Project Category: Multidisciplinary

Come Visit us In Person!

Date: Tuesday, April 5, 2022

Time: 10:00 a.m. to 12:30 p.m. MST

Location: Atrium CNRL Complex (Schulich School of Engineering)

Land Acknowledgement

We would like to acknowledge the traditional territories of the Blackfoot and the people of the Treaty 7 region, which includes the Siksika, the Piikuni, the Kainai, the Tsuut’ina, and the Stoney Nakoda First Nations. The City of Calgary is also home to the Metis Nation of Alberta Region 3. Over the past year our group has had the opportunity to work on our project within this area and have explored the history of the land and its peoples and we are grateful for the opportunity to visit within this area.

About our project

The aim of this project is to develop an open-source conversion kit for remote Northern communities to replace a UTV’s gasoline engine with an electric motor. The conversion will reduce dependency on expensive fossil fuels and provide a long-term, sustainable solution for Northern Indigenous communities.

BACKGROUND: Electricity prices in northern Canada are significantly higher than the rest of Canada, households in these northern communities pay between 13.6 – 30 cents per kW.h of electricity – well above the Canadian average of 12.9 cents per kW.h. Due to the low population density and remote location of these communities, electrical needs are primarily being met by relatively expensive and carbon-intensive energy sources such as gasoline and diesel generators. Many communities are now looking for more environmentally friendly and less carbon-intensive energy production methods as these technologies are becoming more cost-competitive in northern Canada. In conclusion, remote communities located in northern Canada are searching for ways to reduce their reliance on expensive and carbon-intensive fossil fuels (C.E.R. Government of Canada, 2021).

The capstone project has created a design for and completed the conversion of a Kubota RTV 500, owned and operated by the Arctic Institute of North America’s Kluane Lake Research Station (KLRS) from its current 2-cylinder, gas, 15.8 HP engine to an electric motor. The purpose of this conversion is to reduce the KLRS dependence on gasoline for the reasons explored above. The conversion was completed in a manner that is modular, affordable, and easily replicable so that surrounding Indigenous communities may also take advantage of this project’s findings and solutions.

Details about our design

Our Design Solution

To complete the conversion an AC9 48V electric motor, a 450-amp controller, and four GC12 150AH Deep Cycle batteries were chosen. These three main components were chosen for their performance capability, affordability, convenience, and compatibility. The electric motor will provide more power and torque than the original engine, surpassing the original technical specifications. All components were chosen with performance in mind and as such they can all withstand extreme temperatures, rugged train, and the elements. Overall, the ten-year lifetime cost of the design is less than both the original petrol engine as well as purchasing a new electric UTV. Finally, and most importantly, all components can be easily ordered online or purchased from local stores. Anyone, from anywhere, could order the required parts and replicate the design. Also, the simplicity of the design allows anyone with a simple mechanical understanding to complete the conversion.

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

As previously mentioned, the main goal of this capstone project is to develop an open source conversion kit The main practical issues that were addressed with the project were meeting the pre-conversion Technical Specifications, ensuring Performance Capability, and keeping Affordability.

Technical Specifications:

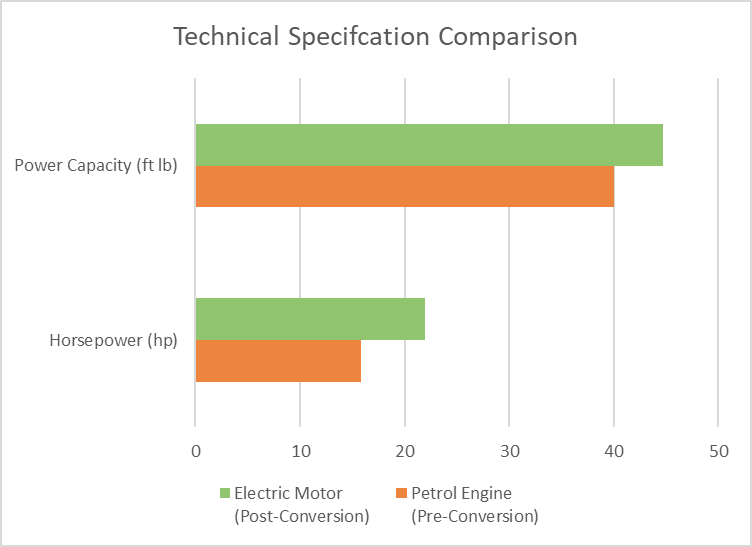

The two primary technical specifications that had to be maintained were the power capacity and the speed.

Power capacity is the ‘strength’ of a vehicle i.e., how much a vehicle can pull/haul. The metric used to measure power capacity is engine torque. The petrol engine had an initial torque of 40 ft-lbs., and the electric motor has a torque of 44.7 ft-lbs. The conversion resulted in an increase of 4.7 ft-lbs. or a 12% increase.

The horsepower of an engine is indicative of a vehicles top speed. The initial horsepower at 3600 RPM of the petrol engine was 15.8 hp, and the horsepower of the electric motor is 22.0 hp. The conversion resulted in an increase in 6.2 hp or a 39% increase. Due to mechanical loses the top speed may not increase 39% from an initial 40 km/h to 56 km/h, however the user will experience an increase in both speed and acceleration.

Performance Capability:

The function of a UTV is to perform in extremely cold temperatures, rough terrain, and wet conditions due to snowfalls. To ensure functionality was maintained analysis was performed in these areas. The batteries and motor were chosen based on their ability to perform in cold weather as well as effective waterproofing has been applied to ensure off-road capabilities are maintained.

The vehicle will be operating with temperatures reaching -40 ℃ in the Yukon and will affect the vehicle’s start-up and efficiency (Travel Yukon, n.d.). A gasoline engine functions through the combustion of fuel to start up which can be kept warm through the release of heat while operating. Yet, they can take time to start up due to sub zero temperatures freezing up the engine oil if the vehicle is not being kept inside overnight. Similarly, the Curtis AC motor selected can be treated the same as it was with the petrol engine in cold conditions. Heat will be generated with the motor and distributed throughout multiple components in the system as it operates.

The Kubota RTV 500 was created to endure rough terrain, handle rugged conditions and these are key aspects that are still maintained post-conversion. These off-road qualities are brought through its mechanical systems such as its hydrostatic transmission, hydraulic brakes and stock tires which are adequate for heavy-duty work. Throughout the conversion, these systems were maintained to preserve the UTV’s off-road qualities.

Affordability:

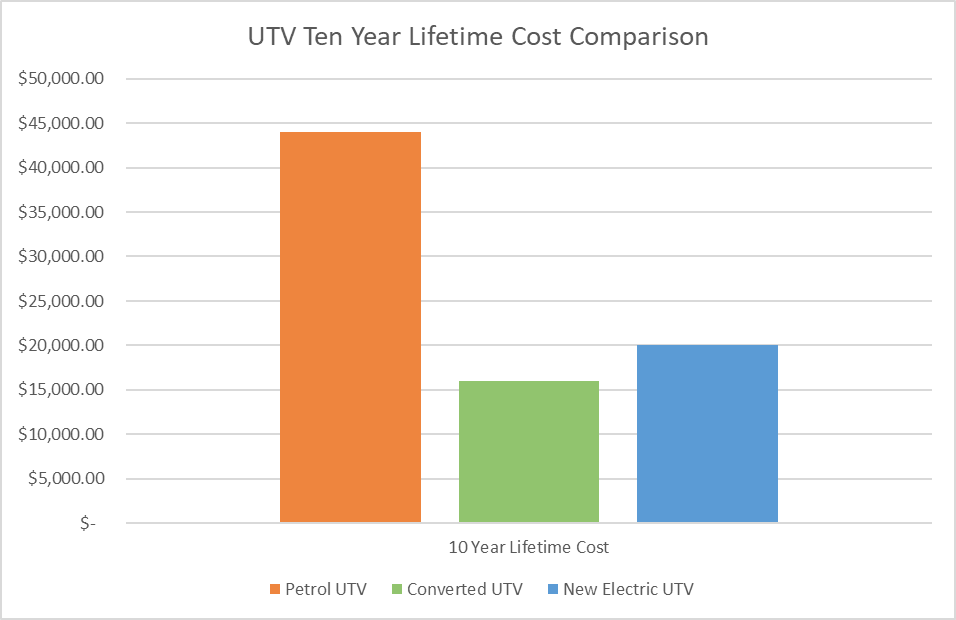

A main aspect of the project is the ability for anyone to replicate it and as such affordability must be considered. The cost of the electric motor and the rest of the required materials for the conversion are easily recuperated in cost savings from purchasing fuel.

The original petrol engine required 20 L and currently fuel prices are as high as $1.77/L resulting in $34.50 to fill up the UTV completely. Based on a fuel efficiency of 0.3222 L/km, the fuel cost $0.57/km. The batteries of the electric motor require a full charge time of 20 hours on a standard outlet. Given the current electricity prices of $0.187 per kWh it costs only $2.69 to fully charge the batteries. With a continued range of 20 km the cost drops to $0.13 per km.

Overall, the ten-year lifetime cost of the conversion is approximately $16,000 (including charging, maintenance, and the conversion costs). This is approximately $4000 less expensive than the lifetime cost of a new electric UTV and nearly one third the lifetime cost of a petrol UTV.

WHAT MAKES OUR DESIGN INNOVATIVE

There have been many electric conversion projects however, what makes this project innovative is the involvement of communities. From the very beginning of the planning phase the “why” of this project was never just to complete a conversion but was to help reduce dependency on expensive fossil fuels and provide a long-term, sustainable solution for Northern Indigenous communities.

A large aspect of this project is the community context in which the project takes place. As mentioned previously, the surging fuel prices in Northern communities has greatly increased the cost of living for people. Alongside the conversion additional educational resources were created for anyone to replicate our conversion. Additionally, in late April, the team will fly to the KLRS. The purpose of this visit is to better understand how the product fits within the day-to-day operation of the station and within the context of broader Northern communities. We will also visit the local school to discuss the project with the goal of sparking an interest in STEM in the local youth. In addition, to the in-person discussions, the project documentation and supplementary educational resources will be shared to guide others in converting their gas-powered vehicles to electric. As the purpose of the project is to meet the needs of remote communities, all of the acceptance criteria was rooted in these considerations.

WHAT MAKES OUR DESIGN SUSTAINABLE

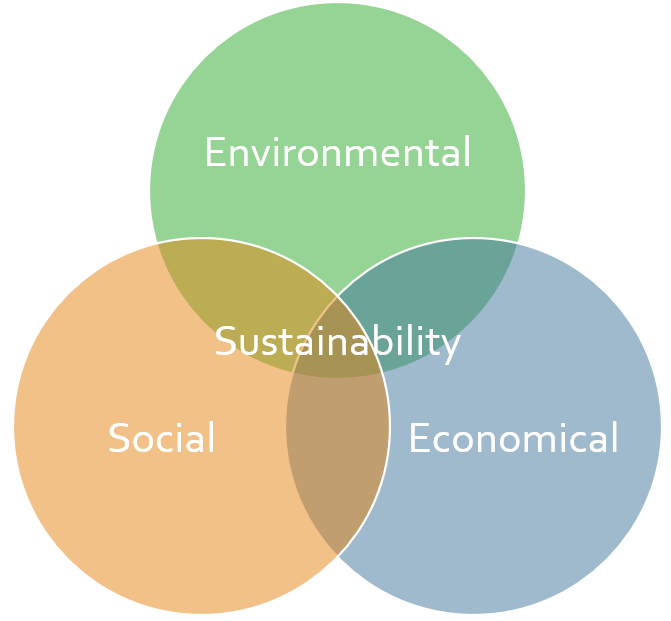

Sustainable design requires the consideration of Environmental, Economical, and Social aspects, also known as the triple bottom line of sustainability.

Environmental: The project assists directly and indirectly in the reduction of greenhouse gas emissions, improvement of air quality, and reduction in land use impacts. The conversion directly results in a reduction of fossil fuels which reduces greenhouse gas emissions. By converting as opposed to purchasing new, less raw materials are required in production as many parts are reused. This results in unseen improvements in many aspects of environmental sustainability.

Economical: The project will decrease the amount of energy costs for Northern communities. Overall, the cost of electricity is much less than the cost of petrol and electricity is easily able to be produced through greener methods such as wind and solar. The conversion results in energy cost savings for individuals and lessens their dependency on expensive and price volatile fossil fuels.

Social: The project provides many educational opportunities along with assists in energy security. The team will be traveling to the Yukon for the Renewables in Remote Communities 2022 Conference. (Pembina Institute, 2021) We will also visit the local school to discuss the project with the goal of sparking an interest in STEM in the local youth.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

The design solution is effective as it meets all required criteria set forth in the planning phases of the project. The six main criteria of the project and the effectiveness at which they were met are summarized below:

- Community Engagement: The project was created on the idea of supporting communities and it is important that this was kept at the top of mind while working on the project. Throughout the project it is evident that every decision was made while keeping the community context in mind. At the end of April, the team will be traveling to the Yukon to directly engage with the community and attend the Renewables in Remote Communities 2022 Conference. (Pembina Institute, 2021)

- Sustainability: The goal of the design was to provide a sustainable solution for rising petrol prices for Northern Indigenous communities. As mentioned above the design proved to effectively provide a sustainable solution as it positively impacts the environmental, economical, and social aspects of sustainability.

- Affordability: The project had to remain affordable to ensure it was not ineffective. Overall, the initial budget was surpassed due to unforeseen circumstances, however over the long term the project still proved to be an effective cost savings method. Originally the UTV would cost $34.50 to fill up on petrol and with the conversion the cost to fully recharge is now $2.69. The ten-year lifetime cost of the conversion is approximately $16,000 which is approximately $4000 less than buying a new electric UTV and nearly one third the cost of the original petrol engine.

- Replicability: A large aspect of the project was ensuring that anyone could replicate the design. To effectively account for this, support documents were created that outline materials required as well as drawings are provided. Throughout the design process we ensured that every part could be ordered online or purchased in local stores.

- Technical Specifications: The initial criteria of the project were to meet the manufacturer’s technical specifications for hauling capacity and speed. The project was able to effectively surpass the manufacturer’s specifications in both categories. Both the power capacity and horsepower increase after the conversion. As mentioned above the power capacity increased by 12% resulting in an increase of hauling capacity and the horsepower increased by 39% resulting in a higher top speed.

- Performance Capabilities: The capabilities of the UTV had to be maintained to ensure functionality was not lost. The project effectively met all performance capabilities that were originally present. Both the batteries and motor were chosen based on their ability to perform in cold weather to ensure top performance in the frigid northern temperatures. The off-road capabilities of the UTV are provided through its mechanical systems. To maintain performance these systems were preserved, and effective waterproofing was completed to ensure off-roading capabilities were maintained.

HOW WE VALIDATED OUR DESIGN SOLUTION

The projects design solution was validated through theoretical Analysis and physical Testing. For all major components, availability of off the shelf parts were primarily considered to ensure anyone could easily replicated the project. In the planning phase analysis was performed to ensure that the selected motor, batteries, and electrical components would meet the requirements of the project. During the execution phase testing was performed to ensure the analysis in the planning phase was accurate.

Analysis:

The first major component of the analysis was the electric motor. Two main types of electric motors were analyzed Direct Current (DC) and Alternating Current (AC). The most notable difference between these two types of motors is that AC motors, in general, boast more desirable specifications in terms of horsepower and torque than a similarly sized DC motor. Based on analysis of horsepower, torque, and dimensions an AC9 48V motor was chosen with a 450A controller. At first glance of the table below, the AC12 motor coupled with a 350A controller seemed to be the obvious choice; however, it was communicated to the team by a few dealers that the 350A controllers are no longer available. It is for this reason that the team decided to procure an AC9 48V with a 450A controller.

| Kubota RTV 500 | AC9 48V | AC12 48V | AC 12 48V | |

| Controller (Amps) | – | 450 | 350 | 450 |

| Torque (ft lb) | 40.4 @ 2000 RPM | 44.7 @ 0 RPM | 53.4 @ 0 RPM | 69.9 @ 0 RPM |

| Horsepower (hp) | 15.8 @ 3600 RPM | 23.3 @ 3000 RPM | 17.7 @ 2000 RPM | 19.33 @ 1500 RPM |

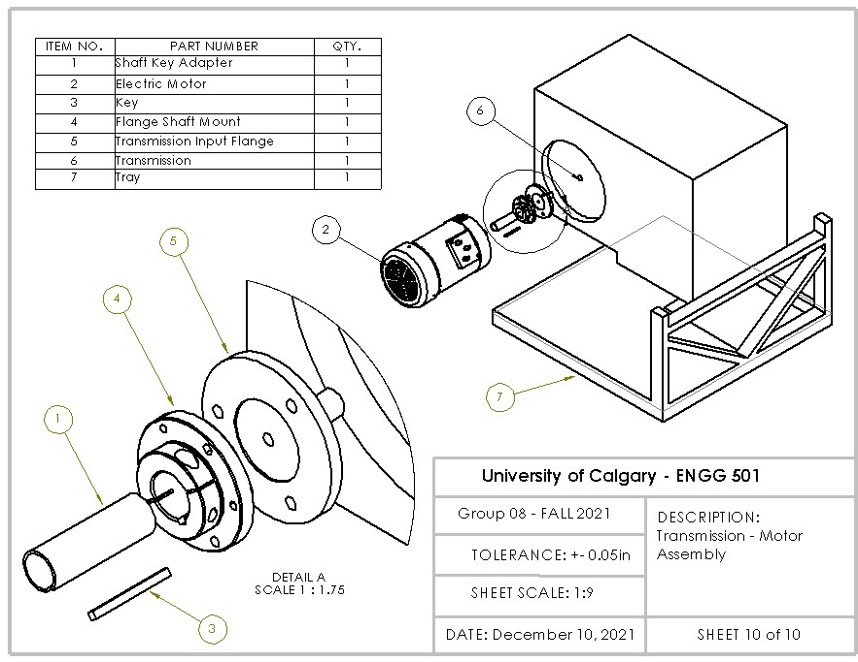

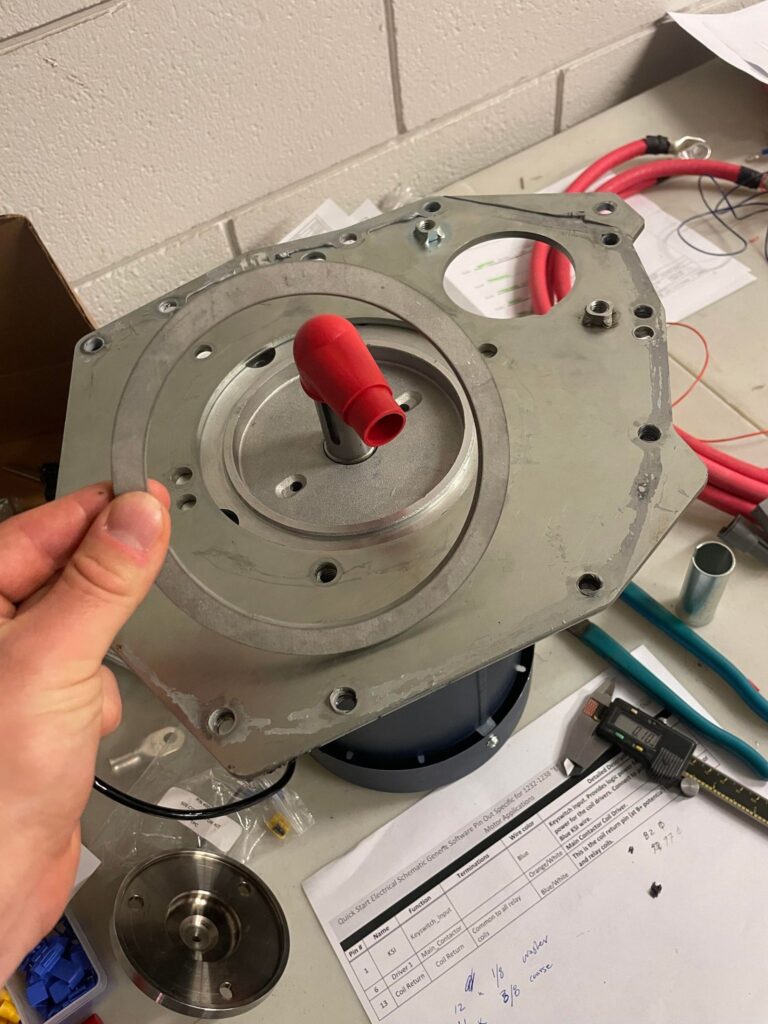

The dimensions of the motor were analyzed in solid works to confirm the fit of the electric motor with the transmission. As shown below a key shaft and flange were required however, the selected motor was confirmed to be a perfect fit for the transmission.

The second major component of analysis was the batteries. Batteries provide a wide range of choice such as performance enhancement, reliability, safety, affordability, etc. The battery selection for the Kubota UTV was assessed between two types which were Lead Acid or Lithium based deep-cycle batteries. Relating back to the design being affordable and easily replicable four GC12 150AH Deep Cycle batteries were chosen. To keep the batteries within their operational range, the team identified “Canadian Polar Pads” as the most effective means of heat transfer. The pads operate similarly to an electric blanket, only requiring 120V, and have a sticky adhesive that allows them to be attached to a wide variety of surfaces. Moreover, the polar pads are capable of heating components from -30 °C to a temperature of +20 °C and are widely used and available in the arctic regions.

Once the motor, controller, and batteries were selected, research was conducted to choose the appropriate electrical components to charge the batteries as well as charge them to the motor. The battery charger itself will be a 48V 15A golf cart battery charger, that is able to automatically charge the batteries, while protecting them from short circuiting, over voltage, over temperature, and reverse polarity (Battery Specialist Canada, 2022). The reason for choosing a golf cart battery charger is that the voltage requirement for the Kubota is similar to what is used in golf carts, and as well for ease of replicating it was agreed upon that having an off-the-shelf system was the best solution.

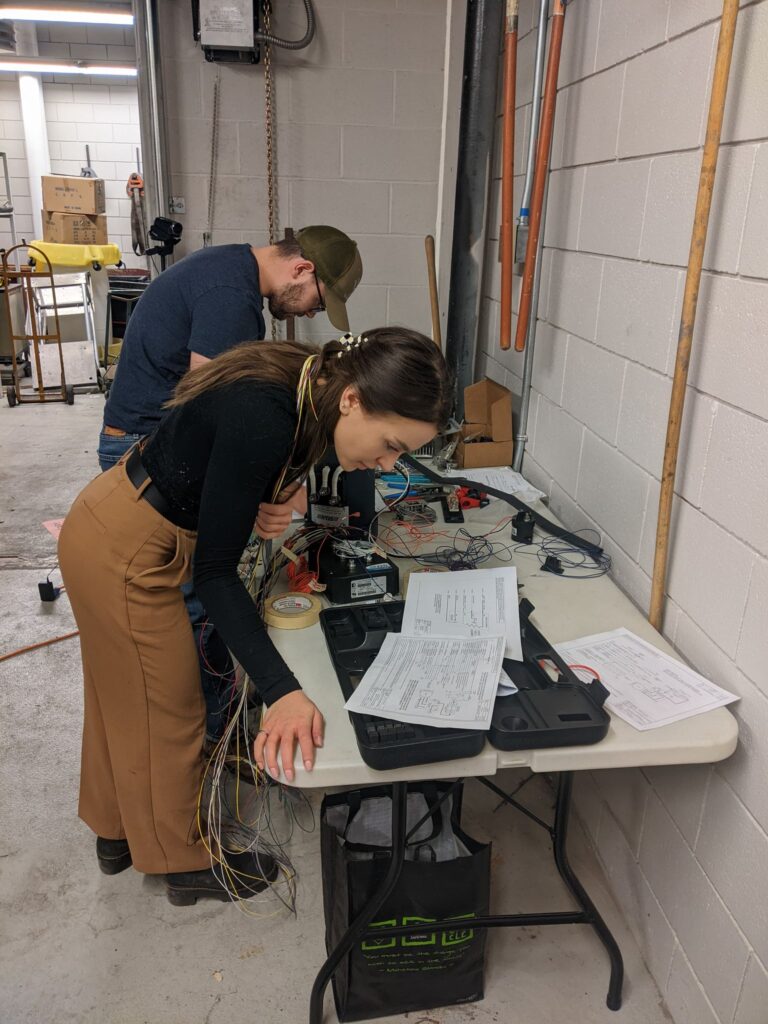

Testing:

Before installation of the electric motor and components it was essential to set up the system beforehand to ensure all components properly work (referred to as a Bench Test). The bench test was performed, and all electrical components were confirmed to be compatible. The voltage across the system was checked during the bench test to ensure that no components were being overloaded.

After the bench test was performed, the dimensions were confirmed to ensure the motor would be compatible with the transmission. Some slight modifications were required for the heat transfer plate. As well the batteries were required to be relocated to a different space. Once all components were installed and the UTV reassembled a road test was performed and the throttle was adjusted to ensure the best comfort for driving.

FEASIBILITY OF OUR DESIGN SOLUTION

Throughout the project, as with most projects, the pressing question was “Is our design actually feasible?” For the project to be feasible the conversion not only had to be completed by the group, but it was also required to be easily Replicated and Affordable.

To ensure that the project was able to be replicated it was essential that all components were easily available off the shelve and supporting instructional materials were provided. While looking into parts and suppliers it was decided that anything that could not be found at the local hardware store must instead be easily available to be shipped anywhere in Canada. Therefore, all parts are able to be acquired from the Northern most communities.

Affordability was a key consideration when determining if the project was feasible. If the design proved to be too expensive the conversion would be rendered impractical. Despite the design costing more than originally speculated the conversion still proved to be the most cost effective option when comparing a ten year lifecycle cost. The lifecycle conversion cost was approximately one third the cost of the lifecycle cost of the original petrol engine and nearly $4000 less than purchasing a new electric UTV.

Overall, the design proved to be feasible. Considerations were made throughout the design process to ensure the project was able to be easily replicated. The project also proved to remain the most affordable option when compared to other similar options.

Partners and Mentors

We would love to thank the many people who helped us with this project! Our advisors Dr. Kerry Black, Dr. Henry (Harry) Penn, and Dr. David Wood who guided us through the process with patience and were able to provide kind words of wisdom through our projects many ups and downs.

We would also like to extend our extreme gratitude to our sponsors the Arctic Institute of North America Kluane Lake Research Station and the Yukon Government

Finally a special thanks to Tractorland Kubota Calgary for their generous and varied support throughout the project.

Our photo gallery

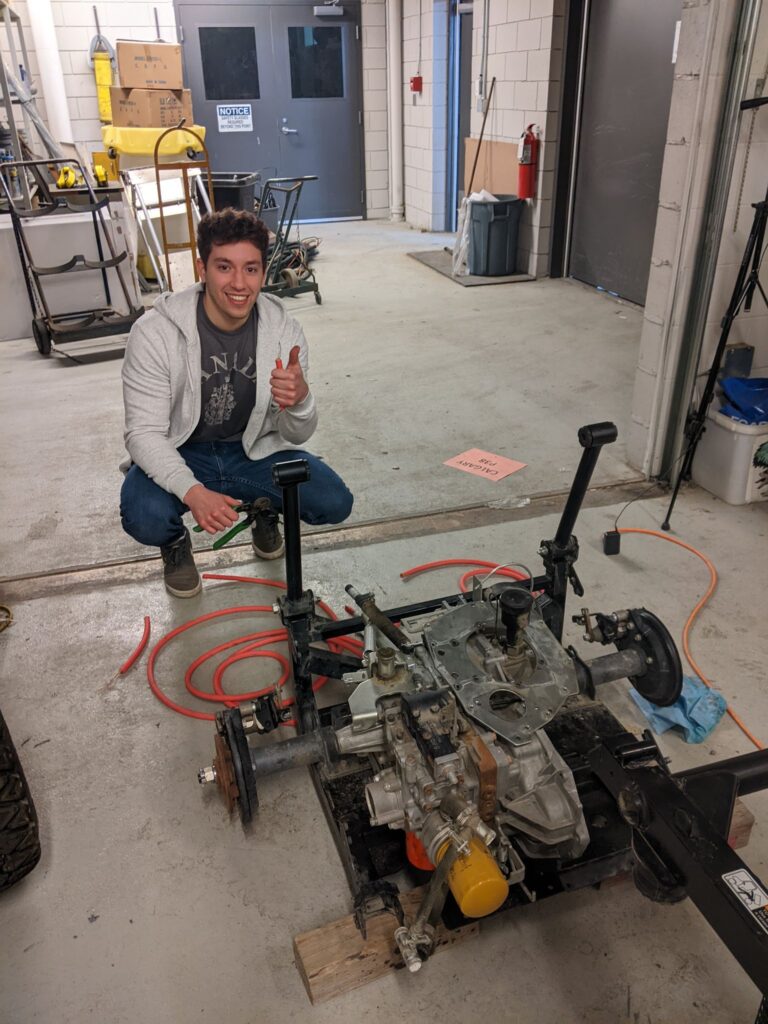

Installing the Motor

Our Mascot Benjie

References

Battery Specialist Canada. (2022). 48 Volt 15 Amp Golf Cart Battery Charger with RXV Plug. Retrieved from Battery Specialist: https://www.batteryspecialist.ca/48-volt-15-amp-golf-cart-battery-charger-with-rxv-plug/

C.E.R. Government of Canada. (2021, February 11). Market Snapshot: Explaining the high cost of power in northern Canada. Retrieved from CER: https://www.cer-rec.gc.ca/en/data-analysis/energy-markets/market-snapshots/2017/market-snapshot-explaining-high-cost-power-in-northern-canada.html

McFarland, J. (2022, April 4). UCalgary students hope to drive change in Indigenous communities. Retrieved from University of Calgary – Schulich School of Engineering: https://www.ucalgary.ca/news/ucalgary-students-hope-drive-change-indigenous-communities

Pembina Institute. (2021). Renewables in Remote Communities 2022. Retrieved from Renewables in Remote Communities: https://www.pembina.org/event/rirc2022#conference

Travel Yukon. (n.d.). Yukon in the Winter. Retrieved from Travel Yukon: https://www.travelyukon.com/en/discover/seasons/winter