Project Category: Mechanical

Join our presentation

About our project

An endoscope is a medical instrument used to look deep into the body in a minimally invasive way [1]. Today most endoscopes are made of stiff straight rods, or are flexible tubes that require a natural conduit such as the intestines, and are therefore very limited in the areas they can reach.

Our team has developed a novel, robotic endoscope that is capable of accessing any location in the body.

Our design uses a series of stiff links to form a robust, snake-like robot. The project showcased today focuses on the external body and actuation of the robot joints, but in the future it will use tail-follow head technology to move through the body and around organs.

Current robotic endoscopic technology is very expensive, such as the da Vinci system being upwards of $1.2 million USD [2]. However, our design is easily manufacturable, and uses a low cost, shape memory alloy to move the joints of the robot, giving an estimated cost of $180,000.

Details about our design

DESIGN OVERVIEW

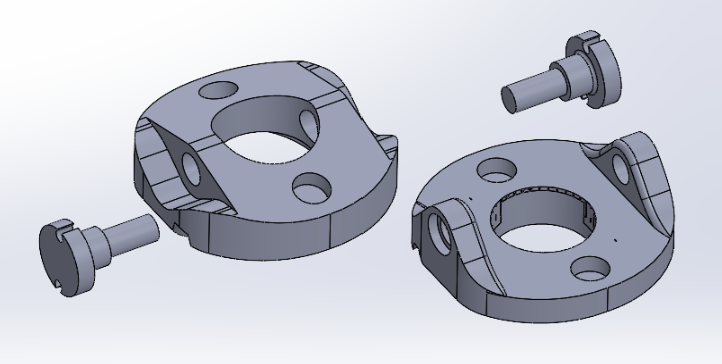

Nitinol is a shape memory alloy made of nickel and titanium that when heated returns to its preset memory shape [3]. We chose it as our method of actuation since it is scalable and cost effective. The Nitinol Torsional springs were handmade by forming Nitinol wire around a cylinder and heating them to set their “resting state”.

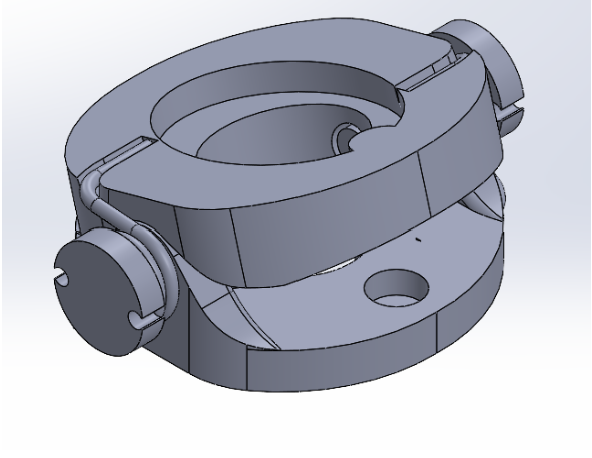

By connecting the Nitinol torsional springs on either side of the hinge in a circuit, they are able to be “activated” by the heat produced when current runs through them. When one of the springs is activated it will compress, and pull the hinge to one of its two locked positions. The hinge will then be locked in place using rare earth magnets until the opposing Nitinol torsional spring is actuated pulling the hinge to its other position, 30 degrees apart.

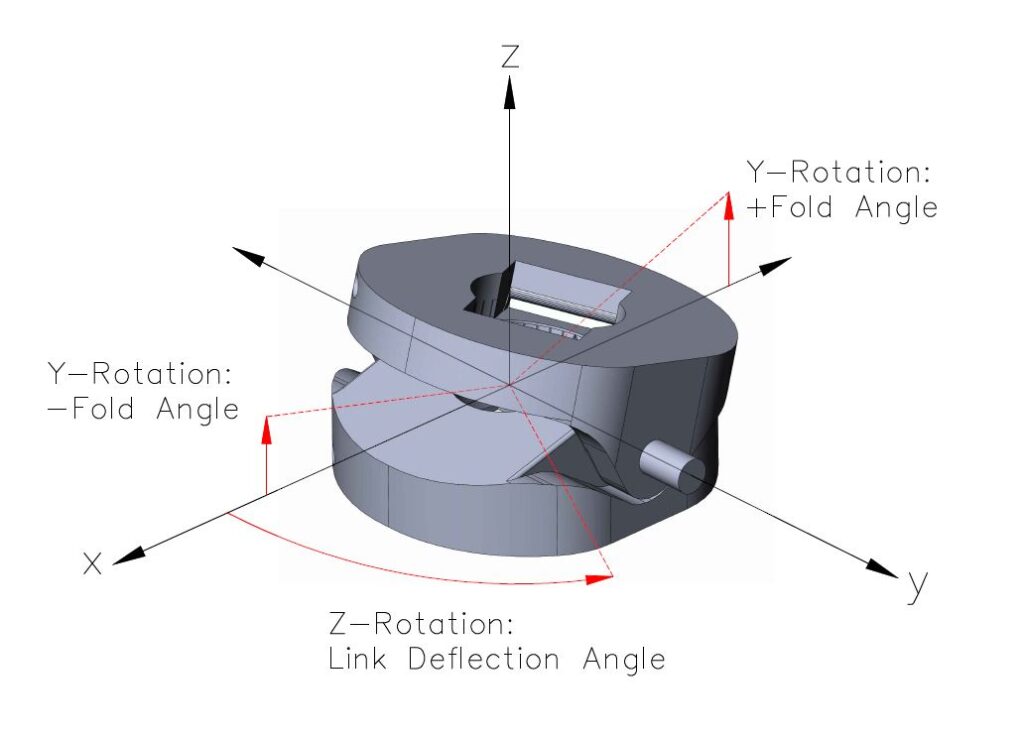

The snake-like endoscope is formed by stiff links stacked atop one another. Each link is 60 degrees offset from the last. This allows the robot to turn in many directions, increasing dexterity and precision

Each link consists of two hinge pieces that connect on a rotational axis in the middle. This creates a strong, stable design. The two pieces are then held together with pins that also support the Nitinol torsional springs.

ADDRESSING PRACTICAL ISSUES

Our design produces an endoscope that can access small areas, such as the brain and maneuver independent of conduits. The design is also more affordable and easy to assemble.

INNOVATIVE DESIGN

The smallest endoscopes currently on the market have limited mobility due to the lack of actuation options. To resolve this issue, we chose Nitinol actuators for our design, which are scalable and cost effective. Conventional motors, although widely used, cannot be scaled down much further than the centimeter range. Since the final goal is to develop a 2 mm diameter endoscope, any actuator assembly must be significantly smaller than 2 mm, which is permitted by Nitinol actuation. Furthermore, Nitinol is relatively cheap: about $4/ft for a 1 mm diameter Nitinol wire.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

Our design solution is effective because of the following:

• Endoscope modular links lock in two discrete fold positions and each link contributes rotational angles in two axes

• Relative link positions are easily monitored by knowing the fold positions of each link

• Nitinol actuators are more easily scaled than alternative actuators

• Manufacturing costs are minimized by using a simple, repeating modular design

VALIDATING THE DESIGN

By using the following methods, we were able to validate our design:

Testing:

• Tested endoscope dexterity with special steering protocols against real-world human body geometries

SolidWorks:

• Identified areas of high stress concentration and validated materials selection

• Simulated link body reaction to actuated spring and cool-down to analyze heat transfer properties

Simscape Multibody:

• The number of links that can be held up in a straight horizontal position was determined

• Identified the actuation torque in the first link required to lift the endoscope versus the number of links

Prototype:

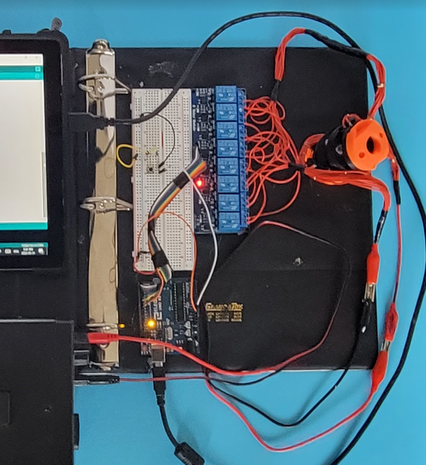

• A 4-link segment was constructed and operated successfully

FEASIBILITY OF OUR DESIGN SOLUTION

We have proved it feasible to build an upscaled, short segment of our modular design.

Though our group has advanced this concept as far as we were able this Capstone period, there is still much to be improved upon. Some aspects of this design that still call into question its feasibility are:

• It is impractical to have wire leads powering every spring (as with our prototype). Links will likely require an onboard relay and capacitor connected to a central power cable to avoid this.

• According to our simulations, the torque required to actuate the first link increases exponentially with the endoscopes length. However, the magnets can hold a maximum of 20 links horizontally, and therefore this current locking mechanism limits the endoscope length to a maximum of 29cm. Since the intent is to achieve endoscope lengths in the hundreds of links, improvements must still be made.

• Observations from constructing the Nitinol actuators in different shapes and at different quench rates suggest that the torsional spring as they exist in our finalized design could still be improved upon.

• Early indications show that the cool down time required between link actuations may lead to impractically long operational sessions. Heat management when multiple links are actuating inside the human body will also be of concern.

Meet our team members

Simon Helmer

Simon is a returning student with experience in the heavy civil construction industry. His hobbies include woodcarving and boatbuilding. Simon developed MATLAB simulations to better understand the mobility and limitations of our endoscope design. This included developing a steering protocol to enable the endoscope to follow a defined path. He also was responsible for creating the Nitinol spring actuators, assembling the prototype, and developing the Arduino control system necessary for operating the prototype.

Rizvi Ibrahim

Rizvi is a final year student with experience in Pipeline Integrity. His friends and family know him as an avid soccer player, and photographer/videographer. Rizvi was responsible for constructing and analyzing the SolidWorks simulations on multiple design iterations. He also produced the video showcasing our final design and analysis.

Caylyn MacDougall

Caylyn is a 5th year student that enjoys 3D modeling and using MATLAB. Initially Caylyn performed research on previous endoscopes of the market, their current methods of actuation, and improvements to be made. She then imported some of the design iterations from SolidWorks to Simscape Multibody, automated block diagram construction for any desired number of links to then simulate and analyze.

Swe Thane

Before returning to University, Swe worked as a material coordinator lead for oil sands projects at Syncrude. She enjoys traveling, hiking, and being involved in humanitarian efforts. As Project manager, Swe was in charge of hosting team meetings, recording meeting minutes, and liaising with professors and our project sponsor. Additionally, she conducted experiments to determine actuation requirements and analyzed the temperature dependent properties of Nitinol.

Alecia Wickenberg

Alecia is a 5th year student with experience in 3D printing and using SolidWorks since High School. She has a passion for 3D-printing, writing and creativity. With previous experience using SolidWorks, Alecia took charge of modeling new design solutions and 3D printing them. She also helped perform the simulations in SolidWorks. Additionally, she ensured that all reports were completed in an organized and timely fashion.

Justin Yoon

Justin is an energetic student with passion for music and singing, often performing at Open Mic Nights with Schulich Soundstage, a music club. He spends his free time either practicing guitar, singing, or playing video games. As material coordinator, Justin was responsible for selecting the most optimal 3D-printing materials and enhancing each 3D printed link to meet performance requirements. He was also responsible for overseeing the design and production of the presentations.

Partners and mentors

We want to thank the many people who helped us with this project. Our mechanical engineering professor Ahmed Ghasemloonia guided us through the process and gave us technical advice with patience. Additionally, our collaboration with our project sponsor Dr. Matthias Amrein and Matthew Topham was important to the projects progression. Finally, the help from the 3D printing technicians at the Maker Multiplex proved to be invaluable in our design prototyping.

Our photo gallery

References

- MicroscopeMaster. “Endoscopes – parts, uses and New Technologies,” [Online]. Available: https://www.microscopemaster.com/endoscopes.html. [Accessed: 03-Oct-2021].

- PubMed. “Robotic laparoscopic surgery: cost and training,” [Online]. Available: https://pubmed.ncbi.nlm.nih.gov/19451894/ [Accessed: 08-Oct-2021]

- “Introduction to Nitinol,” Memry. [Online]. Available: https://assets.website-files.com/59fcbaf103e295000131288b/5a2550c4b1a83e0001a6434b_Introduction%20to%20Nitinol_V2.pdf. [Accessed: 07-Oct-2021].

- Behance. [Online]. Available: https://www.behance.net/gallery/77082489/Lotus-Lamp [Accessed: 03-Apr-2022].