Project Category: Mechanical

Join our presentation

About our project

Through the development of technologies, machine becomes more advance which helps people to work smarter than harder. Automachines become one of the popular, efficient, fast effecting technologies that can save time, decrease of human error, and increase safety. However, there are still machines that requires humanwork instead of being fully automatic which lack of improvement.

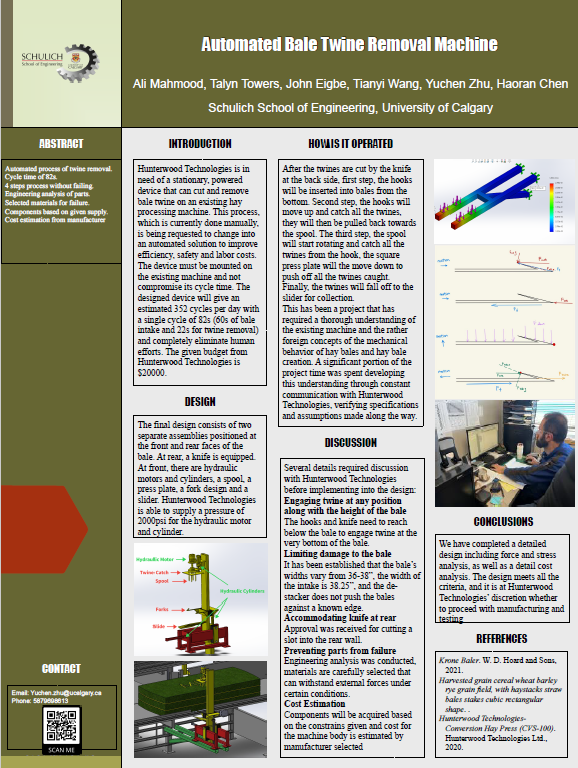

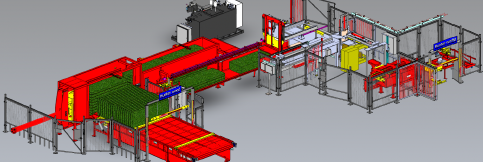

Hunterwood Technologies designs forage processing machines that will process the field bales into small, high-density packages for optimal export. However, the twines that hold the bales are currently removed manually. The objective of this project is to design an automated twine remover that can cut and pull away twines in a fixed time period per cycle. The result of this project will eliminate human effort and bring efficiency into the twine removal process.

Meet our team members

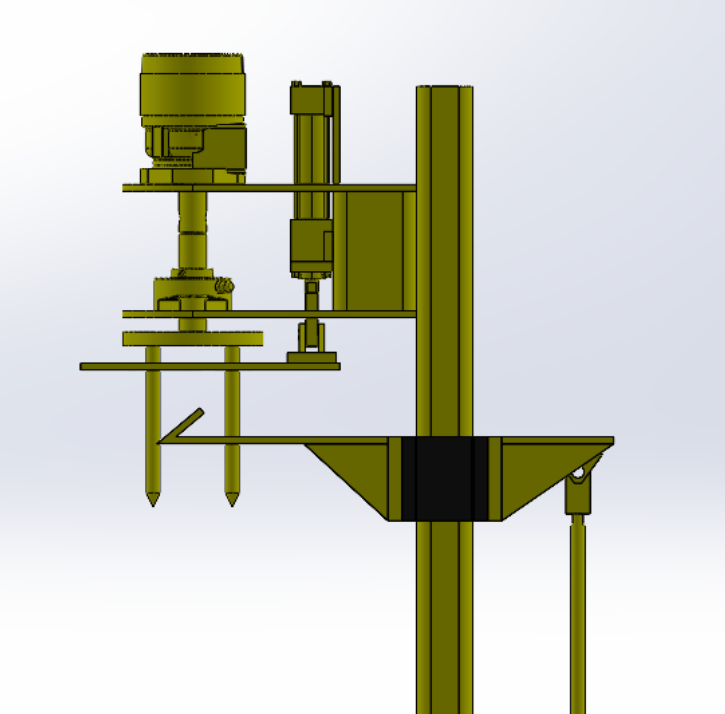

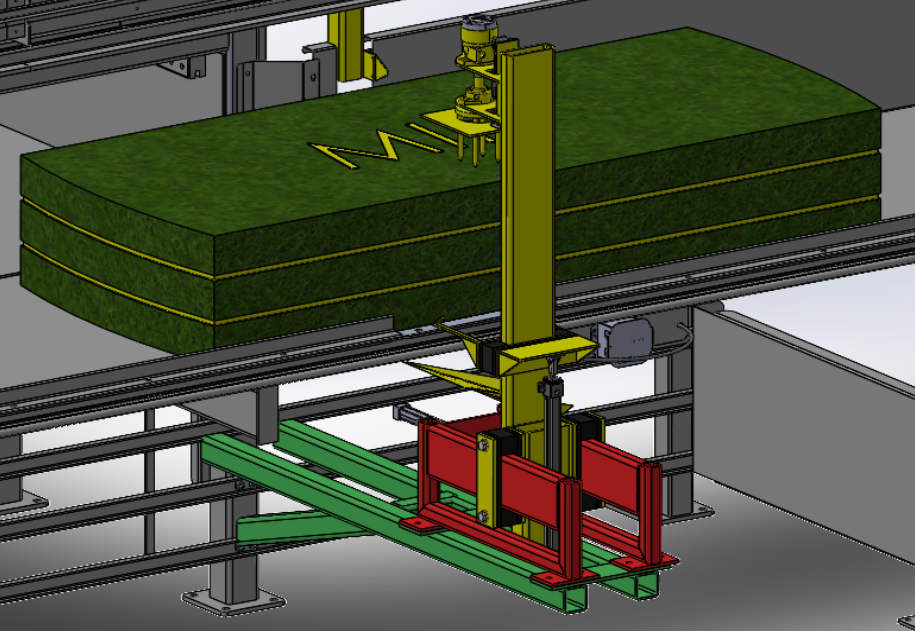

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

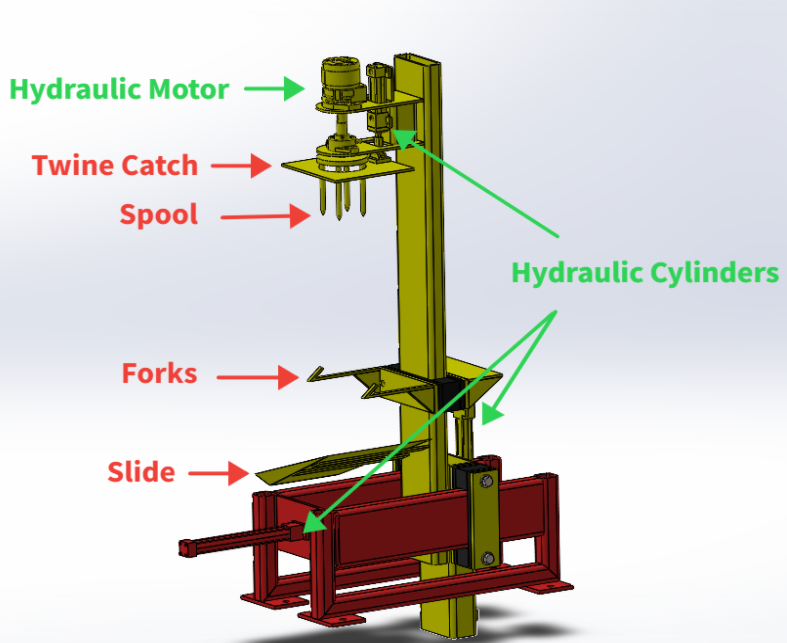

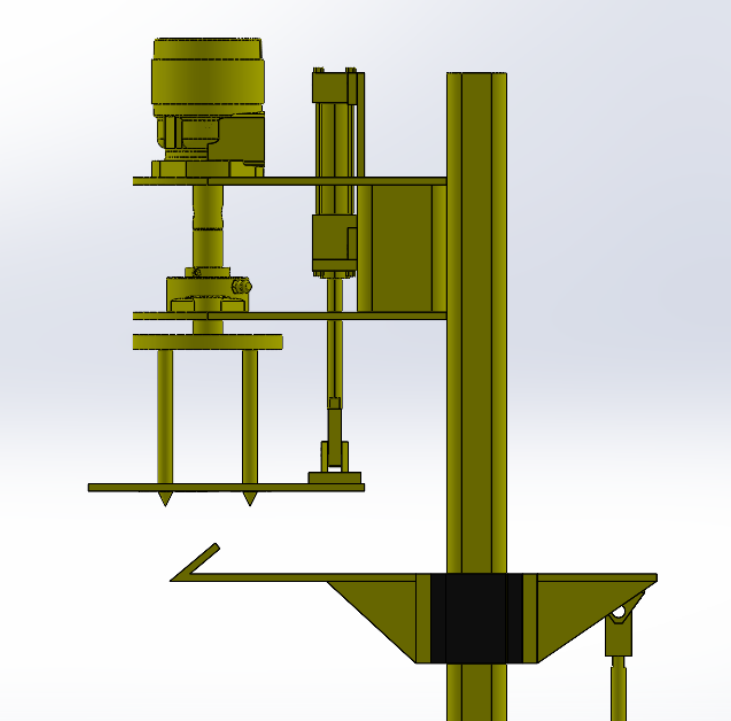

Our design addresses practical issues by inventing a device mounted to the existing hay processing machine – changing a manual process into an automated machine process. Once this process (cut and remove bale twine) becomes automated, it can eliminate human effort completely. By combining hay processing machine and our twine remover, the processing time of completing a work cycle will be fixed, this will significantly improve efficiency in workplace.

WHAT MAKES OUR DESIGN INNOVATIVE

The main factor that makes our design innovative is that once the machine is put into use, it can reduce company’s unnecessary labor cost. There will be no need to manually manage bales in workplace and to concern about worker’s safety issues because machines do it all. On the other hand, since the work cycle time is fixed, the company will be able to calculate a more accurate work output for further use.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

With the insert device mounted on the machine, twine removal cycle is designed to be 22 seconds, the intake cycle is approximately 60 seconds. This gives an estimated 352 cycles per day with no human labor involved. On the cost side, the minimum wage per hour to hire a worker is $15. Comparing the machine cost with labor cost, after a maximum of 167 days, the company will start to benefit from the machine with zero labor cost for the rest of the machine’s lifetime (approx. 10 years).

HOW WE VALIDATED OUR DESIGN SOLUTION

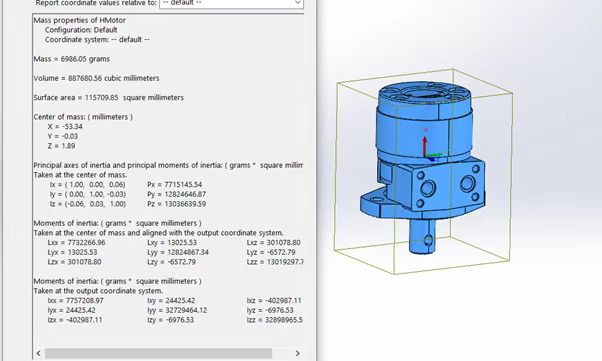

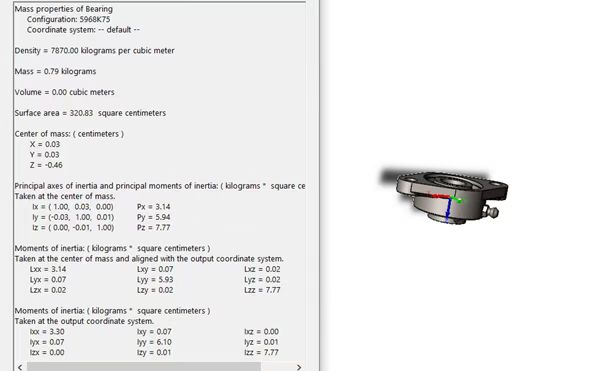

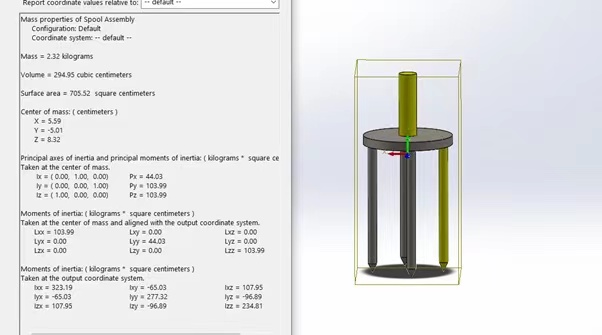

To validate the design solution, computer simulations and algorithms were utilized to optimize the twine removal machine design. To combine with the current hay processing machine in the workplace, dimensions of the processing machine are measured for determination of our twine removal machine dimensions. Stress analysis of design component using analyzing software is conducted for the durability of the final design.

FEASIBILITY OF OUR DESIGN SOLUTION

This project demonstrated that it is feasible to cut and remove bale twines in a hay handling process. We were able to have the opportunity to discuss our project with our sponsor—Hunterwood Technologies for designing and making improvements. The current design is still a conceptual design, but Hunterwood Technologies gave us positive feedbacks on the design solution and how it could benefit the company. It will be at the discretion of Hunterwood Technologies whether or not to proceed with prototyping and manufacturing

Partners and mentors

This project would not have been possible without the continual support received from several individuals.

The team would like to thank Hunterwood Technologies, specifically Mr. Talha Siddiqi, for the extensive guidance and constant feedback, as well as for providing all necessary information and specifications regarding the project.

The team is also grateful to Dr. Paul Tu and Dr. Deyi Xue of the Department of Mechanical and Manufacturing Engineering of the University of Calgary. Their expertise in the manufacturing industry has been invaluable to the success of the project.

Lastly, we would like to thank Dr. Philip Egberts and Mr. Danny Wong for overseeing the project and providing necessary feedback for the improvement of the team as a whole.

Our photo gallery

References

- Krone Baler. W. D. Hoard and Sons, 2021.

- Harvested grain cereal wheat barley rye grain field, with haystacks straw bales stakes cubic rectangular shape. .

- Hunterwood Technologies- Conversion Hay Press (CVS-100). Hunterwood Technologies Ltd., 2020.

- J. R. McAfee, K. J. Shinners, and J. C. Friede, American Society of Agricultural and Biological Engineers, St. Joseph, Michigan, rep., 2018.

- Continental Western Corporation, 2016 Ag Catalog-Gloves. Continental Western Corporation, Tukwila, Washington, 2018.

6. Small bale alfalfa from The Gombos Company flakes apart naturally and easily. Natural Press Fresh Flake™. The Gombos Company.