Project Category: Mechanical

Join our presentation

If you have any questions or would like to chat about our design please join our live meeting!

About our project

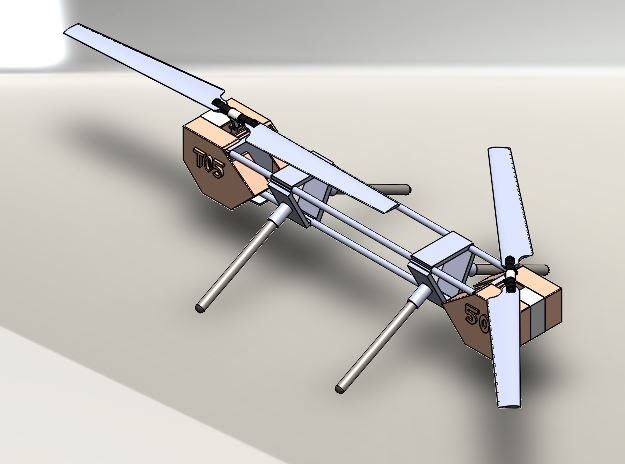

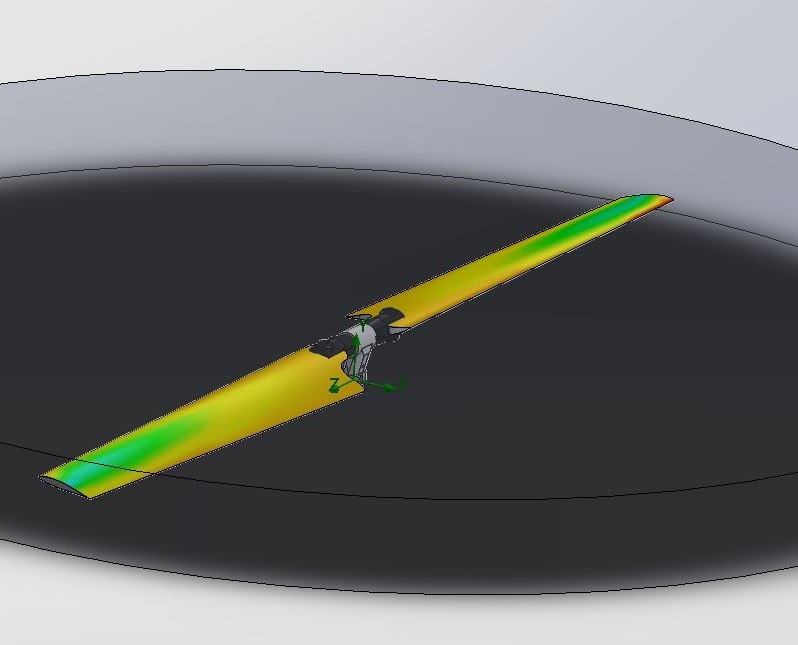

Our project has the goal of creating a dual rotor helicopter drone that utilizes its superior lift to weight ratio to perform larger package delivery than the current quad copter models. The first step towards a lower lift to weight ratio was reducing the number of motors from four to two as they, along with their batteries, are responsible for most of the drones weight and the amount of weight saved is greater than the lift generation lost. Further, the blades were analyzed with multiple different profiles to find an optimal shape for maximum lift. The blades on the dual rotor drone spin in opposite directions form each other in order to balance out centripetal force and prevent the drone from spinning.

Cost: $2321.85 CAD +GST

Meet our team members

Michael Bessem (top left)

Soibi Asinye-igoni (top right)

Sultan Chowdhury (bottom left)

Tyler Kiyonaga (bottom middle)

Zoran Blagojevic (bottom right)

All five team members are currently fourth and fifth year mechanical engineering students at the University of Calgary. The group came together as a function of their sheared interest in this project.

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

Current drones are almost exclusively quad rotor and thus have an inefficient lift to weight ratio. The presented dual rotor design creates an improved ratio due to the smaller amount of motors. Secondly, the dual rotor design is much more narrow than its quad rotor counterparts.

WHAT MAKES OUR DESIGN INNOVATIVE

| Both the blades and swashplate are custom designed to maximize the lift and mobility while not causing too much stress on the parts. The innovative two rotor design helps address the practical issues of a quad rotor drone mentioned above. |

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

| The two rotor design only requires two motors and batteries which is the primary source of weight in a drone. This reduction of weight is a huge factor in the improved lift to weight ratio of the drone. |

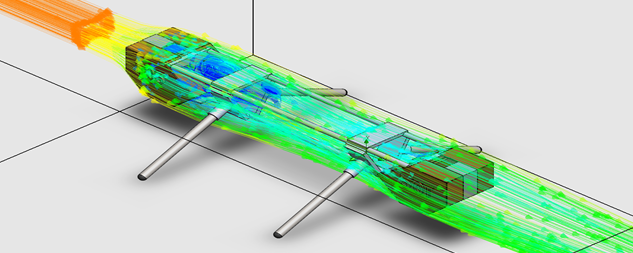

HOW WE VALIDATED OUR DESIGN SOLUTION

| Our design was validated through use of the simulation programs solidworks and ANSYS. Through solidworks we were able to run aerodynamics, and lift simulations on the frame and blades respectively. We further used ANSYS to analyse the forces on our frame and blades to ensure that nothing would cause failure. |

FEASIBILITY OF OUR DESIGN SOLUTION

Through our tests we were able to see that our design could easily surpass all of our initial requirements. The only detriment to feasibility is the size and therefore cost of the batteries needed for operation. While the cost remains within scope it is not a cheap solution to an improved lift to weight ratio.

Partners and mentors

We want to thank the many people who helped us with this project. First of all we would like to thank Dr. Jeff Pieper for design idea of a dual rotor drone, along with is guidance throughout the project. We would also like to thank our professor and T.A. Dr. Philip Ebgerts and A.J. Ebufegha for their guidance and suggestions.