Project Category: Mechanical

Join our presentation

About our project

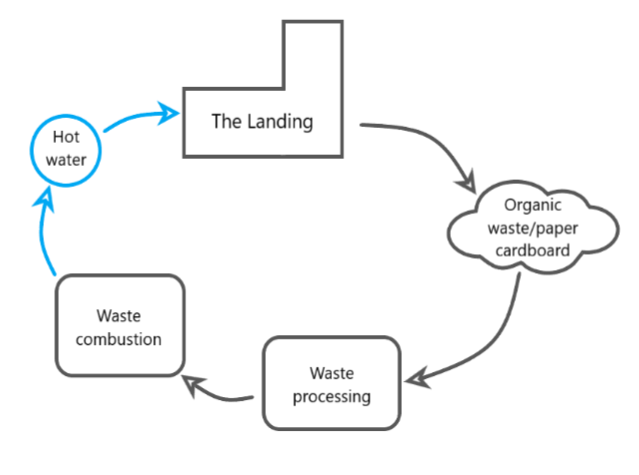

Our project focus was designing a closed loop system to manage the organic waste produced at the University of Calgary’s resident dining center – The Landing. The University has many sustainability and emissions-based goals, including a target of a carbon neutral campus by 2050. The Landing offers a unique opportunity to implement technology that will help meet this goal since it has a completely organic waste stream. To create a closed loop system, we first investigated different waste management techniques and subsequently identified the technology that would create the most effective system. We found a local manufacturer and supplier called Eco-Growth that provided suitable technology. A complete analysis of three closed loop systems using Eco-Growth components was performed to better understand the unique benefits of each. This engineering analysis compared the systems based on processing capability, efficiency, carbon accounting, economics and logistics. The most beneficial solution is to install a system complete with an organic waste dehydrator, boiler, and shredder. This system has sufficient processing capability, a reasonable payback period, the highest efficiency, and creates a carbon benefit to the University.

Meet our team members

Eva Sombrowski

Laura Krett

Laura Petrillo

Natasha Gordey

Sebastian Leblic

Details about our design

DESIGN COMPONENTS

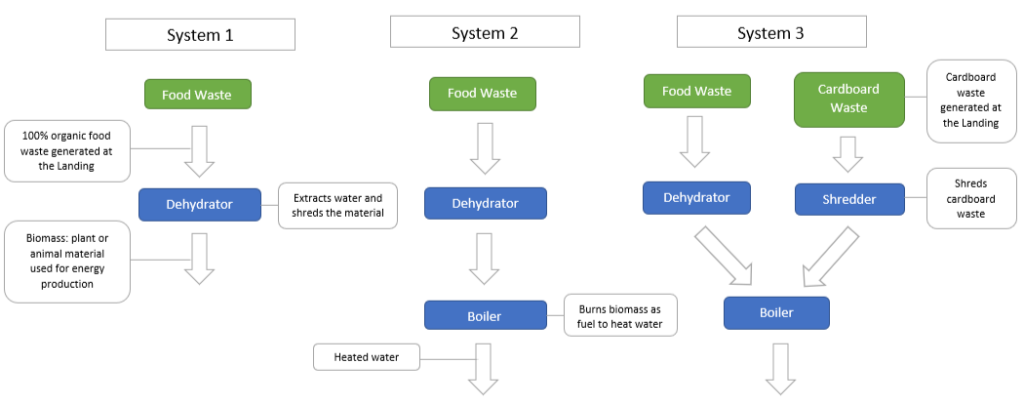

During preliminary design, research of existing food waste processing technologies and feedback from project sponsors identified the value in assessing the performance of three distinct waste management systems. This would highlight the unique benefits of added components to the closed-loop processing of organic waste. All three designs make use of technology that is manufactured and supplied locally in Calgary, by a green energy company called Eco-Growth. Through engineering analysis, System 3 – the “Plug and Play” system – proved to be the most feasible and effective for application at The Landing. This system design option is an alternative that exceeds the project requirements but includes components that provide additional benefit. All components come in an insulated shipping container – a dehydrator for wet organic waste, a shredder for solid material waste like cardboard and paper, a conveyor that feeds the dehydrated waste and the shredded material into a hopper, and a boiler. Potential energy from the dehydrated biomass and paper cardboard is captured in hot water produced by combustion in the boiler. The resulting energy would be used to heat water for the dishwashers in the dining center’s kitchen, reducing the need for water heated by natural gas. This design allows for the most effective management of the organic waste and returned benefits of reduced emissions, cost savings and a new energy source to The Landing.

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

The proposed system addresses several practical issues for the University including reducing waste management costs, reducing emissions and providing an in-house source of clean energy. Eliminating the need to transport waste has financial, sustainability and logistical incentives. The organic food waste and cardboard produced at the Landing are currently both being frequently hauled from campus for disposal, which incurs cost and creates emissions. The proposed closed-loop waste management system allows for the waste produced at the dining center to be eliminated directly on campus. This also allows for utilization of the potential energy in organic and cardboard waste to produce useable energy and offset electricity requirements which provides additional cost savings. The University of Calgary has set a goal in their Climate Action Plan to be a carbon neutral campus by the year 2050, and this system reduces emissions from the current waste management methods by eliminating trucking emissions and offsetting natural gas used to heat water with electricity produced by the boiler. In terms of logistical improvements, the dehydrator in the system extracts moisture from the organic waste, resulting in an inert, odourless food waste product that can be stored for long periods of time. This allows flexibility in the storage and use of the biomass, unlike untreated organic waste which needs to be handled immediately to avoid odour and pest issues.

WHAT MAKES OUR DESIGN INNOVATIVE

The system design offers an innovative waste processing solution for the University of Calgary, diverting waste from landfill, as well as harnessing and applying the stored potential energy for direct use on campus. The project hopes to establish the efficacy of organic waste-to-biomass processing technology and highlight the value of transforming waste streams into sources of potential energy wherever possible. Using food waste as a source of energy would be a meaningful progression in the University’s sustainability goals. This system utilizes the potential energy stored within the organic food waste stream, which is currently unharnessed. This waste would otherwise be processed off-campus, incurring transportation costs, and not providing any benefit to the University. Further, the use of food and paper cardboard waste as a fuel for on-site energy generation moves the campus away from its dependency on fossil fuels used in transportation and heat generation. The proposed waste processing cycle is new and unconventional, but produces unique benefits which would progress the University towards a more sustainable future. Should this system be successfully implemented, it would provide an example of how much benefit could be added by other areas of campus to entirely organic waste streams in the pursuit of sustainability.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

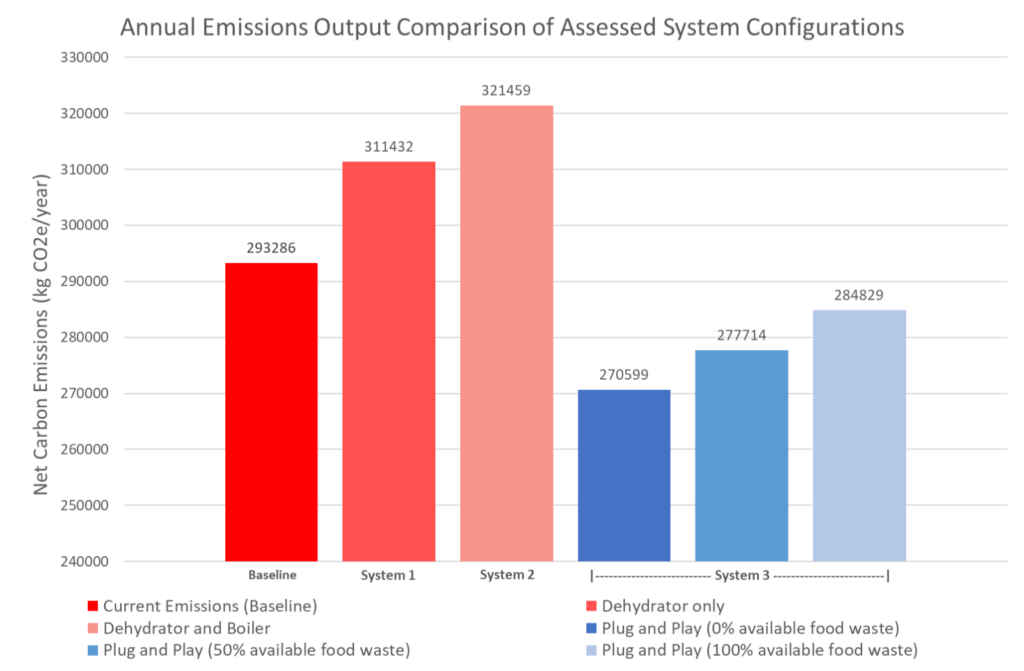

This design is effective because it is capable of handling all organic waste produced at the Landing, as well as providing additional capacity for processing cardboard waste. In addition, the proposed system eliminates the need for organic waste to be transported from the Landing. This will reduce the University’s cost for disposing of organic waste as well as eliminating the emissions associated with hauling organic waste to a compost facility. The system also offers a high energy efficiency and provides a new source of energy for the Landing. The improvement in emissions was quantified by a carbon accounting analysis. It showed that a dehydrator, boiler and shredder system would reduce carbon emissions associated with the waste transportation, burning food waste and utility generation by between 3% to 8%, depending on the proportion of food waste. The design solution creates cost savings for the University by reduced transportation costs, energy savings, and carbon tax savings. For a dehydrator, boiler and shredder system, the net annual savings translate to a payoff period of 9.55 years, and is the shortest pay off period of the three systems.

HOW WE VALIDATED OUR DESIGN SOLUTION

Initial validation of the design was based on the experience of other users of Eco-Growth technologies. The team was able to find working examples of all equipment, including the dehydrator, Eco-Boiler, and the full Plug-and-Play system at other facilities in Canada. This was a preliminary validation to confirm that the systems are effective at diverting waste from its original streams while providing some benefit to the user. To further validate the design solution and determine which of the technologies would be most useful for application at the Landing, an engineering analysis was performed on three different waste management systems, with five areas of focus. The five areas of analysis are processing capability, system efficiency, carbon accounting, economics and logistics. The design solution is validated by comparison to the original system, and between systems to determine performance in each of the five categories.

FEASIBILITY OF OUR DESIGN SOLUTION

The three variations of Eco-Growth systems have been successfully installed and operated at several other organizations. Interviews and feedback from these users have proven the efficacy of the technology for the intended application. A processing capacity analysis and an analysis of logistics of implementation has shown that the proposed systems can handle the waste requirements of the Landing and could be appropriately housed and wired. Three possible locations for external housing of the systems were identified, within reasonable distance of the Landing. Installation would be straightforward due to all components being housed in an insulated shipping container with a single electrical hookup, and one glycol line running in and out. Eco-Growth is a local manufacturer which would allow for convenient training and maintenance. The system requires a considerable investment, but this can be justified by the contributions towards the University’s sustainability goals as well as a conservative estimated payoff period of 9.55 years. In addition, the alignment of the technology with the University’s sustainability goals will have long-term value in offsetting emissions and providing green energy to the campus.

Partners and mentors

We would like to thank our project sponsors, Ana Pazmino and Earl Badger for their guidance throughout this project. They have offered invaluable feedback and guidance over the course of our work, as well as specific project and application insight.

Additionally, we are appreciative of the time and information received from the Facilities Manager for the Landing, Janice Cummins.

Finally, we would like to thank Dr. Simon Li for his continued guidance and direction throughout our design process.

Our photo gallery

Eco-Growth dehydrator with samples of dehydrated organic waste, picture taken on site visit.

Eco-Growth solid waste shredder and conveyor, picture taken on site visit.

Eco-Growth organic and solid waste hopper, picture taken on site visit.

Eco-Growth boiler at the back of R-40 insulated enclosure, picture taken on site visit.

Operator interface to control boiler temperature, picture taken on site visit.