Project Category: Mechanical

Visit our booth in person!

PLACE

Atrium CNRL Complex, SSE, BOOTH 4

DATE

Tuesday, April 5th 2022

Time

10:00 AM – 12:30 PM

About our project

We often take for granted the simple luxuries in life – things like refrigerators, cars, and hot water have changed our lives in ways that people living even just 100 years ago couldn’t imagine. However, these marvels of engineering have also changed the world around us. With extreme weather events, rising oceans and melting ice caps, the time to act on climate change is now. But that begs the question – How do we maintain our lifestyle without causing more damage to the planet?

One of the luxuries we barely think about in our day-to-day lives is hot water. We wash our hands and take nice, long showers in hot water. But have you ever stopped to think about the impact that this has on the environment? You may be surprised to know that water heaters account for 19.3% of all residential energy use in Canada [1]. Who knew water heating used so much energy?

But you may be asking yourself – how can we change this?

That’s where our solar collector comes in. Harnessing the power of the sun, we aim to provide enough hot water capacity to replace an electric or gas-fired hot water tank.

Team Members

Our Design

HOW DOES OUR DESIGN WORK?

Our system is called Direct Expansion Solar Assisted Heat Pump (DX-SAHP). Essentially, this systems transfers the heat energy from the sun into water for domestic hot water use. It does this by using a refrigerant loop. You can think of it as doing the opposite of your fridge at home. Instead of removing heat from a space, it gathers heat and transfers it to a desired location.

There are a few vital components for our project. These components include the solar collector, compressor, condenser, and the expansion valve.

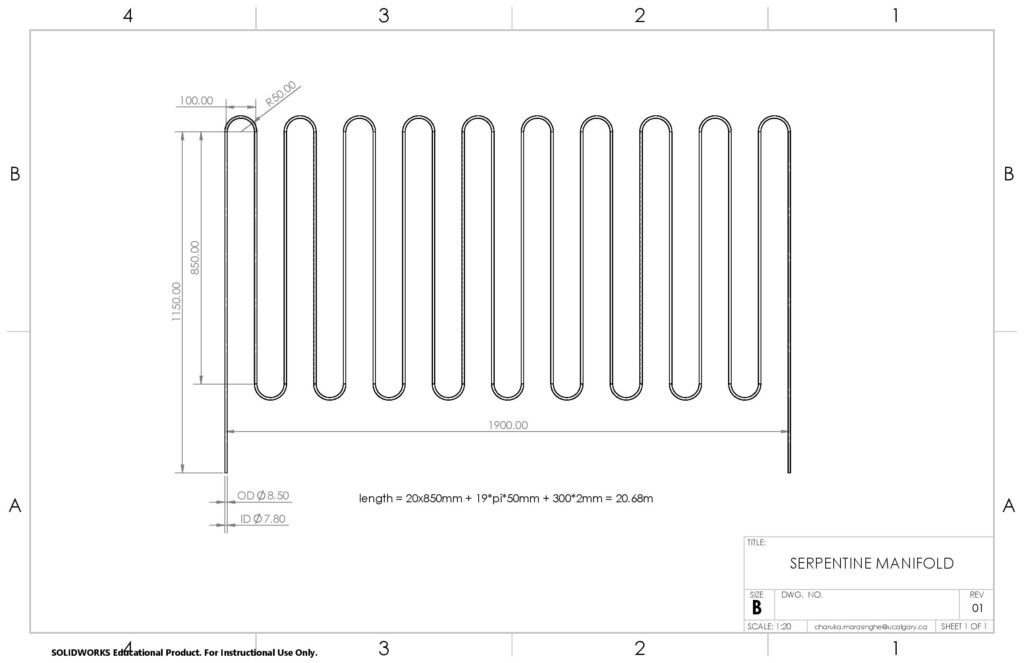

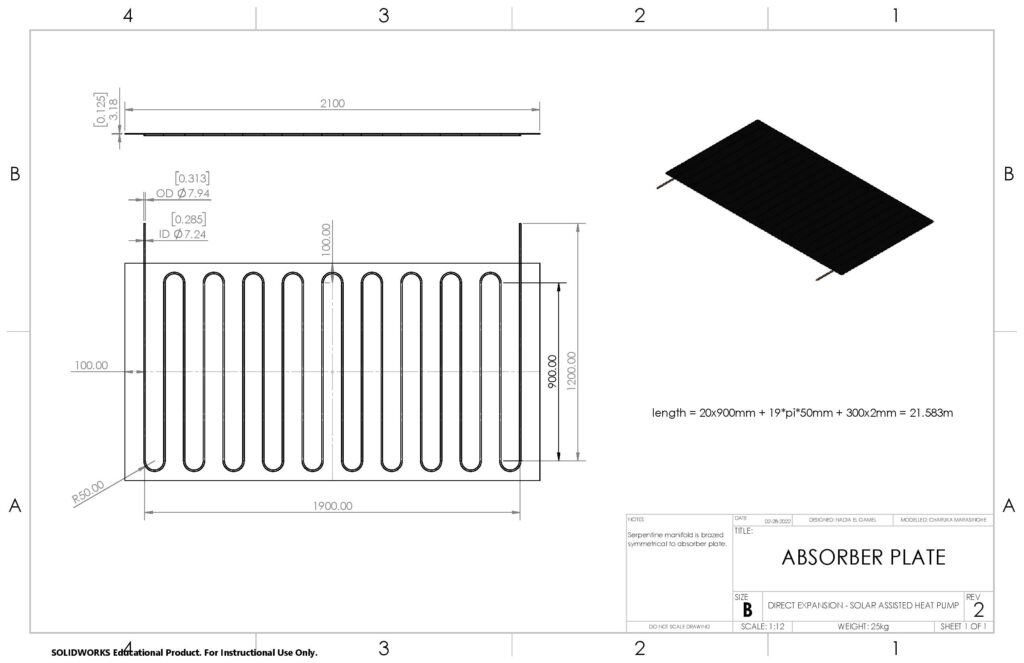

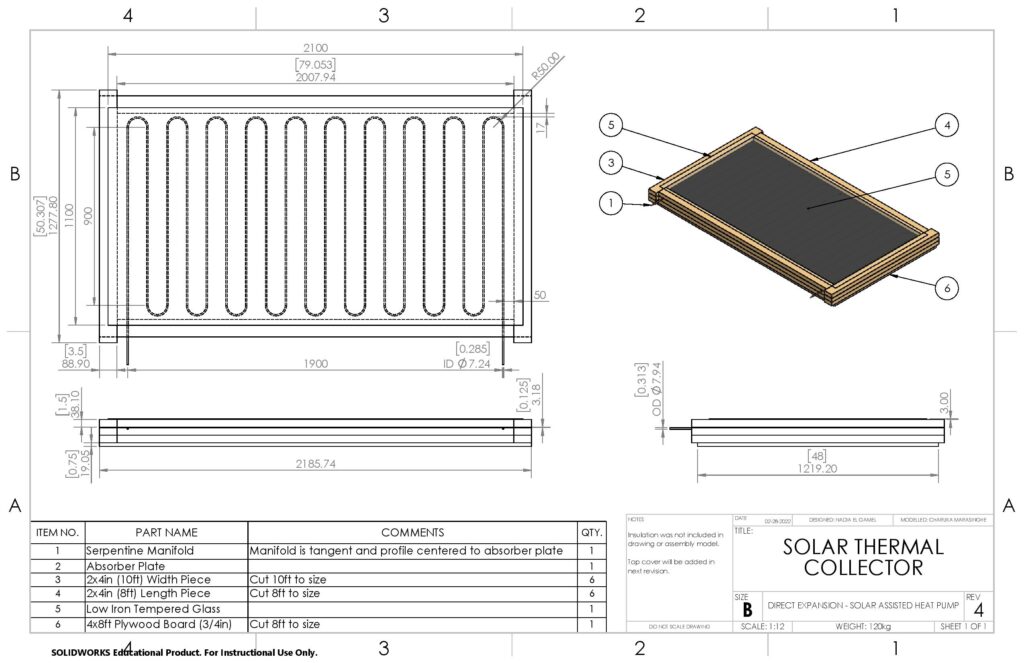

The solar collector is the most important aspect of the project. The solar collector itself consists of an aluminum absorber plate and a serpentine copper coil. The aluminum plate is coated with a silicon-based coating to help absorb the solar energy and transfer it to the copper tubing attached underneath it. The refrigerant is run through this copper tubing to absorb this heat to be used later.

The compressor is another vital component to our system. This component is responsible for driving the flow through the refrigerant loop and the condenser. The compression process also provides a small amount of heat to the refrigerant.

The condensing coil is where all the magic happens. The condenser is essentially a tube within another tube running parallel. One tube contains the hot refrigerant and the other tube contains the cold water. As the water flows through the condenser, the heat from the refrigerant is transferred to the water. Once this process is complete, the hot water is pumped away to the storage tank for future use.

Last but not least, we have the expansion valve. This valve depressurizes the refrigerant back down to the original level and the cycle repeats!

HOW DOES OUR DESIGN ADDRESS PRACTICAL ISSUES?

One of the significant challenges with solar collectors is the difficulty of implementing them in countries with cold climates. Typical solar collectors use a water loop to transfer heat from the collector to the water tank. As you can imagine, this would not be feasible when ambient temperatures drop to subzero levels. Our use of refrigerant in our solar collector prevents this freezing while still enabling enough heat collection from the sun to heat the water.

Another practical issue we wanted to address was the lack of access to warm water in remote communities. In far northern areas of Canada, such as Nunavut, access to gas for water heating is poor. This is mainly due to the cost of shipping this fuel to these destinations. Providing these communities with a reliable and cost effective means to heat water was an important motivation for our project.

Lastly, we wanted to find a way to contribute to Canada’s emissions reduction goals. With Canada aiming to reach a net-zero economy by 2050, the adoption of, innovative, clean energy technologies is imperative if we want to meet these goals while still maintaining our current lifestyles. We are confident that our system has the potential to provide heating for domestic hot water with minimal emissions.

WHAT MAKES OUR DESIGN INNOVATIVE?

While solar-assisted water heaters are already commercially available, our water heater is unique in that is uses a refrigerant loop to heat the water. As mentioned previously, this allows our solar collector to function even in sub-zero temperatures without any freezing or bursting of pipes.

The collector is made from both aluminum and copper. We decided to choose copper piping due to its superior thermal properties and its prevalence in HVAC (Heating, Ventilation, Air Conditioning) applications. Aluminum was a good choice for the absorber plate of the collector due to its thermal conductivity and economical viability. However, joining these two dissimilar metals presented some fabrication challenges. To overcome this, we mechanically fastened the copper piping to the aluminum plate and eliminated air gaps using a thermal paste.

You might also wonder whether snow affects the amount of heat collected. The good news is that unlike traditional solar panels, the operation of our collector is not fully stunted due to snow shading. The other great thing about our design is that since we use an insulated water tank, hot water is still accessible at night even when heat isn’t being collected from the sun. This is contrary to tankless water heaters powered by traditional solar panels.

WHAT MAKES OUR DESIGN EFFECTIVE?

Our design is effective because it is able to provide enough hot water for an average Canadian household consisting of three people as supported by our simulations.

Additionally, our prototype is able to function in colder environments because our model account for the irradiance of the sun throughout the day and the total amount of available sunlight hours to properly size the solar collector and determine its operational requirements.

HOW DID WE VALIDATE OUR DESIGN?

One important consideration when designing systems with refrigeration loops is the Coefficient of Performance (COP). The COP is a parameter that tells us how efficient a system is at moving heat. For example, a COP of 2.0 would mean that for every unit of energy we get from the compressor, two units of heat is transferred.

As seen in the graph below, illustrating the performance of the system during an average January/December day, the solar thermal collector is suitable for winter environments as it’s able to provide 1.1 of the 2.0 kW needed to heat domestic water on a daily basis. This proves that the system runs as expected even during sub-optimal conditions and can provide hot water reliably.

We also conducted an environmental analysis! With our design, we are able to reduce up to 3 tons of green house gas emissions a year. This is roughly equivalent to the amount of green house gases that a small vehicle emits annually. We also considered other important factors such as, the toxicity, the ozone depletion potential (ODP), and the global warming potential (GWP) when selecting our refrigerant.

Lastly, we conducted an economic analysis to determine the payback period of our system in comparison to traditional electric and gas-fired water heaters. The results determined that the payback period of the DX-SAHP in comparison to an electric water heater and a gas-fired water is 9-years and 24-years, respectively. It is important to note that these results are based on the energy costs in Calgary, but in other jurisdictions, where gas is more expensive, the payback period would likely be substantially shorter.

IS OUR DESIGN FEASIBLE?

Yes! This project is the result of iterative engineering and consultation with professionals in the HVAC industry who have jointly validated and contributed to the design from the early stages of its inception all the way to its actualization.

We invite you to visit our booth and see our live-scale prototype in person!

Want to Learn More?

Mentors and Sponsors

We would like to extend our thanks to the many people who made this project possible.

We would like to extend our deepest gratitude to our sponsors at Emerson and FN Insulation for their technical expertise and provision of material and labour. Thank you to Klass Mechanical and Chinook Refrigeration for their valuable insights on development of HVAC systems.

We also want to thank Dr. Aggrey Mwesigye and Dr. Simon Li for their guidance and for graciously providing the funding for this project. Lastly we would like to thank the capstone instructional team as well as the faculty advisors for providing valuable feedback throughout the course of the project.

F N INSULATION CALGARY

Photo Gallery

THE COMPONENTS

PROTOTYPE ASSEMBLY

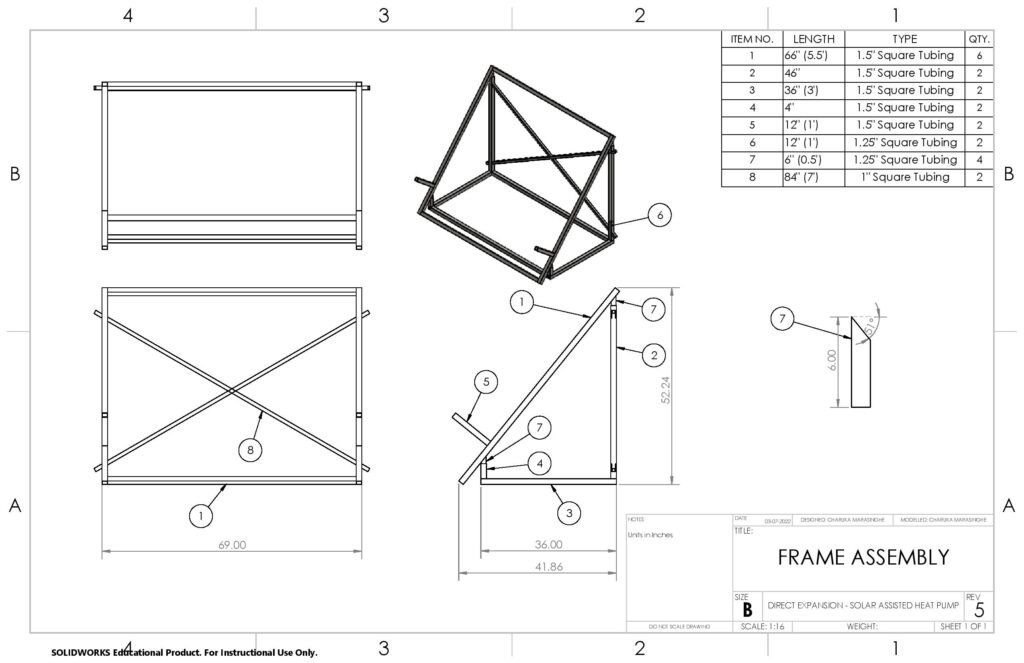

CAD MODEL DRAWINGS

CAPSTONE DESIGN FAIR POSTER

References

- https://www.nrcan.gc.ca/energy-efficiency/products/product-information/water-heaters/13735