Project Category: Mechanical

Join our presentation

About Our Project

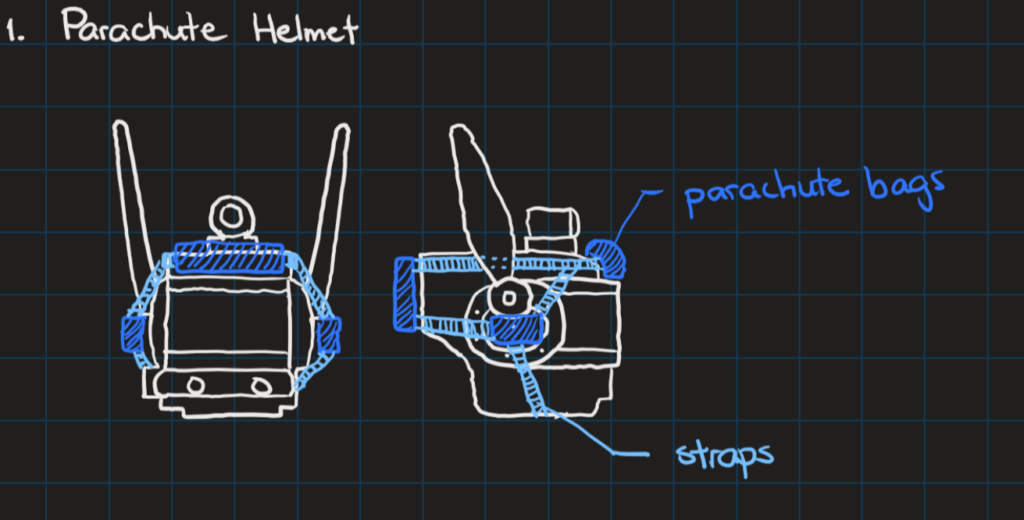

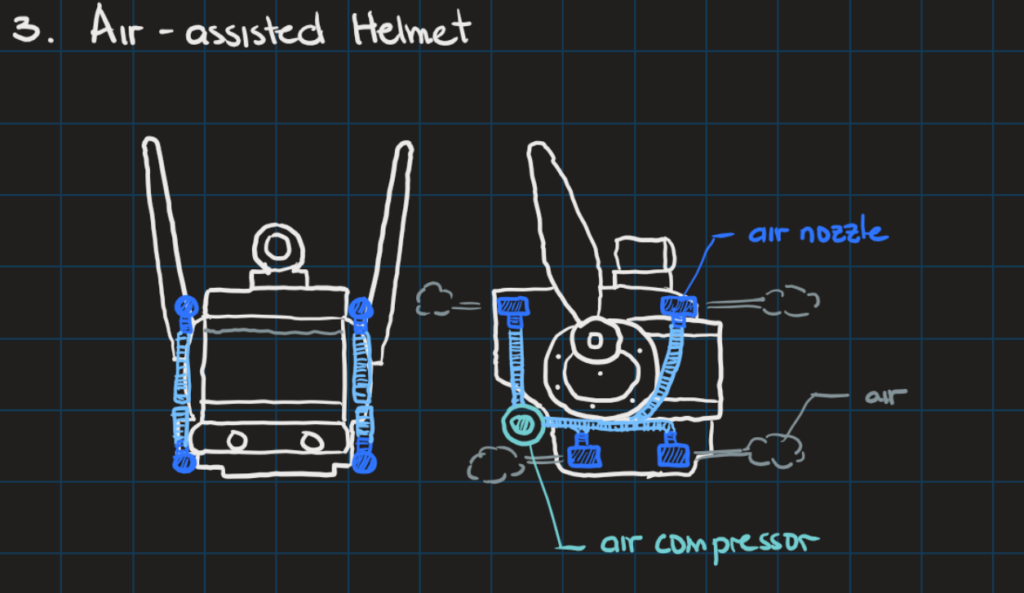

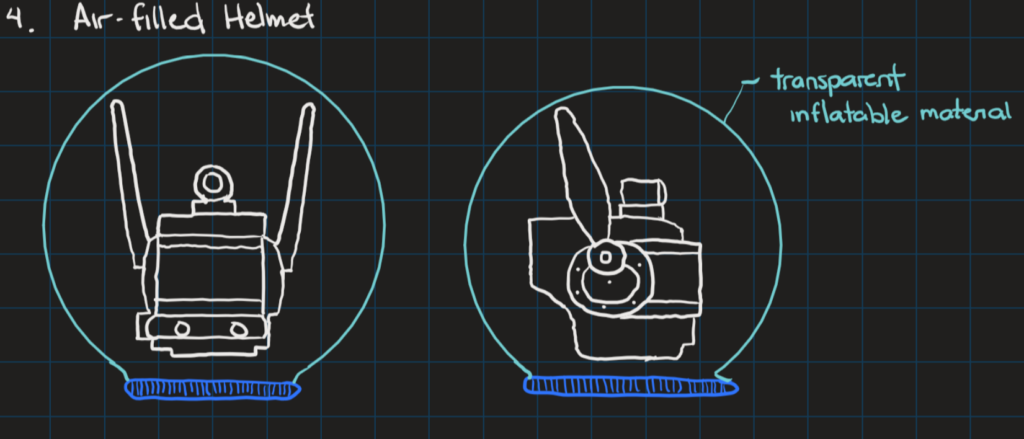

As the field of robotics evolves to produce increasingly more human-like robots, the robots begin to have more human-like problems.

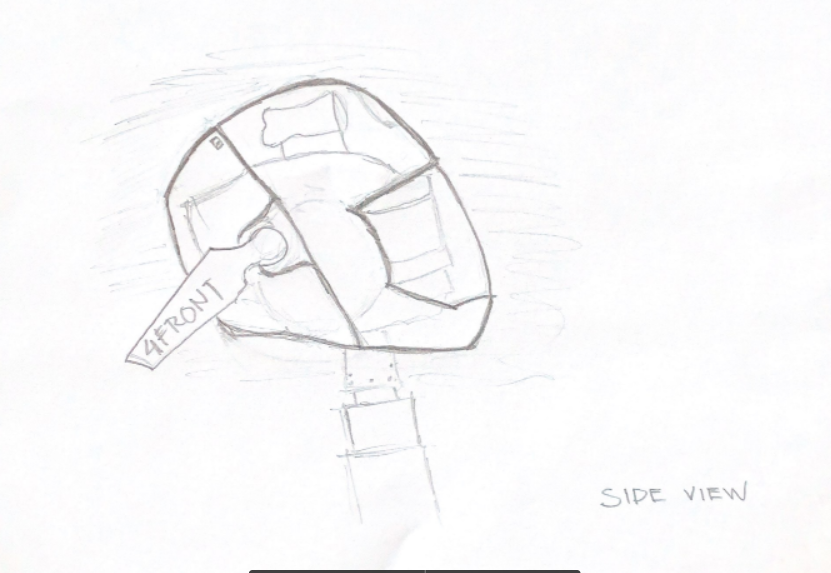

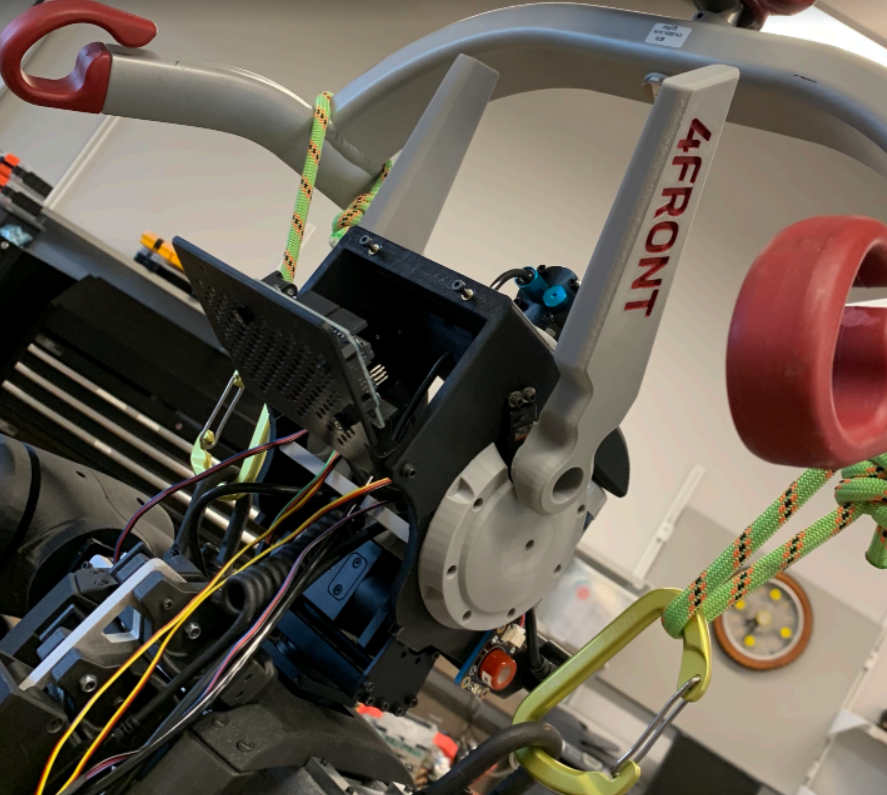

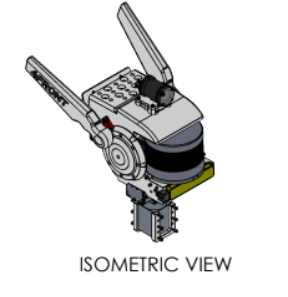

The ‘muse’ of our project is an existing humanoid robot that has been developed by Dr. Alex Ramirez and his team in the UofC Robotarium. This humanoid was conceptualized to aide in disaster search and rescue missions that prove dangerous to humans. Not unlike a human, the most vital area of this humanoid’s body is it’s head. Many of the sensitive and fragile equipment is localized to the skull area, which is susceptible to damage if the robot trips or is bumped.

Helmets were invented to protect the heads of people, and because the robot in question resembles a person, it only makes sense to protect it’s head in the same way.

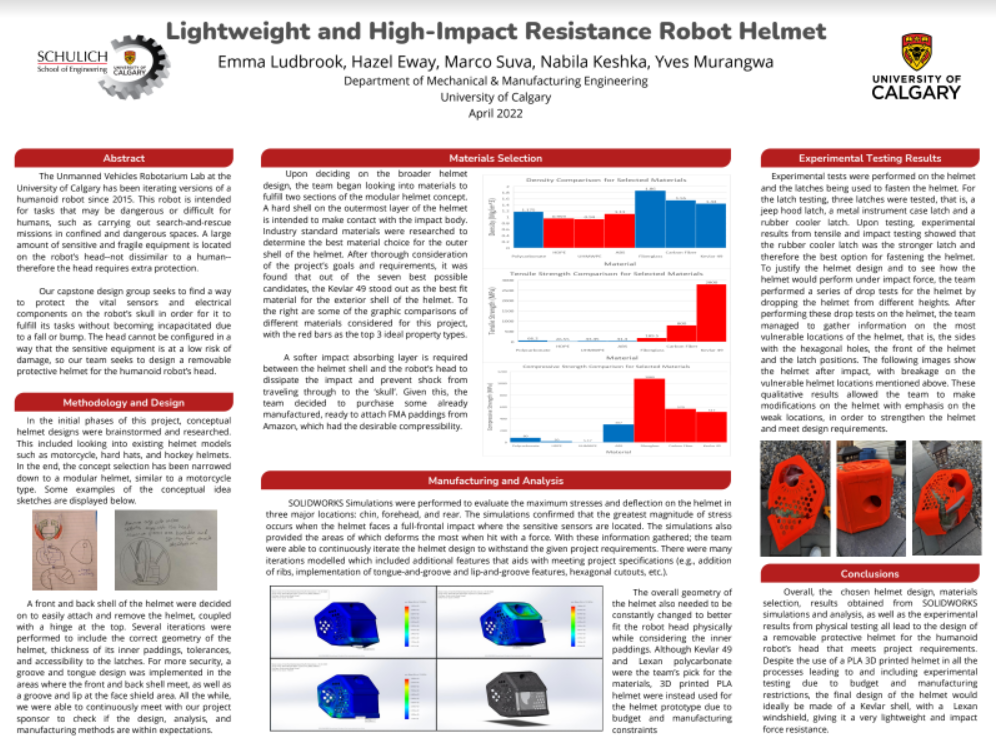

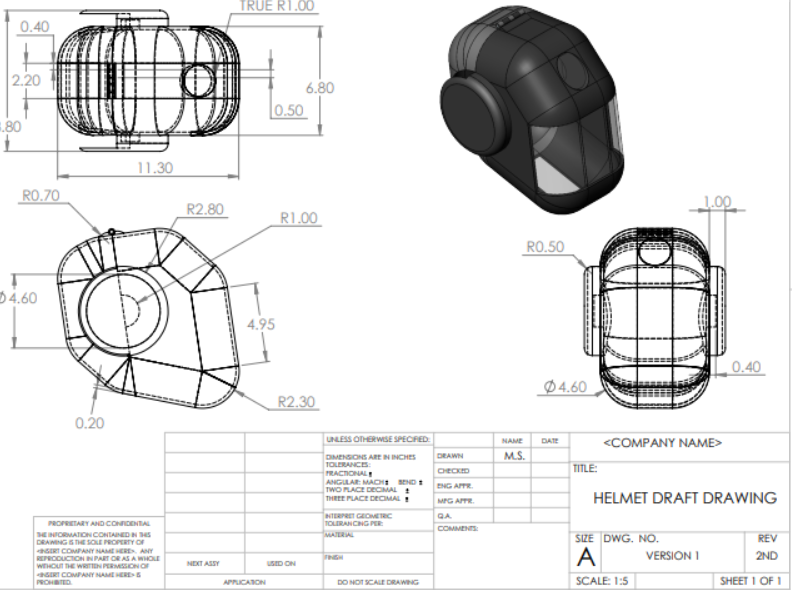

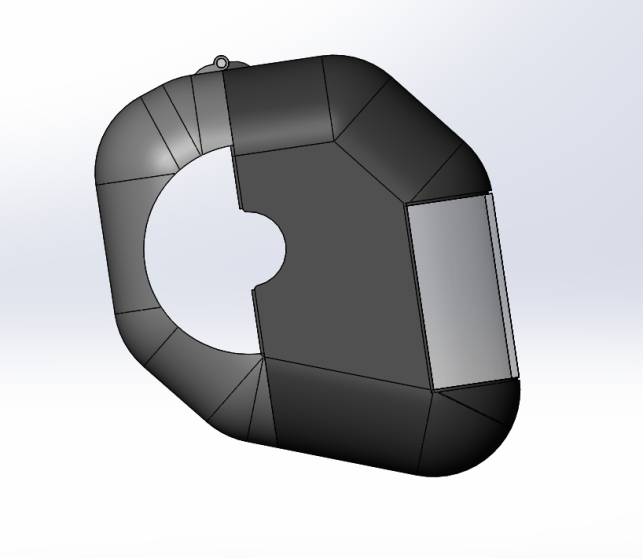

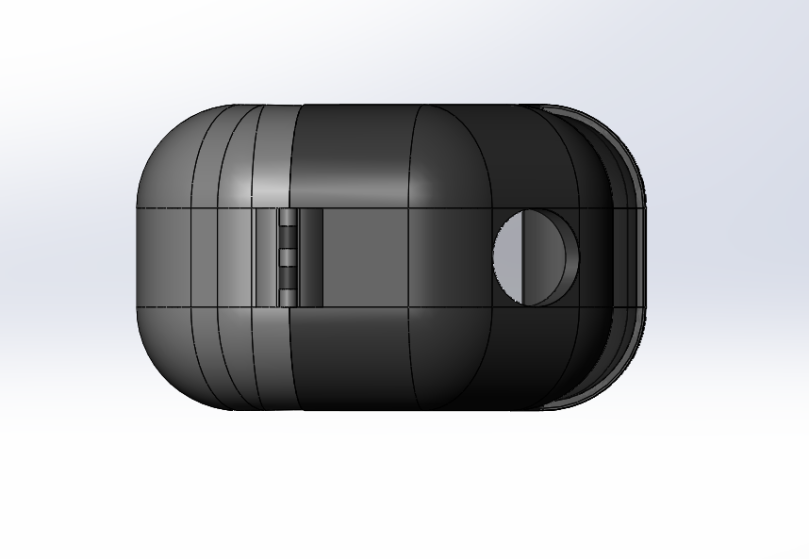

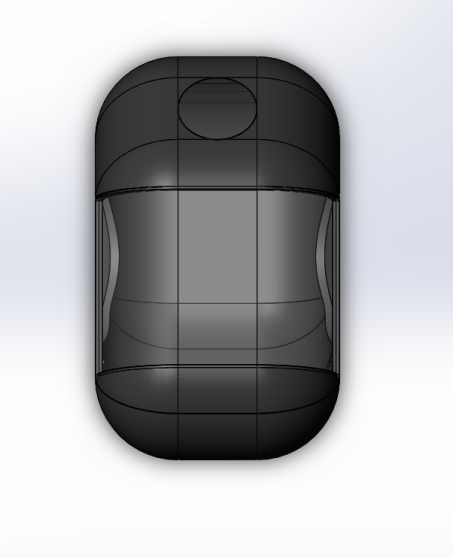

The RoboCap is a helmet that our team has custom designed for the search and rescue humanoid from scratch. It is lightweight, strong, is able to be removed swiftly, and is easily reproduced in the event it becomes damaged

View our video here:

Meet our team members

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

Without our helmet design, the humanoid will run a high risk of damage during normal operation. If the robot were to fall and damage some of the equipment on its skull, it could potentially cost thousands of dollars. Implementing the use of a helmet when the robot is in use significantly reduces the risk of sensitive equipment being damaged, and therefore costing money that could otherwise go towards improving the robot. It is much cheaper for the helmet to become damaged than any other part of the robot.

WHAT MAKES OUR DESIGN INNOVATIVE

The innovation in our design lies in the manufacturing. As our helmet is currently only a prototype, it still has to be finalized. The final stage of our production however, will include a 3D printing of the helmet in Kevlar due to its strength and low weight. This is particularly innovative because most helmets are made through injection molding, which has an extremely high upfront cost and is only economically viable in instances of mass production. Being able to 3D print in Kevlar means that the production is quick and cheap relative to alternatives. It also guarantees that the Robotarium team will be able to print and reprint our design as necessary as the helmet wears.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

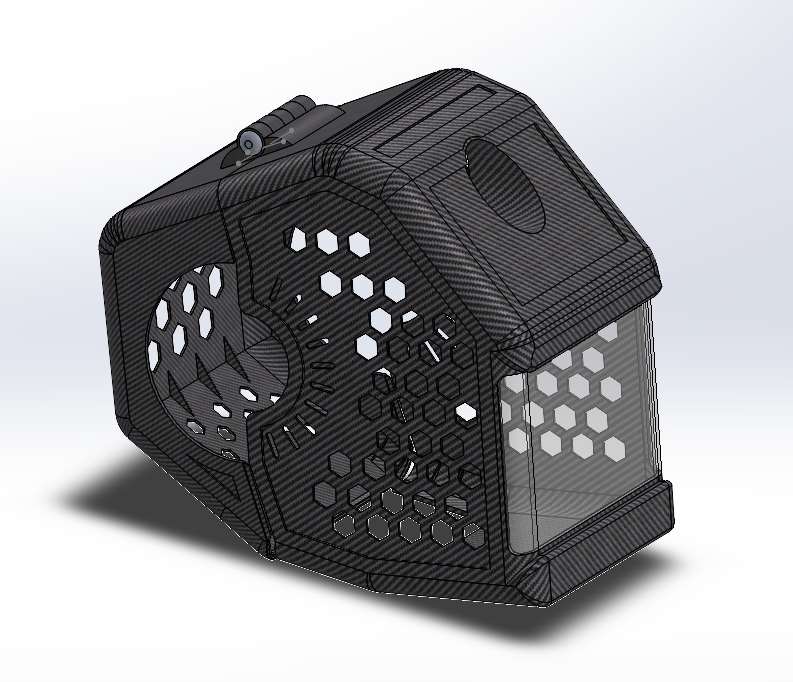

The design we have created will be effective because it includes a soft inner padding similar to a bike helmet, and strong, hard outer shell. The padding absorbs shock and prevents the skull from meeting a hard surface at a high velocity. The padding works in tandem with the outer shell that makers initial contact with the impact surface and maintains its shape while dispersing the impact force over a large surface area

HOW WE VALIDATED OUR DESIGN SOLUTION

Through a series of iterations and tests we were able to validate our design. We implemented impact and stress testing on SolidWorks periodically to identify weak points of the design while adjusting to meet our other requirements. The weight requirement demanded major changes from our original base design and we ended up punching hexagonal holes in the helmet to reduce weight. Ideally physical tensile and impact testing of the Kevlar Helmet would occur, but time constraints did not permit us to print and test our final Kevlar version. We did however tensile and impact test the latches, and compression tested a hockey helmet to observe generalized failure points and relative material strength. A PLA printed version of the final helmet design was also drop-impact tested at a height and weight adjusted to reflect the relative strength of Kevlar vs. the PLA.

FEASIBILITY OF OUR DESIGN SOLUTION

Our design solution is extremely feasible given the accessibility of the Kevlar 3D printer in the science shop at the university. The Robotarium has the ability to commission this print at any time given the final 3D model provided to them

Partners and mentors

We want to thank all those who were involved in the conception and execution of this project. We had many advisors including Dr. Eggermont. Dr. Epstein, the employees of the science shop, Sean Mason of the Makerspace, and our T.A. Tom. We would like to especially thank our project sponsor Dr. Alex Ramirez for his trust in us as well as his invaluable advice and guidance.

Our photo gallery

References

[1] P. Karia, “Who invented the helmet and what is it made of?,” The Times of India, 05-Jun-2010. [Online]. Available: https://timesofindia.indiatimes.com/who-invented-the-helmet-and-what-is-it-made-of/articleshow/6016026.cms. [Accessed: 06-Nov-2021].

[2] D. A. Ramirez-Serrano, “ Design of a lightweight and high impact resistance helmet for a humanoid robot.” University of Calgary, Calgary, 2021.

[3] “Four-bar linkage,” Wikipedia, 24-Nov-2021. [Online]. Available: https://en.wikipedia.org/wiki/Four-bar_linkage#/media/File:Grashof_Type_I_Four-Bar_Kinematic_Inversions.gif. [Accessed: 10-Dec-2021].

[4] Callister, W.D., and Rethwisch, D.G., (2009) “Materials Science and Engineering: An Introduction” (8th ed.). La Habana: Editorial Felix Varela.

[5] “Thermoplastic,” MakeItFrom.com, 30-May-2020. [Online]. Available: https://www.makeitfrom.com/material-properties/Ultra-High-Molecular-Weight-Polyethylene-UHMW-PE/. [Accessed: 10-Dec-2021].

[6] Wilmington, D.E., (1992) “Kevlar Aramid Fiber: Technical Guide.” Dupont.

[7] “Online materials information resource,” MatWeb. [Online]. Available: http://www.matweb.com/reference/compressivestrength.aspx. [Accessed: 10-Dec-2021].

[8] “UHMW (ultra high molecular weight polyethylene),” Poly. [Online]. Available: https://www.polytechindustrial.com/products/plastic-stock-shapes/uhmw-polyethylene. [Accessed: 10-Dec-2021].

[9] “Mechanical properties of carbon fibre composite materials, fibre / epoxy resin (120°C cure),” Mechanical Properties of Carbon Fibre Composite Materials. [Online]. Available: http://www.performance-composites.com/carbonfibre/mechanicalproperties_2.asp. [Accessed: 10-Dec-2021].

[10] “Lexan® polycarbonate, unfilled … – professional plastics.” [Online]. Available: https://www.professionalplastics.com/professionalplastics/MachineGradePolycarbonateDataSheet.pdf. [Accessed: 10-Dec-2021].

[11] “(pdf) influence of layer thickness and raster angle on the mechanical properties of 3D-printed peek and a comparative mechanical study between Peek and ABS,” ResearchGate. [Online]. Available: https://www.researchgate.net/publication/282389395_Influence_of_Layer_Thickness_and_Raster_Angle_on_the_Mechanical_Properties_of_3D-Printed_PEEK_and_a_Comparative_Mechanical_Study_between_PEEK_and_ABS. [Accessed: 10-Dec-2021].

[12] K. P. R. K.K. Herbert Yeung, “Mechanical properties of kevlar-49 fibre reinforced thermoplastic composites – k.k. Herbert Yeung, K.P. Rao, 2012,” SAGE Journals. [Online]. Available: https://journals.sagepub.com/doi/10.1177/096739111202000501. [Accessed: 10-Dec-2021].

[13] “Mechanical properties of glass fiber reinforced polyester composites: Request PDF,” ResearchGate. [Online]. Available: https://www.researchgate.net/publication/318599258_Mechanical_properties_of_glass_fiber_reinforced_polyester_composites. [Accessed: 10-Dec-2021].

[14] M. Margolin, “Hedgehog spines hold the secret to preventing concussions,” Inverse, 29-Dec-2016. [Online]. Available: https://www.inverse.com/article/25760-hedgehog-spine-quills-hedgemon-helmet-concussion. [Accessed: 10-Dec-2021].

[15] WhiteDogBikes, “Inside a motorcycle helmet – whitedogbikes blog,” White Dog’s Motorcycle Blog, 05-Aug-2018. [Online]. Available: https://www.whitedogbikes.com/whitedogblog/inside-full-face-motorbike-helmet/. [Accessed: 10-Oct-2021].

[16] Serrano, A.R., and Egberts P., (2021) “Interim Report Instruction,” University of Calgary, Department of Mechanical Engineering, pp. 1-3.

[17] Serrano, A.R., and Egberts P., (2021) “ICR Instruction,” University of Calgary, Department of Mechanical Engineering, pp. 1-3.