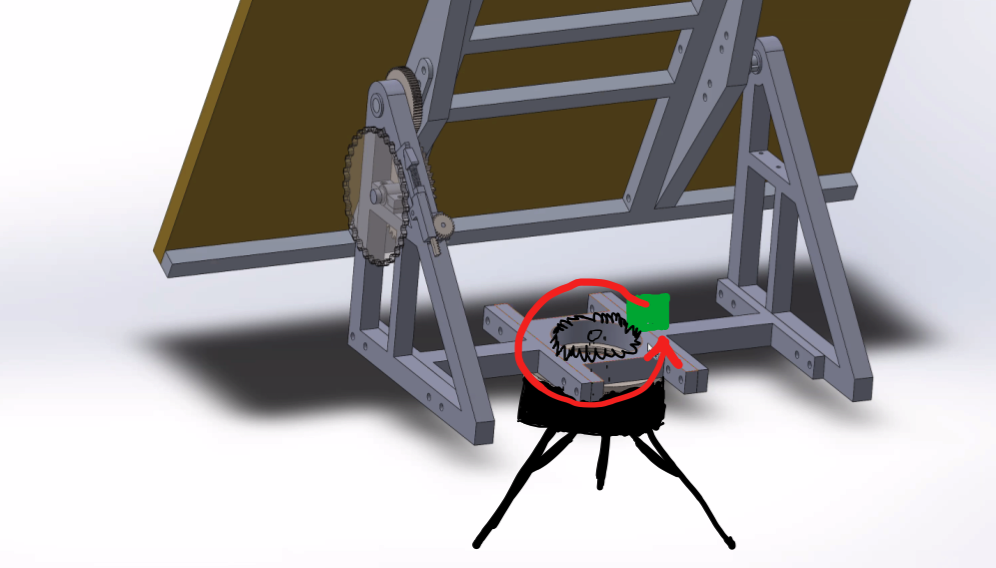

A simulation of the final design mechanism on January 1st is shown on the left, and a short video of the prototype is given on the right.

Frequently Asked Questions

Project Applicability and Feasibility

How does our design address practical issues?

- Many Canadian cities, such as Calgary, have the potential for solar energy application, and almost 50% of Canada’s residential electricity requirements could be met by installing solar panels.

- Research shows that rotating solar panels can increase the net energy production by up to 40%.

- This project increases the annual power production of an industrial solar panel by 21% (on average), and can be applied on an industrial scale (e.g., solar farms).

Design Innovation

What makes our design innovative?

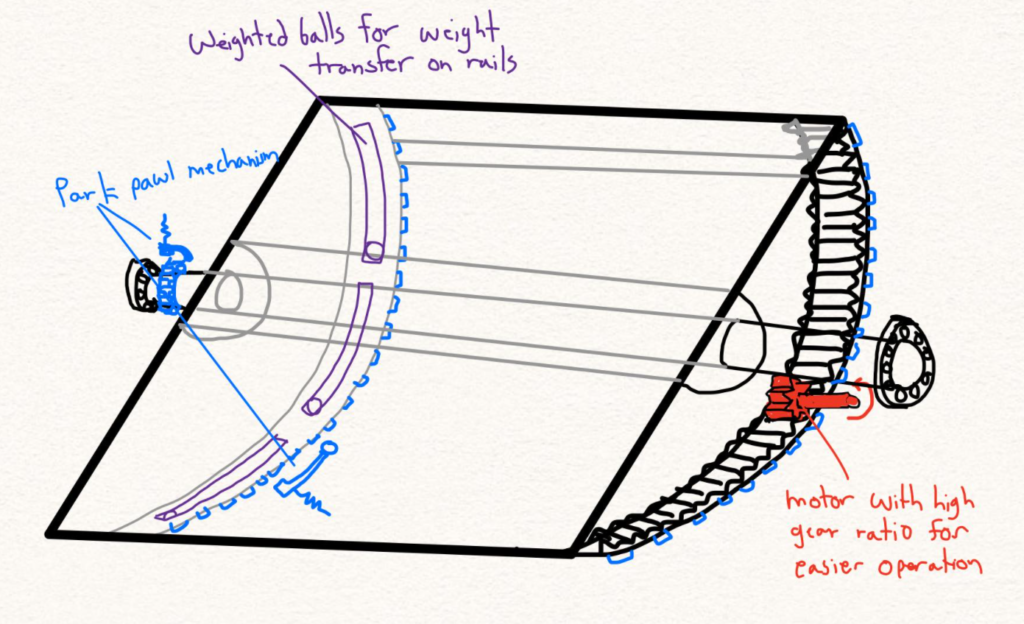

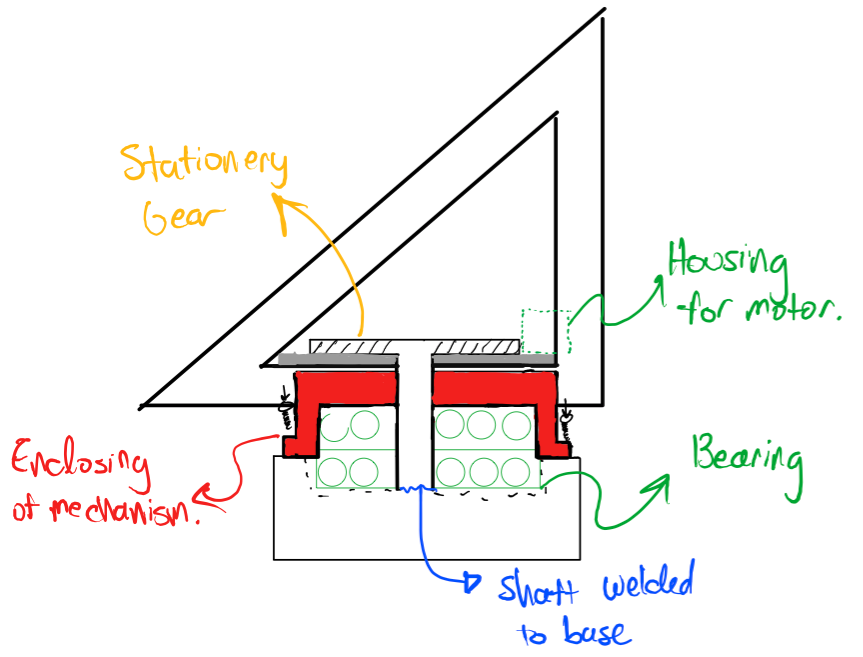

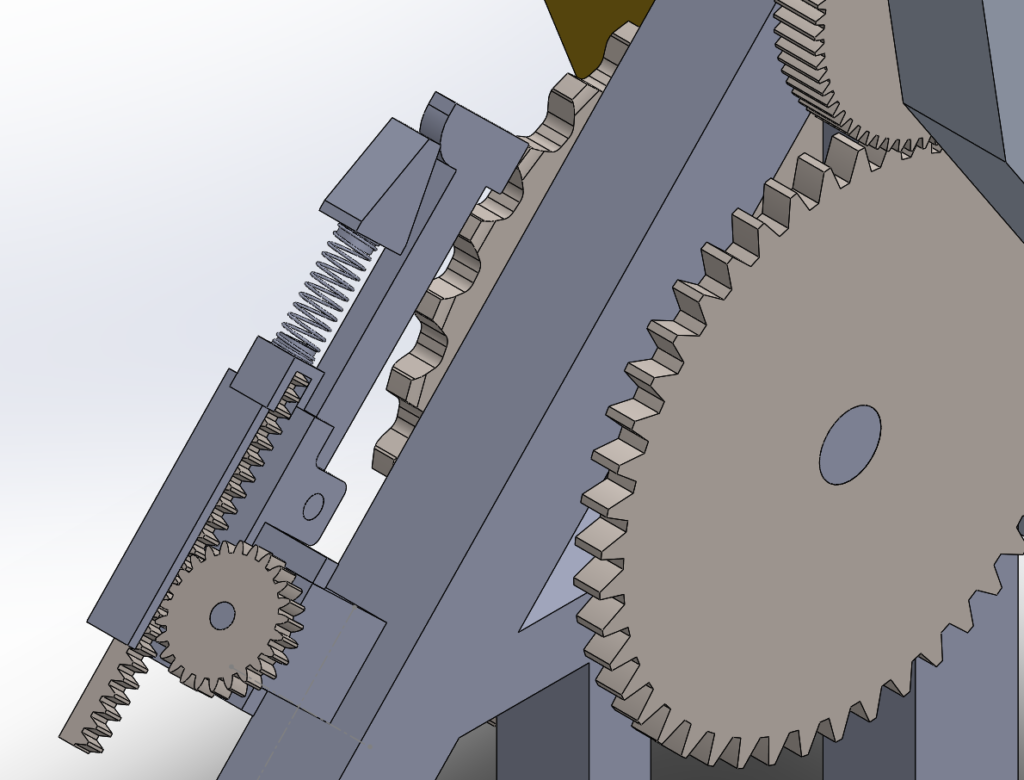

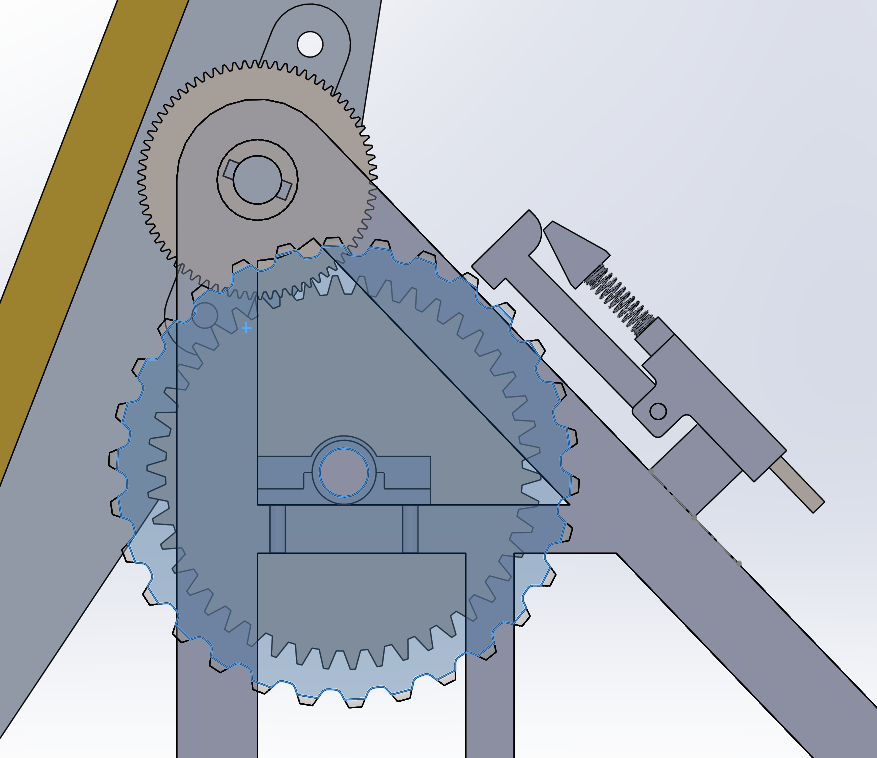

Our design is compact, multi-axial, and implements unique locking and rotary mechanisms to ensure the sturdiness and effectiveness of our project. The locking mechanism (designed based on park-pawl mechanism) is shown on the right.

Design Effectiveness

What makes our design solution effective?

This design produces an average of 21.4% more power than its stationary counterpart, and (not including initial setup costs) has an extremely low operating cost (<$100 annually):

Design Validation

How did we validate our design solution?

The rotating panel consistently produces more power than the stationary panel throughout the year (assuming that the year is 2020). These power values are calculated by considering the solar radiation, irradiation, location, and inclination angle of the panel.

Design Feasibility

How did we confirm the feasibility of our design solution?

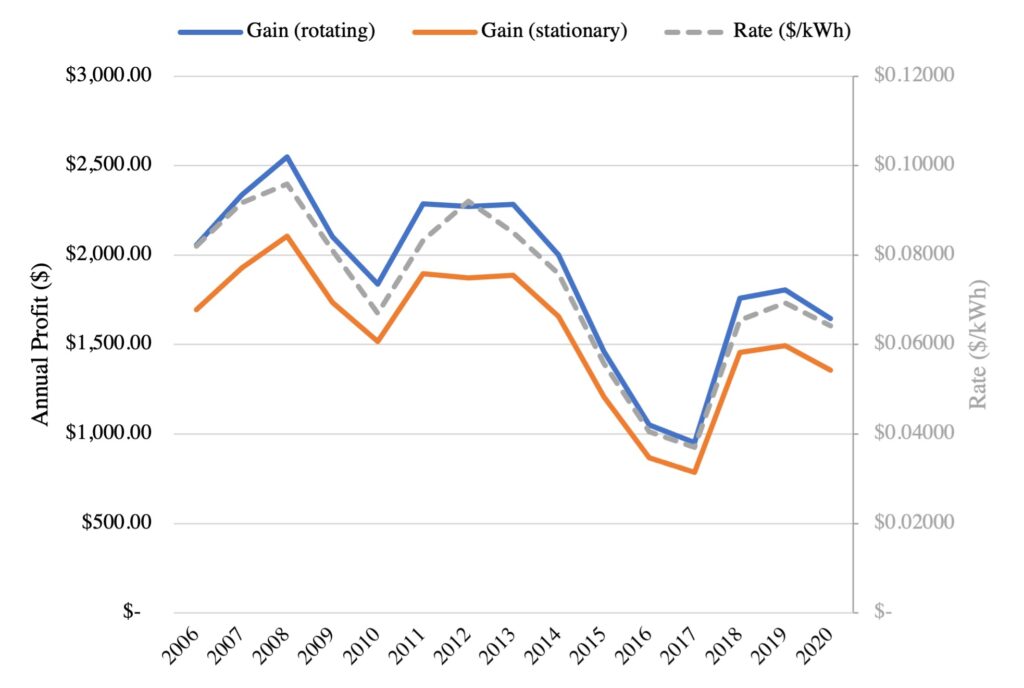

The profit projection of this panel over a 14-year period is shown below. The annual profit is calculated by using the monthly rate per kilowatt-hour ($/kWh) in Calgary from 2006 to 2020.

Partners and Mentors

We want to thank the many people who have helped us with this project. We would like to acknowledge Shell for providing the funding for this project through the SEEL Program. Our mechanical engineering professor Ahmad Ghasemloonia guided us through the process with patience and great advice. Our course instructor Simon Li and teaching assistant Min-hyung Lee provided invaluable insights and support in our many meeting throughout the academic year.

Project Photos

This section includes a compilation of key images from the conceptual to final design stages of this project.

Initial Drafts

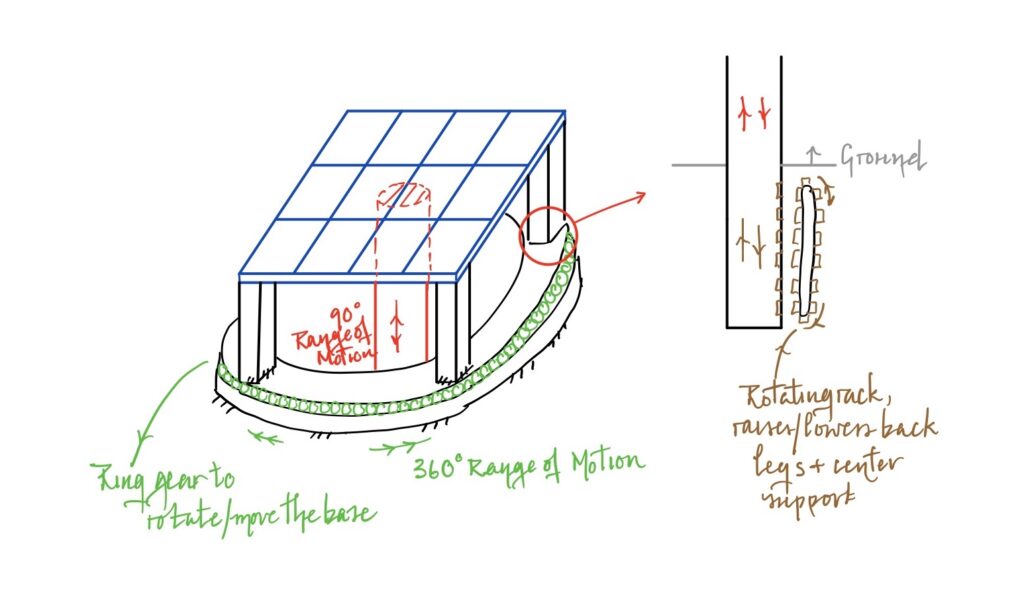

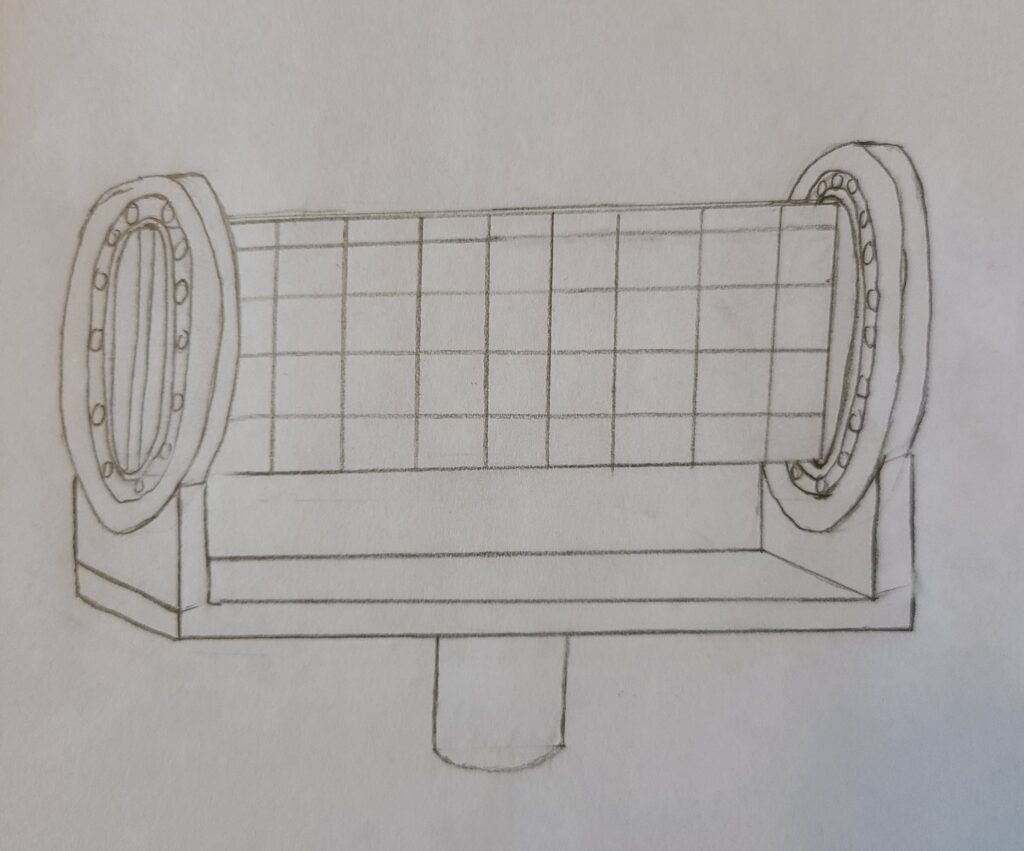

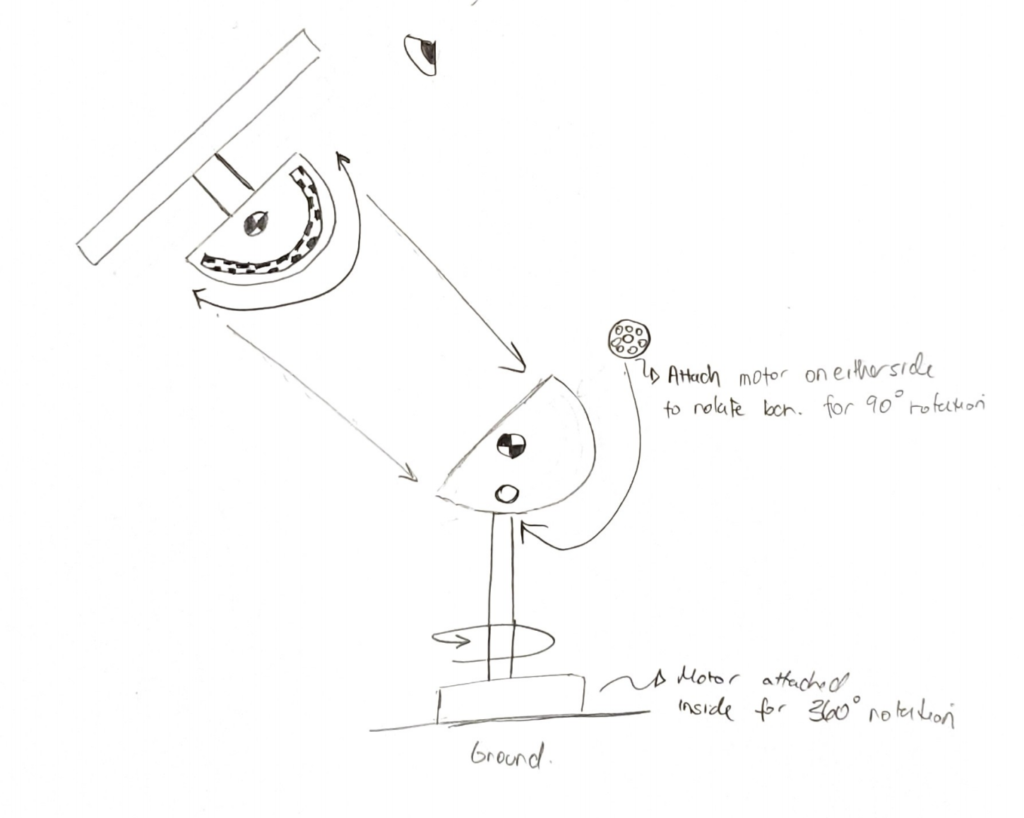

Initial sketches and drafts of our proposed design solution (Fall 2020)

Rotating base design

Concentric half-cylinder design

Concentric cylinder design

Concentric cylinders + rotating base design

Axis 1 (red) and Axis 2 (yellow) ranges of motion

Initial Design Solution

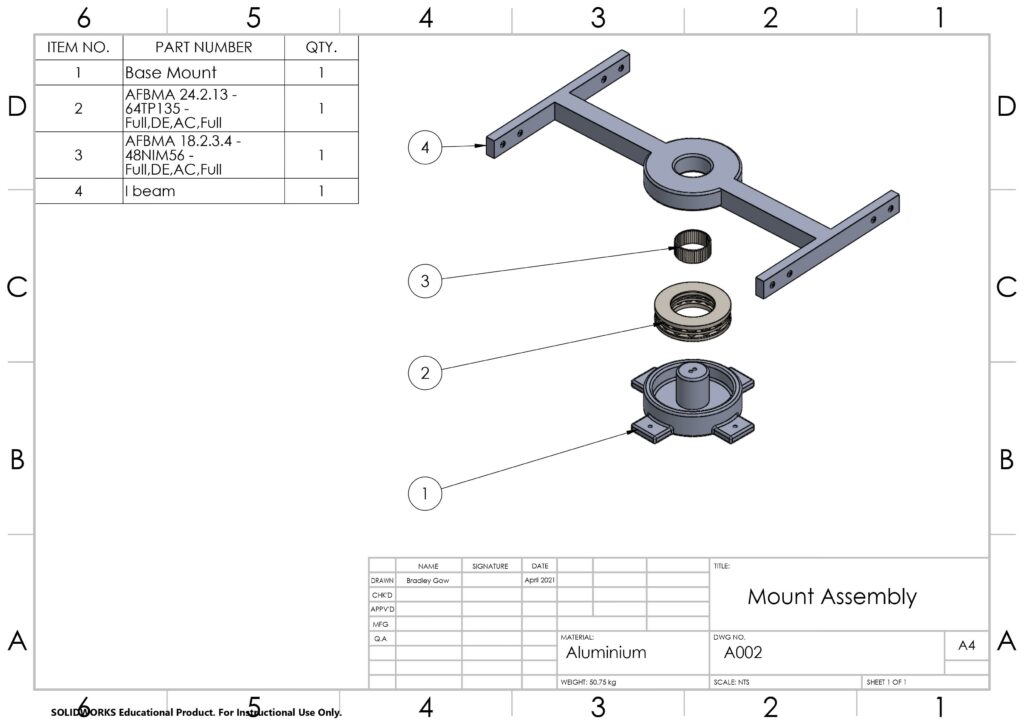

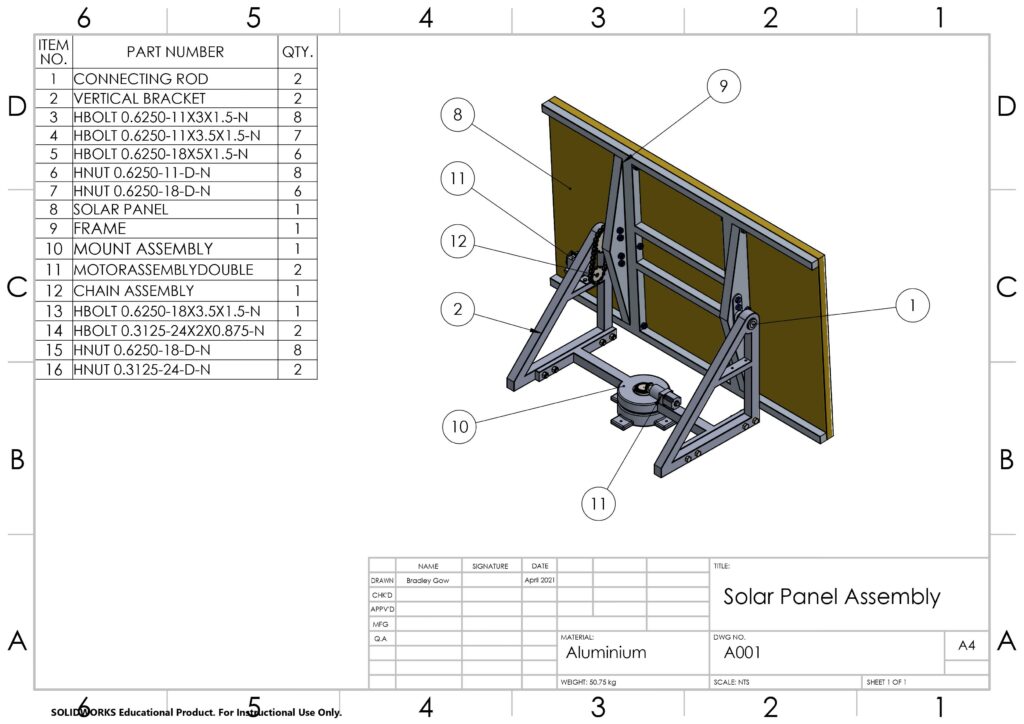

The first draft(s) of the design solution (Fall 2020)

Rotating base design

CAD Model drawing

Additional Media

Addition draft(s) of the design solution (Winter 2021)

Design mounting mechanism

Lighter version of Fall 2020 design solution

Locking mechanism (Axis 2) – isometric view

Locking mechanism (Axis 2) – side view

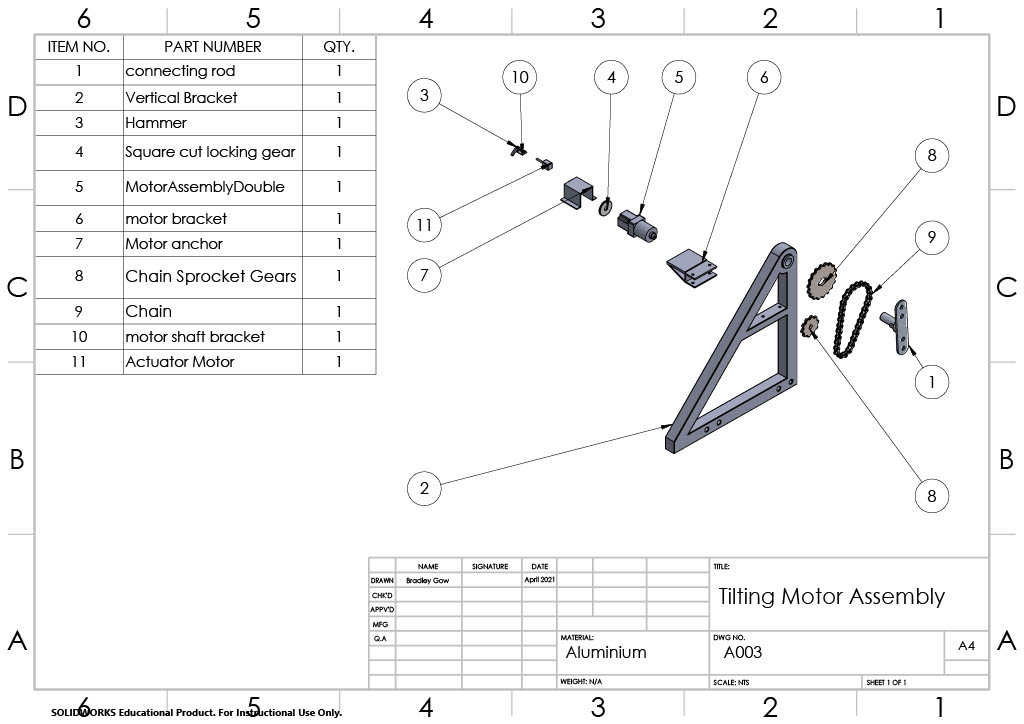

Detailed Drawings

The final design solution and detailed design drawings (Winter 2021)

Axis 2 Assembly

Axis 1 Assembly

Full Assembly

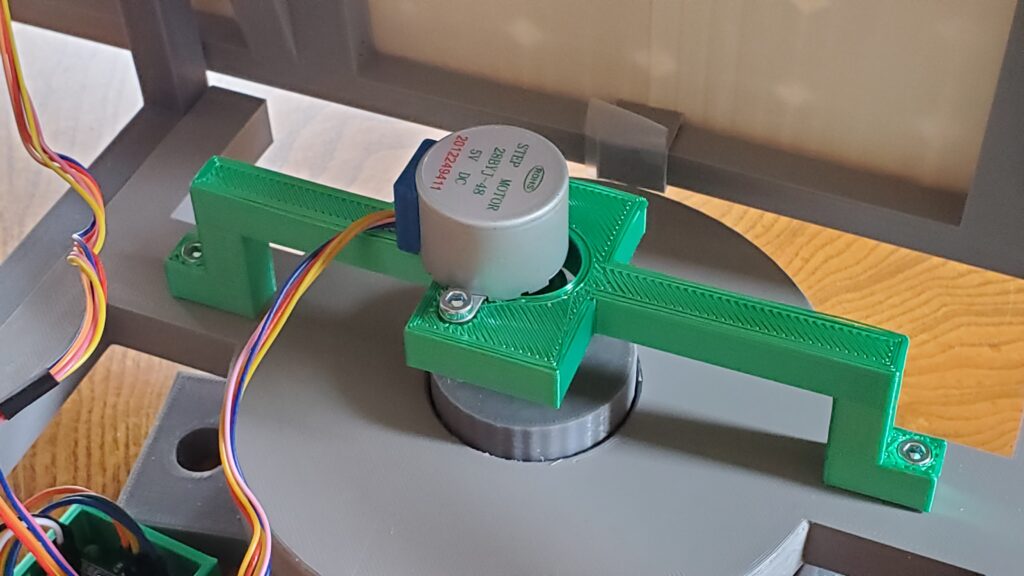

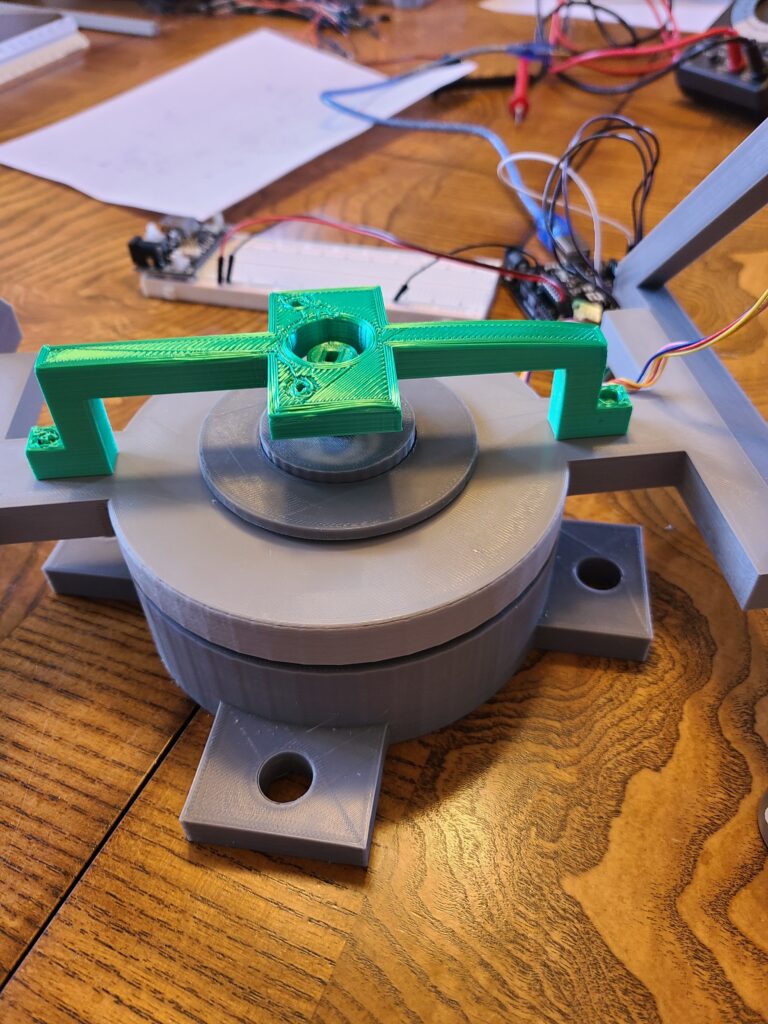

Prototype

The prototype of the design solution

Full base assembly

Axis 2 (gear only alternative)

Axis 1 ( motor attachment)

Mounting

Solar panel (cardboard version)

Axis 1 (mounting and motor)

Thank you for reading about our project!