Project Category: Multidisciplinary

Join our presentation

About our project

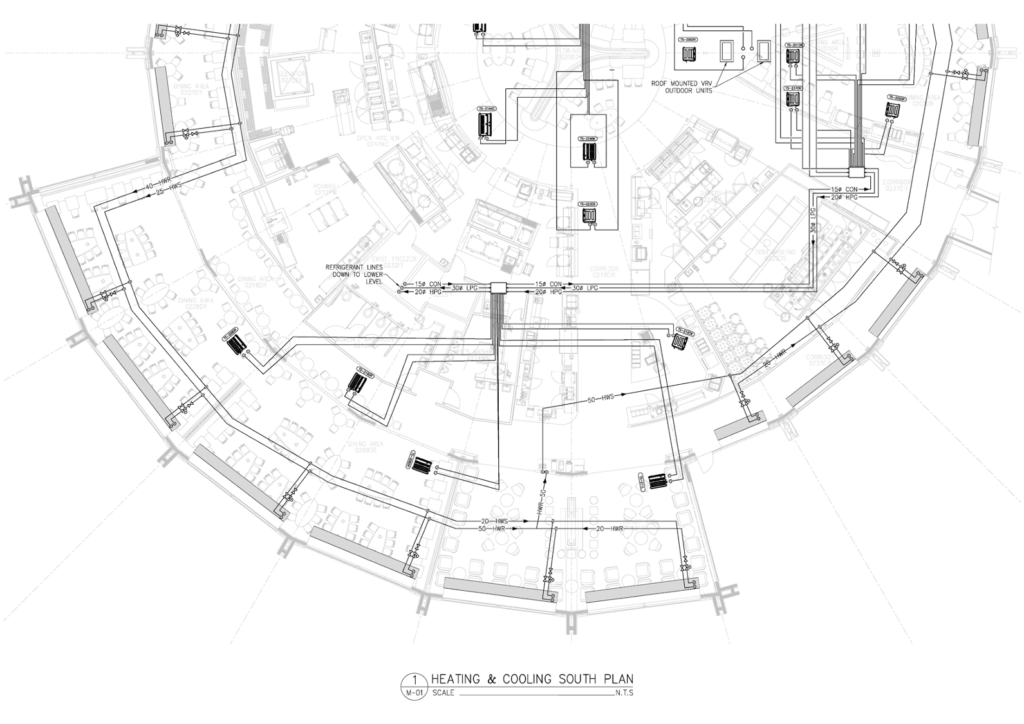

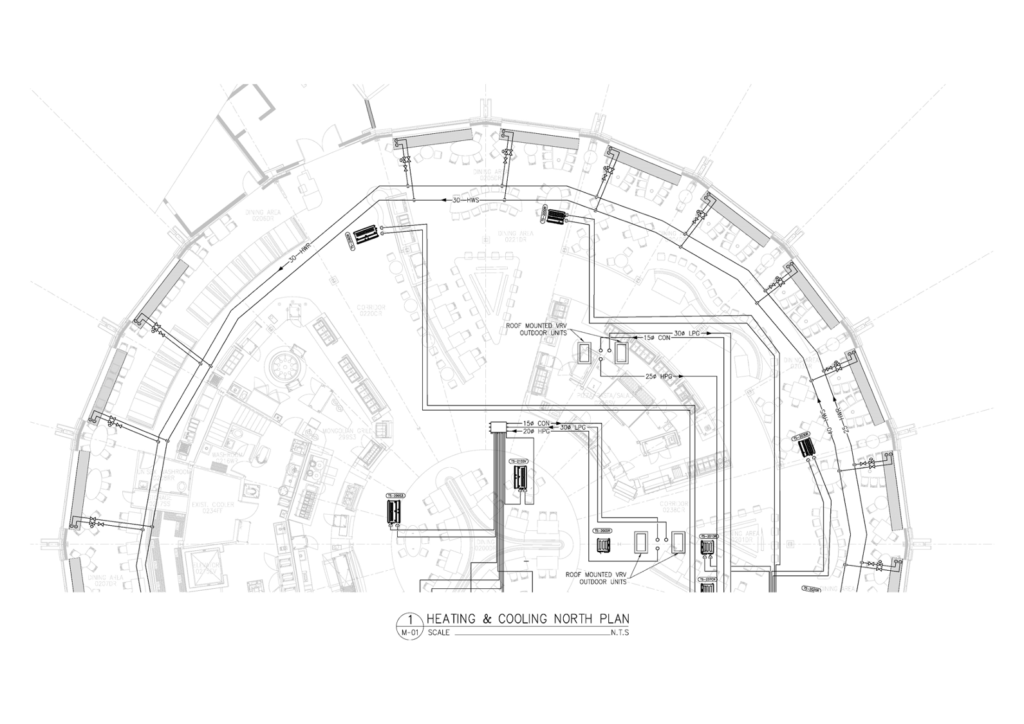

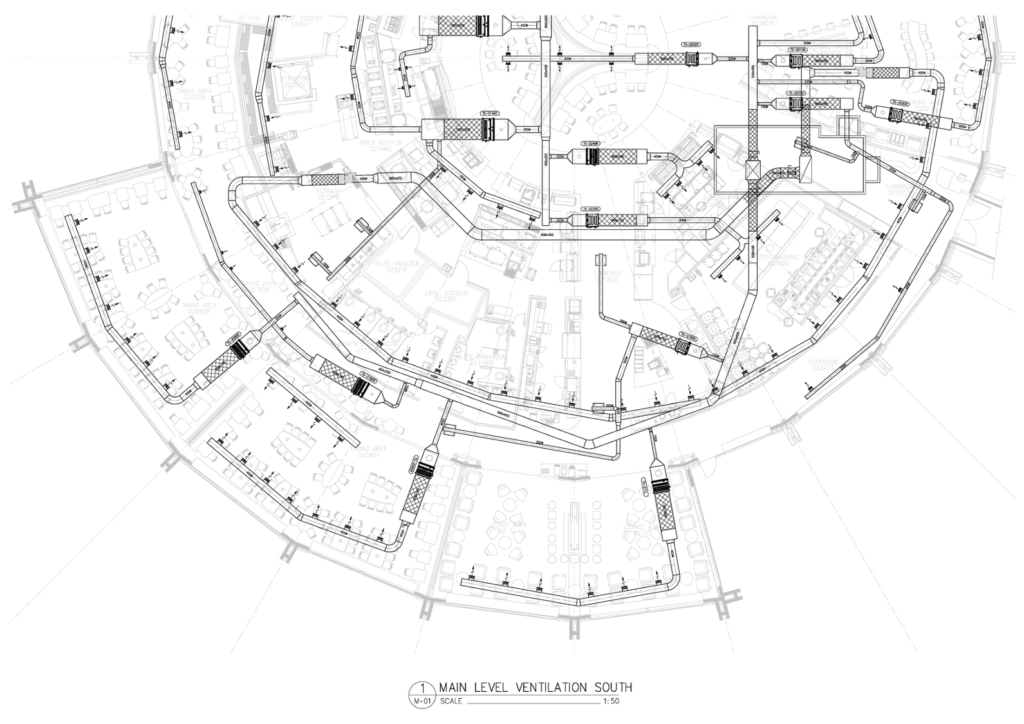

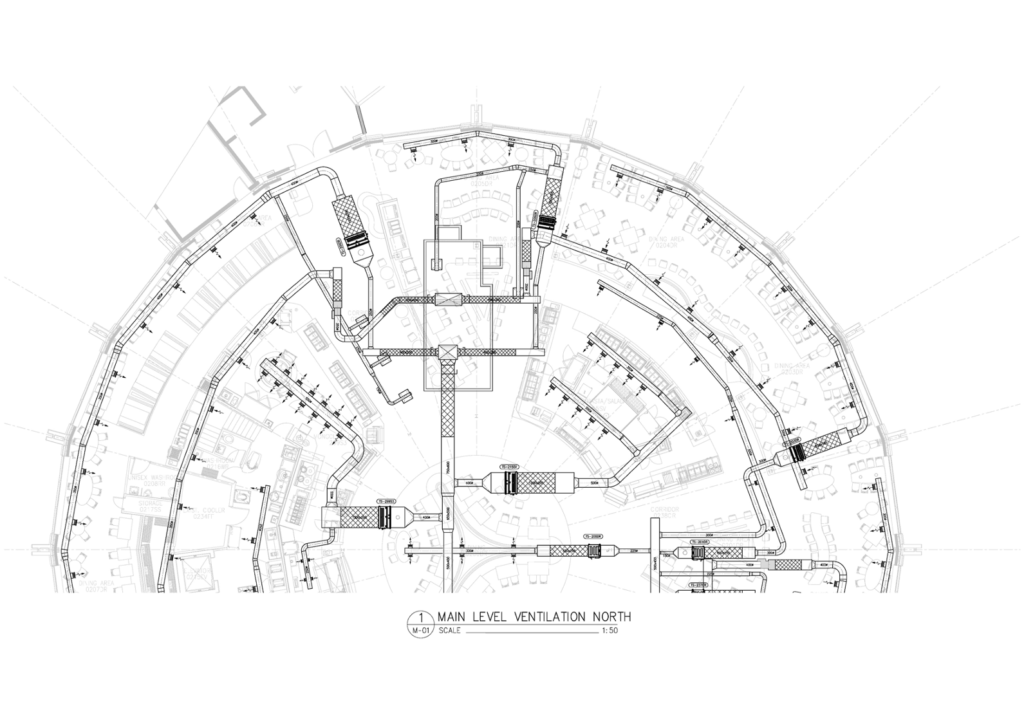

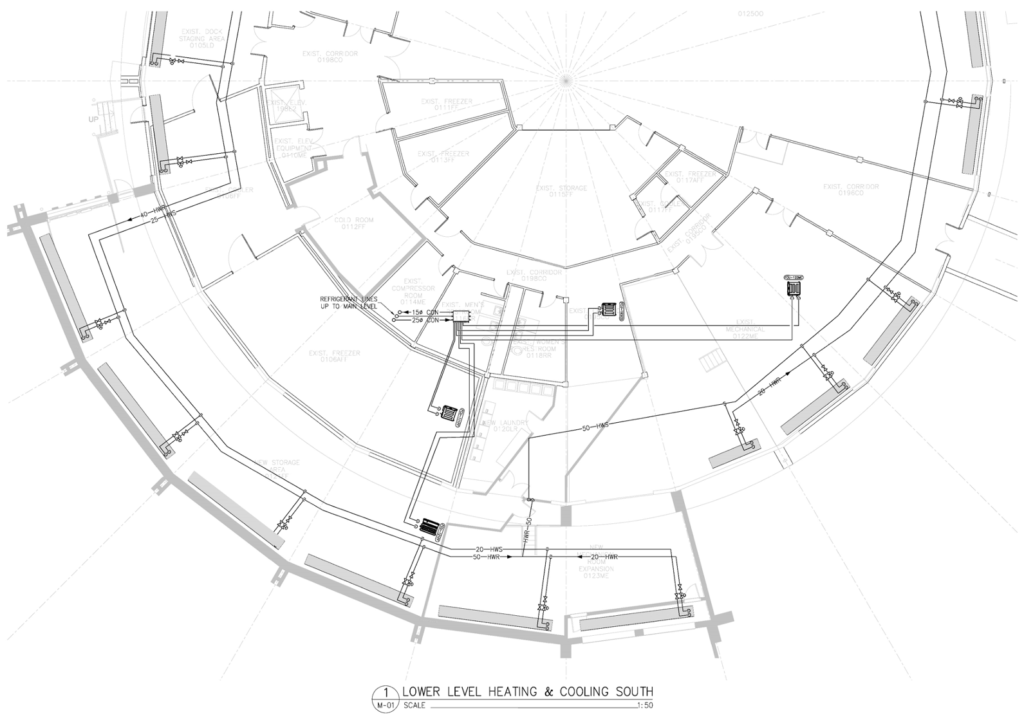

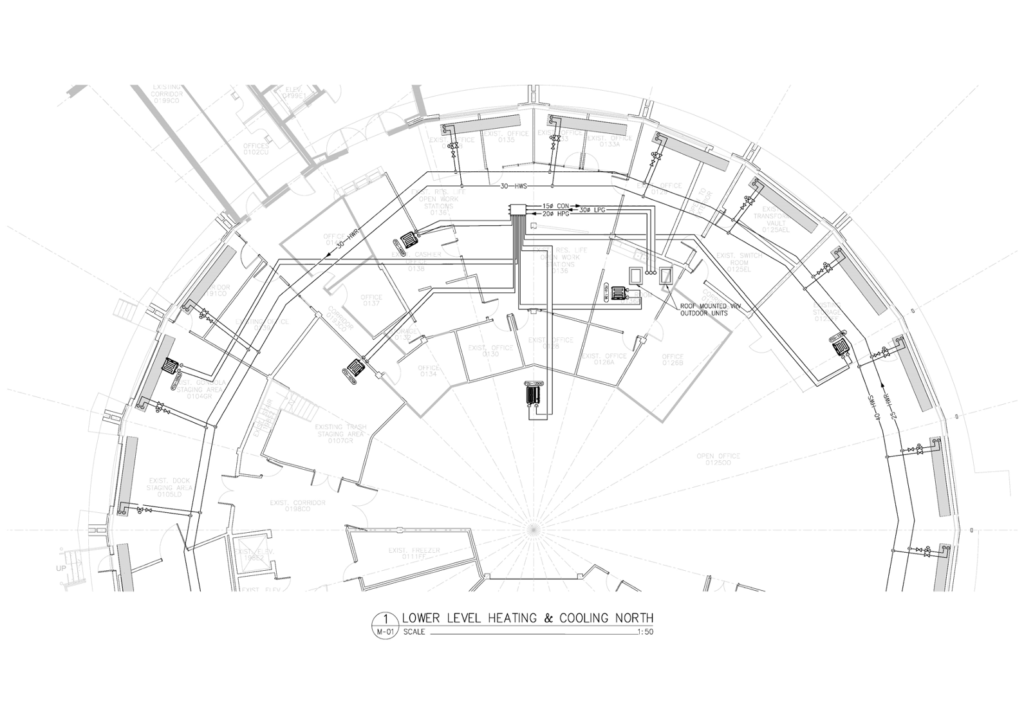

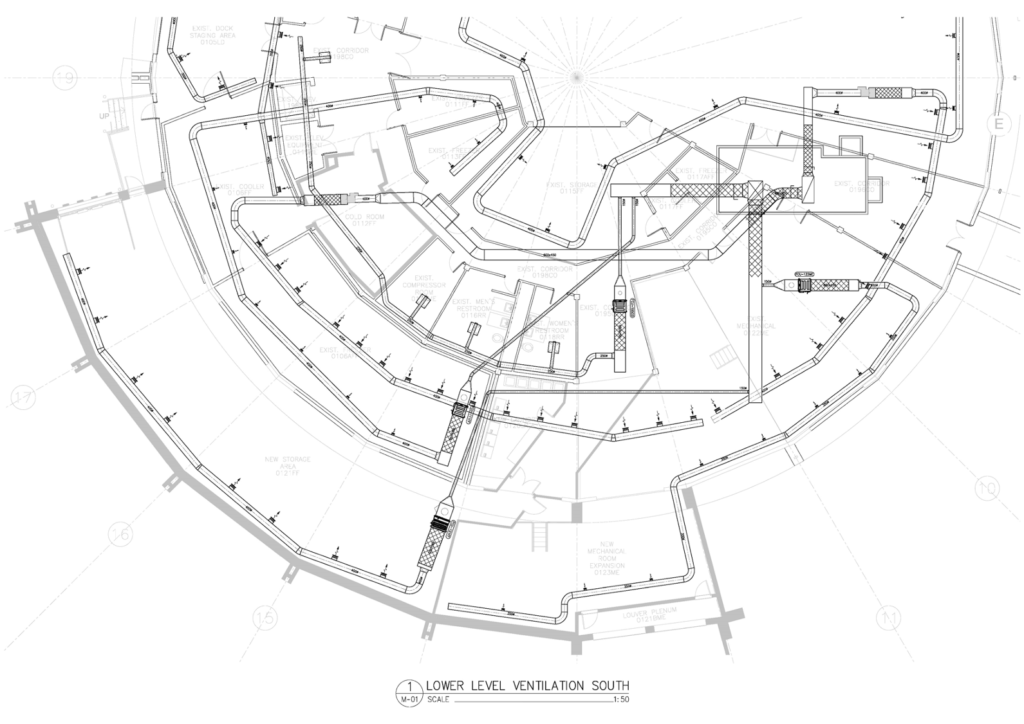

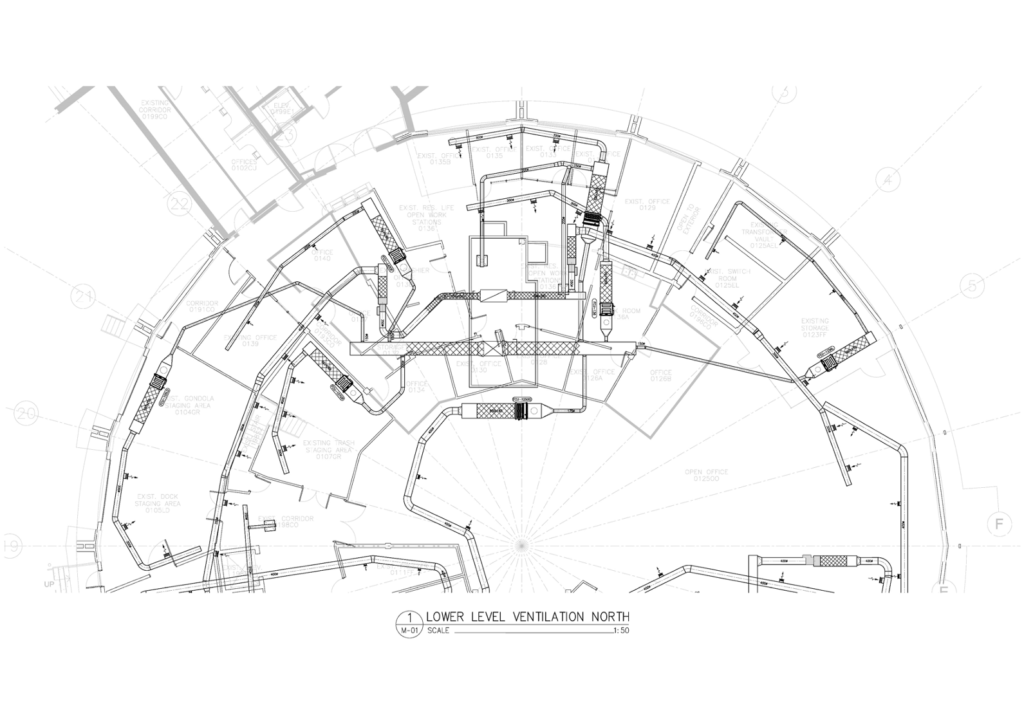

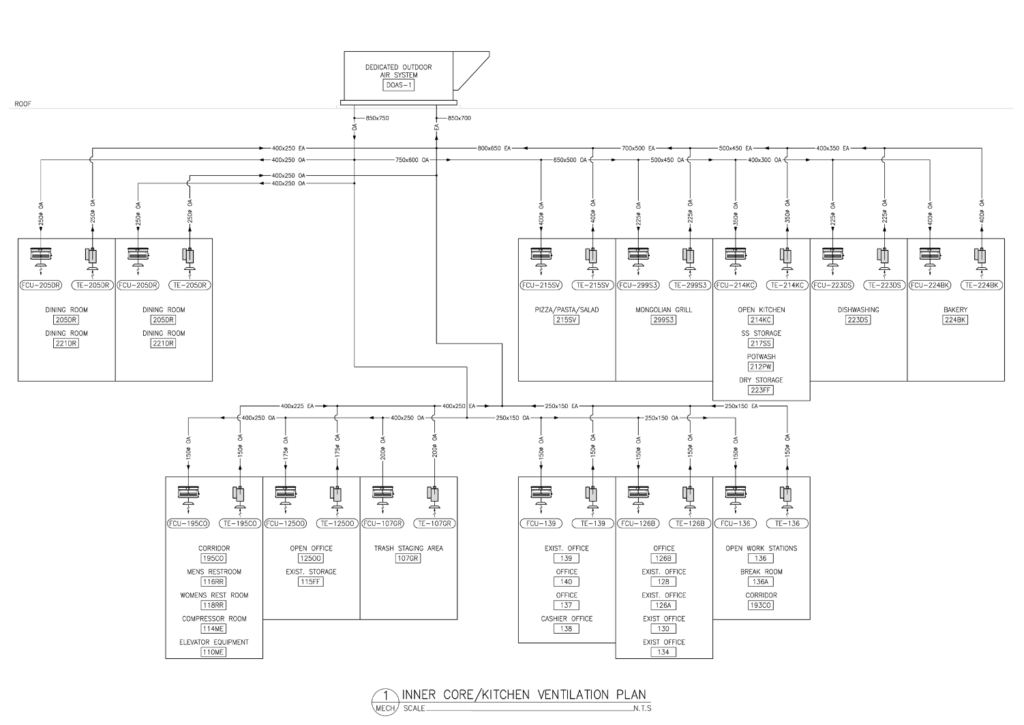

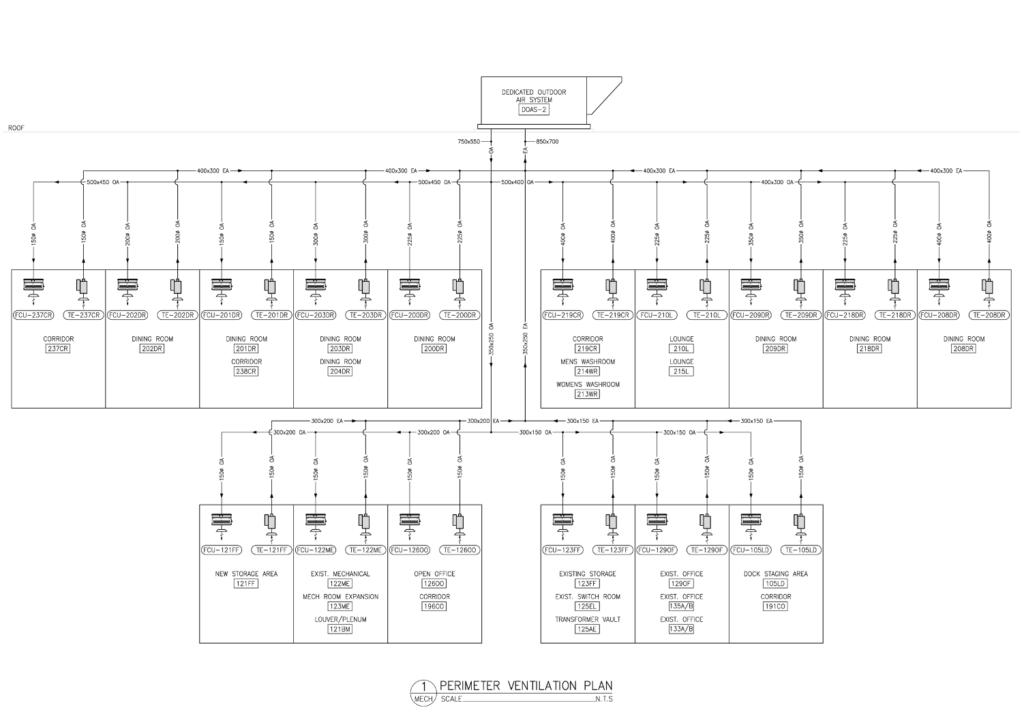

The heating, ventilation, and air conditioning (HVAC) systems account for the largest share of building energy use in Canada, good design of HVAC systems helps in controlling the temperature, humidity and air quality to provide a comfortable indoor environment to building occupants. Our project focused on designing the HVAC system for a new 4,645 m2, two-story cafeteria, associated office, and commercial kitchen in Prince George, British Columbia, Canada. The new facility consists of approximately 2,323 m2 of dining/kitchen/servery area on the main floor and 2,323 m2 of offices and storage space on the lower floor. The cafeteria is meant to serve an average of 3,000 students per day. Our final design also considered the use of a lean integrated project delivery method. The energy-efficient building design has a significant impact on both carbon footprint and energy demand. Improving energy efficiency means making use of energy-efficient hydronic systems, heat pumps, ventilation units, and/or air conditioners to ensure that the operating costs remain low.

Meet our team members

Gabriel Guzman Martel

Carrie Thiessen

Isaiah Odagwe-Onyenuwe

Moyosore Hassan

Yu Zhang

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

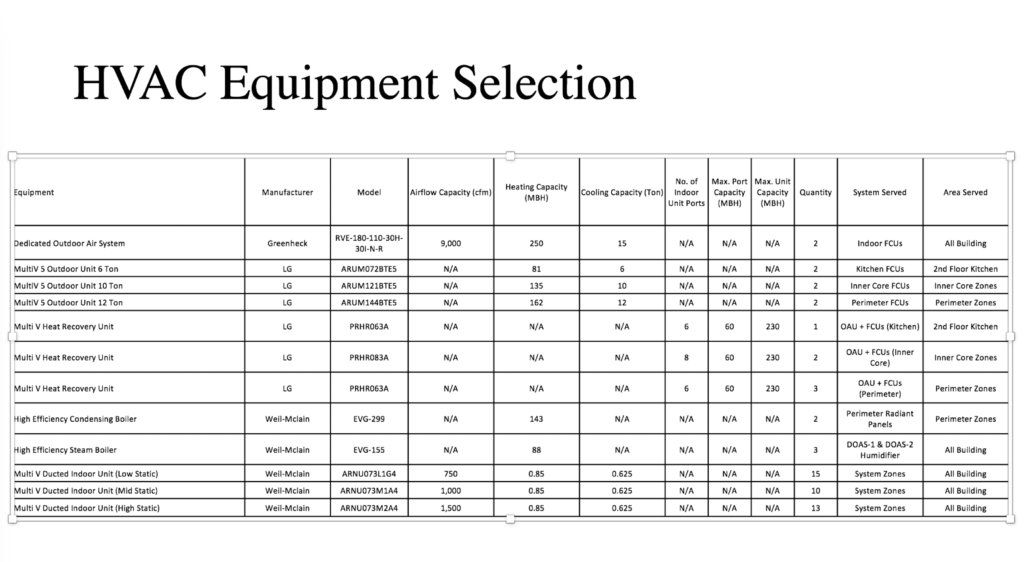

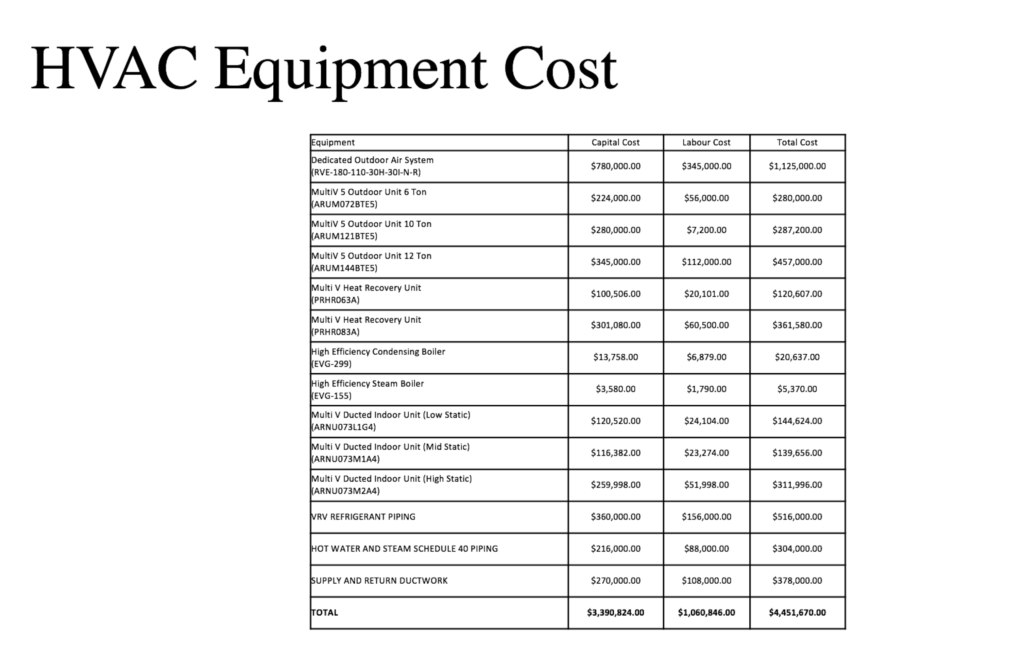

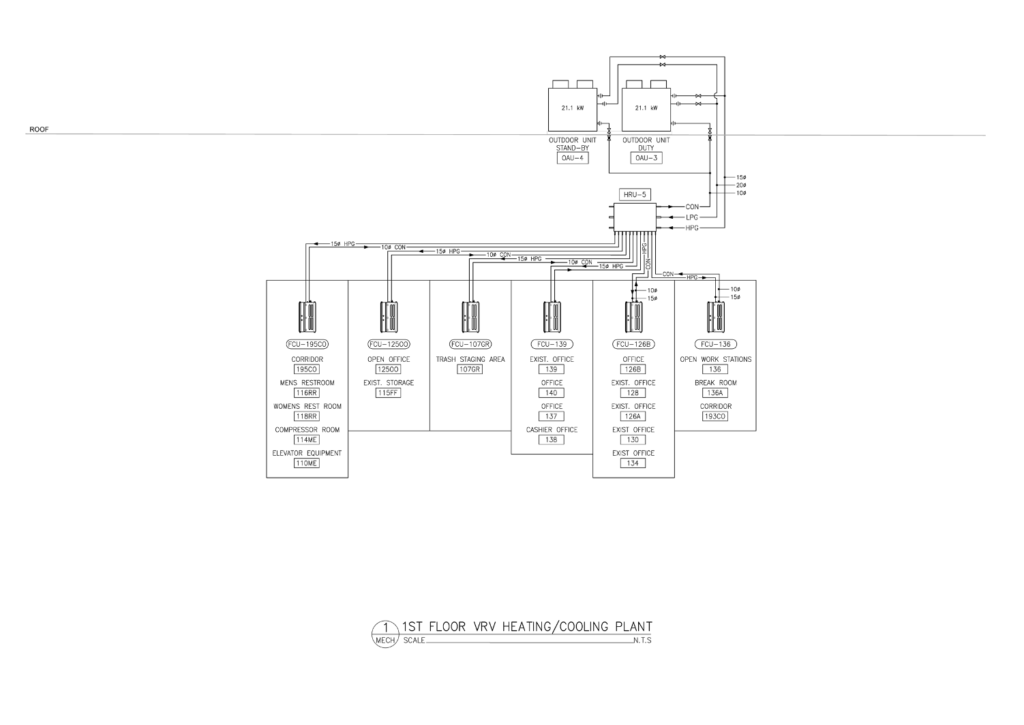

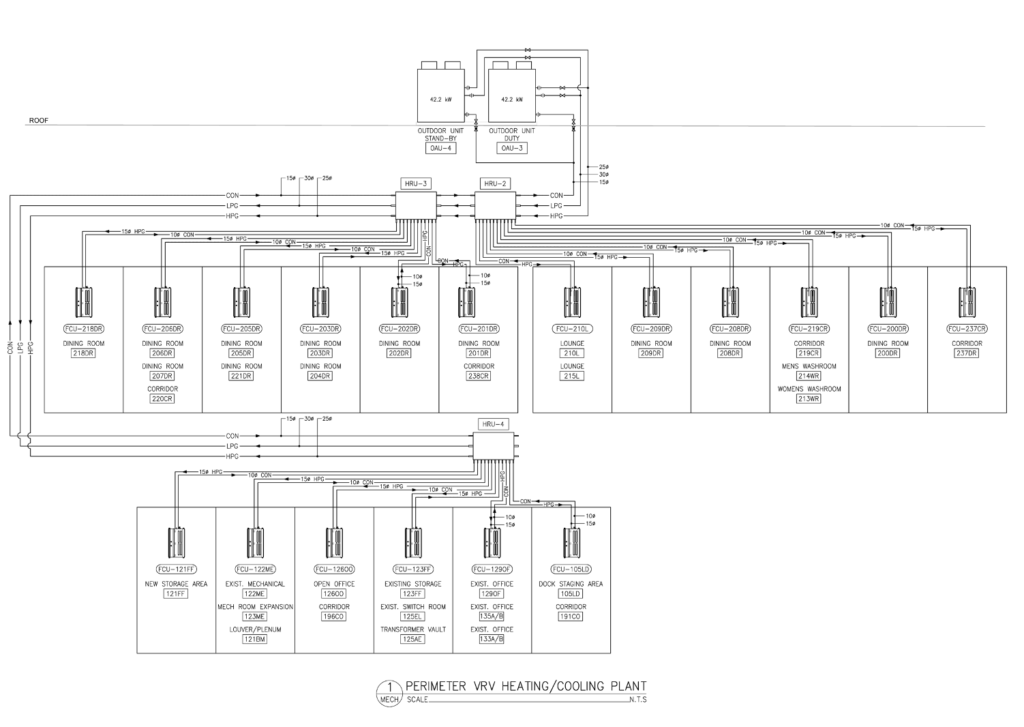

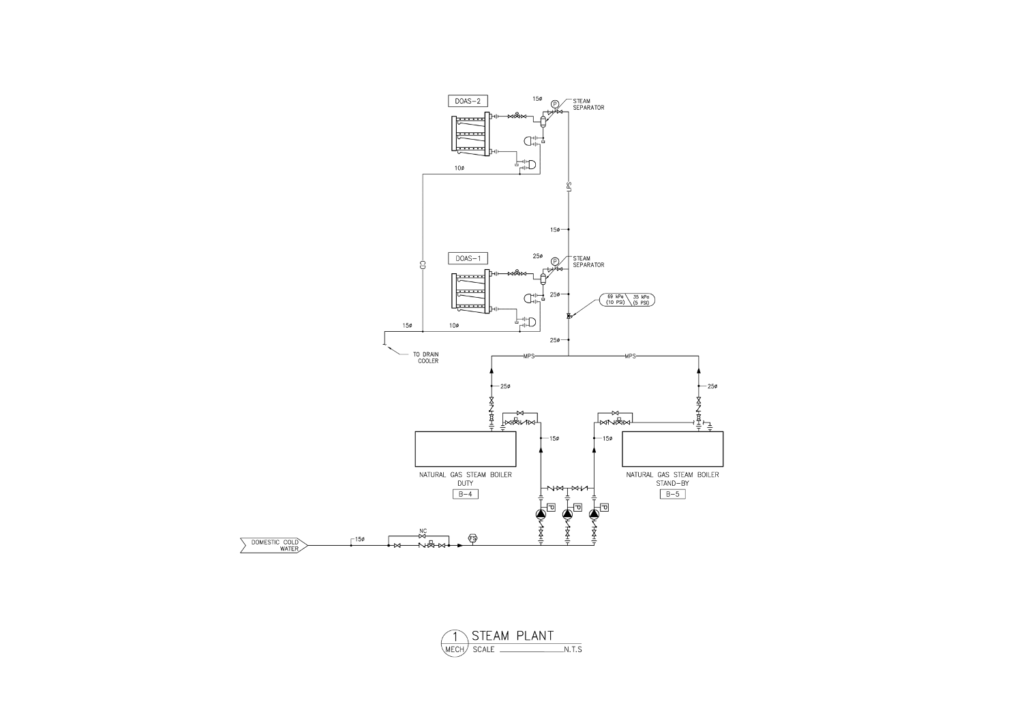

The Heating Ventilation and Air Conditioning (HVAC) system design of a building is one of the most crucial factors in creating a pleasant and healthy environment for the occupants and for contributing in a sustainable energy-efficient system. To achieve such system while satisfying the client’s requirements and constraints, the team is proposing the following key systems:

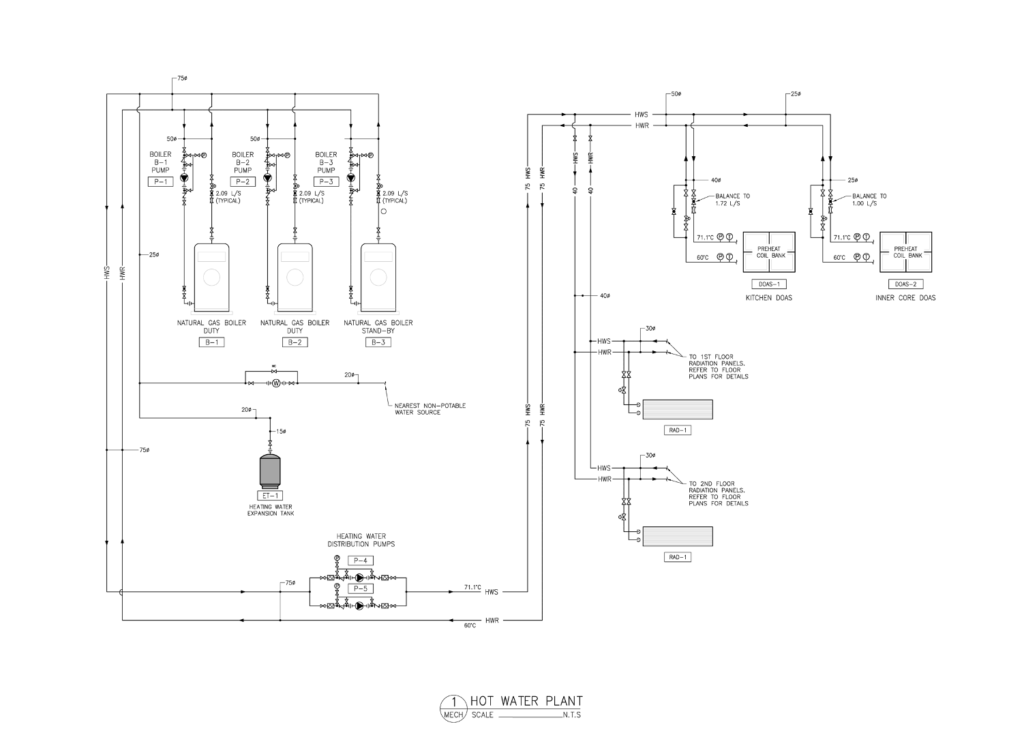

- Radiant panels on the perimeter of the building above windows to provide heating for critical areas.

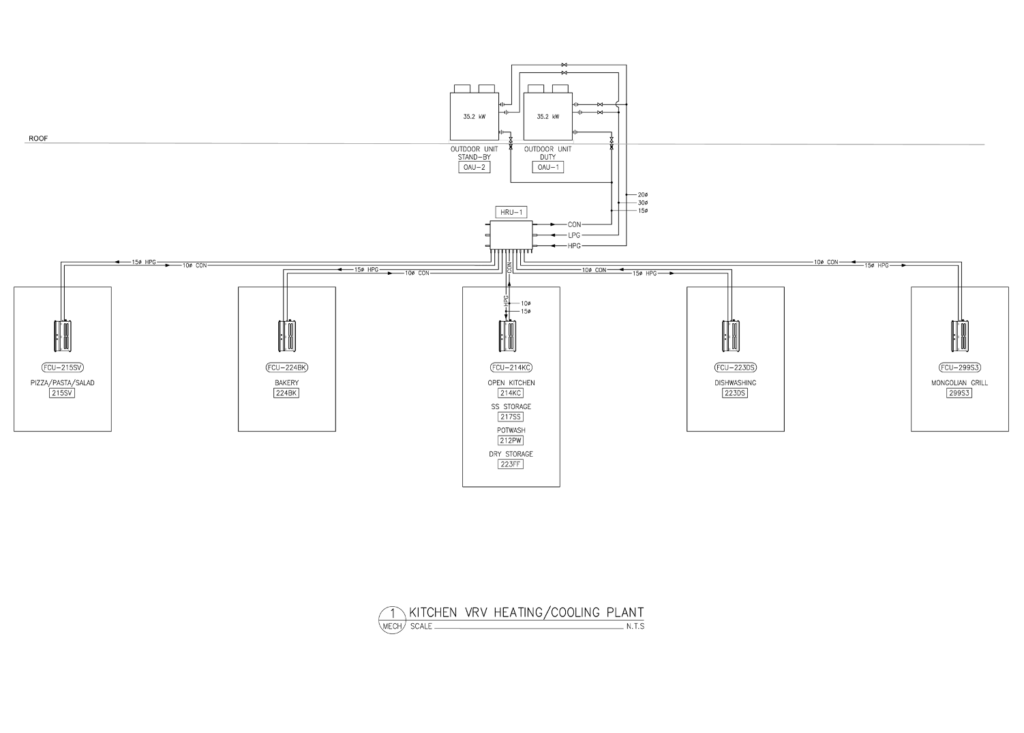

- Indoor refrigerant loop with heat recovery feeding indoor Fan Coil Units (FCU) serving all thermal zones in the building

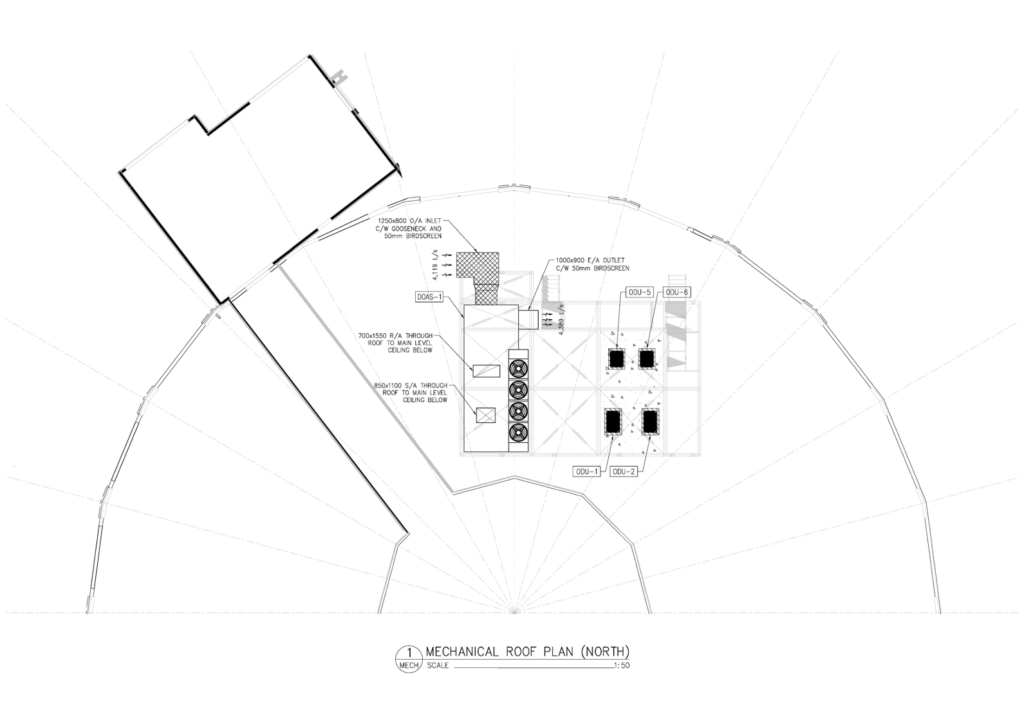

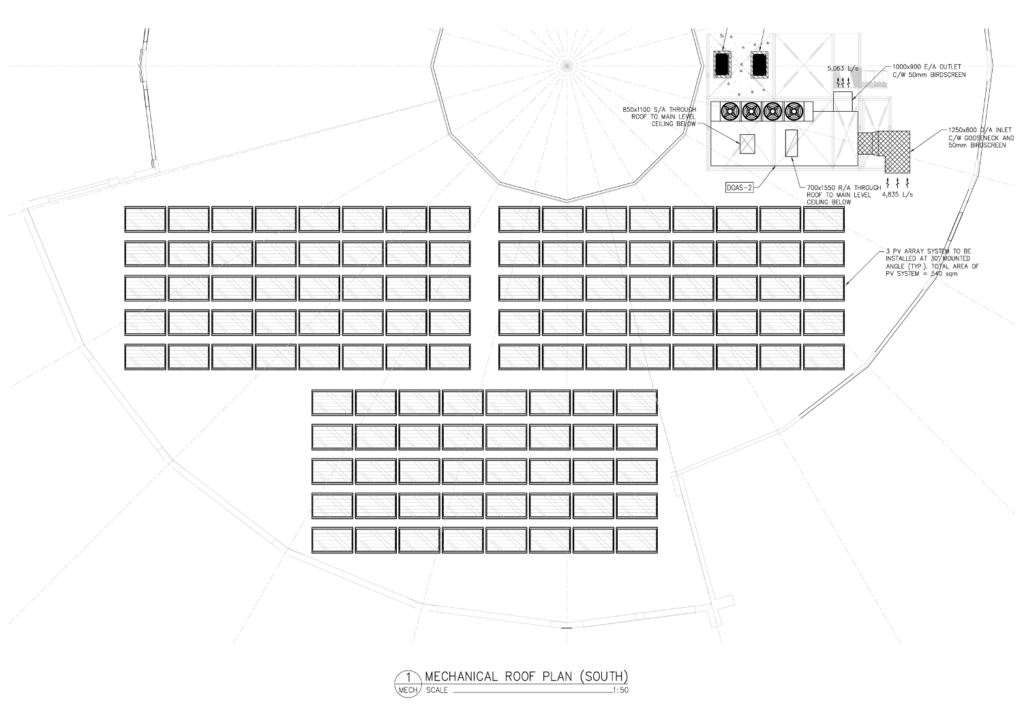

- A 100-kW solar PV system that supplies approximately 30% of the building’s total electrical consumption during occupied hours

- Dedicated Outdoor Air System (DOAS) providing 100% outdoor air to the building’s thermal zones packaged with an Enthalpy Wheel (EW) to extract sensible and latent heat from exhausted air to supply air

WHAT MAKES OUR DESIGN INNOVATIVE

The team uses Variable Refrigerant Volume (VRV) systems to deliver simultaneous heating and cooling in recovering energy from zones of excess heat and re-distributing it to zones requiring heat. A VRV system with heat recovery offers numerous advantages over more conventional systems such as VAV with re-heat, dual fan dual duct, and raised floor systems. In a building with different zone profiles simultaneous heating and cooling operation is required to provide desired comfort to the occupants. A VRV system achieves this level of comfort via a Heat Recovery Unit (HRU) to deliver high pressure refrigerant gas or condensate refrigerant to the indoor units.

HOW WE VALIDATED OUR DESIGN SOLUTION

The heating and cooling loads of a building are highly dependent on envelope loads, they comprise of infiltration, conduction and radiation heat transfer between the building and the environment. ASHRAE Fundamentals Handbook and ASHRAE Standards 55, 62.1, 90.1 and 189.1 are used to ensure the adequate load criteria, thermal conditions, outdoor air ventilation rates and building envelope are maintained throughout all zones in the building.

To validate our final design, Hourly Analysis Program by Carrier™ was utilized in efforts to ensure these standards will be met by the system. We have used Hourly Analysis Program to preform the energy simulation. The results from the energy simulation model are compared with ASHRAE 90.1 baseline. The comparison showed that our design has a energy use savings of 36.8% and energy cost savings of 35.1%. At 36.8% energy savings below baseline, the majority is due to reductions of electric space heating energy demand, making up to 83.7% of the savings.

Partners and mentors

We want to thank the many people who helped us with this project. Special thank you to our mechanical engineering professor Simon Li guided us through the process with patience and great advice.

Our photo gallery