Project Category: Mechanical

Join our presentation

The team is available on this zoom link on April 13 from 10 a.m.-12:30 p.m. to answer any questions about the project.

About our project

In 2020, the novel Coronavirus spread at alarming rates around the world. The design team, like many entrepreneurs born from this pandemic, decided to come up with a solution to reduce virus and bacteria transmission in everyday life. The Portable Anti-Viral Septic System (PASS) was the small contribution the team hopes to make to combat the spread of the coronavirus and common washroom viruses and bacteria.

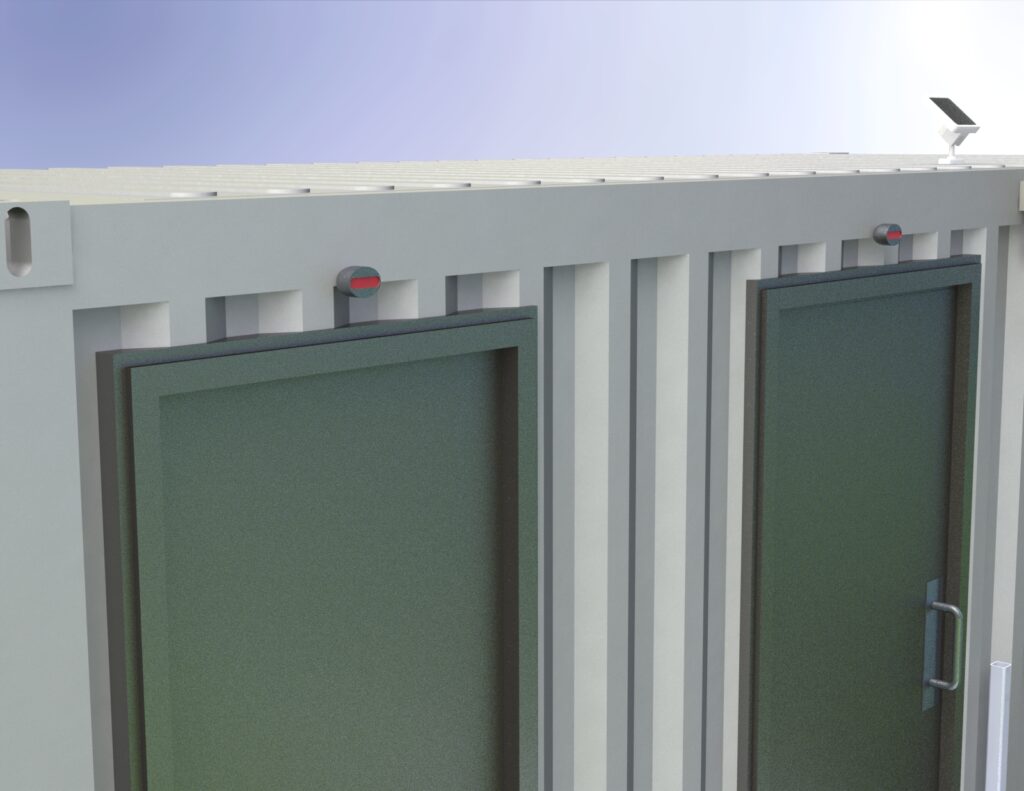

PASS is a portable washroom unit retrofitted inside a shipping container. This washroom unit boasts affordability for the client with the added benefit of reducing virus and bacteria transmission at an event or workplace. Public and private enterprise have felt the detrimental financial impact of this pandemic and are required now to perform sanitization and social distancing protocols where they haven’t had to in the past.

PASS features separate unisex washrooms to promote social distancing and general cleanliness between users. Within each washroom the user will have the standard amenities such as a toilet, urinal, and sink, but with touchless considerations. After a user is finished the door is closed and the PASS washroom automatically starts a disinfection cycle. This cycle uses a high-powered germicidal UV light that kills viruses and bacteria on surfaces. After this cycle is over the washroom is now sanitized and ready for another user.

Meet our team members

Alex Chester

Graduating Mechanical Engineering with a minor in Mechatronics at the University of Calgary. Completed a 16-month internship at Shawcor Composite Production Systems working in the product engineering team. Enjoys playing guitar and watching F1.

Jada Li

4th year Mechanical Engineering student with a minor in Computer Science at the University of Calgary. Completed a 16-month internship with TC Energy as a Quality Management Engineering Intern. Hobbies include cooking and spending time with her dog.

Alexander Schober

4th year Mechanical Engineering student at the University of Calgary. Worked with Imperial Oil as a Facilities Engineering Student for 16-months in Cold Lake, AB. Hobbies include car maintenance and modifications, and iOS app development.

Lauren Sentis

Graduating Mechanical Engineering this year and starting work at Canadian Natural Resources Ltd. as an EIT where she completed her 16-month internship. Enjoys walking her dogs, skiing and camping.

Jeremy Stark

4th year Mechanical Engineering student who interned at CNRL Horizon oil sands in the reliability department. He will be starting as and reliability engineering EIT at the Horizon mine in June 2021. He enjoy travelling, hiking, biking, and skiing.

Eric HS Yang

4th-year Mechanical Engineering student at the University of Calgary. 3 years of IT work with Apple, now relocating to ARITZIA’s head office in Vancouver for technical work. Currently working on MySQL certification followed by Tableau and BI certifications. Loves to cook and feed his friends.

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

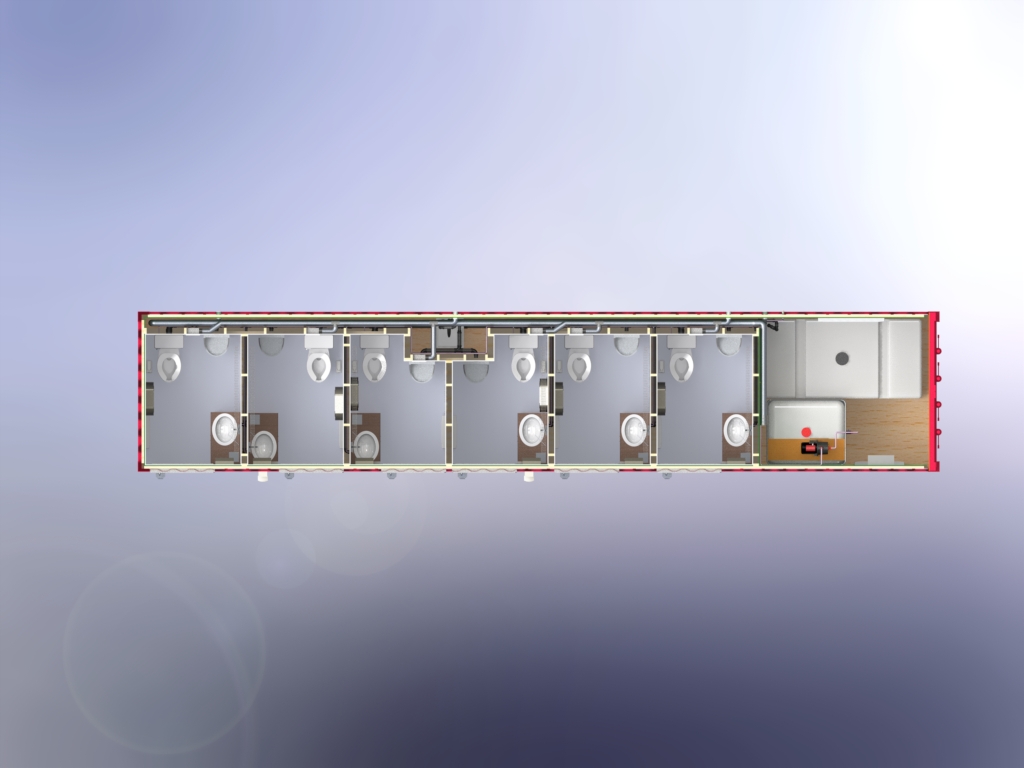

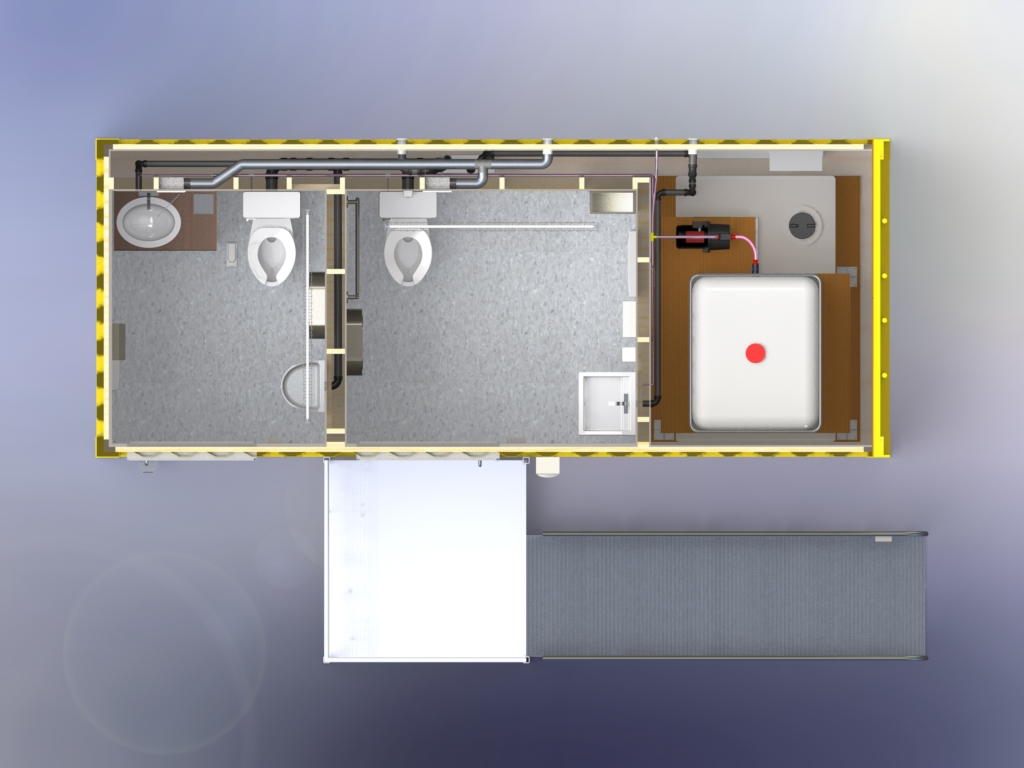

Washrooms are a crucial component of any building and PASS offers a virus-free alternative to the conventional restroom trailer for rent in events and construction sites. Currently, portable restrooms are not known to be particularly sanitary and allow for easy transmission of viruses and bacteria. The units are designed to be transportable and will be constructed in both a 20ft and a 40ft shipping container option as needed by the client. Heaters and spray foam insulation allow for the PASS unit to maintain 5ºC inside in even -41ºC weather. The 20ft PASS unit includes one standard and barrier free washroom. The 40ft shipping container has six standard washrooms.

STANDARD WASHROOM

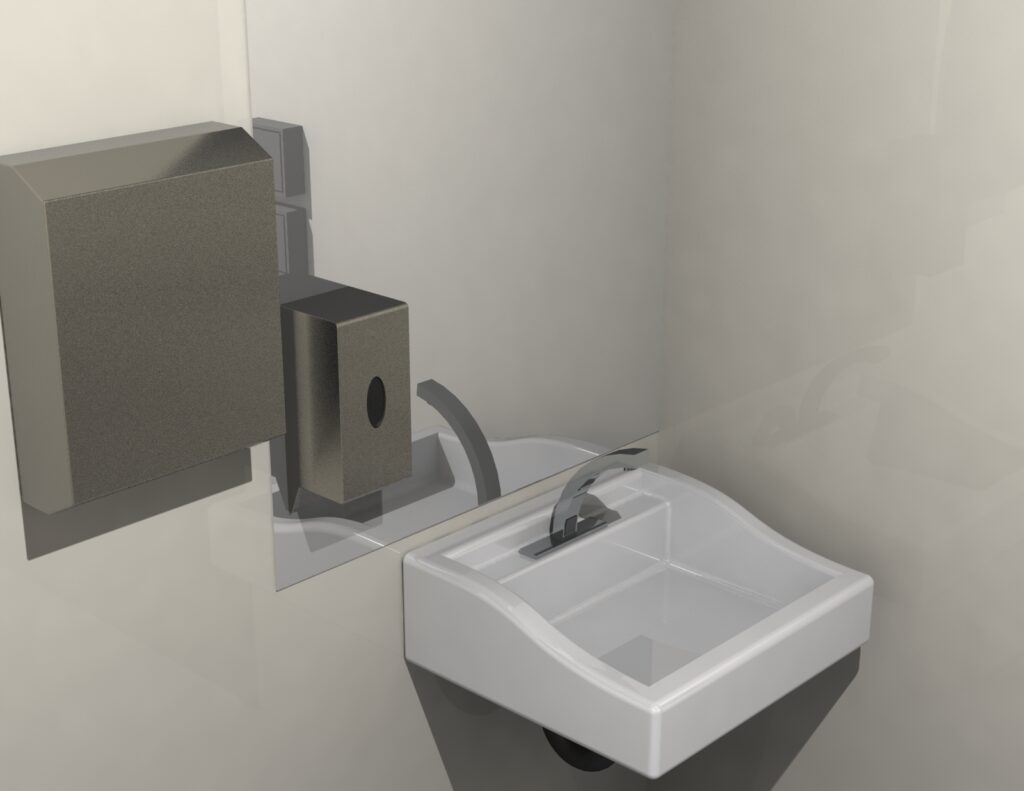

The standard washroom includes sink, soap pump, toilet, urinal, paper towel dispenser, toilet paper dispenser, and garbage disposal.

BARRIER FREE WASHROOM

The additional barrier free features include wheelchair accessible sink, ramp and platform to access washroom, accessible door opening system, handrails along the wall beside the toilet, and 1.5 m diameter open space to permit wheelchair to turn.

WHAT MAKES OUR DESIGN INNOVATIVE

DISINFECTION CYCLE

Our design for a portable washroom aims to reduce potential transmission of bacterial pathogens by providing a sanitary solution using a germicidal ultraviolet lamp installed in each washroom. Ultraviolet Germicidal Irradiation is a proven method used to disinfect water, air, and surfaces. It is most common to use a UV lamp at a 254 nm wavelength, also known as UVC, to inactivate a wide spectrum of microorganisms, such as viruses and bacteria.

There are many risks associated with using UVC lamps to terminate cells. UVC is intensely absorbed by most organic materials meaning there are additional considerations for this project such as potential exposure to humans and choice of materials used in the washroom designs. Each washroom features a door locking mechanisms that works in tandem with sensors to ensure the restroom is vacant and the door is closed before starting the disinfection cycle. A red indicator light turns on for the duration of the cycle to alert users that the washroom is unavailable and when it is occupied.

Currently, most portable washrooms are made of plastics which are vulnerable to compound breakdown when exposed to UV light without proper protection. Plastics in general are susceptible to colour fading, loss of strength, cracking, and even disintegration due to UV exposure. All material chosen to be within the exposed area of our shipping container has superior UV resistance such as metals, ceramics, and porcelain.

TOUCHLESS CONSIDERATIONS

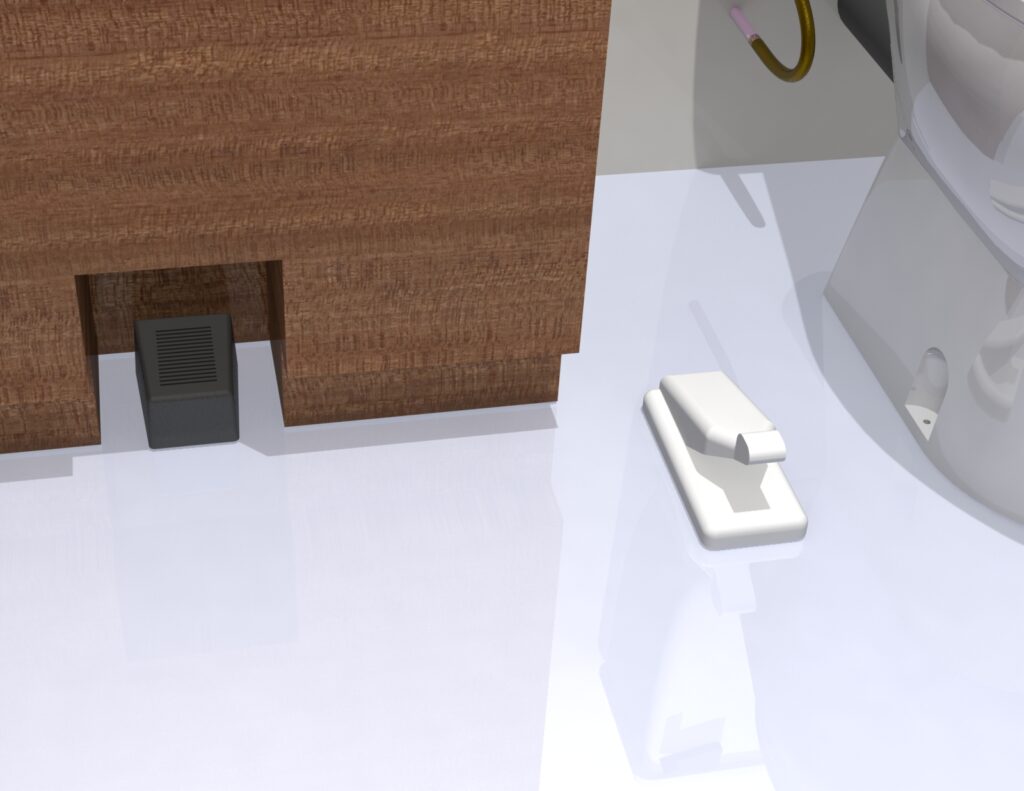

In areas that are high touch surfaces and cannot be changed out with a foot pump (such as the door locking buttons) a nanoSeptic sticker is used that kills bacteria and viruses that come into contact with it.

Standard Washroom Design Features:

- Soap pump and toilet operating foot pumps

- Automatic sink sensor

- Doors can be opened with StepNPull

- Doors can be locked by pushing a button with an elbow

Barrier Free Washroom Design Features:

- Soap pump and toilet operating automatic sensors

- Automatic sink sensor

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

Our design can be built from prefabricated materials. It follows specific Canadian codes and standards to ensure our design is compliant with national engineering practices listed below.

- National Fire Code of Canada

- National Plumbing Code of Canada

- National Energy Code of Canada for Building

- National Building Code – Alberta Edition

- International Plumbing Code – Methods of Venting Plumbing Fixtures and Traps

- ANSI/ASHRAE Standard 62.1-2013 – Ventilation for Acceptable Indoor Air Quality

To determine if the PASS unit can be used in a real life application, multiple calculators have been created to determine how many 20ft or 40ft units are required for an event or a construction site. These calculators factor in the time it takes to run the disinfecting germicidal UV light cycle.

These calculators consider if:

- alcohol is served at the event

- the percentage of women and men who will be using the PASS unit

- the time the unit(s) are used (duration of event or workday)

- if a barrier free washroom is required

PASS EVENT APPLICATION EXAMPLE

Global Fest is a yearly firework festival that happens in Calgary over five nights. The below table is assuming that 50% of women are in attendance to Global Fest that runs 6 hours, and that alcohol is served with a maximum attendance of 2000 people. There must be one barrier free washroom to ten standard washrooms. This table is double what is generally recommended to factor in the disinfection cycle.

| Number of Event Attendees | Number of Individual Washrooms | Number of 40ft PASS Units | Number of 20ft PASS Units | Ratio of Standard to Barrier Free Washrooms |

|---|---|---|---|---|

| 250 | 8 | 2 | 2 | 14:2 |

| 500 | 10 | 2 | 2 | 14:2 |

| 1000 | 16 | 3 | 2 | 20:2 |

| 2000 | 30 | 5 | 4 | 34:4 |

| 3000 | 42 | 7 | 6 | 48:6 |

| 4000 | 58 | 10 | 6 | 66:6 |

| 5000 | 72 | 12 | 7 | 79:7 |

| 6000 | 84 | 14 | 8 | 92:8 |

| 7000 | 96 | 16 | 9 | 105:9 |

| 8000 | 112 | 19 | 13 | 127:13 |

For the Global Fest event it would be appropriate to have five 40ft PASS units and four 20ft PASS units. The tanks for all units will need to be filled and emptied once a night over the course on the five-night event. This could mean that the next day a maintenance team can be sent to prepare the PASS units for the next night. Assuming that there can be two event contracts that can be secured in one year for roughly $60,000 each (like Global Fest) the PASS units will see a return on the initial investment in two years.

HOW WE VALIDATED OUR DESIGN SOLUTION

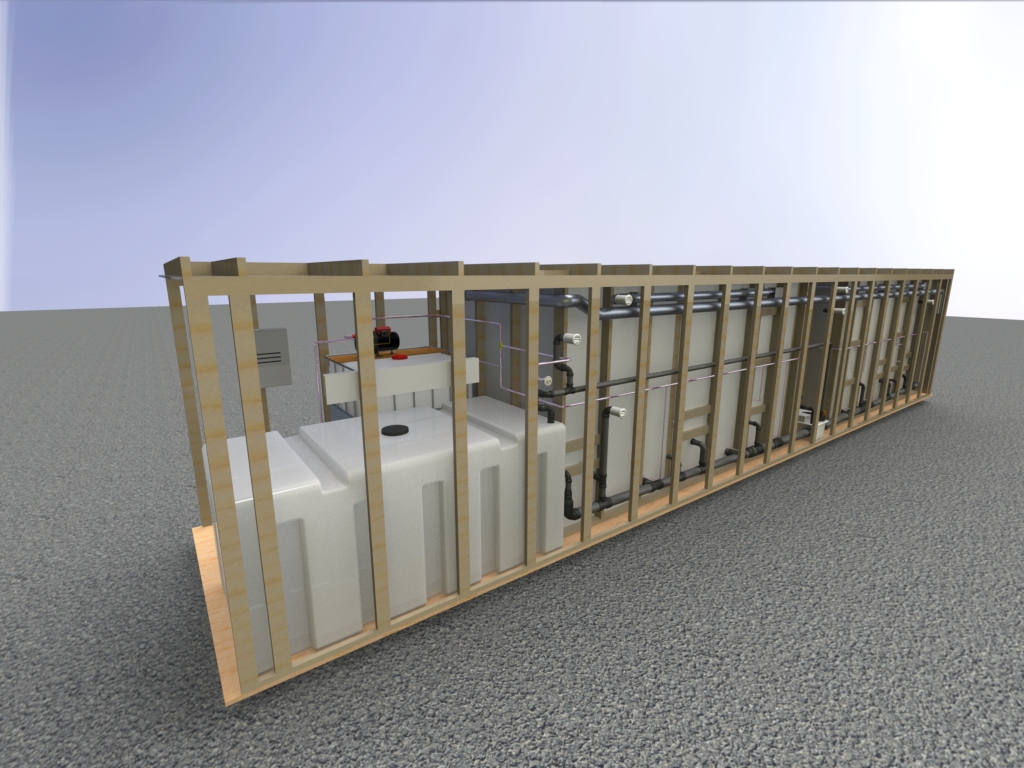

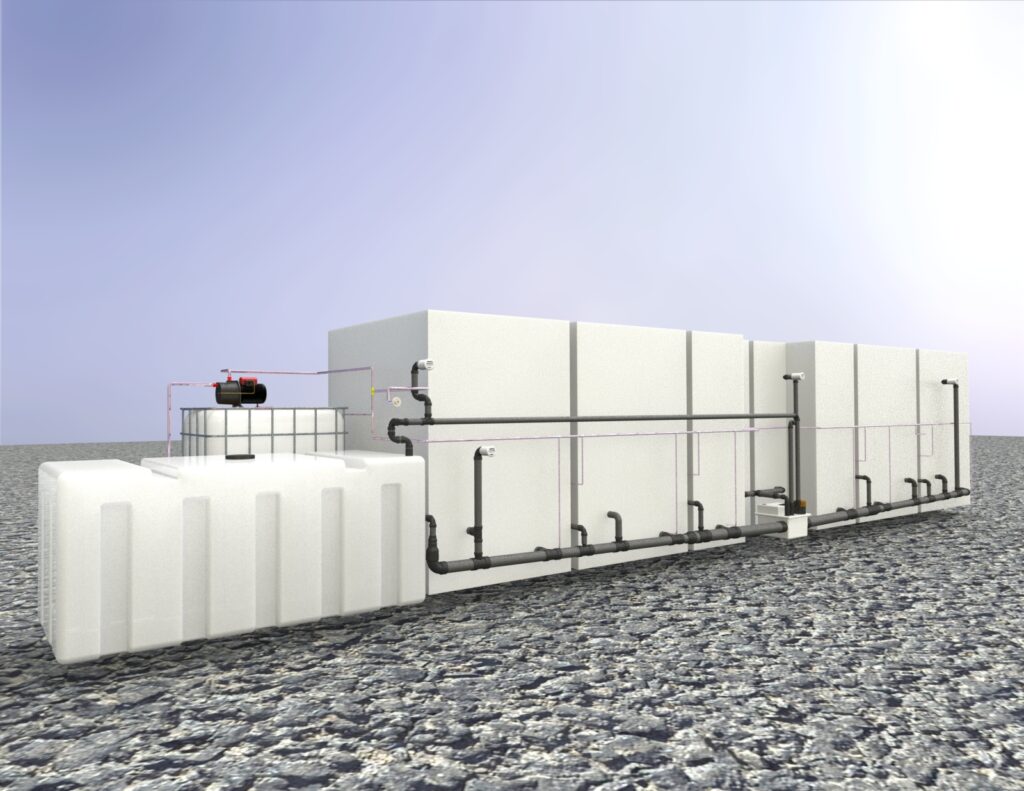

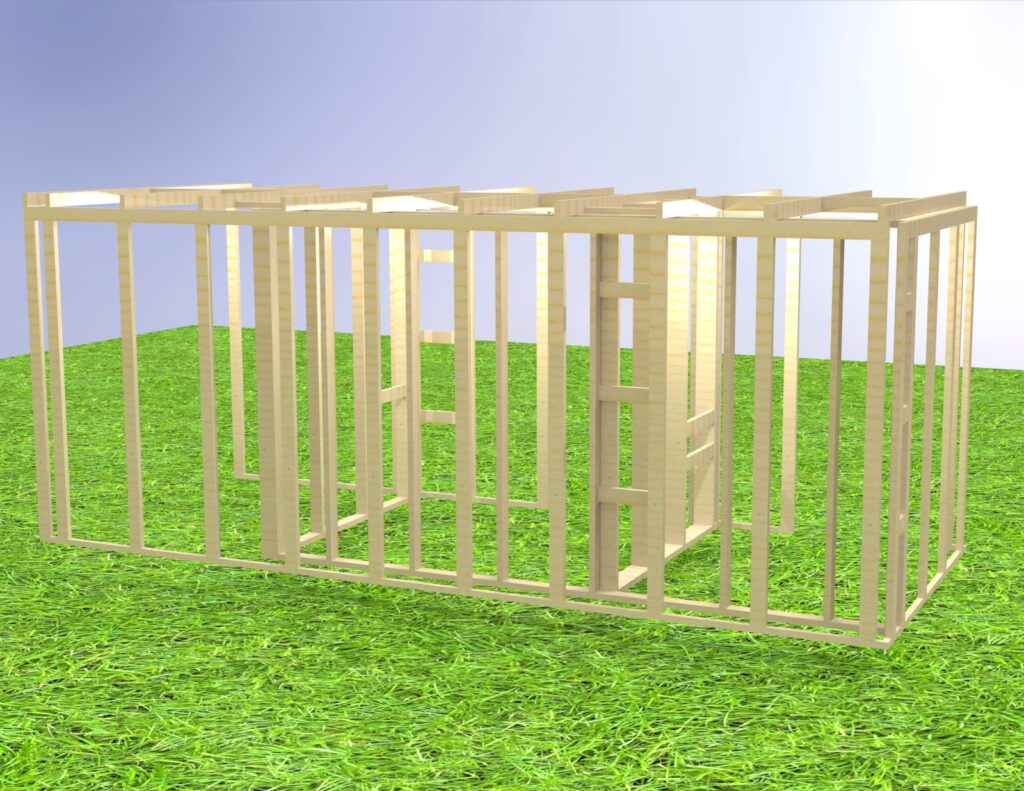

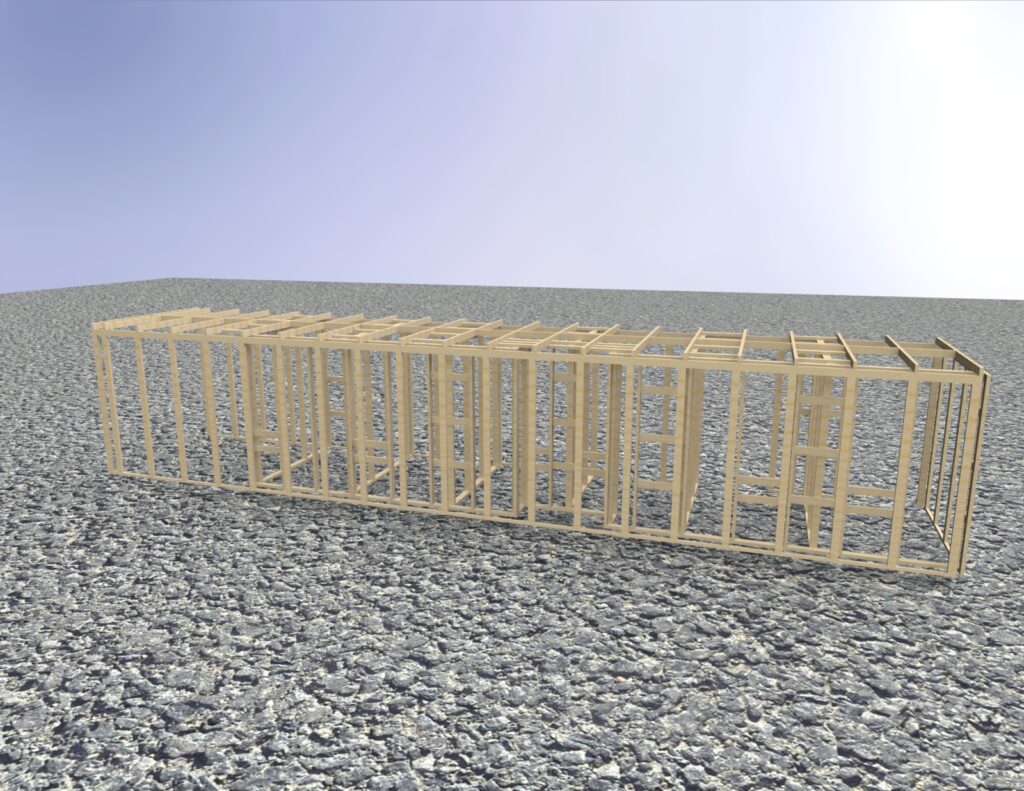

3D MODELLING

The design team chose prefabricated materials that would be used to build a physical PASS unit and modelled each component in SolidWorks. This was to ensure that each component would fit inside the washrooms and that the user would have enough space to use the facilities. The piping and framing were built in SolidWorks to ensure it would fit within the space constraints of the shipping container unit while still meeting national building and plumbing standards. The modelling is an excellent visual for our design and would act as a blueprint if a physical unit was ever constructed.

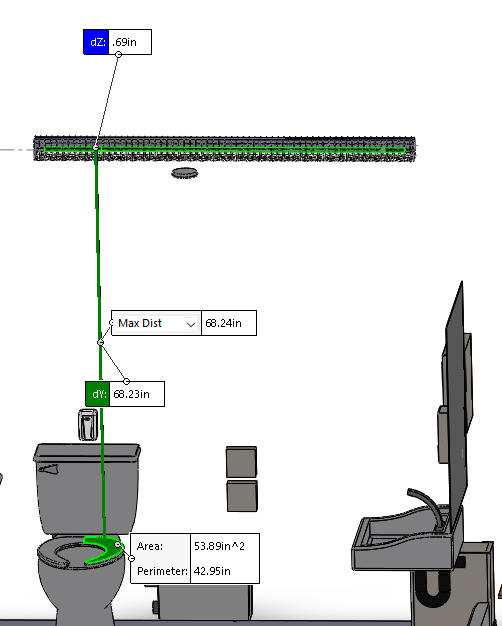

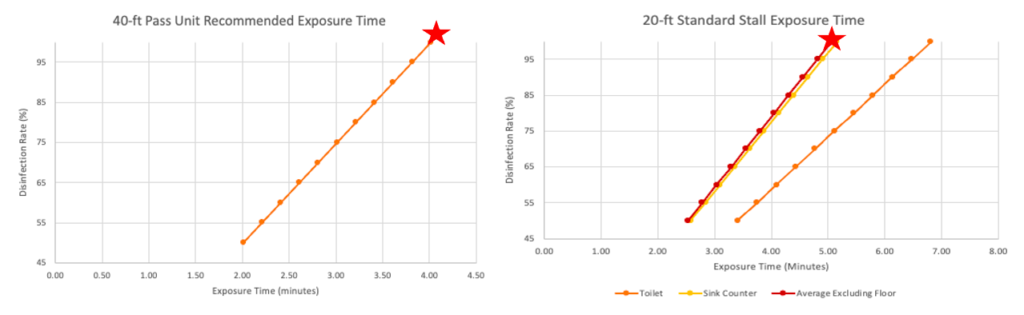

DISINFECTION CYCLE TIME

Without access to lighting simulation software, the design team had to come up with a solution to determine an estimation of a germicidal UV lamp exposure time and dosage that would meet a goal of 99.9% deactivation of viruses and bacteria. In the model the distance from each surface to the light is measured to determine the light intensity on that surface, an example of this is shown below.

The sink was an area the team wanted to focus on since that is where most common touch surfaces are. By averaging the calculated recommended exposure time from multiple locations on each surface, the team determined the overall recommended exposure time for the 20 ft unit standard washrooms is 5 minutes, the barrier free washrooms is 6 minutes, and the 40 ft unit standard washrooms is 4 minutes.

FEASIBILITY OF OUR DESIGN SOLUTION

The design team’s goal was to ensure the PASS unit would be affordable to build and could be used as a replacement to many restrooms trailers on the market. Below the table shows the initial capital investment required to build each PASS unit. There is a 15% contingency applied to each total to factor in any changes that might need to be made with material procurement or during construction. Both PASS units are competitive with the initial building costs of restroom trailers currently on the market.

| 40 FT | 20 FT | |

|---|---|---|

| Total Cost of Components | $31,154.40 | $18,823.85 |

| Construction Material/Labour | $16,239.90 | $11,113.57 |

| Contingency (15%) | $7,109.15 | $4,490.61 |

| Grand Total | $54,503.45 | $34,428.04 |

| Competitor Cost | $70,000-83,000 | $57,500-70,000 |

PASS CONSTRUCTION APPLICATION EXAMPLE

To show how feasible the PASS units are to build and use a real life example of a construction site with 60 workers is examined. The below table is based on how many portable washrooms are chosen for a 40-hour work week or 12-hour workday.

| Number of Workers | Number of Standard Washrooms | Number of 40ft PASS Units |

|---|---|---|

| 01-10 | 2 | 1 |

| 11-20 | 4 | 1 |

| 21-30 | 6 | 1 |

| 31-40 | 8 | 2 |

| 41-50 | 10 | 2 |

| 51-60 | 12 | 2 |

| 61-70 | 14 | 3 |

| 71-80 | 16 | 3 |

| 81-90 | 18 | 3 |

| Over 91 | Additional 2 washrooms per every 10 workers | 3+ |

In general, it would be wise to assume that two 40 ft units can be used in this construction project assuming the client does not require a barrier free washroom. A vac truck and maintenance crew is needed twice a week to fill the fresh tank and empty the septic. The PASS units in this example need to be filled/emptied every 3 days. A return-on-investment calculation was determined for the construction site example and the PASS unit will be profitable in 2 years.

Partners and mentors

Our capstone group would like to extend our gratitude to Dr. Simon Li and Danny Wong for their expertise and advice in the progress of our project. We would like to thank Jerry and Dawn Gautreau for being excellent mentors in the design of the portable washroom unit. We want to extend our gratitude to Mike Stewart, Justin Fehr and Matt Palsky for providing advice in building the PASS unit along with labour costs and material quotes. Finally, thank you to the Schulich School of Engineering and the University of Calgary for creating this platform for us to share our design.

Our photo gallery

20 ft Plumbing System

40 ft Plumbing System

20 ft Framing Structure

40 ft Framing Structure

20 ft Venting System

40 ft Venting System

40 ft Layout

20 ft Layout