Project Category: Multidisciplinary

Join our presentation

Please join us in person at Atrium CNRL Complex (Schulich School of Engineering)

About our project

Gas pipeline pitting corrosion is an issue that affects both industry and public safety however the difficulty in obtaining pipe specimens for testing has made the study of pipeline pitting an incredibly difficult task. To solve this issue Dr. Hugo and his research team have asked us to design and construct a machine that can be used to replicate real-world pipeline damage on new segments of pipe, for the purposes of destructive testing

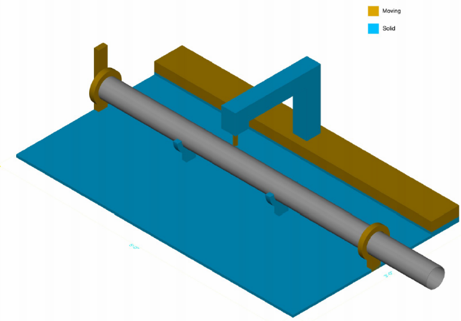

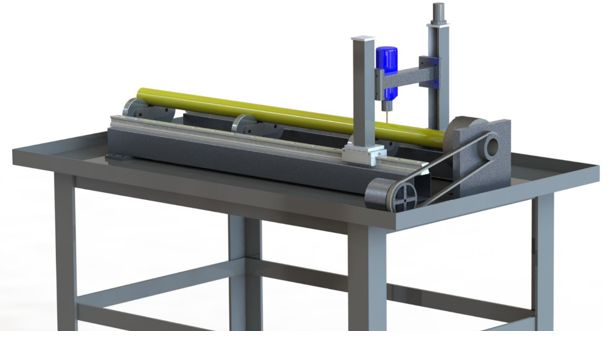

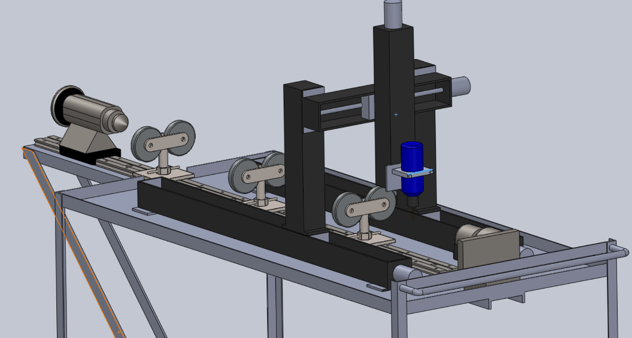

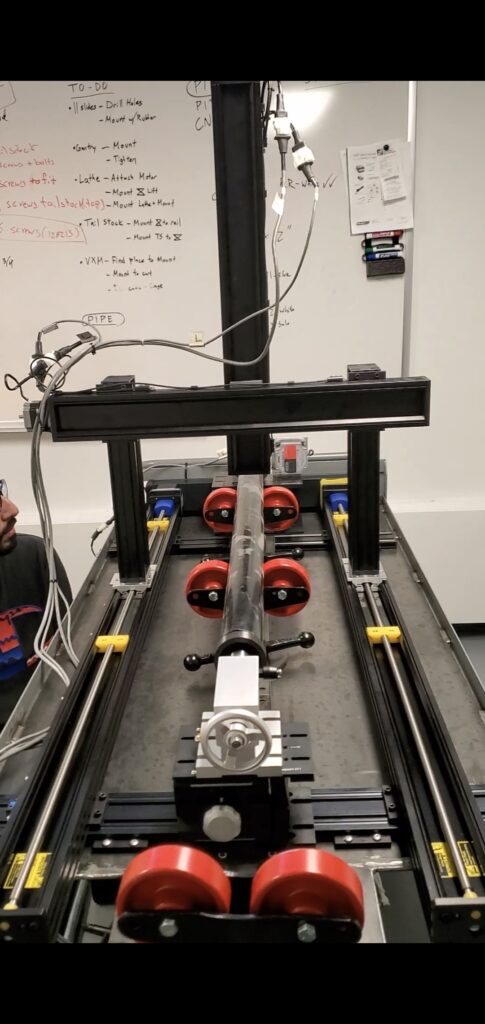

For this purpose, we have designed a CNC machine with fourth axis capabilities. Our machine is capable of holding and rotating lengths of pipe up to 6 feet while a milling tool travels down the length of the pipe. By simultaneously controlling the horizontal and vertical position of the milling bit, and rotating the pipe we are able to remove complex morphological patterns from the pipe. Through the use of computer controls Dr. Hugo’s team will be able to reproduce scans of real-world pitting damage onto new pipes to assist with their research.

Meet our team members

Mustafa Al-Asadi

Nicholas Webster

Wade Hill

Mariam Djibril

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

In the oil and gas industry specifically, the pipeline sector, pitting corrosion is a large threat to the integrity and safety of live service lines. It is very difficult to detect, prevent and foresee excessive damage when legit pigging procedures cannot be performed. Consequently, an analysis of the pitting needs to be done to know approximately the amount of damage on the pipe.

WHAT MAKES OUR DESIGN INNOVATIVE

Our machine uses controls the position of the milling bit in three dimensions allowing for accurate removal of material at desired depths along the entire length of the pipe. The fourth axis of motion is possible through the use of a motorized lathe head which rotates the pipe exposing the entire outer surface for milling. At the request of our client our machine has been designed to take pipe segments up to six feet in length, various inches in diameter, with the possibility for flanges in the middle and end sections.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

Our machine uses factory-new Velmex Bi-Slide translation tables to perform the positioning functions, mounted on a Uline Jumbo steel cart and controlled with new Velmex control units. By combining Bi-Slides with a rotating motorized head we are able to align our milling head with any point on the outer surface of a pipe, allowing us to remove material in specific desired areas.

HOW WE VALIDATED OUR DESIGN SOLUTION

We involved our advisor in every step along our way as well as our sponsor, capstone instructor, and the TAs. These assurances made the building of the project easier. We checked our flex on the table by adding 1/4 in steel plate on top of the cart and C channel under the cart. We also validated our total motor current supply, no bending/ stresses on the gantry

Partners and mentors

We want to thank the many people who helped us with this project. Our Capstone professor Dr. Ron Hugo and his PhD student Peter Chen along with our advisor Dr. Jeff Pieper. Also, We want to thank our capstone professor Dr. Arief Budiman and our TA Mohsen Hassani who guided us through the process with patience and great advice.

Our photo gallery