Project Category: Mechanical

Join our presentation

About our project

Autonomous Guided Vehicles, or AGVs, are an exciting and emerging technology in the world of manufacturing. The main task of an automated guided vehicle is to transport and store inventory items in a large facility such that it supports the organization’s inventory management. With increasing interest in improving manufacturing process efficiencies, it has become necessary to implement these innovative technologies. AGVs provide inventory management capabilities with increased productivity, reliability, material handling, safety, and economic feasibility.

Our team wanted to do research on the control systems that are behind these automated vehicles to determine which type of control system provides more stable and consistent operations. Currently, two of the most popular control systems used in the industry are Conventional Control System (Proportional Integral Derivative) and Artificial Intelligence Control System (Machine Learning).

The main goal of this project is to evaluate the vehicle accuracy, productivity, obstacle avoidance, and system operations for each control system. For quantitative measurement, the AGV will be put in a test course that will resemble the setup of a manufacturing facility. This project will explore the benefits of each approach and tests the accuracy of each based on detecting, positioning, and organizing of materials. Each method will be implemented using the latest trend algorithms and innovative solutions to manage inventory. The findings will present which control logic is more effective in improving the net efficiency and economic feasibility.

Project Budget: $500

Team Members

Syed Rizvi

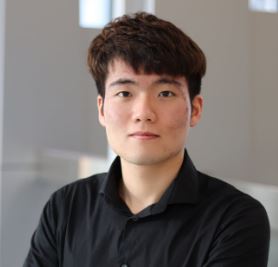

Aiden Kim

Max Kim

Hari Gunesakera

Design Details

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

The interest in AGV’s market has led to a compounded annual growth rate of 13.6 % and will reach a market size of $7.3 billion by 2025 [1]. Organizations like Amazon and Toyota are investing heavily in AGVs to make self reliant and computerized smart factories. As the manufacturing industry expands towards automation, there is a lot of need for innovation and research in inventory management using AGVs.

Our team performed extensive research on the Conventional and AI control systems that are behind these automated vehicles to determine which type of control system provides a more stable response and completion of tasks. Our design addresses practical issues by evaluating key parameters of control systems used in the industry to validate an AGV.

- Object detection: Ability of the vehicle to navigate through the facility and recognize materials of interest that need to be assigned to a storage area.

- Obstacle avoidance: Ability of the vehicle to handle materials with care and avoid collisions with surrounding objects..

- Labor productivity: Ability of the vehicle to organize and manage inventory with a high productivity and efficiency.

- Operational Robustness: Ability of the vehicle to reliably operate and reduce the process downtime during operations.

This project addresses the need for innovation in the manufacturing AGV industry and provides key findings on the practicality of the Conventional and Artificial Intelligence Control Systems in the areas mentioned above.

[1] Tao, M. (2019, February 25). Automated guided vehicles market size forecast to be worth $7.3 billion by 2025. Robotics & Automation News. https://roboticsandautomationnews.com/2019/02/25/automated-guided-vehicles-market-size-forecast-to-be-worth-7-3-billion-by-2025/20106/

WHAT MAKES OUR DESIGN INNOVATIVE

Both the Conventional and AI control systems implemented in our AGV employ the use of an innovative object identification system for inventory management. Currently, material handling is completed using bar code scanners and radio frequency identification (RFID). Barcode technology is undesired because it requires a direct line of sight of the bar code and a close placement of the reader to the object. On the other hand, RFID involves complex assembly and implementation onto the object, resulting in a higher cost to the operation. Also, these methods limit the amount of information to manufacturer and product name when classifying products.

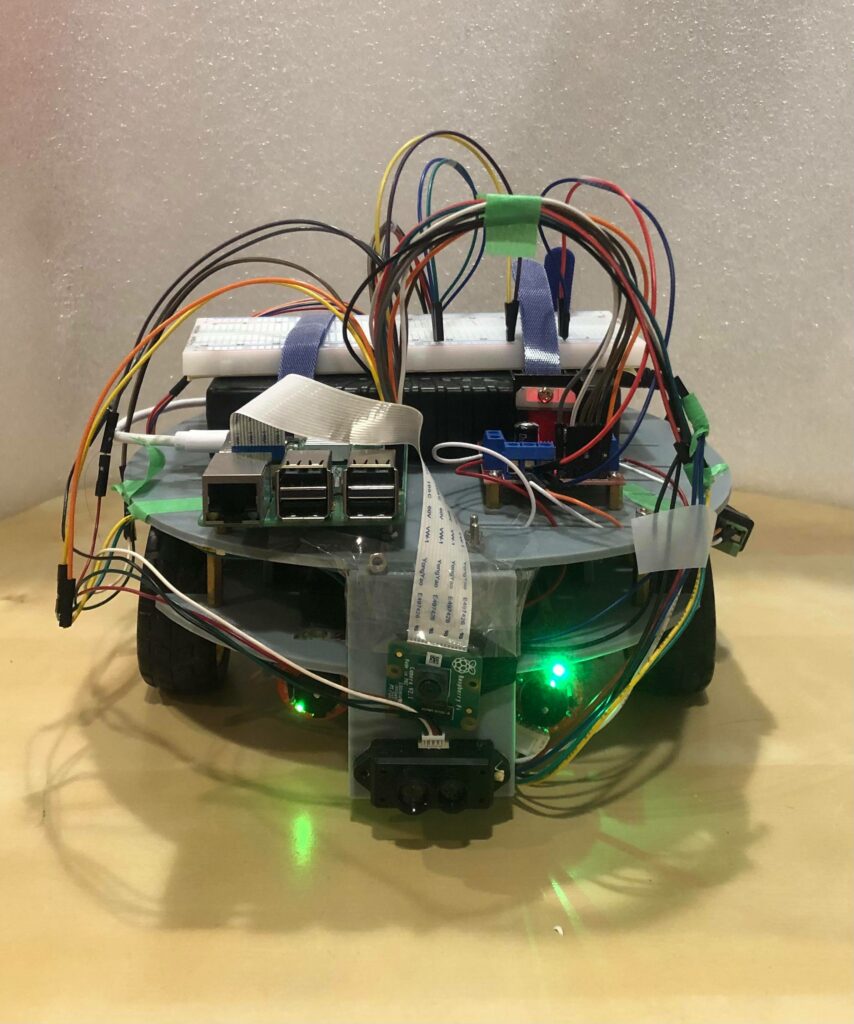

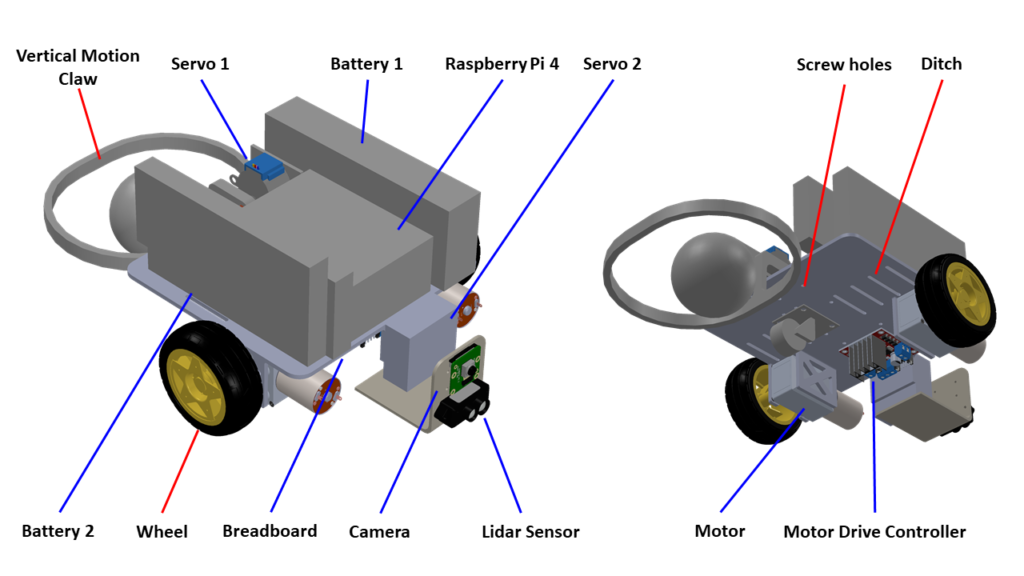

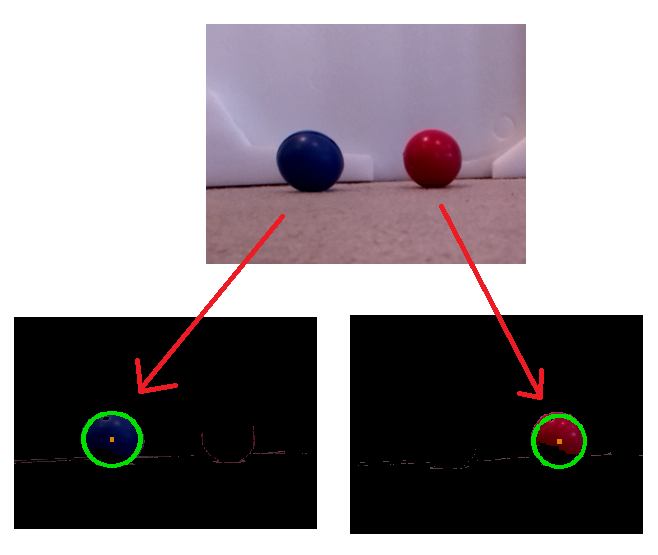

As part of the conventional approach, the control includes a innovative solution to identify objects using a camera. Using the camera stream, the object data points are collected to determine its visual aspects such as color and shape (edges). These features allow the control system to extract information such as object type and 2D size when completing the scan. The advantage of visual identification is the storage of comprehensive data information and detailed log of product condition after transportation.

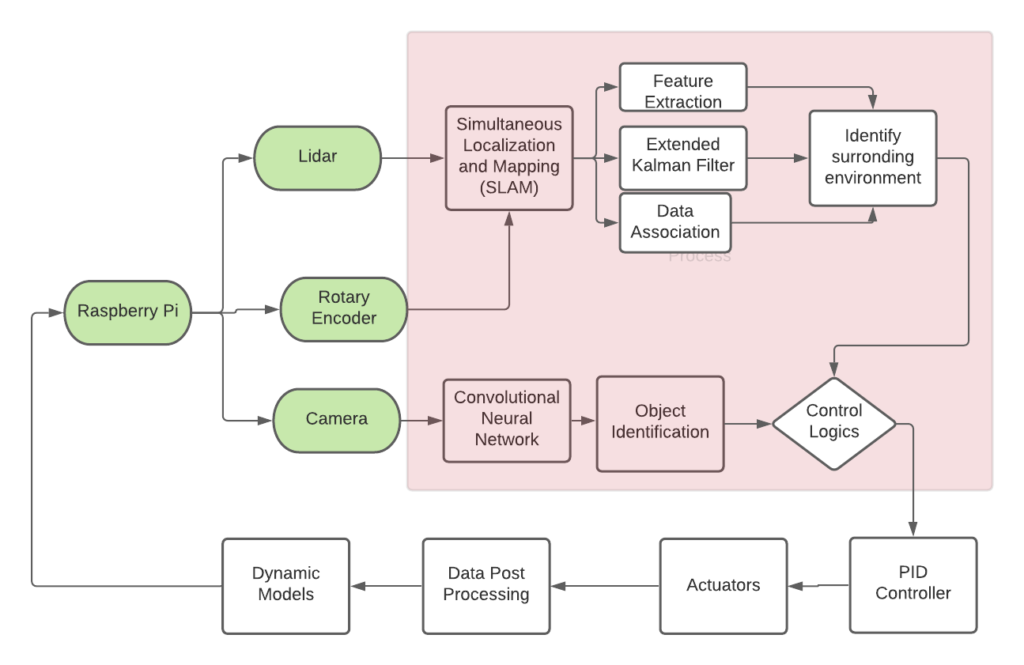

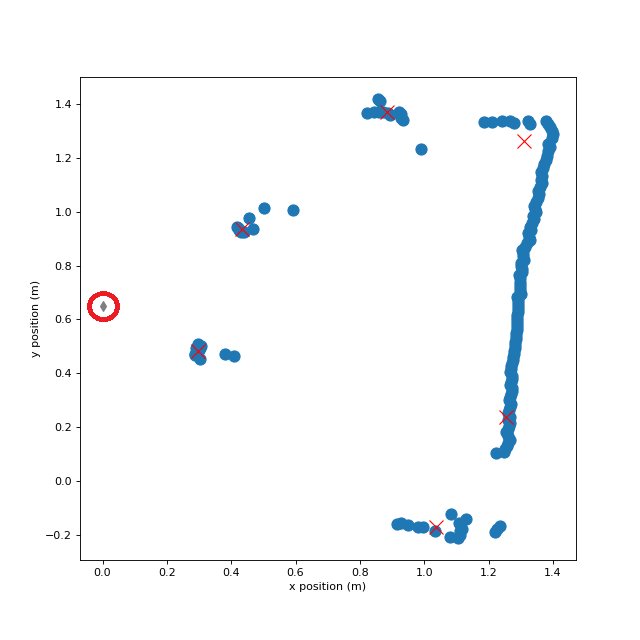

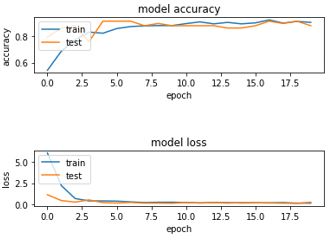

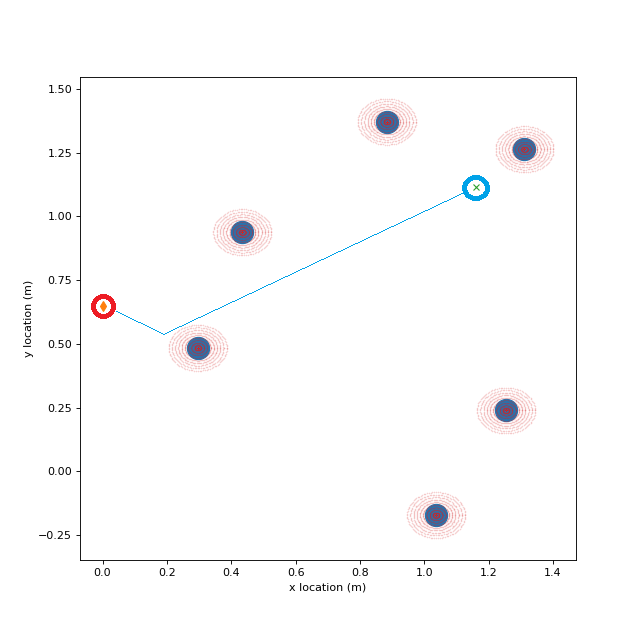

As part of the AI approach, the control system uses machine learning to identify objects using landmark extraction in SLAM and image processing in CNN. This methodology uses the lidar and camera sensors to retrieve key data points to determine its visual aspects such as size, depth, and object type. The SLAM algorithm uses the lidar to extract key features of the landmark (object) in terms of 3D aspects. The CNN is a trained image processing model that predicts the object type and its characteristics using the visuals given by the camera.

Traditionally, AGVs are required to follow some sort of pre-determined path that is built by the manufacturer. This is a very inefficient way to complete tasks as vehicles are restricted in their movements. In our control systems, path planning has been implemented to allow our AGVs to effectively plan a path based on the surrounding environment by guaranteeing that the path they will travel will be short and safe for travelling. This innovative solution to path planning allows tasks to be completed faster and economically.

The solutions provided above allow organizations to reduce unit costs and maintain product quality during transportation. Following the modern trend in inventory management, our identification interface and path planning have been designed to be incorporated with leading automation technologies.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

The effectiveness of our design is determined by its operational limits for management of inventory. The primary goal of of an AGV is to reduce the unit cost of organization by use of automation. Automation is preferred over manual labor because of increased productivity, reliability, material handling, and safety. By utilizing the mapping and planning algorithms in collaboration with accurate sensory data , we are able to create an efficient AGV that checks off all the items mentioned above.

The design system considers practices employed in warehouse facilities to manage inventory and promotes efficient use of facility space. Implementation of principles likes work line flows and diagonal storage units has maximized the ability of our AGV to produce efficient control of inventory. The use of mapping and localization techniques to map out the warehouse facility allows the AGV to pre-plan its next move. The solution from the mapping algorithm is effectively used in our path planning model which considers the vehicle’s odometry to determine the shortest path of organization with obstacles avoidance criterion. Lastly, the use of popular programming languages used in the control logics aligns with best industry practices and creates a solution that is easily implementable on industrial AGVs.

Overall, the control systems developed in this project provides efficient application of inventory control while reducing financial costs. The logics and algorithms implemented in both systems provide precise object detection and obstacle avoidance . Higher productivity is achieved by the use of path planning as the complex model algorithm determines the shortest travel path for each task set. In terms of reliability the control logics are built on closed loop systems that are robust and consistent. Adding all the qualities mentioned above yields a successful candidate for an effective industrial AGV.

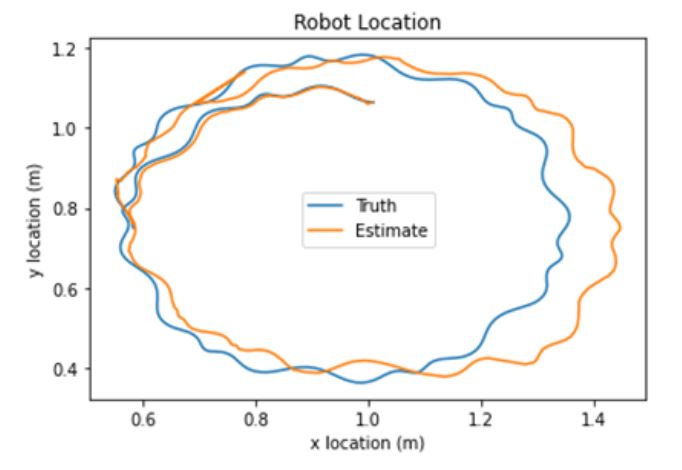

HOW WE VALIDATED OUR DESIGN SOLUTION

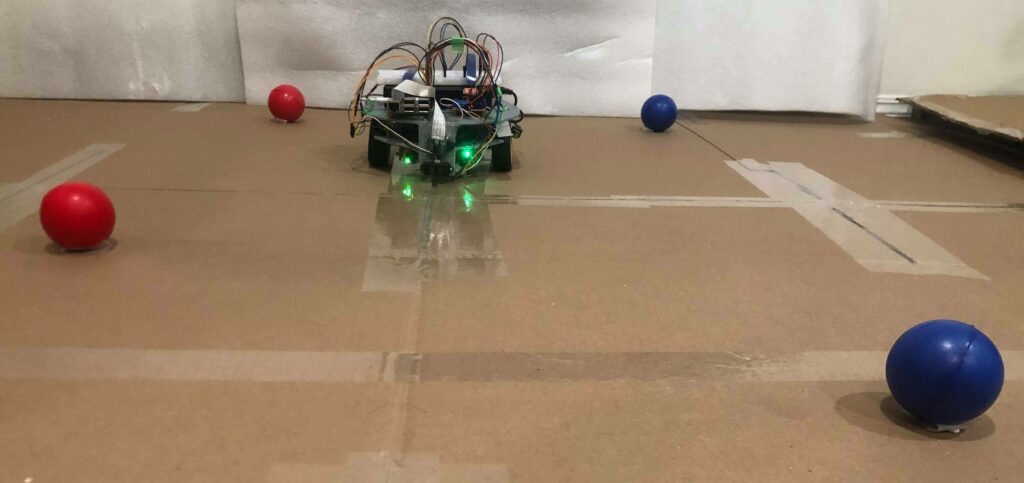

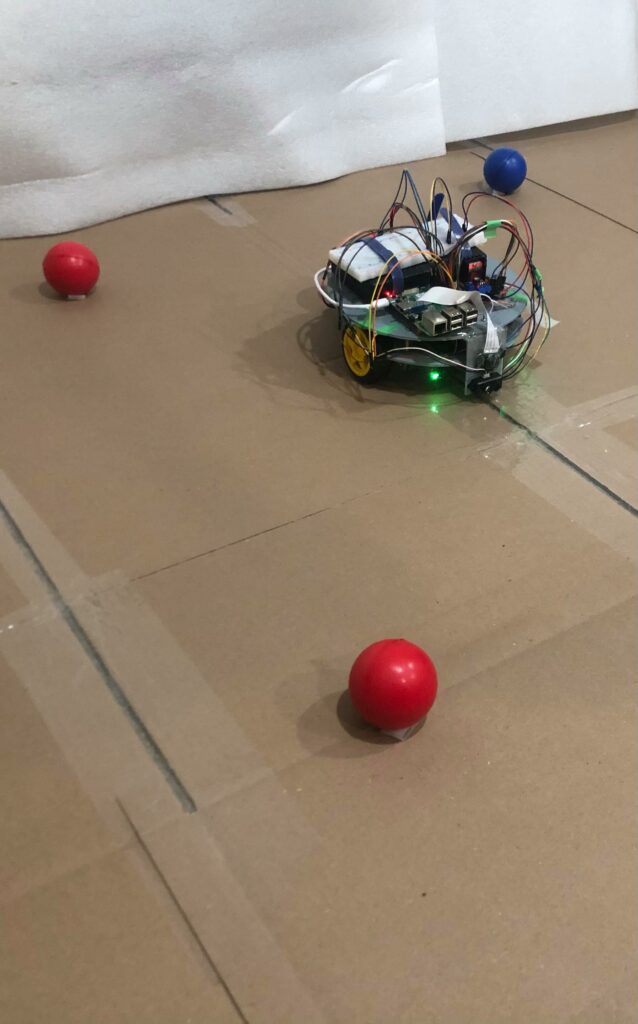

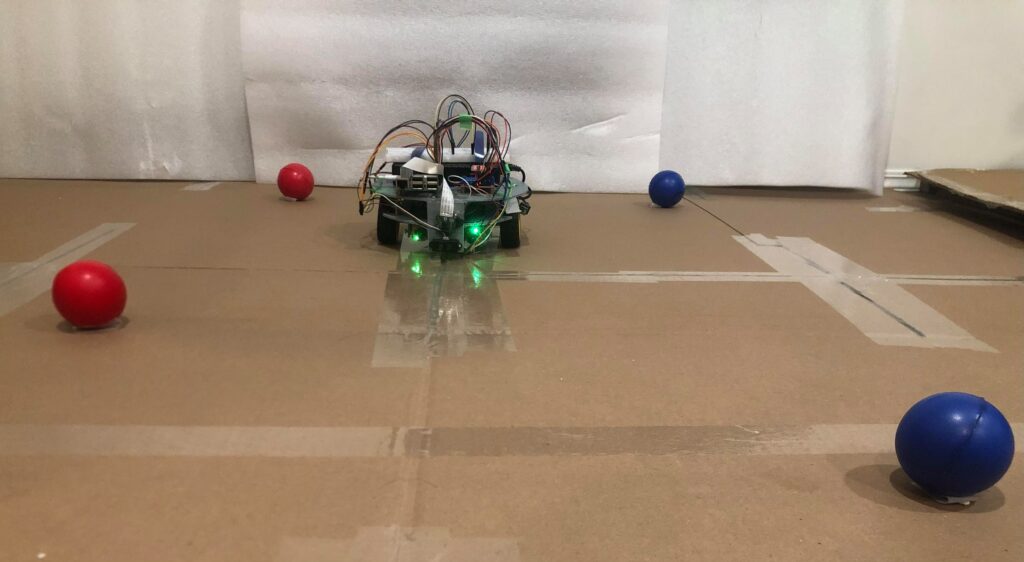

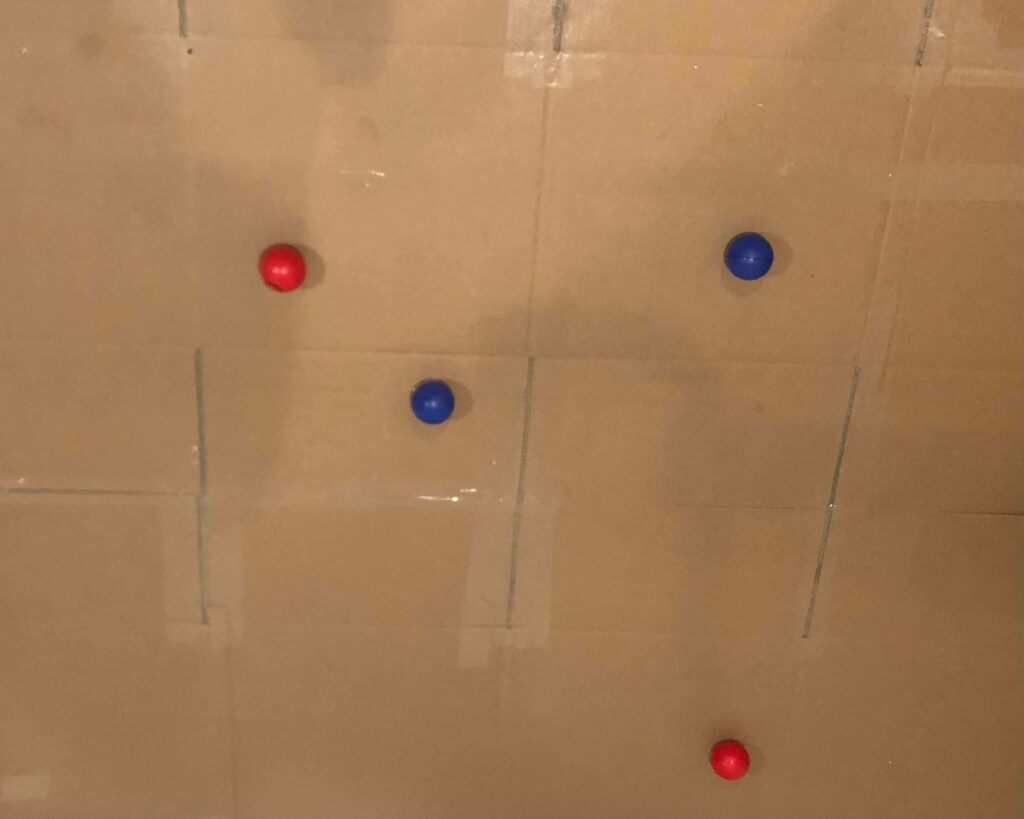

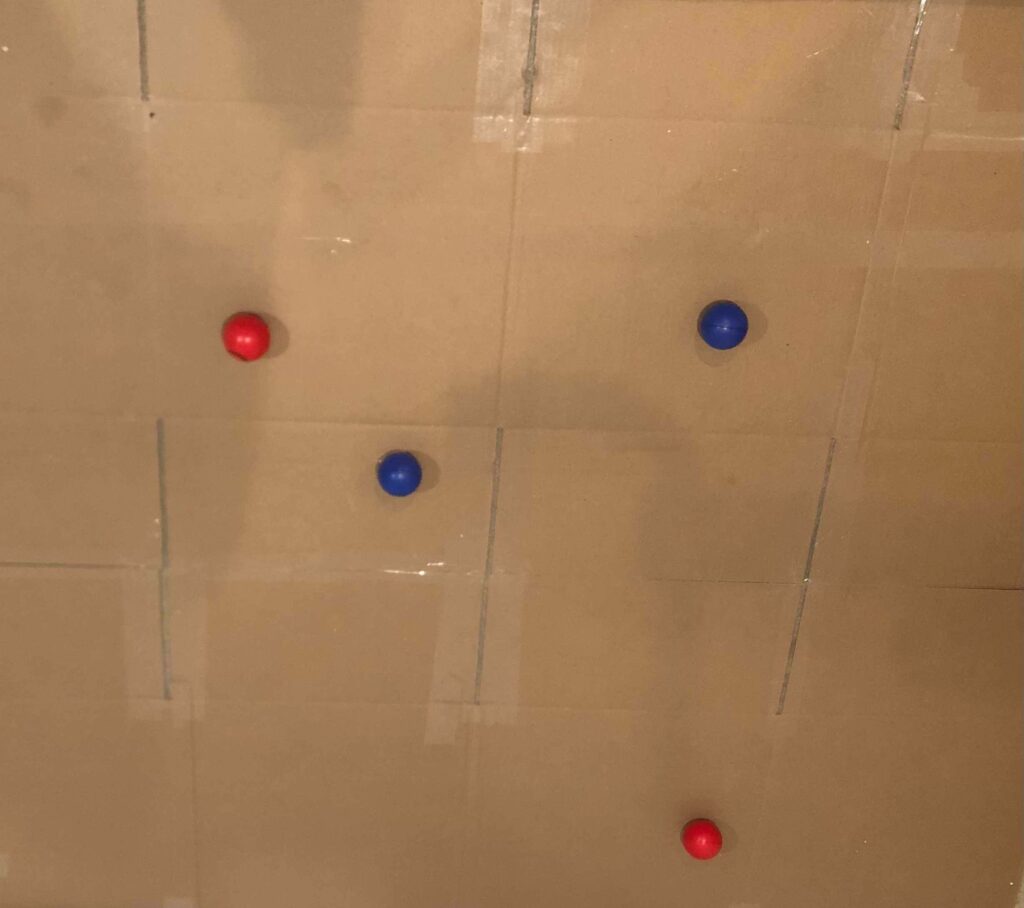

The vehicle and its control logics are evaluated on parameters that are used in the industry to create and evaluate such vehicles. To achieve the objectives mentioned earlier the vehicle must be competent in the following tasks: object detection, obstacle avoidance, efficient productivity, and reliability. We will simulate a course set-up to that of a manufacturing facility and allow the vehicle to operate in the setting. Testing will be performed on multiple configurations to shows that the control logics are competent in the areas of interest. The following shows course configuration 1 of 3 that are used to test the vehicle’s capabilities.

Object detection is meant that the vehicle will be able to navigate through the course and recognize materials of interest that need to be assigned to a storage area. The material in this case will be red and blue balls scattered in the course that the vehicle will need to precisely determine the object location and proceed towards the ball closest to itself. Once the vehicle has locked its target, it will then identify the type of ball it is and return it to the allotted storage area. Our criteria will evaluate how well the robot is able to locate the ball and retrieve it. The accuracy will be judged by comparing the observed experimental ball coordinates with the actual values.

Obstacle avoidance would be measured on by averaging the total number of collisions observed during the vehicle’s operation. The vehicle should be capable of using the camera and lidar sensor to evaluate its surrounding and determine an optimal path to avoid such obstacles.

Labor productivity can be defined as the total number of balls sorted by the robot in a minute. This a very important component because it involves time and cost aspects. This metric will be a direct measurement to compare the two control systems at the end of this project.

Operational aspect determines the stability of the system by measuring the number of malfunction occurrences during its operation. This will let us know how often the robot is not able to complete the given task and fails to acknowledge the command by the computer processor. As discussed earlier, system failures can be very costly as they can lead to downtime and stoppage of a processor.

Each control system will have a total of 9 test runs on 3 different course setups, with 3 runs on each setup. The results will be averaged to determine the vehicle evaluation. The results will allow our team to provide a direct evaluation of the control systems and its practicality.

FEASIBILITY OF OUR DESIGN SOLUTION

The design solution is developed with an open concept that allows it to be implemented in any AGV that incorporates the use of camera and lidar sensors. The ability to implement the control logics on any robust controller and operate at it in any warehousing facility is the advantage of our design. The control language has been written with respect to best practices to make it easier for integration and development for others. The design was verified with continuous feedback, tests, and constant development throughout the project.

Cross checking between industry AGV standards and comparison of different technologies within this area allowed for a development of a suitable inventory management control system. The developed controls have the capacity to take on same material handing responsibilities by meeting the requirements in terms of object detection, obstacle avoidance, efficient productivity, and robustness.

In conclusion, the demand for automation in manufacturing has given a rise to AGVs. The practicality and effectiveness our control logics provide a stable management system for material handling purposes. The ability to provide a reliable, consistent, and efficient control system makes our design a feasible candidate for an AGV controller.

Control System Design

Conventional Control System

Artificial Intelligence Control System

Partners and mentors

We would like to express our appreciation to Dr. Jihyun Lee for giving us the opportunity to work on this project. Her constructive suggestions during the planning and development of this product were a valuable asset for the team . Thank you for giving us your time so generously!

We would also like to thank Dr. Philip Egberts and A.J. Ebufegha for giving the team valuable feedback and guidance throughout the project.

Project Photo Gallery

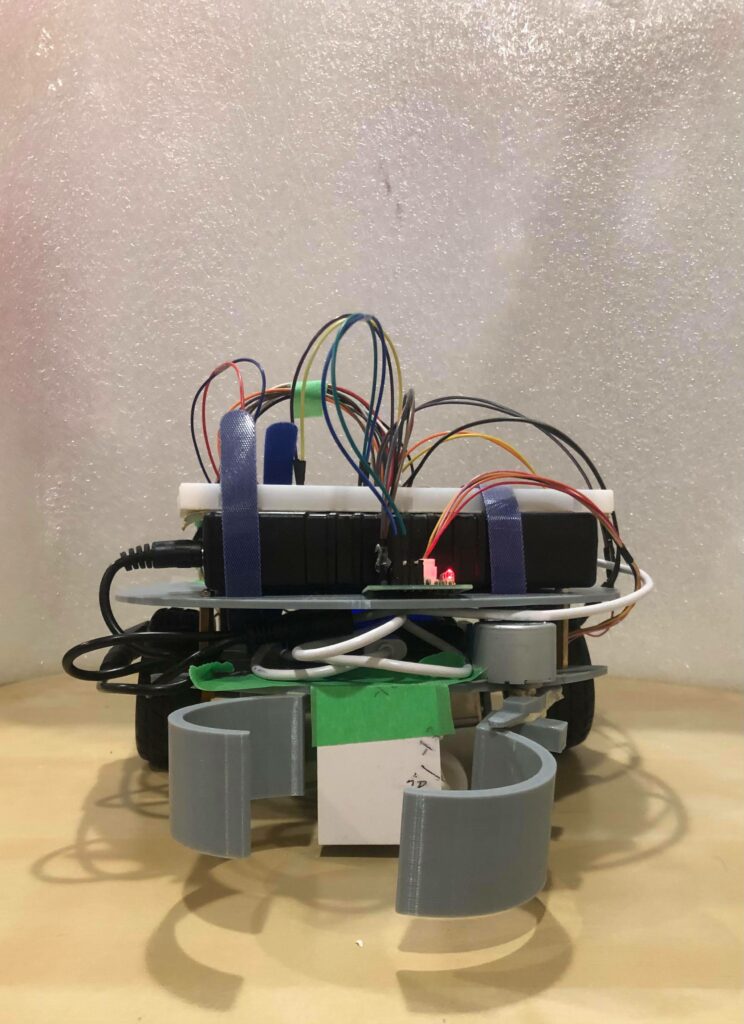

Vehicle Design

Course Design

Facility Setup

Results

Conventional Object Identification

AI Localization & Mapping

SLAM

CNN Model Parameters

AI Object Identification

AI Path Planning

Thank you!