Project Category: Mechanical

Join us live on April 13, 10:00am-12:30pm MST

About our project

Cargo shipping is one of the most prominent sources of greenhouse gas emissions in the world – comprising about 3.1% of all global emissions and consuming, on average, 286 million tonnes of fuel per year. Due to its low cost and the indulgent GHG regulatory requirements set by the International Maritime Organization (IMO), the shipping industry currently relies on heavy fuel oil (HFO) to power its vessels. Although cheap, this fuel is detrimental to the environment and contributes to around 400,000 premature deaths each year.

Additionally, the IMO has also been applying increasingly stringent fuel restrictions. Although the resulting decrease in air pollution will most likely be counteracted by the continued growth of the shipping industry, these regulations give rise to another major problem. To retain their high level of fuel efficiency, shipping companies will be forced to limit their speed and reduce their service time, ultimately resulting in deficient service standards.

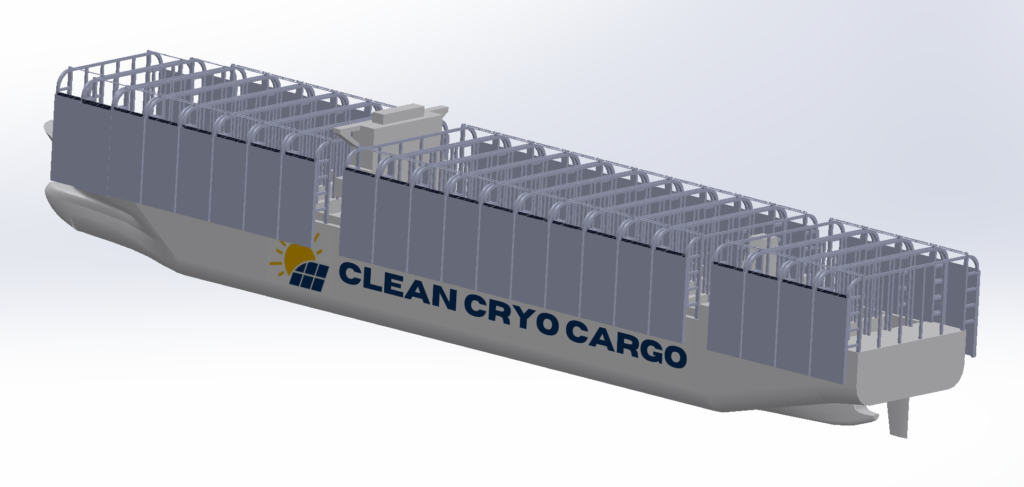

We want to transform the shipping industry and reduce GHG emissions by providing a way for ships to consistently harness the power of renewable energy. Our project is a conceptual design that aims to prove the feasibility of using solar panels to produce emission-free energy on maritime vessels while neutralizing the intermittent nature of renewables through the application of cryogenic energy storage (CES) systems. To do this, we have chosen to retrofit an existing 14,074 TEU cargo ship known as the CSCL Star. Through the combination of solar power and CES, we have created a system that can produce a power output of 86,550 kW and reduce HFO consumption by more than 18%, allowing us to power cargo ships reliably and sustainably.

Meet our team

For our project, we spilt into two sub-teams of solar panel mechanism design and the LAES system development.

Solar Team

Greg Cuaresma is a mechanical engineering student with interests in logistics, manufacturing, maintenance, and automation. He has internship experience as a maintenance coordinator intern with Westmoreland Mining. Greg was responsible for initial research and calculations regarding container ship energy usage and solar power generation, as well as the design of the solar panel lifting mechanism.

Haiqua Javed is a mechanical engineering student with interests in innovative design, sustainability, and data analytics. She has internship experience abroad as a researcher at the Technische Universität Berlin Aerodynamiks department and as a Student Leadership Coordinator at the Engineering Career Centre. Haiqua’s role with the project was focused on developing and designing the sliding solar panel mechanism.

Alexander Kruger is a mechanical engineering student pursuing a minor in mechatronics. With interests in circuitry, programming, and robotics, his passion is bringing together the worlds of electrical, mechanical, and software engineering to create innovative solutions to existing problems. Alex was responsible for the sun tracking algorithms that help the solar panels obtain the optimal amount of power, as well as power generation calculations and system animations.

LAES Team

Ross Leclair is currently working as an intern at Smith + Andersen. He specializes in thermodynamic cycles and HVAC systems. Ross was responsible for the creation of the liquefaction system that creates the liquid air for the ship.

Suzanne Ghorbanpour is a mechanical engineering student with interests in reliability, maintenance, and sustainability. She has oil and gas internship experience as she worked as a reliability intern at Suncor’s upgrader in Fort McMurray. Suzanne’s role in the project was focused on determining the types of mechanical equipment used in the ship’s LAES system and estimating its cost.

Hesham Mohammed is a fourth-year mechanical engineering student with interests in aerodynamics, fluid mechanics, thermodynamics, and engineering design. He was responsible for the design and prototyping of the cryogenic energy extraction method that enables us to recover the stored power.

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

- The main issue our design addresses is the unrestrained and negligent use of bunker fuel in the shipping industry, as it produces an overwhelming amount of GHG emissions. Our energy production system is reliant on renewable energy and uses liquid air as a working fluid for the discharge cycle, therefore, the only gas released into the atmosphere throughout our entire process is air. Although we are not be able to solely run the ship on solar power and stored liquid air energy (LAES) for the entire trip, we are able reduce GHG emissions by more than 18%.

- The sun doesn’t shine all day, and arbitrary sources of shading such as clouds or large impediments on land can greatly reduce the potential of solar power. Our design addresses the issue of intermittency by incorporating a clean energy storage method that can easily fit on any cargo ship. This allows us to store energy from the solar panels when the ship is docked or during off-peak hours at sea and reuse it when solar energy is unavailable.

- Current methods of energy storage such as lithium-ion batteries aren’t suitable for shipping, provided they are a major fire hazard and lack the energy density needed to power large cargo ships. Our LAES system design solves both the issue of safety and energy density as it can be stored safely on the ship with minimal hazards and has a higher energy density than conventional storage methods.

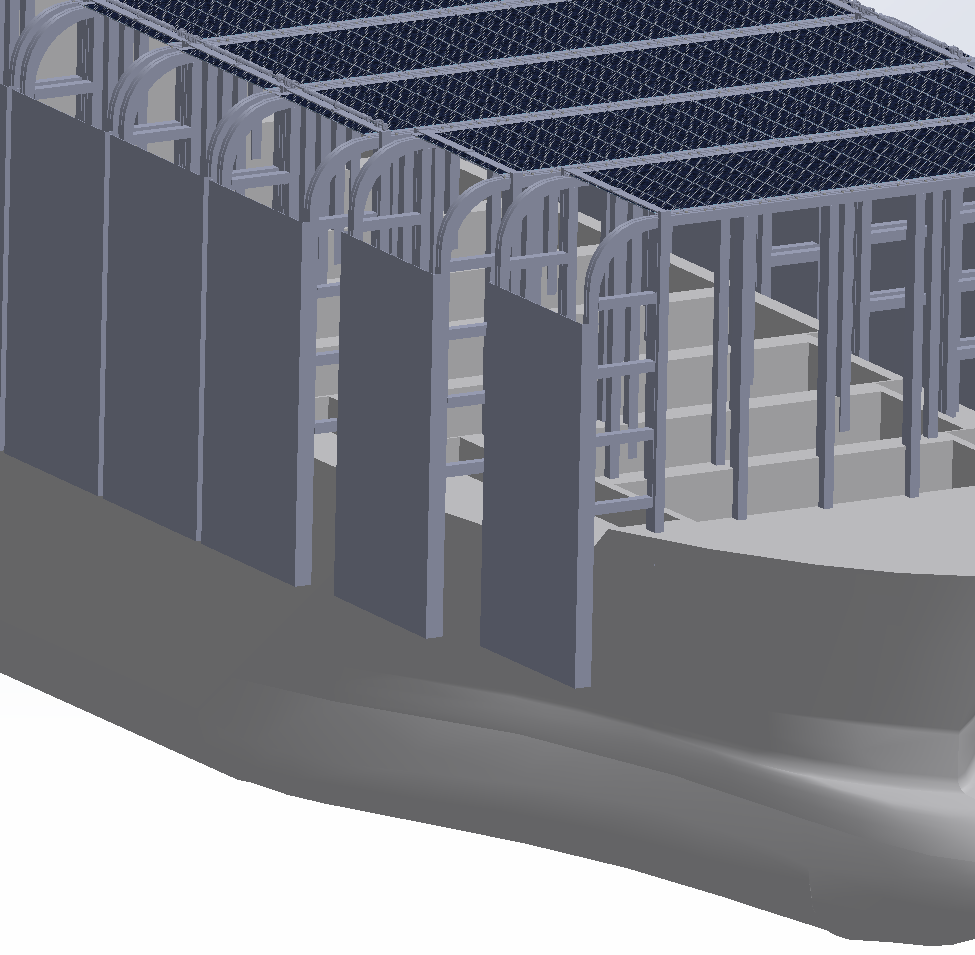

- Each year, about 2,000 cargo containers are lost in sea due to the rough weather conditions causing the containers to fall off deck despite being supported by tightly tied ropes. This unfortunate occurrence results in lose of customer goods and merchandise thus wasted supplier investment. Our railing system with its casing not only protects the solar panels, but also encloses and protects cargo containers, ensuring no goods or merchandise are lost at travel.

WHAT MAKES OUR DESIGN INNOVATIVE

100% Clean Energy Storage

Traditional cargo ships consume approximately 225 tons of bunker fuel per day. Our proposed design is a transformative solution that reduces the current environmental impact by introducing a 100% clean, liquid-air energy storage method, as a form of storing solar energy. Our simulations have proven that we can reduce fuel consumption and GHG emissions by over 17%, which is an unmatched result in the shipping industry.

Scalability and Liquid Yield

Although liquid air energy storage is currently being tested as a practical storage method, up until now, it has only been introduced for large scale power plants on land. Our design explores the scalability of LAES systems and proves the feasibility of implementing it on any cargo ship. We also make use of different liquefaction cycles. The current system being tested uses the Linde-Hampson cycle to produce the liquid air. For our design, we chose to incorporate a modified version of the Claude cycle, which allowed us to increase the liquid yield while also producing a small amount of power during the storage process.

Optimized Discharge Cycle Efficiency

We optimize the efficiency of the LAES energy discharge cycle by incorporating multiple turbine stages. By opting out of a single expansion phase, we’re able to reheat the flow between each intermediate turbine and increase the overall power output. Additionally, we make use of waste heat from the main engine when reheating the flow. With exhaust gases easily reaching temperatures of 425K, making use of waste heat collection allows us to greatly increase the efficiency of the cycle.

Resilient and Adaptable Solar Panel Design

Although the use of solar energy is becoming increasingly popular, it has never been implemented on cargo ships due to volatile weather conditions and potential corrosion caused by seawater, both of which could limit the capabilities of solar panels. Our design introduces a safe method for solar panels to be outfitted on cargo ships while neutralizing these concerns. We also provide a solar panel design that does not impact the amount of cargo a ship can carry as it takes up no space and allows for easy loading and unloading of merchandise.

Reliable and Advantageous Storage

We increase the safety of energy storage methods by using air as a working fluid, allow for long duration storage, and make use of downtime. When the ship is docked at port, we can consistently produce and store energy for later use.

DESIGN FEATURES

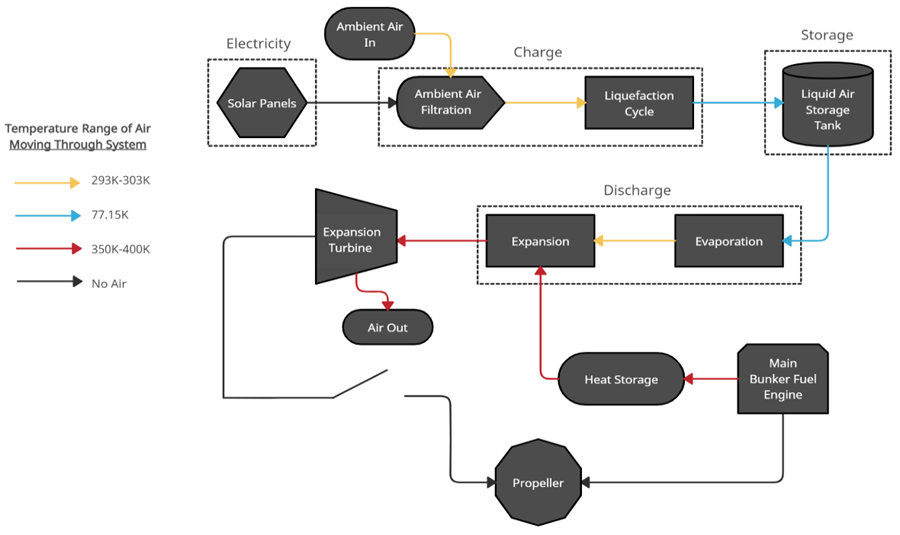

Overall LAES System Diagram

Our system will have two major components:

- Solar power system that collects solar energy along the shipping route as well as when the ship is docked at port and uses it to produce liquid air.

- Liquid air energy storage system that stores the liquid air in large cryogenic tanks and evaporates it to produce energy when its required.

This system is used in tandem with the ship’s original bunker fuel engine and the on-board diesel-powered electrical generators, as they would provide energy for the ship when there is not enough liquified air to be used.

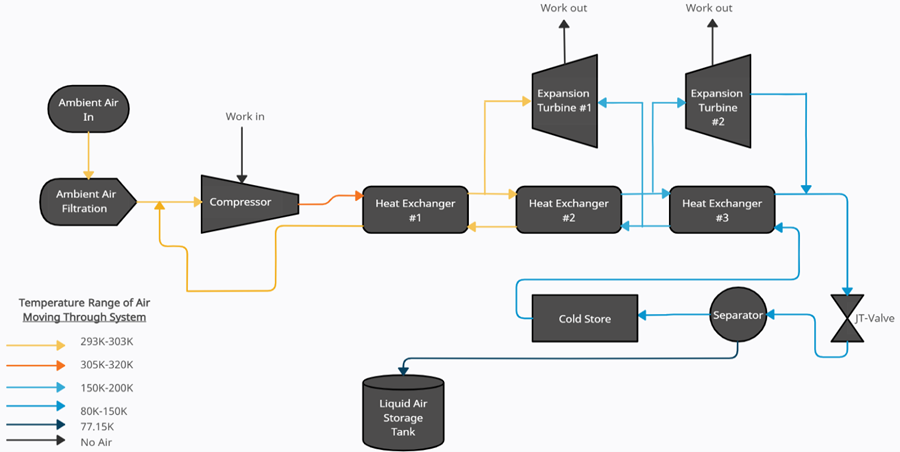

LAES Liquefaction Cycle

Our LAES system is separated into a liquefaction cycle and an energy extraction cycle.

The diagram below depicts the final conceptual design for the LAES liquefaction cycle. We chose to model our system on the Claude cycle due to its’ comparatively high efficiency.

Considering that cargo ships are isolated with a limited supply of power, this optimized efficiency is a major advantage as it ensures that more air is liquefied using the same amount of energy. Another advantage to using this method is that it offers useful work in the expansion stages. This is an important advantage because it allows the LAES system to provide power during off-peak hours and having an extra source of work output is very beneficial.

The choices behind the number of turbines and heat exchangers was heavily based on our prototype simulation results. Our aim was to be able to reduce the temperature of air to 77.15K to liquify it, without increasing the capital costs by adding excess turbines and heat exchangers. Using this setup, we were able to achieve the desired final temperature and keep our costs to a minimum.

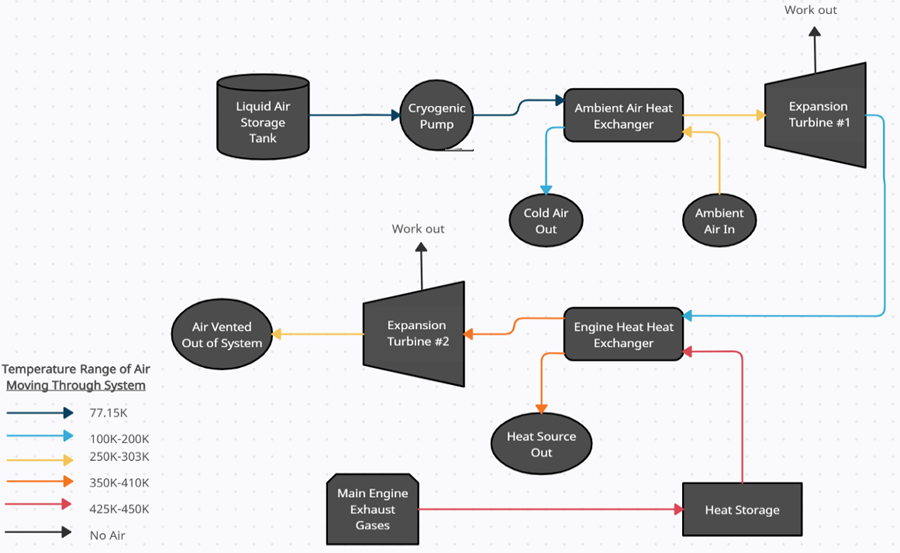

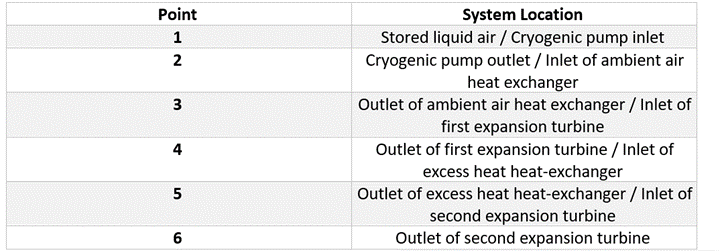

LAES Energy Extraction Method

The diagram below depicts our final conceptual design for the LAES energy extraction method. We chose to base our design off the direct expansion method alone as it would be the most cost effective while also generating sufficient power to completely replace the ships current fuel source. Since the ships main bunker fuel engine and the four diesel gensets produce 86,240 kW of power, we needed a discharge cycle that could easily match this. Using the setup below, we were able to achieve the desired power while keeping our costs to a minimum.

The number of heat exchangers chosen for the discharge cycle is based on the different types of heat sources that we have. By utilizing ambient air and excess heat from the ship’s engine in separate stages, we were able to implement multiple turbines in our system rather than a have a single expansion phase. This allows us to reheat the flow between expansions and produce more work.

LAES Mechanical Components

For our LAES section, mechanical components were chosen based on research of current existing liquid air energy storage plants. Operating conditions such as allowable operating pressure and temperature were taken into consideration while choosing types and sizes of mechanical equipment. Design parameters chosen for LAES components were used in design validation in Simulink models.

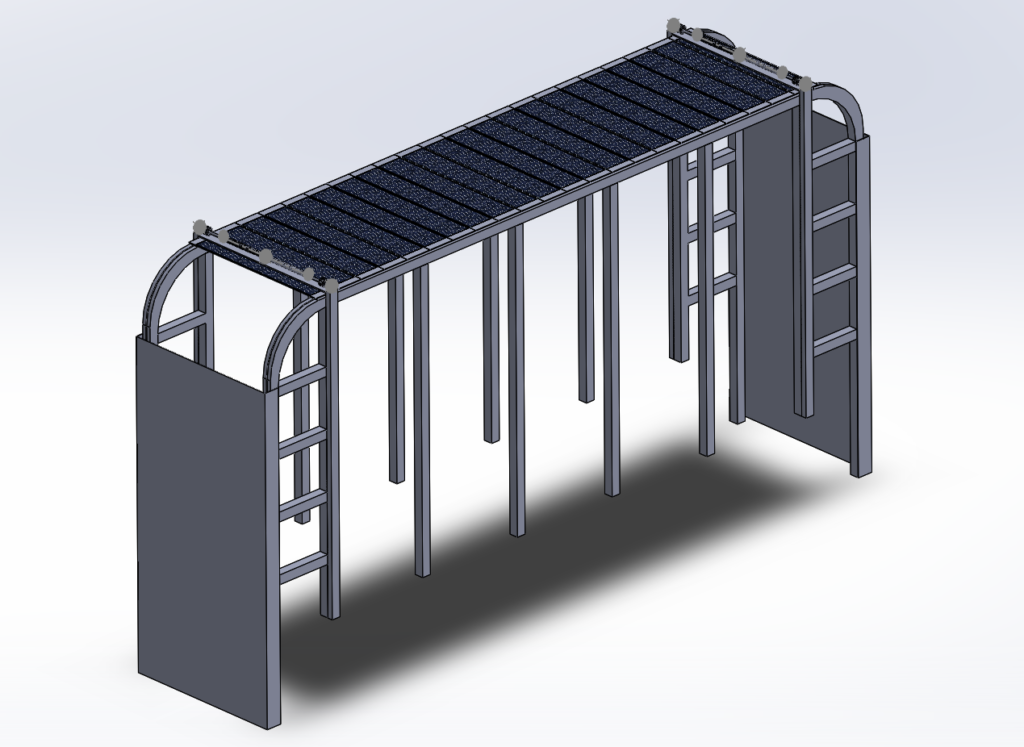

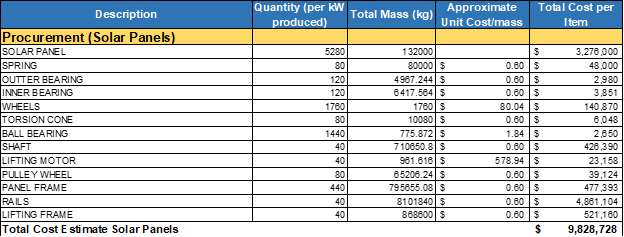

Solar Panel Sliding Mechanism

Our solar panel system maximizes the amount of solar energy generated possible while at sea and at port. Our system contains 5280 solar panels, which combined can generate up to 1 terajoule of energy over the course of the voyage. These solar panels are attached to movable rails 27 meters above the upper deck of the ship, which can be moved to the side when needed. This simple yet complex design allows port cranes to load and unload containers as needed without the risk of damaging the solar panels, while also not hindering the number of containers that can be loaded onto the ship.

The first image above shows the panels slid to the top, which would occur while the ship is at travel. And the the second image shows the panels spilt to the sides inside the protective casing to allow for loading operations of the cargo containers to take place. This simple yet complex design solution is able to hold 5,280 panels on the ship without comprising the area on deck for the container storage nor interfering with cargo loading and unloading operations.

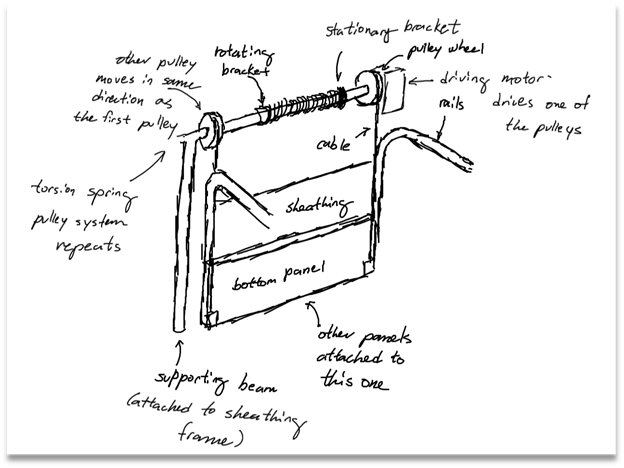

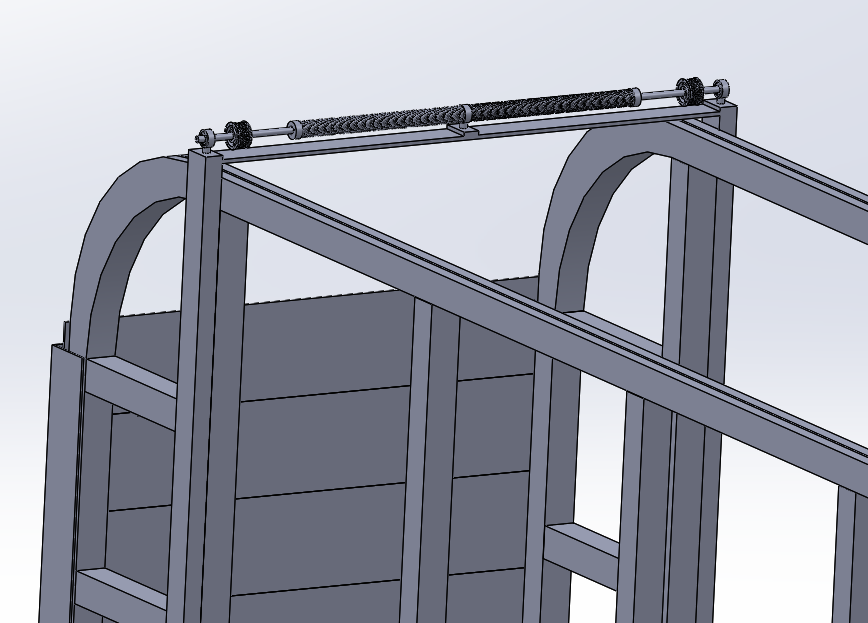

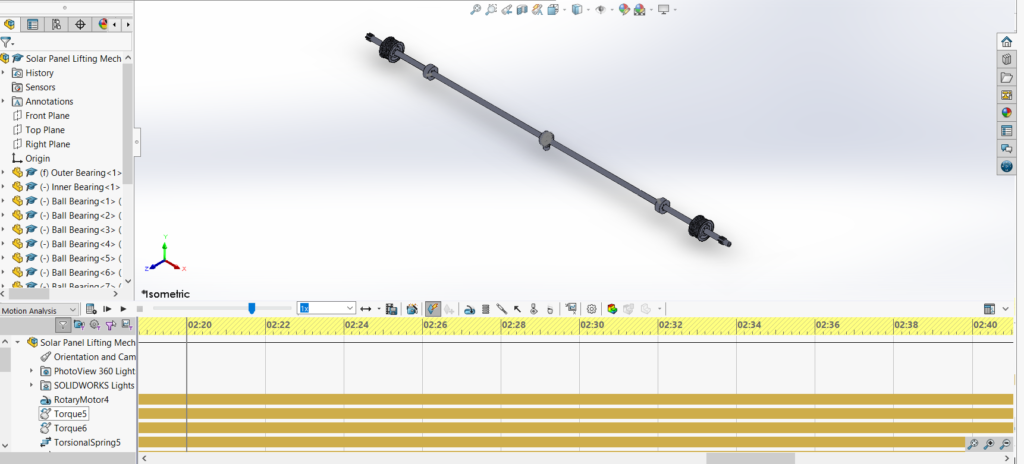

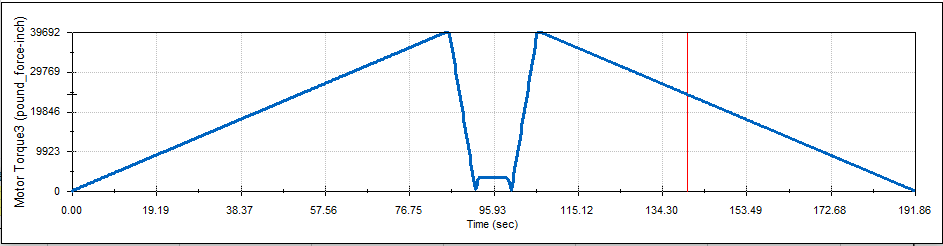

Solar Panel Lifting Mechanism

In order to allow our solar panels to move, we have designed a lifting mechanism that will lift each section to the desired position. Inspired by garage door mechanisms, our system can lift and lower our solar panels to the desired position in less than two minutes, ensuring that container loading and unloading is not impacted. Our system also only requires a minimal amount of energy, about 200 W for each row of solar panels, which ensures that the vast amount of energy generated by the solar panels goes to powering the ship.

HOW WE VALIDATED OUR DESIGN SOLUTION

LAES System

To validate our LAES system, the liquefaction cycle and energy discharge process were both built in Simulink with supporting calculations carried out through MATLAB. We created a 2-phase fluid system that uses the property tables of air to predict the thermodynamic behavior throughout the model.

Using the liquefaction cycle prototype and the values for the energy produced from the solar panel setup, we were able to measure the amount of liquid air our system produces in the 3 days that the ship is docked at each port. Since the CSCL Star stops at 3 different ports throughout its journey, we found that in these 9 days, our system can produce 4500m3 of liquid air using the 63.1MJ of power that the solar panel setup provides per day.

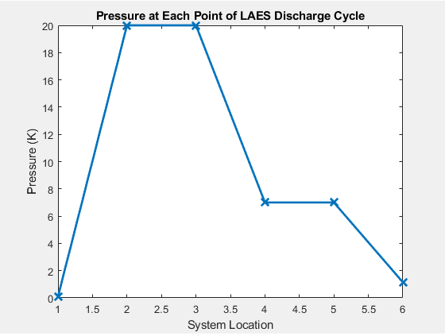

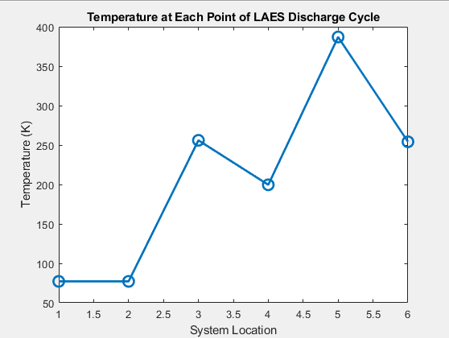

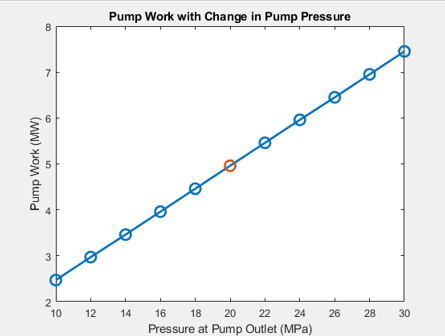

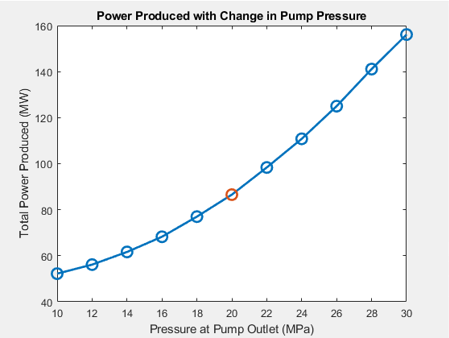

The energy extraction prototype allowed us to validate the feasibility of completely replacing the ships fuel system, verified the thermodynamic properties of our working fluid throughout the system, and provided us with the required pump pressure differential for our system.

The red data points on each figure indicate the chosen values.

Solar Panel System

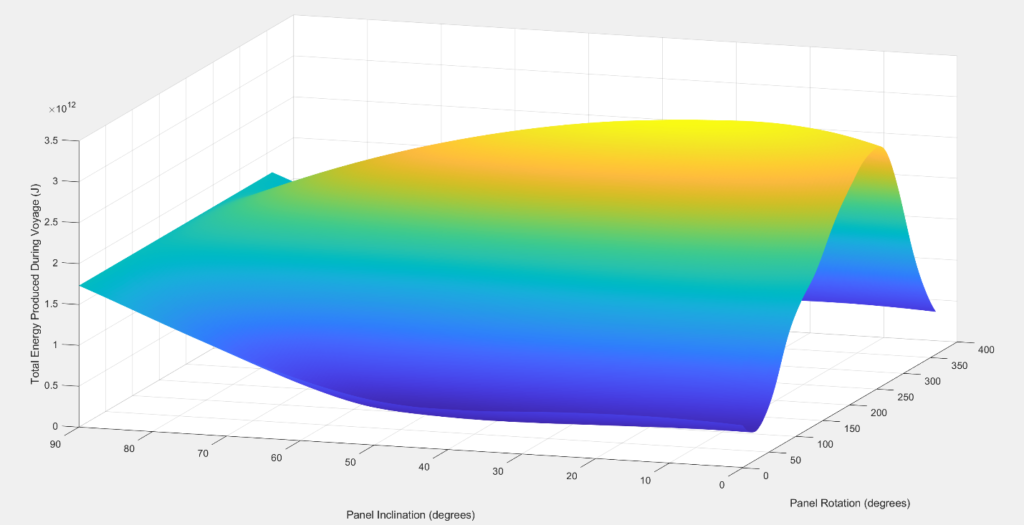

To validate the solar panel systems, we created multiple simulations using MATLAB as well as the Processing language. The position of the sun was calculated using well known formulas, determining its azimuth and elevation at any given date and time. We compared real world data to our calculated positions to ensure they were all accurate. The power generated throughout the trip was determined using this positional data.

To further ensure the data was accurate, we developed a simple program using Processing, checking to see that the position of the sun was changing in a realistic and expected manner.

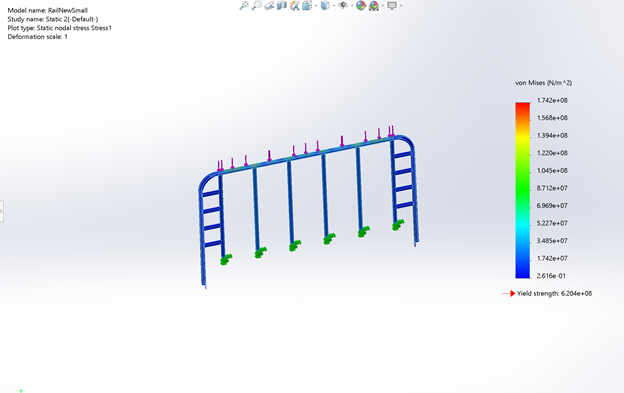

FEA analysis was also performed on the rails as well as the lifting mechanism to ensure that they would not break under loading. A load of 64kN was applied to the rails from the frames. The gradient of blue and slight green showed the strength of the rails and their ability to hold the load without deforming.

FEASIBILITY OF OUR DESIGN SOLUTION

Our design incorporates tried and tested methods in order to ensure the feasibility of our system in pre-existing cargo ships. Liquid air energy storage is a new and powerful technology providing many homes and factories with the power they need, however, although new, the components used, such as heat exchangers, pumps, compressors, etc., have been thoroughly investigated and are currently widely used throughout many industries.

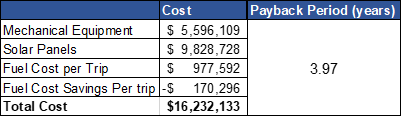

While the cost of purchasing the equipment needed to run our system would be expensive, it significantly reduces the need to pay for fuel – one of the largest environmental and financial costs. With the fuel savings, the system pays for itself in approximately 3.97 years, making the monetary aspect very feasible.

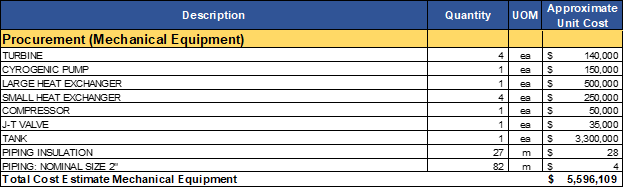

Below is a general cost estimate for procurement of major mechanical equipment used in the LAES system. The approximate unit costs are estimates based on similar existing mechanical equipment in industry. Please note that the approximate unit cost of mechanical equipment is subject to change from vendor to vendor.

Partners and mentors

We would like to extend a special thank you to the many people who helped us with this project:

Our mechanical engineering professor Dr. Simon Li and our teacher assistant Danny Wong, who guided us through the process with patience and great advice.

Monty Kruger for being extremely generous with his time and his invaluable mentorship throughout the creation of our project video.

Erica Cuaresma for her useful and appreciated feedback and guidance with our video and website.

Our photo gallery