Project Category: Mechanical

April 13, 2021 10:00 AM – 12:30 PM MST

About our project

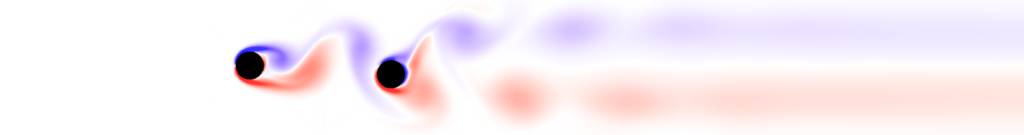

As the demand for alternative clean energy continues to rise, more novel sources of energy generation are being researched and explored. One technology that has been getting attention is the energy of vortex-induced vibration (VIV) harvesting system. Typically, engineers want to reduce the effects of flow-induced vibrations, but by placing bluff bodies in a flowing fluid where vortex shedding occurs, the motion of the bluff body can be harnessed into electrical energy.

This type of hydropower energy has advantages over regular methods of hydropower. VIV energy can be extracted at lower flow speeds and this versatility means that it can be stationed in various locations. Additionally, the low resource requirement causes minimal disturbance to the ecosystem and marine life. When considering the vast geography of Canada and the sparse location of many rural communities, there exists a need for small-scale power systems that can bring power to these remote communities. The nature of the VIV energy system design allows for minimal maintenance costs compared to other traditional sources of wind and solar.

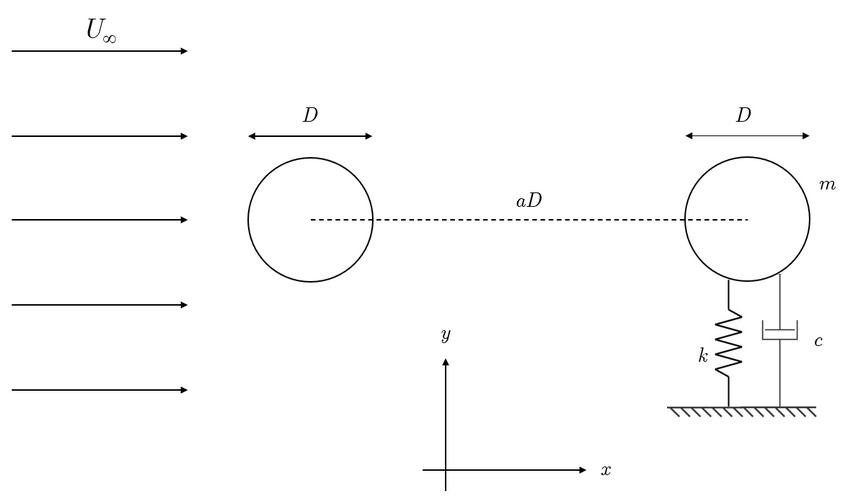

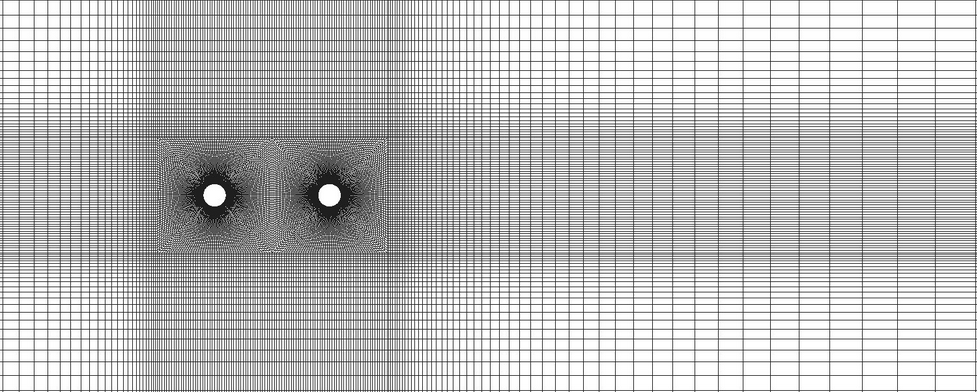

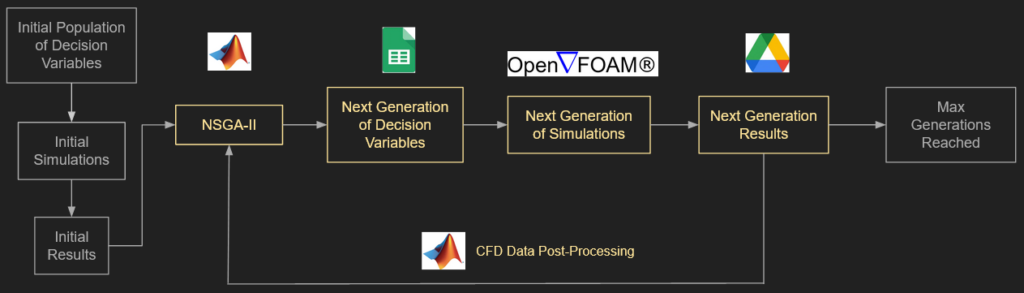

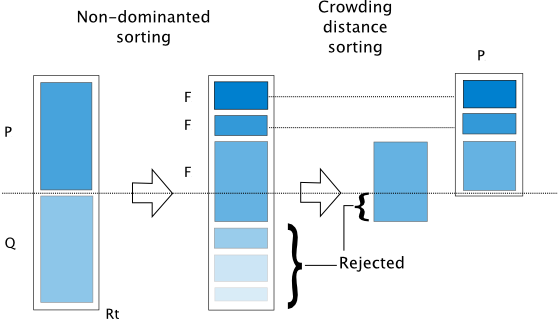

Although this technology has many benefits, it is not commercially available for power generation. One of the challenges with this technology is how much energy can be converted into electrical power. This issue can be addressed through the use of machine learning or optimization methods. This project will explore how to maximize the power harvested from the oscillations using a multiobjective evolutionary algorithm, NSGA-II. By designing a system where a rigid upstream cylinder will induce vortices on a moving downstream cylinder, the evolutionary algorithm will optimize the mechanical parameters of the system for maximum power generation. The system being studied consists of a two-cylinder system where vortices shed from the upstream cylinder are intended to amplify vortex-induced vibrations on the downstream cylinder. The evolutionary algorithm will then optimize the mechanical parameters of the downstream cylinder to maximize power generation.

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

Around 66% of the world’s population identify a river as their closest body of water. With the current climate crisis, it is becoming even more crucial to develop renewable sources of power for not only the largest population centres but also for rural communities that may lack access to cheap and clean power. Our project aims to address this concern by developing a low cost, small scale power generation system that harnesses the hydrokinetic energy in low-speed, low head rivers.

Additionally, these communities generally also tend to lack the expertise for sustaining complex mechanical machines such as wind turbines. For example, most northern British Columbian communities are only accessible by boat or air and this makes sending maintenance crews to large and complex wind and solar farms more expensive. The cost issue is one concern our team will address by proposing a system with very few mechanical components that require little to no maintenance and upkeep.

The biggest issues with the VIV technology proposed is the lower conversion of hydrokinetic energy to electrical energy. Due to the lack of research into the optimization of this system, the energy conversion is not as efficient as other renewable energy sources such as wing, which host peak power coefficients of 45%. There is opportunity to explore this issue and optimize the mechanical parameters of the system to increase the power generated.

Machine Learning (ML), data driven modeling and optimization have extensive use in the technology industry with applications ranging anywhere from fraud detection to image recognition to self-driving vehicles. One field for these techniques to grow is the field of fluid mechanics where the advancements of more powerful computers allows for the processing of large datasets into knowledge about optimization and flow control of systems in fluids. Our project focuses on using a multiobjective evolutionary algorithm in conjunction with computational fluid dynamics using OpenFOAM as compared to more traditional methods to analysis. Using optimization methods such as NSGA-II allows us to explore a large parameter space that would otherwise be restricted to a couple of cases. Using the NSGA-II algorithm as the optimization method, we were able to explore a large parameter space across two optimization methods to develop an optimal mechanical system.

WHAT MAKES OUR DESIGN INNOVATIVE

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

The NSGA-II algorithm used for the optimization method allows for us to efficiently explore the parameter space of mass, stiffness and damping across two objective functions. Having the ability to analyze a two-objective problem, we can confidently address the effect different physical parameters have on the amplitude, velocity, and power generation of the cylinder. Additionally, NSGA-II is a fast sorting and an elite multi-objective evolutionary algorithm commonly used for similar optimization problems. As a validated and common model, we are confident in its ability to sort, rank and create parameters that consistently explore new parameters spaces which improve the results of the objective functions evaluated.

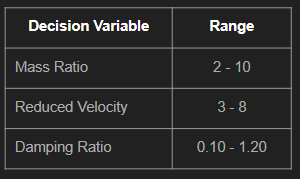

Additionally, the parameter space we explored is purely non-dimensional. This allows the group to easily scale the results to different scenarios and flow environments. Different flow conditions create different flow physics, and the fluid structure interactions can become highly complex and unpredictable. Non-dimensional mechanical parameters allow us to easily adapt the mechanical system to different flow fields that our system can be used in. For example, scaling from a river flowing at 1 knot requires different dimensional quantities for mass, stiffness and damping compared to a flow speed of 2 knots. This method ultimately allows us to generate a universal solution to the optimization problem that is easily scalable.

To ensure a realistic, and scalable outcome from the optimization process our group undertook, the decision was made to non-dimensionalize the complete parameter space. This decision is made because it allows for easy validation of our results with those obtained through research by other academic scholars studying the field. The three parameters that make up our space are:

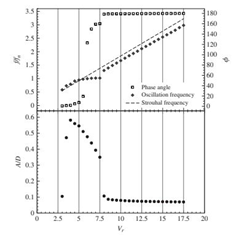

Our results were validated by comparing the optimized parameters with literature reference values for the same non-dimensional parameters. P.W. Bearman’s research paper on flow-induced vibrations at low Reynolds number is used as an initial baseline to compare how our reduced velocity parameter converged compared to the results provided in this research paper. What we find is that the range for reduced velocity converged to the “lock-in” range as defined by P.W. Bearman.

Lastly, we compared the results of our optimization with the work conducted by the Marine Renewable Energy Laboratory (MRELab) at the University of Michigan. We compared our maximum power coefficient of approximately 0.2 to their 0.22, however, we believe our optimization process and methods would generate a greater power coefficient and a better-optimized system when a greater number of generations can be run for the problem. The team at MRELab hypothesized a maximum coefficient of power being 0.37 and this value would serve as the goal for our algorithm.

HOW WE VALIDATED OUR DESIGN SOLUTION

FEASIBILITY OF OUR DESIGN SOLUTION

By formatting our project results into non-dimensional parameters and variables, we are able to scale our results to real-world applications. For instance, the maximum power coefficient found from the optimization process can be applied to a hypothetical system in the Bow River. The flow of the river is around 3 knots or 1.5m/s. For a cylinder diameter of half a meter, the power output of one cylinder per unit length is around 170 W/m.

Under the Electric Utilities Act and the microgeneration regulation, where small-scale micro-generators are less than 150 kW in capacity, this energy generation system would require a maximum of 880 cylinders in an array to be classified as a small scale micro-generator. Since the harvester uses simple and cheap cylinders, the cost of operating and maintaining this system would be much less than even other sources of renewable energy. The cylinder dimensions are easily scalable to the point where you could have a large array of large cylinders or a small array of small cylinders. This source of cheap mechanical to electric energy would be ideal in the rural communities in Canada or in communities in developing countries as around 66% of the world’s population is at least near a small river.

Partners and mentors

We would like to offer our greatest gratitude towards Dr. Martinuzzi and Dr. Morton for guiding us through this novel and exciting problem to solve. Through their patience and time, all the team members have a much greater understanding of fluid mechanics, CFD, machine learning and project management.

We would like to additionally extend our thanks to Maziyar Hassanpour for helping us through some challenges we faced in the CFD process.

Lastly, we would like to extend our thanks to A.J. Ebufegha and Dr. Egberts for guiding us through some of the problems we faced.

Our photo gallery