Project Category: Mechanical

Please join us!

April 13th, 2021 at 10:00 am to 1:00 pm MDT

About our project

Modern residential houses use regular air vents that permit heating or cooling airflow to designated areas upon the operation of the house’s HVAC system. These vents are typically manually operated: there is no automated system that will activate the vent to open or close its louvers. Also, as a standard HVAC system runs airflow openly for all hours of the day, it uses heating and cooling loads on operating hours that are typically not desired by homeowners who are interested in saving energy and cost.

The goal of this project was to investigate how smart vents can be used to provide an automated system for homeowners to open and close air vents, and to have schedules outlining the desired temperature of certain rooms at specific times. This is to say that for different members of a residential household, each member can configure the vents in their rooms to automatically provide heating or cooling. This system would allow for more comfortable living, while ensuring that energy costs are saved annually.

Our project focused on the redesign of a vent that allows for electronic actuation, a control system (including smart control), and the modelling of a 2-storey residential house in Calgary to perform energy simulations on.

Meet our team members

David Jacob

I am a final year mechanical engineering student at the University of Calgary. Over internship, I spent 20 months working in project management and construction management, helping manage an assortment of projects. I am looking forward to using my skills to assist in future roles, while gaining more hands-on experience in the industry. In my spare time, I like to play soccer, read, and spend time with family and friends.

Jaden Riggins

I am a final year mechanical engineering student at the University of Calgary. I spent 24 months on internship working in project management and estimating working on 5 projects in the field and bidding on many more; including one project award for a bridge in Calgary. In my free time I enjoy skiing, hiking, watching sports, and trying as many new restaurants as possible.

Marc Salib

I am a final year mechanical engineering student at the University of Calgary. I have been working at MGA Engineering for the last two years where I have specialized and worked on material handling and mechanical conveyor systems which includes designing, flow testing, and site mechanical inspections. In my free time, I tend to play basketball, snowboard, or golf.

Emery Tetreault

I am a final year mechanical engineering student with a strong interest in mechanical design/testing as well as data analysis. I completed a year long internship at Verity Studios in Switzerland where I had to opportunity to work with autonomous drones designed for the live events industry as a field support engineer. During my free time, you can find me out in the mountains skiing or climbing as well as coaching ski racing.

John Marquez

I am a 4th year Mechanical Engineering student in UCalgary with a previous Mechanical Engineering Technologist diploma from SAIT. Currently, I work in TransAlta as the Mechanical Engineering Intern for the wind fleet, assisting the Mechanical Engineer and the Technicians in operation and maintenance procedures and standards. Outside of academics and building my career, you’ll usually find me designing my own mechanical keyboards and scrambling up the Canadian Rockies for the views.

Shamail Goraya

I am a final year mechanical engineering student. I completed a year long internship with Nanalysis Corp. as a Magnet R&D intern, where I have directly assisted their Product Development team in helping them build their new and current Benchtop NMR instruments. In my spare time, I read books, try to learn new things, and spend time with family and friends.

Salman Cheema

I’m a 4th year Mechanical Engineering student. Having worked with reliability and materials at Suncor, I have 2 years of field experience that I plan to build on after graduation. I spend a lot of time reading and researching anything of interest.

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

Current vents (also known as “air registers”) only provide manual control to adjust airflow within rooms. This is inconvenient for a user as they are forced to physically adjust individual vents to reach comfortable temperature levels. Typically, air vents are just left in the open position and are never adjusted as they can often be placed in hard-to-reach places. As a result, energy that goes into heating a home is wasted. Our vent design incorporates principles of smart technology to allow a user to control all vents in their home, increasing convenience, lowering energy consumption, and maximizing energy savings.

WHAT MAKES OUR DESIGN INNOVATIVE

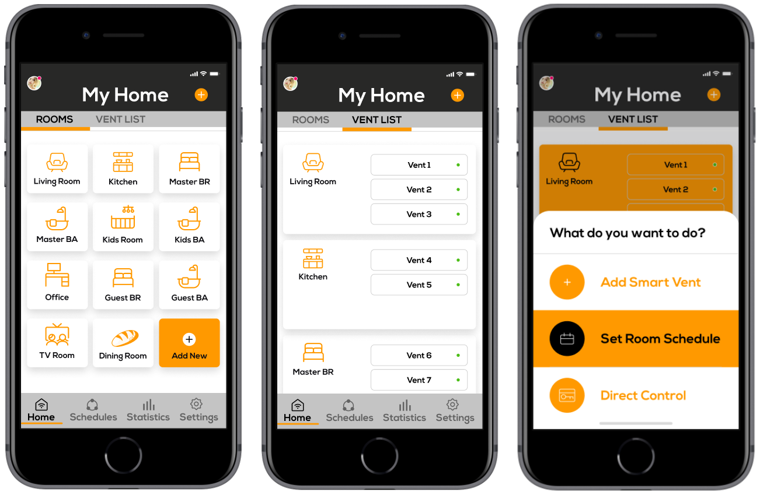

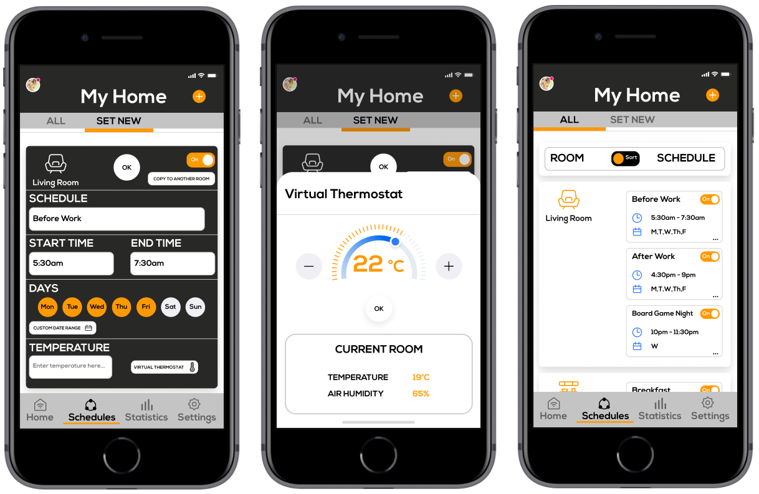

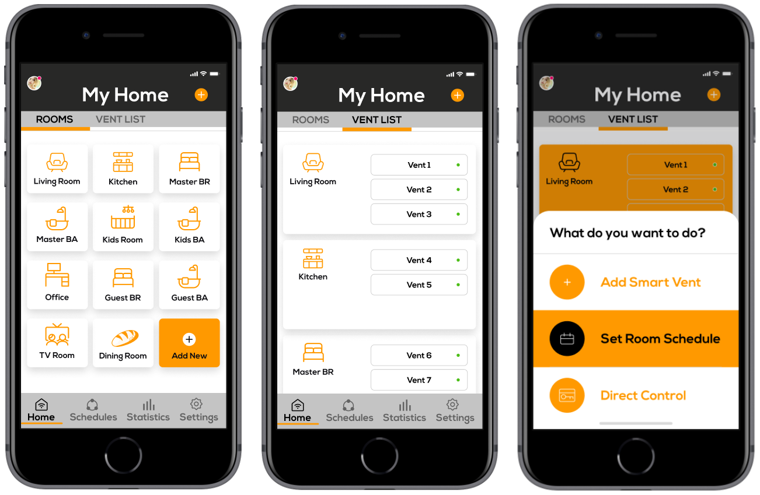

Compared to a standard vent, our vent design employs the use of electronics and a wireless connection to control the temperature and airflow within individual rooms of a house. The addition of a control system in the vent allows for the user to set scheduled operations that enables control of the temperature of the room that particular vent resides in. As the vent’s control system can be controlled autonomously to adjust for the user’s preference, the system may also control the individual room temperatures to optimize energy savings. There are other smart vents that currently exist in the market. Our design focuses on the vent, with no external sensors or peripherals required, in conjunction with a mobile app (UI prototype).

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

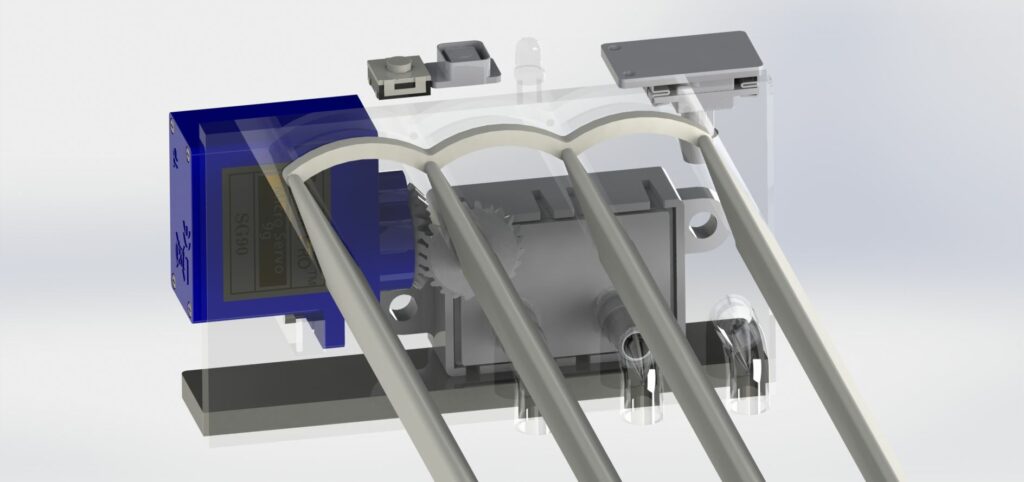

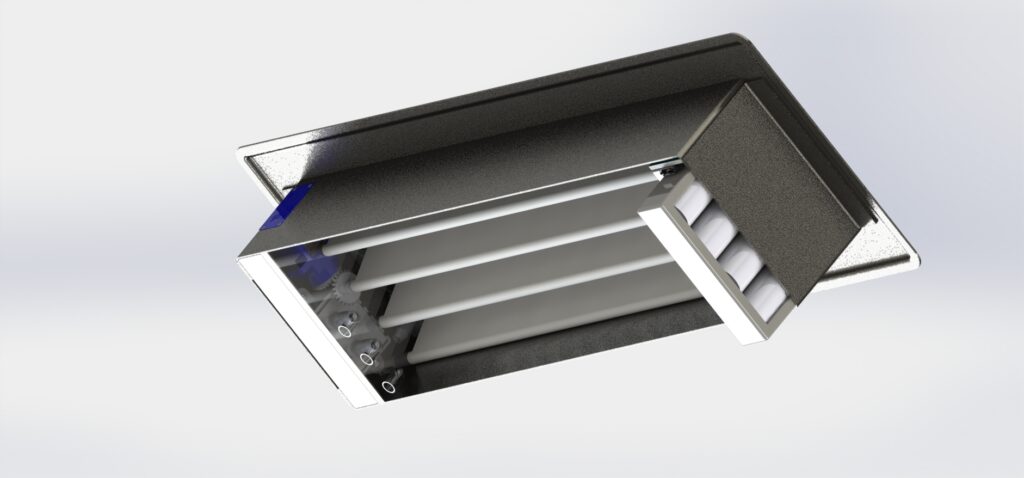

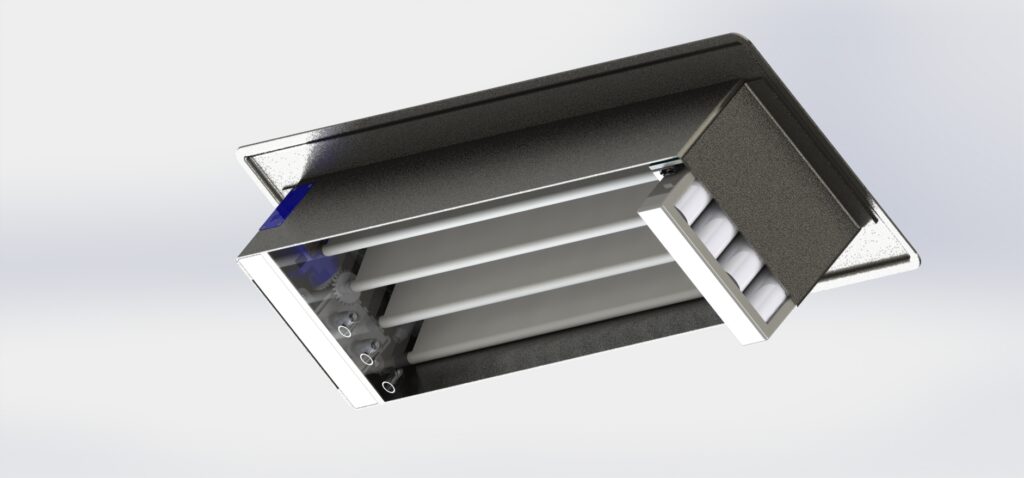

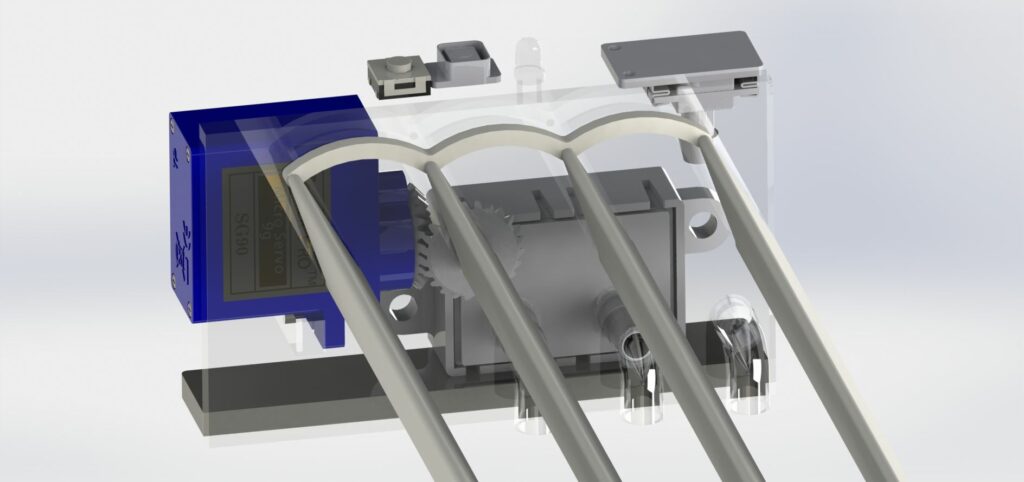

What makes our design solution so effective is the combination of many small design choices that allowed for the smart vent to achieve a 20% reduction in annual energy cost. Some of the key design choices have been listed below. The vent has a low power consumption (from a mechanical and control system perspective) as the vent utilizes 4 AA batteries, which provides an approximate battery life of 2 years. AA batteries were selected as they are readily available for consumers. In order for the control system to function correctly small, highly accurate, and low voltage sensors (temperature/humidity, pressure, mass airflow) are used in conjunction with an Arduino microcontroller to fit a standard vent size of 4”x10”. Components were fitted carefully while maintaining a good quality of airflow. The selected standard size ensures larger vent sizes would perform equally or better than a standard air register. The Arduino (Pro Micro) controller was selected due to its small footprint, onboard voltage regulator, capability to accommodate input from different sensors, and because the Arduino development environment allows for easier programming. The actuation louver mechanism uses a 1-pin assembly to open and close the vent to regulate airflow. This method is simpler than alternatives and efficiently regulates airflow while being lightweight, durable, and while consuming less power.

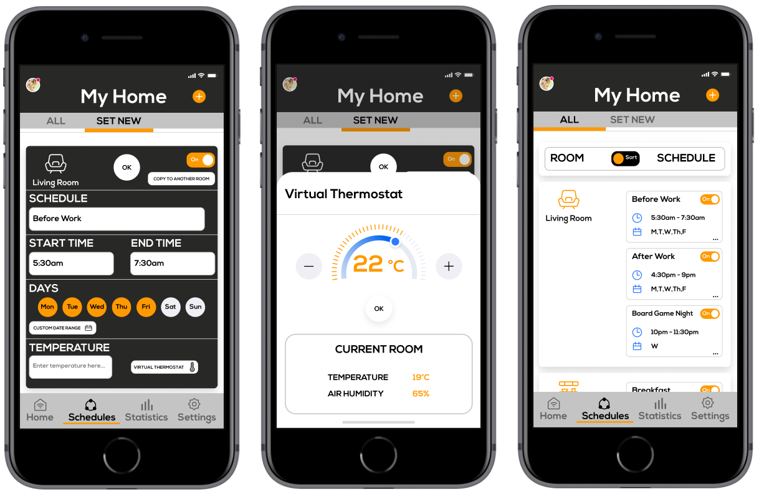

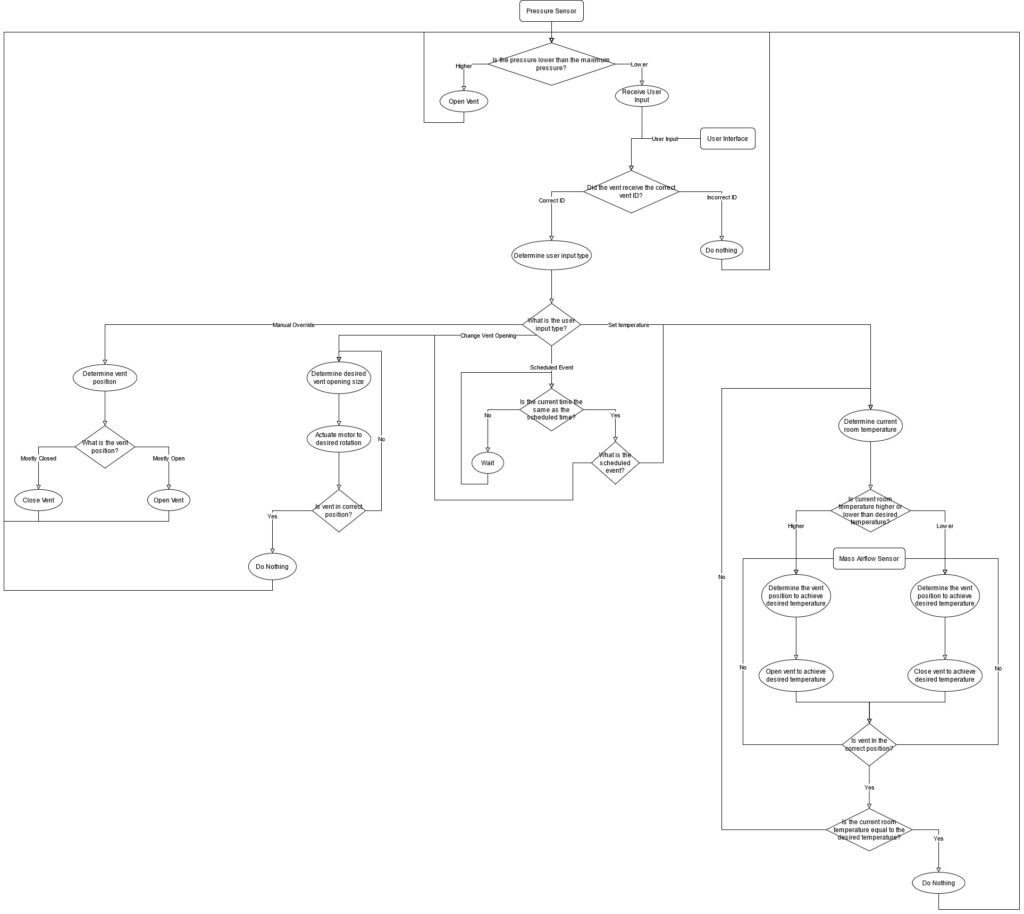

The control system accepts user input for scheduling purposes via a user interface (such as a mobile app), allowing a user to set a temperature for each vent location. Alongside scheduling, the control system provides direct control through the user interface for each vent. The smart vent also has a physical button to allow for manual operation. The vent communicates wirelessly with all vents in a home, utilizing Bluetooth or Wi-Fi signals. A Cloud platform application is required to connect all smart vents, and exchange and store data. A proof of concept user interface was created to demonstrate the possible functionality of the vent.

The control system has a high-pressure alarm for safety purposes. If the maximum pressure threshold is crossed, the system will relieve pressure by simultaneously opening all vents until the pressure returns within a safe operating range. The system will assume its previous state once completed. A flow chart for the control system of the vent was designed in order to demonstrate the logic behind the smart functionality.

HOW WE VALIDATED OUR DESIGN SOLUTION

Our design solution was validated through two methods: Air Register Simulations and Energy Simulations.

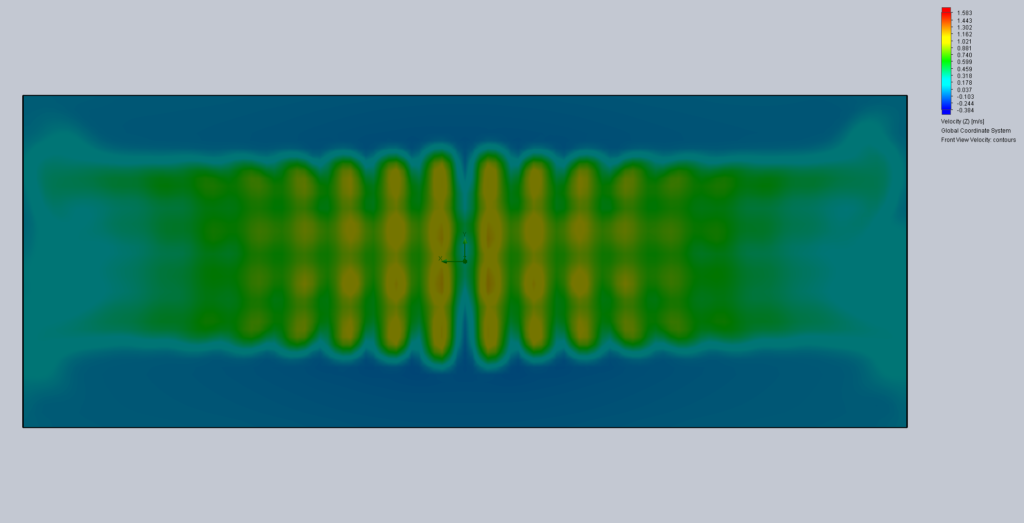

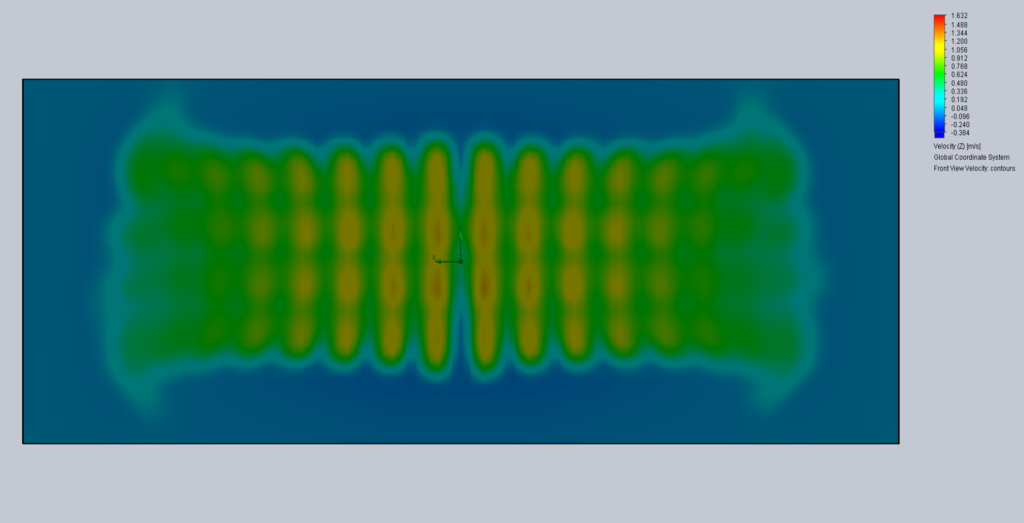

For the air register simulations, a model without electrical components was created first to serve as a baseline to compare the performance of our smart vent. SolidWorks simulations were run for the vent in both open and closed positions to determine how the vent operates. Design changes were made through this iterative process. One of the goals was to maintain 90% of standard vent output. This goal was set at the start of the project to ensure our smart vent did not hinder the airflow of the vent. These airflow simulations allowed for confirmation that the goal was met. In addition, a motion study was conducted via SolidWorks to determine energy and torque requirements for the internal motor, which allowed us to determine that the vent has an approximate battery life of 15-24 months.

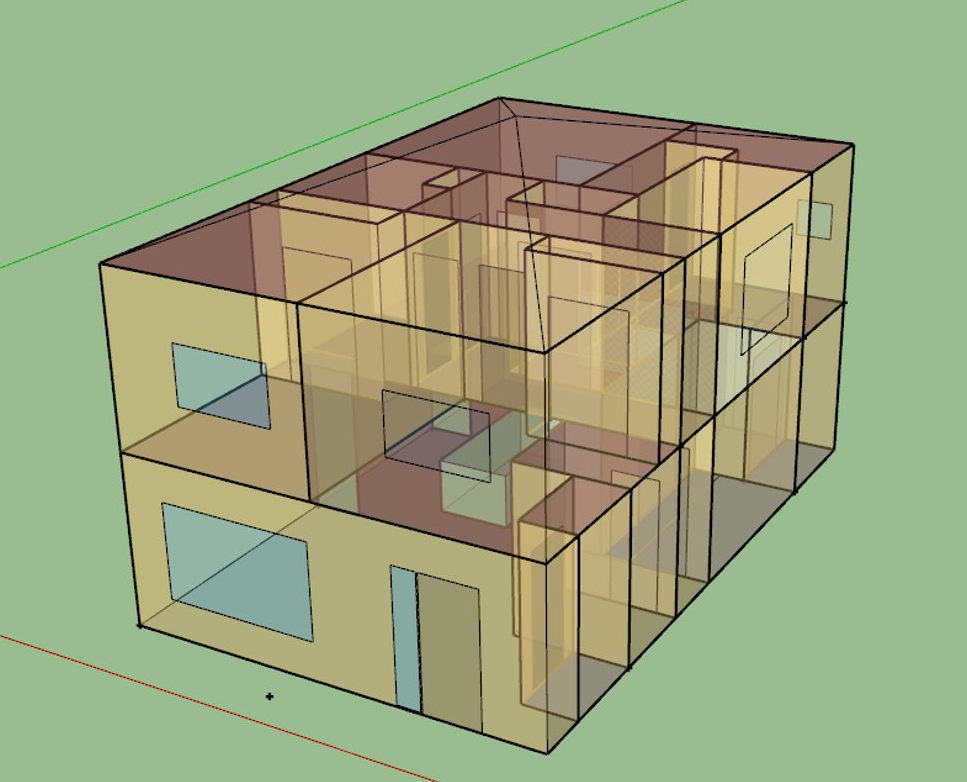

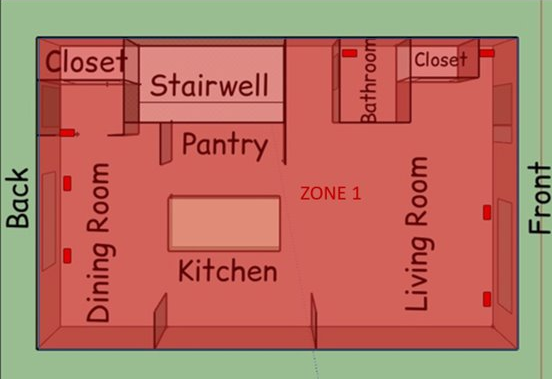

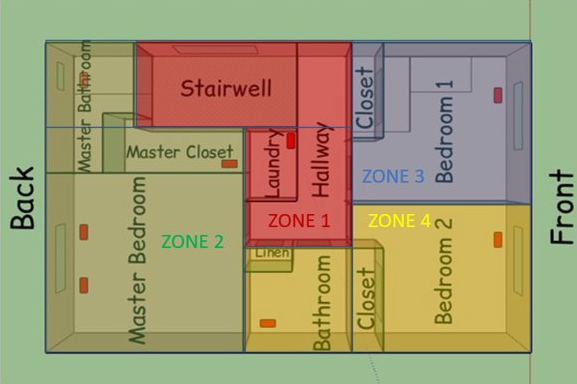

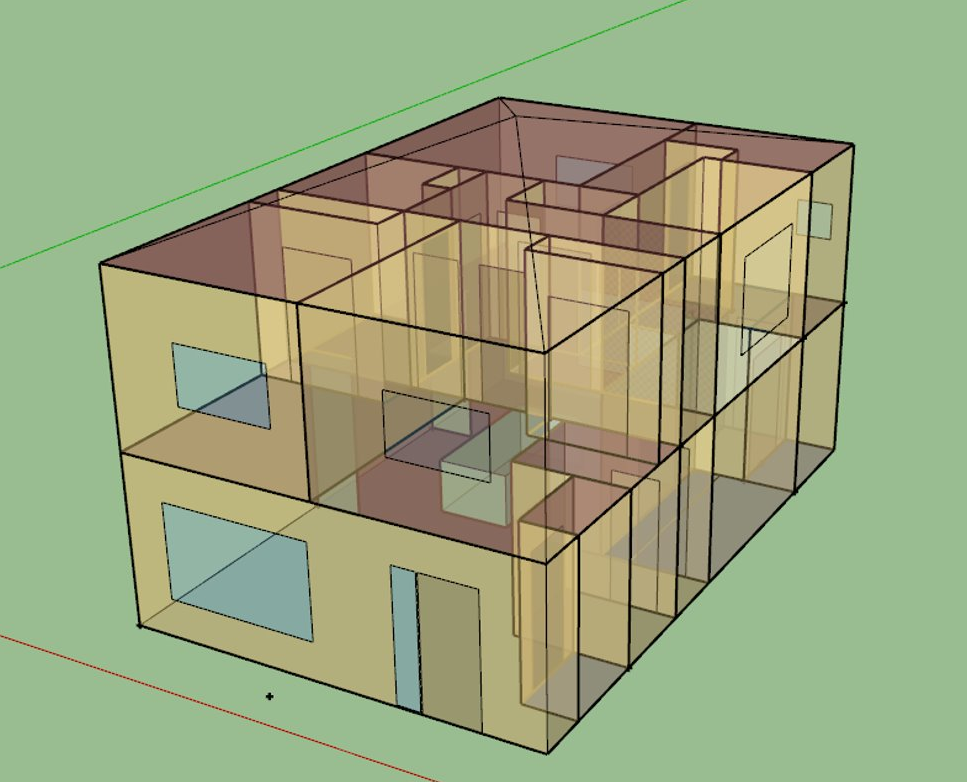

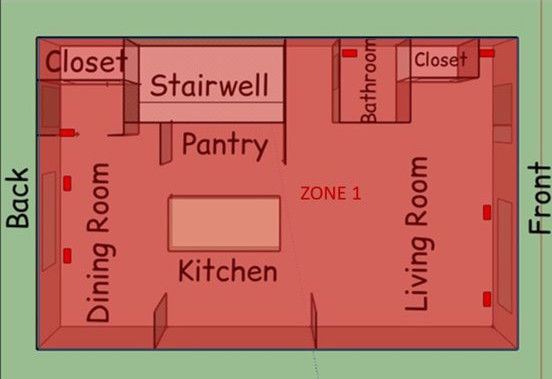

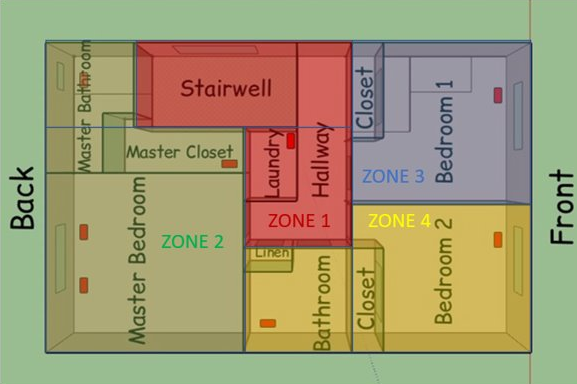

As for the energy simulations, after research was conducted, a typical residential house in Alberta was modeled. A 2-story, 1496 ft2 house, with 3 bedrooms was constructed in Sketchup/Open Studio. Construction materials for the house were specified through the number of layers and thermodynamic properties of each material. The house model was composed of several different thermal zones that operated differently (to mimic the individual control of the smart vents that are acting independently from one another). Based on typical vent guidelines and research, 15 smart vent locations were identified on the floor plans.

Annual weather data for Calgary was used to create a baseline scenario for simulations. More complex schedules were developed based upon different living configurations for a typical family. Multiple different scenarios were considered for the household members (i.e. couples living together, roommates with different jobs, and so on). We also considered temperature preferences ranging from cold to warm, covering as much variability as possible.

| Scenario | Living Arrangement |

|---|---|

| 1 | Working family: 2 working parents and 2 kids in school |

| 2 | Typical family: 1 working parent, 1 stay at home parent, 2 kids in school |

| 3 | University Roommates: 3 roommates with varying schedules |

| 4 | Couple without kids: 2 working adults |

| 5 | COVID-19 family: all family members at home |

| Scenario | Away Temperature | At Home Temperature |

|---|---|---|

| 1 | 16 | 20 |

| 2 | 18 | 22 |

| 3 | 20 | 24 |

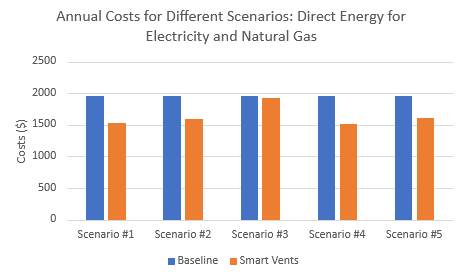

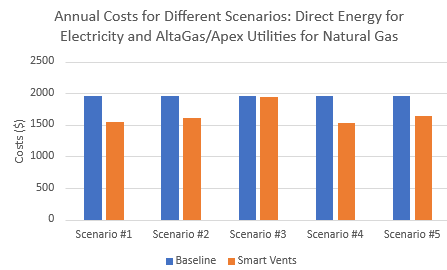

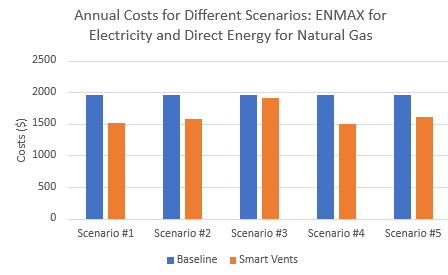

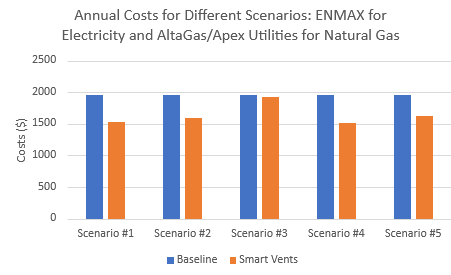

The results of our energy simulations gave us the monthly and annual energy consumption for each case, which we then translated into total costs by multiply the energy loads with the energy rates per unit of energy consumption. We did this for different energy providers (Direct Energy, ENMAX, and AltaGas/Apex Utilities) for the electricity and natural gas rates reported by the Alberta Utilities Commission (AUC) in the last three years. With all these results, we averaged them across all years and across all temperature preferences and added the total electricity and natural gas contributions together. We compared our final costs between a house with regular vents (baseline), and a house that is equipped with smart vent technology. The average energy consumption of a typical family using Smart Vents proved to be approximately 20% better (that is, they saved about 20% in their annual heating/cooling bill) than if the household was using standard vents. Therefore, we validated that smart vents will be able to reduce the energy consumption for heating/cooling, and showed that on average, across multiple scenarios, household members will generally be able to save up to 20% spending when it comes to their yearly energy bill.

FEASIBILITY OF OUR DESIGN SOLUTION

The feasibility of our solution is solely dependent on the total cost of the necessary vent in a home. Essentially, the total cost of the vents must be less than the annual energy savings accumulated over a reasonable time period. To calculate the maximum price for an individual vent, it was assumed that a standard home needs 15 vents. The cost of the vent will be calculated for a time period of 10, 15 and 20 years to make back the initial cost. It was calculated that the smart vents provide an annual savings of $400 dollars. The results were calculated for an annual interest rate of 2%, 3%, and 4%.

| Time Period (years) | Interest Rate | Total Cost of Vents | Individual Cost of Vents |

|---|---|---|---|

| 10 | 2% | $3,593.03 | $239.54 |

| 10 | 3% | $3,412.08 | $227.47 |

| 10 | 4% | $3,244.36 | $216.29 |

| 15 | 2% | $5,139.71 | $342.65 |

| 15 | 3% | $4,775.17 | $318.34 |

| 15 | 4% | $4,447.35 | $296.49 |

| 20 | 2% | $6,540.57 | $436.04 |

| 20 | 3% | $5,950.00 | $396.73 |

| 20 | 4% | $5,436.13 | $362.41 |

After calculating the present value of the energy savings, the vents must cost less than approximately $315 for the purchase of the vent to be economically feasible. The maximum cost of the vent will also change depending on many factors such as the number of smart vents required, external temperature, annual energy savings, and the schedule of the tenants.

Partners and mentors

We want to thank the many people who helped us with this project. Our mechanical engineering professor Dr. Simon Li was a huge help in providing us guidance throughout the duration of the project.

Our photo gallery