PROJECT CATEGORY: MULTIDISCIPLINARY

REVERSING DEFORESTATION IS COMPLICATED; PLANTING A TREE IS SIMPLE

MARTIN O’MALLEY

Date: Apr 13, 2021 Time: 10:00 AM - 12:30 PM Mountain Time (US and Canada)

Meeting ID: 992 7320 9694

(Please email anne.pacios@ucalgary.ca if you have trouble joining and need assistance in joining the zoom room)

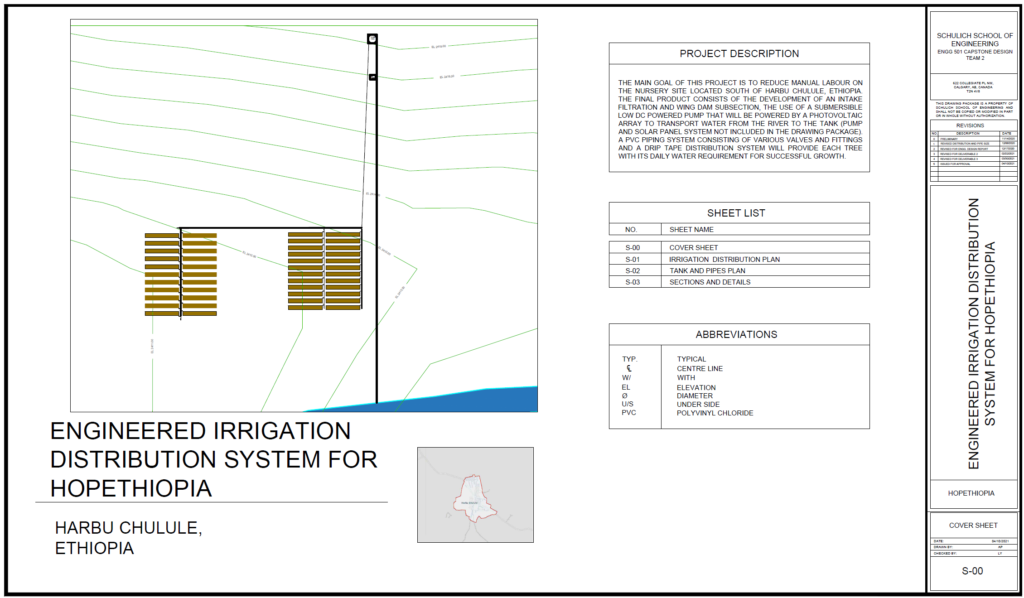

ABOUT OUR PROJECT

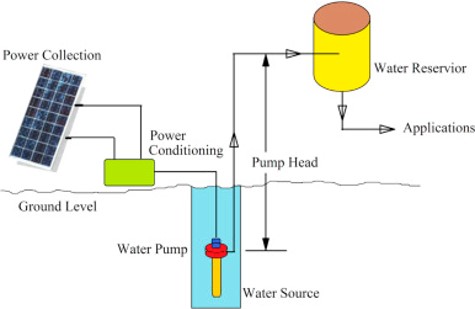

The purpose of this project is to research and design an off-grid drip irrigation distribution system to accommodate the reforestation nursery located at Harbu Chulule, Ethiopia. This design will help increase the irrigation efficiency and capacity of trees grown to aid in local reforestation initiatives to combat erosion and deforestation in Ethiopia. The main criteria considered, include the feasibility of building and operating the system in a village where technical knowledge is not readily available and also to minimize cost and complexity while efficiently servicing the nursery. The selected design includes five main components: Water intake from a stream, pumping, solar panels and wiring, water storage, and distribution.

HISTORY AND MOTIVATION OF THE DESIGN

The Federal Democratic Republic of Ethiopia is a country known for its diversity and exceptionally rich history and over the years the country has suffered extensive losses of forestation due to growing demand for resources. As a result, the country has seen a loss of approximately 98% of all forested regions in the last 50 years. The lack of trees in the area has directly contributed to prolonged periods of droughts, increased soil erosion, and reduced biodiversity. HOPEthiopia is a non-profit organization based in Calgary, Alberta with numerous projects located in the community north of Harbu Chulule, Ethiopia and is currently operating a tree nursery located adjacent to the Gong river on the south side of the city.

The photos above show Google Earth Images of the land near the HOPEthiopia Reforestation site. The tree nursery is visible on the right-hand corner. Throughout the years we can see that reforestation efforts have improved vegetation and land conditions.

Currently, trees in the nursery are hand-watered, requiring volunteers and workers to walk to and from the river nearby, carrying buckets of water. Our main goal is to reduce manual labour to allow HOPEthiopia to focus on the reforestation of the land rather than on the tedious task of tree watering. To do this, we are developing a solar-powered pump system that pipes water uphill into a tank and a gravity-fed distribution line and drip irrigation delivery system for the tree nursery. Overall, we are proposing a low-cost system that will be straightforward to assemble and maintain and that can cater to over 100,000 saplings currently in the nursery.

DESIGN OVERVIEW

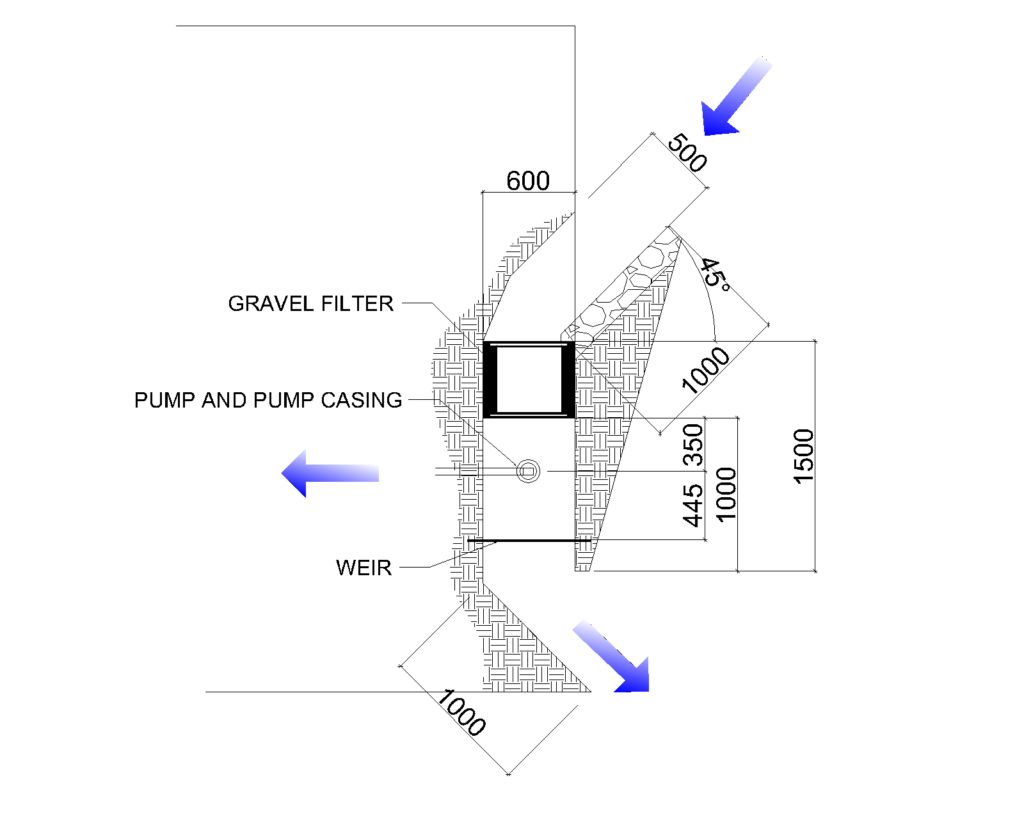

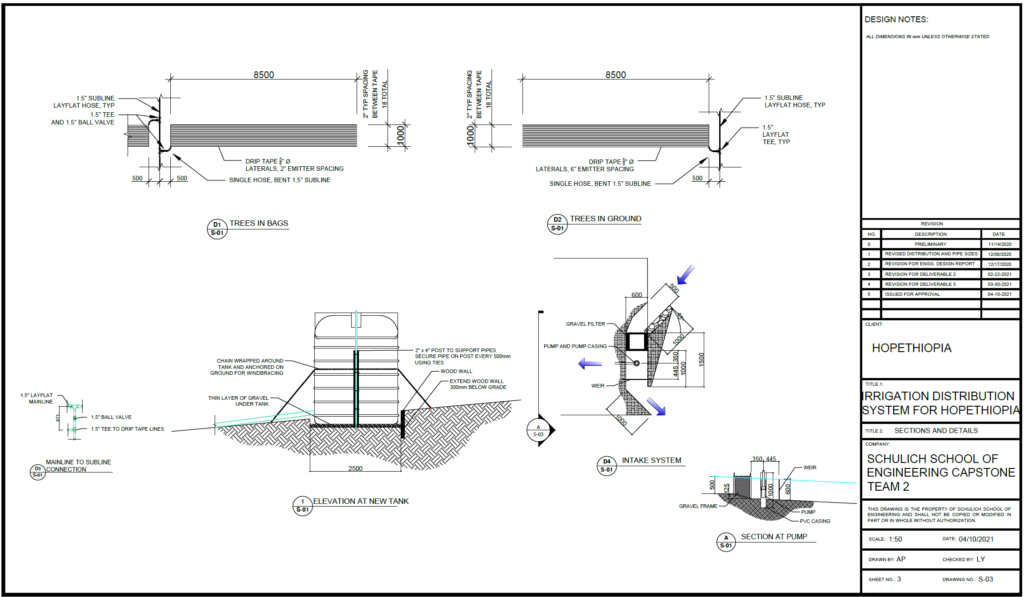

INTAKE

The intake system is specifically designed to accommodate the low water depth and flow of the adjacent river near the nursery. A short diversion channel with a wing dam is designed to direct water to the pump, also making sure that unused water can go back to the main river to reduce disruption in the flow as much as possible. Sections of the intake include:

- A wing dam to direct water flow in the channel

- A two-step filter using gravel and filter sheets

- A PVC pump casing to prevent sediment from damaging the pump

- A weir upstream of the pump to ensure flow level is maintained in the channel

MORE DETAILS ON THE INTAKE

Key Features:

- Diversion Channel to direct water to pump

- Gravel Filtration System

- Channel Dimensions: 0.5m x 0.5m x 0.5m

- Depth at pump: 0.750m

A stream test was conducted on the river by our local contact, Obsa Negesso, and it was found that the river on average has a flow of 0.47m/s and a depth of 101.6mm (4”) at the riverbank and 228.6mm (9”) at the centre. The river is also very rocky and erosion from the riverbank is evident due to its brown murky colour. The pump we have chosen has a height of 310mm and therefore will not be able to submerge fully in the water. Also we would need to include filtration in the river as well as casing for the pump to protect it from damage. Our diversion channel will allow the pump to be submerged at all times and keep the pump undamaged.

PUMP

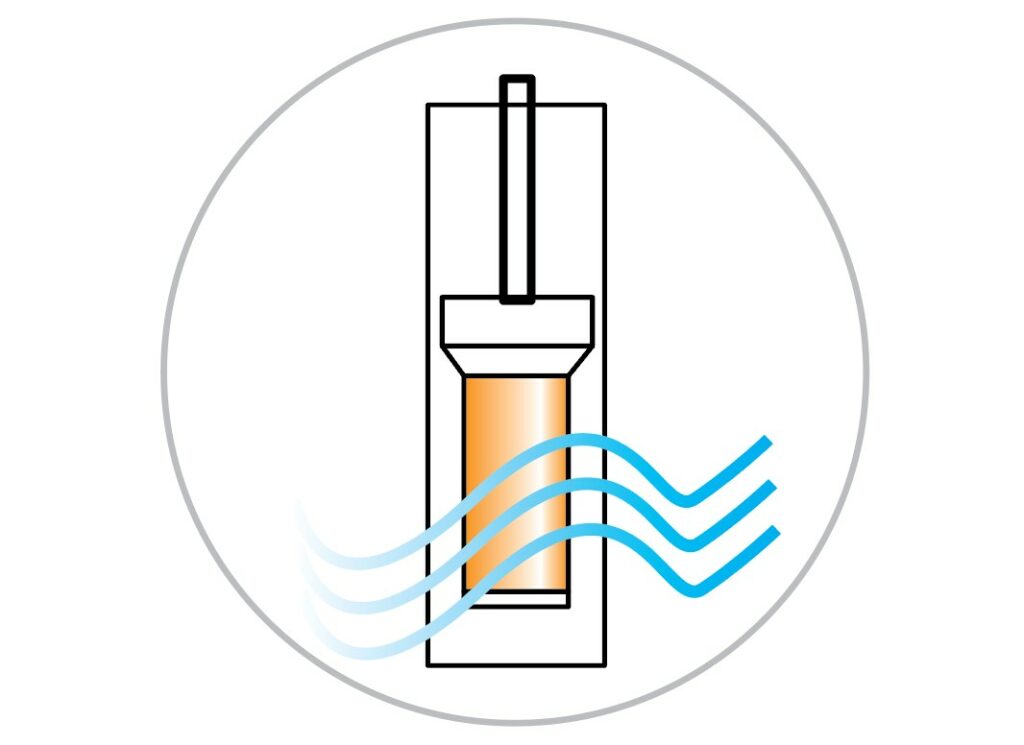

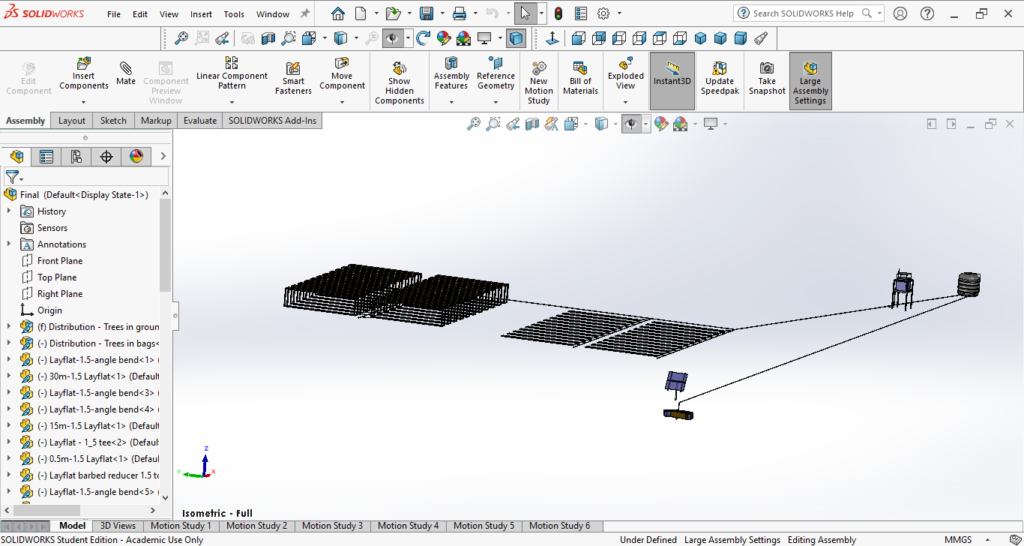

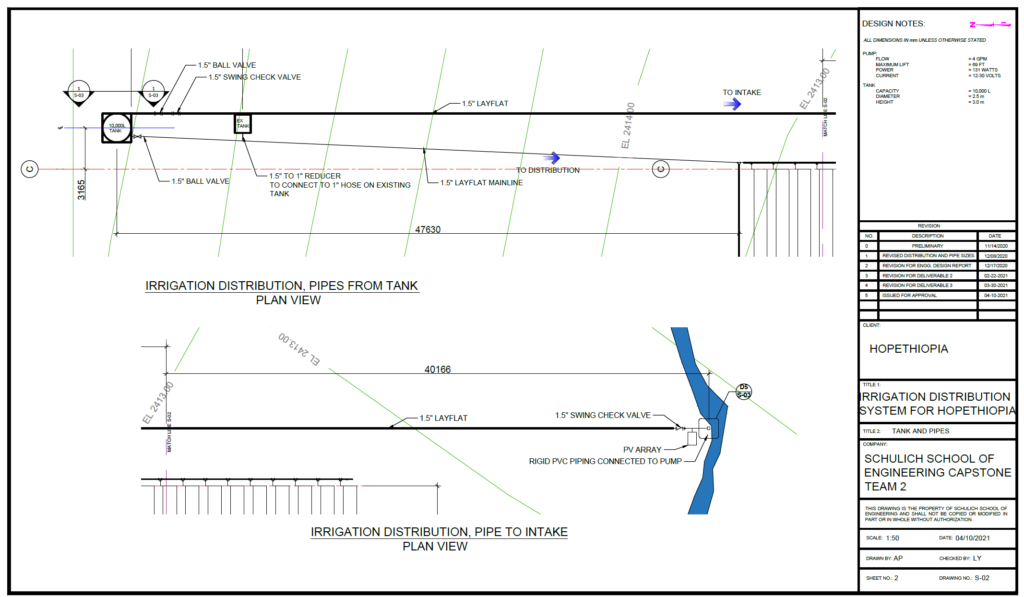

The pump system uses a positive displacement pump that can operate at low voltage and is DC powered, therefore there is no need for batteries or inverters. This pump can provide the required static head at a flow rate near to 0.28 L/s. The submersible pump will be attached to a polyethylene pipe that connects to a PVC lay-flat hose that can sustain about 80 PSI of pressure. The hose will lead from the river to the nursery tank and connect to a permanent setup of rigid PVC piping.

MORE DETAILS ON THE PUMP

SunPumps SDS Q-135

Key Features:

- Low Voltage Requirement

- DC Powered, no need for batteries or inverters

- Hydrostatic Head of 14.8m

- Flow rate: 0.28L/s (4.44 US GPM)

- Operates on 12-30 Volts of DC Current

- Requires 137 Watts

Pump Timing

The calculated daily demand of water is about 3000L per day, or 1500L per watering period. Watering will be done in the morning and late afternoon. The pump will operate for 3 hours a day to reach the 3000L of water required, given that there is ideal sunlight hours.

PV ARRAY

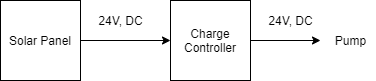

The photovoltaic array system is designed to supply off-grid power to the irrigation system. One key design focus for the electrical system was to reduce component costs as much as possible. This was achieved by having a DC system with no additional batteries or inverters required. Therefore, only when there is sufficient solar irradiance incident on the solar panels will the pump be capable of operating.

MORE DETAILS ON THE PV ARRAY

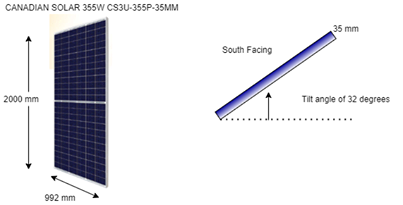

Canadian Solar CS3U-355P-355MM

Key Features:

- 1.8m2 Solar Panel Area with a Max power of 355 Watts

- Improved Shading Tolerance

- High PTC rating of up to 93.11%

- Lower Hot Spot Temperature

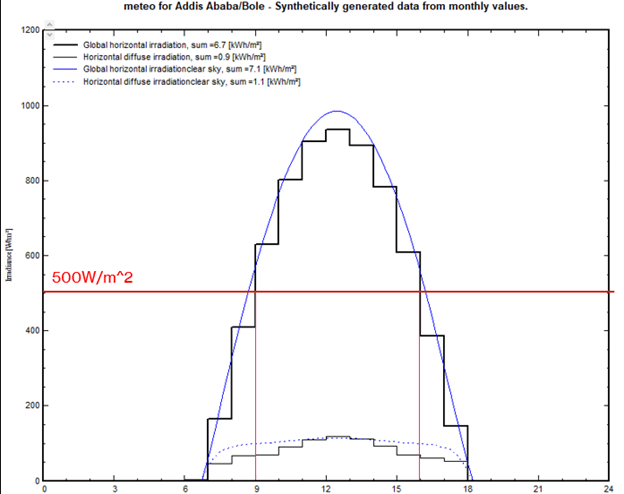

Solar Irradiance

- Minimum 500W/m2/hour between 9am and 4pm

- Maximum output of 355W possible at peak irradiance, maximum output of 178W between 9am to 4pm

We used a simulation software called PVSyst to gather irradiance data from the closest city to Harbu Chulule, which is Addis Ababa. Between 9 AM and 4 PM, there is at least 500W/m2. The wattage of the panel we chose allows us to operate the solar panel even at lower irradiance.

Furthermore, in case of cloudiness or otherwise low light conditions, we have included a charge controller capable of current boosting. The charge controller also protects the circuit as it behaves similarly to a bypass capacitor in which it will hold a small amount of charge that lets it bypass temporary losses of sunlight.

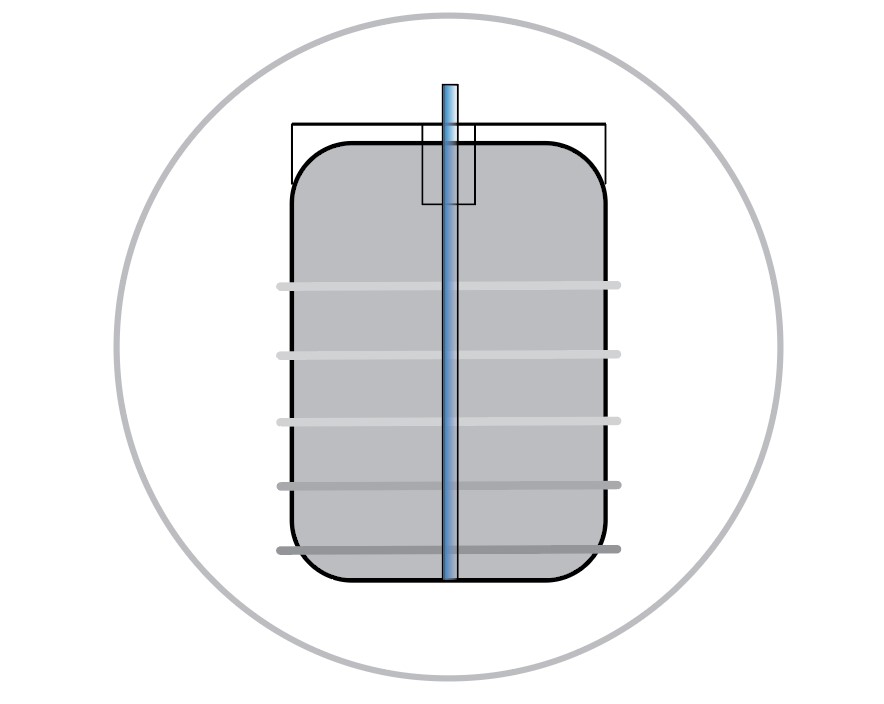

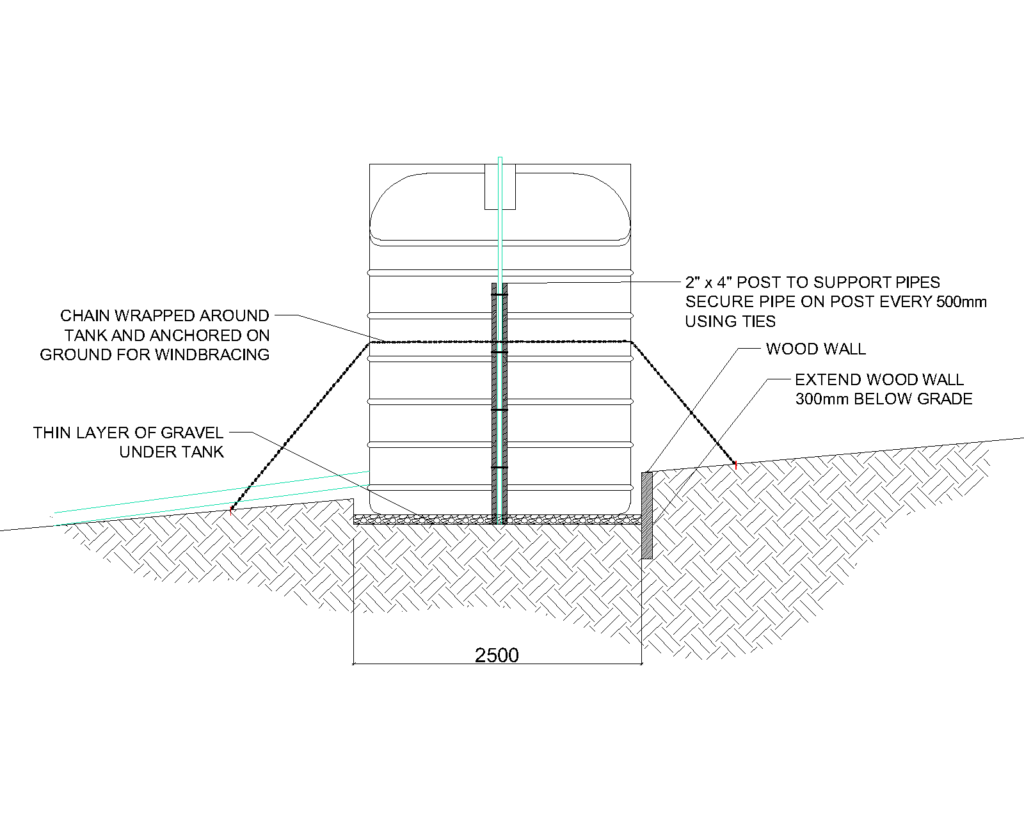

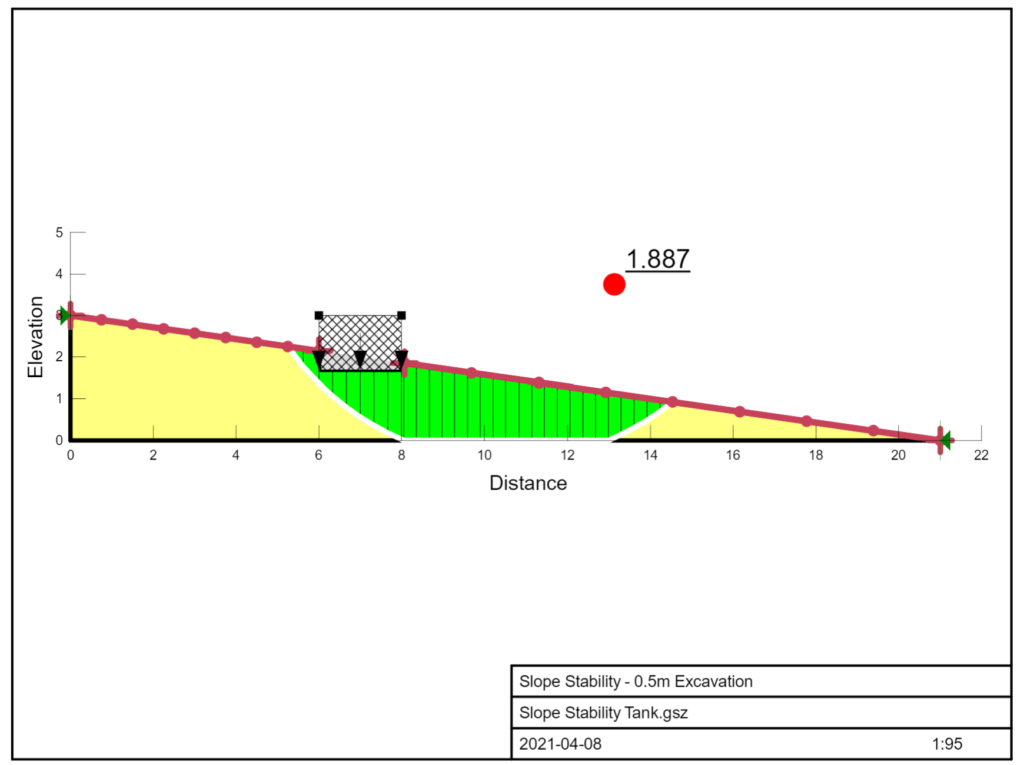

STORAGE

The storage system is designed to hold sufficient water for the system to operate in the dry season, this includes contingent storage to allow for operation during overcast days with low precipitation, where the solar panels will be unable to operate, and the amount of precipitation is insufficient to water the saplings. Water is to be stored with at least 6m elevation gain above the nursery, requiring a hill behind the nursery. This arrangement is ideal for nurseries located adjacent to a larger riverbank.

MORE DETAILS ON THE STORAGE TANK

KEY FEATURES:

- 10,000L Storage Tank selected (enough for 3 days of water storage at maximum capacity)

- Allows system to operate during dry and cloudy weather conditions in all but one or two days per month.

TANK RATIONALE

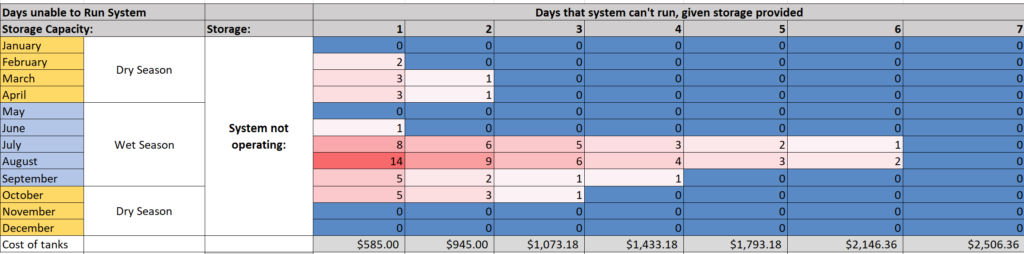

We studied weather data for Addis Ababa, the closest major city to Harbu Chulule, and observed how many days had cloud cover over 40%. Then from those days, considered days with less chances of getting at least 10mm of rain. From studying different storage scenarios, it was found that 3 days of extra storage would provide a good balance between cost and reducing the need for hand watering during the shoulder seasons.

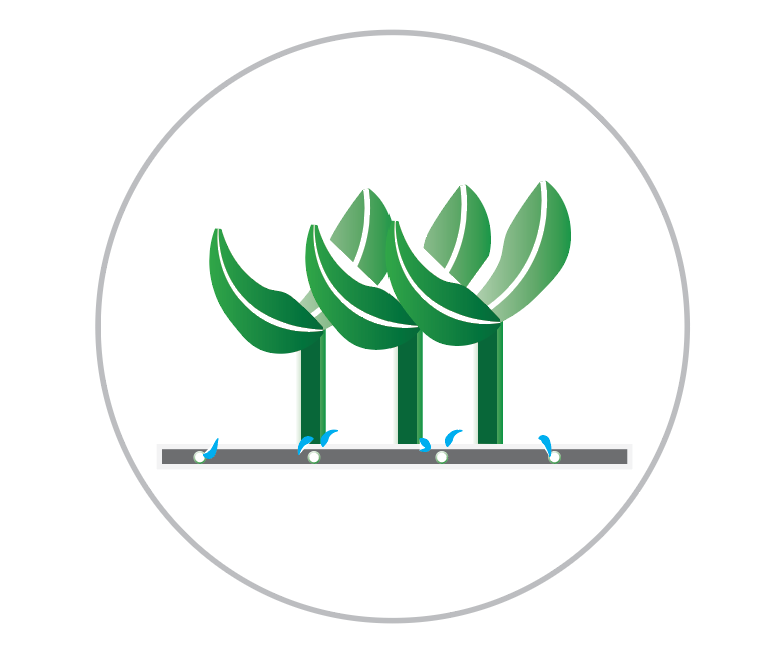

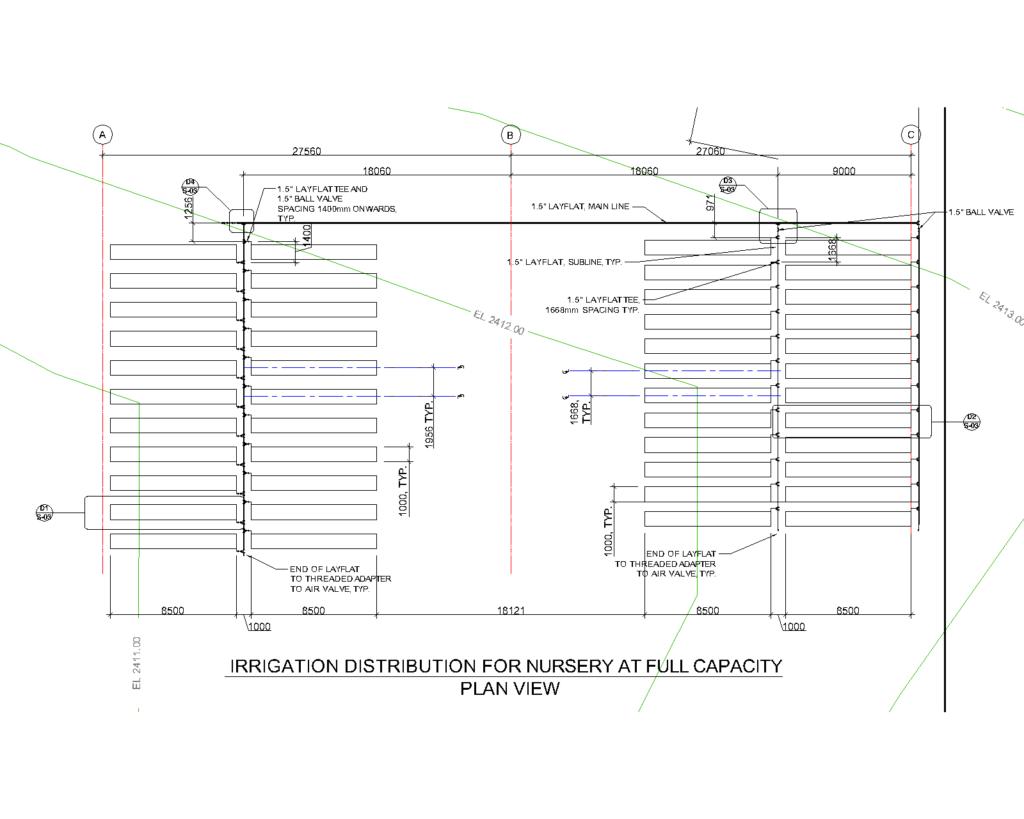

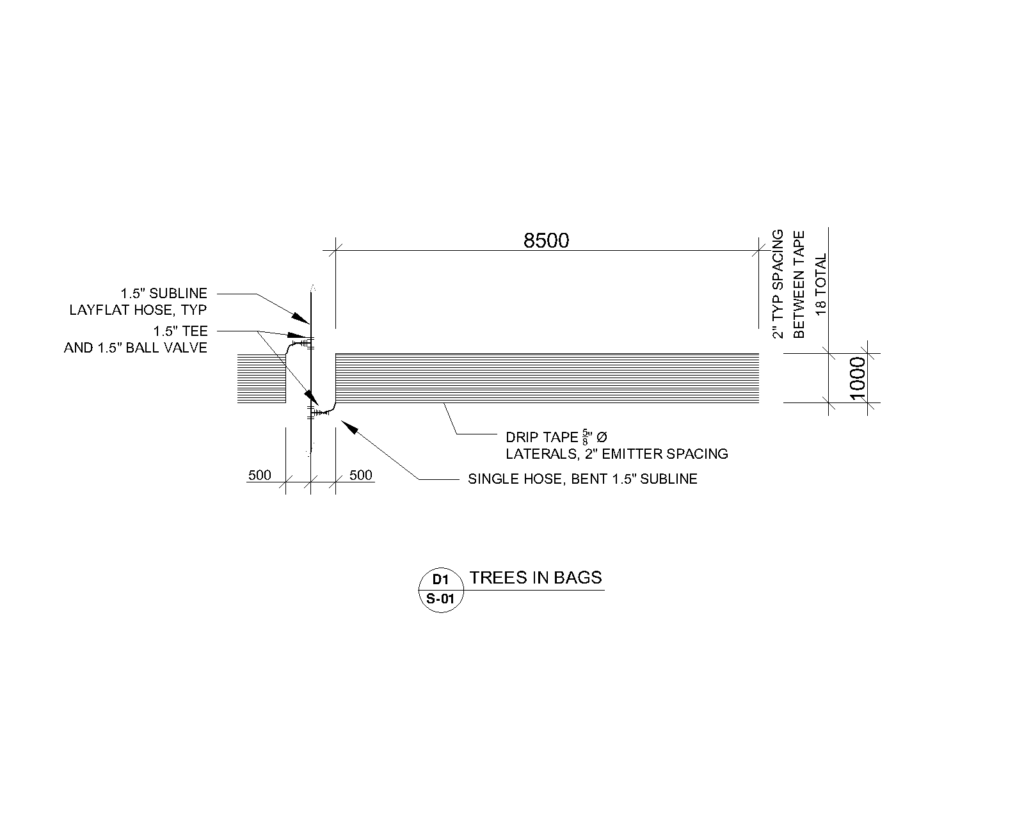

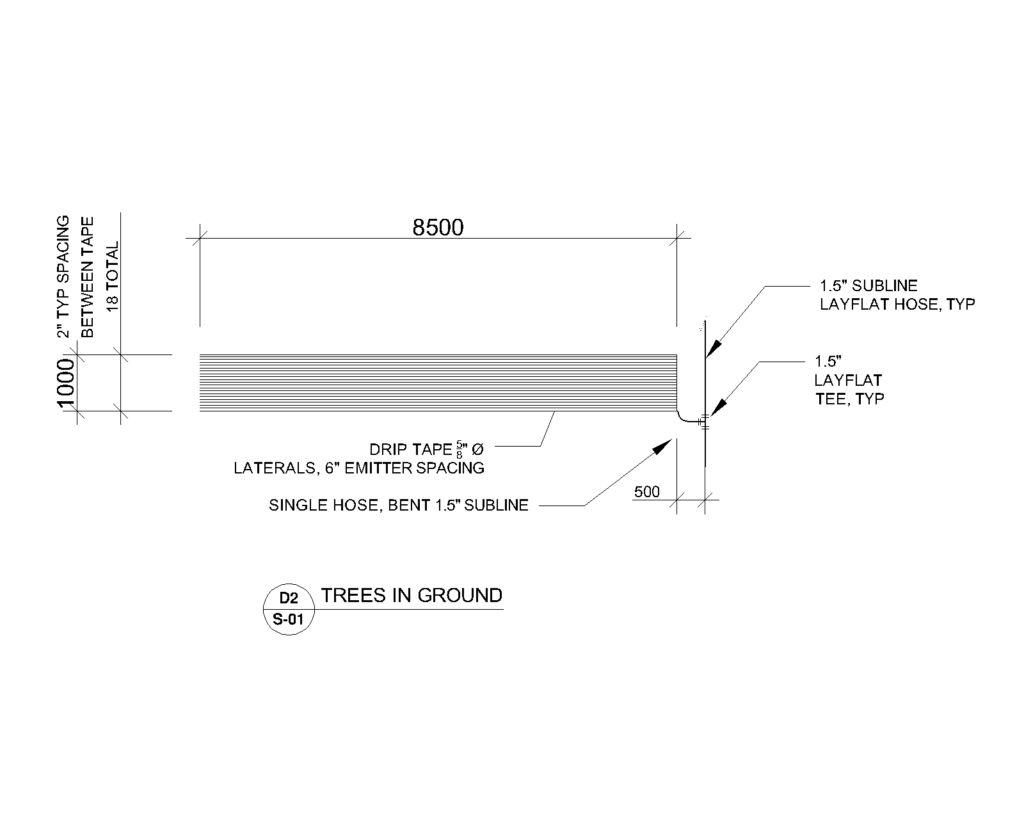

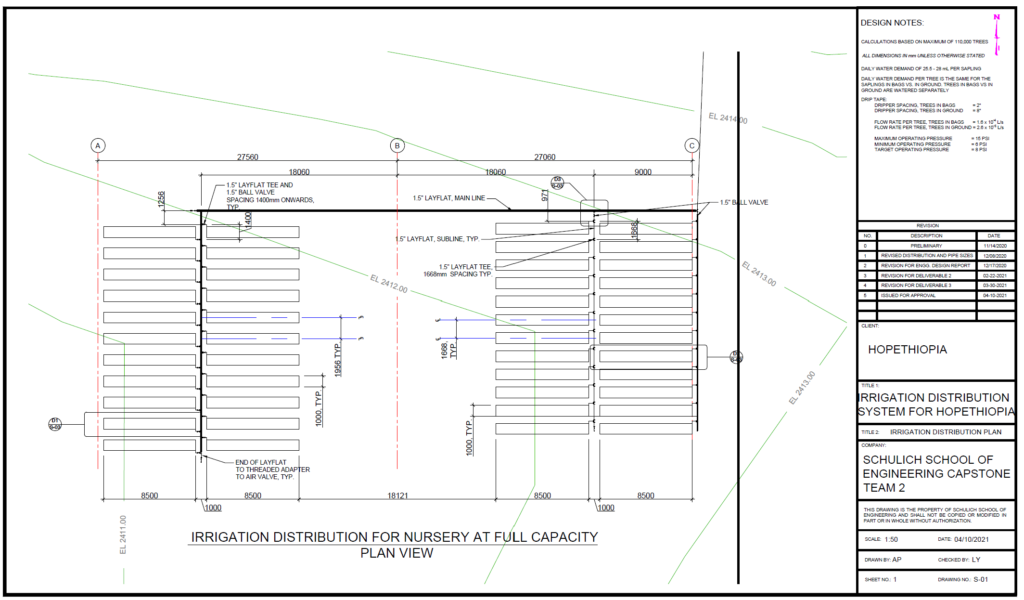

DISTRIBUTION

The distribution system takes water from the storage tanks on the hill to the saplings that need watering. A large lay flat hose mainline carries the water to multiple sub-mains that are individually opened and closed to water the saplings. Drip tape is used to apply water to the saplings at low pressure and low flow rates, resulting in more efficiency where water is not wasted during application.

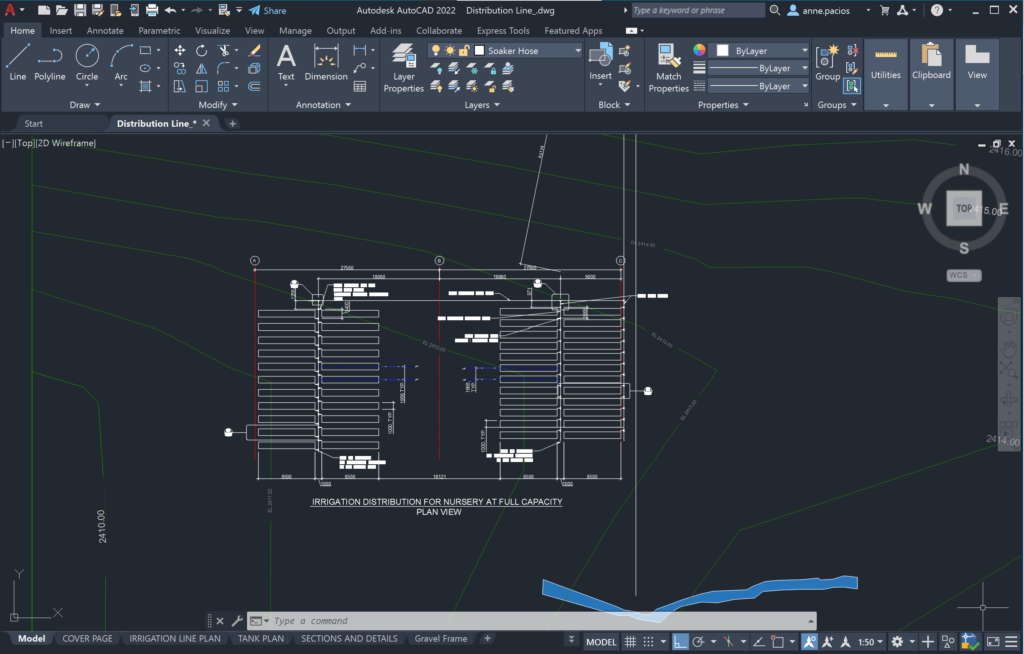

MORE DETAILS ON THE DISTRIBUTION SYSTEM

Key Features:

- Target Pressure of 8 PSI in drip tape (5.63m of head)

- Head Losses kept below 1m

- Up to 3000L per day applied to nursery

- All trees receiving 25.5 – 28 mL of water per day.

- Drip tape for trees in bags has emitters spaced every 2” with flow rates of 1.6×10-4 L/s per tree.

- Drip tape for trees in ground has emitters spaced every 8” with flows of 2.6 x10-5 L/s per tree.

The nursery has two main areas: saplings in bags and saplings planted in ground. There are 22 plots, each plot 1mx8m, for the saplings in bags, and 24 plots of the same size for the saplings planted in ground. At full capacity, which is what we have designed our system for, there are approximately 110,000 saplings in the nursery.

We have chosen lay-flat hosing for the main and sub lines as it is cheap and comes in low volume reels that are easy to install. Water will be applied to the trees using a product called drip tape. This tape has prefabricated holes that regulate the flow to each tree.

DETAILS ABOUT OUR DESIGN

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

Cost

Working with a non-profit NGO, HOPEthiopia, we wanted to balance system efficiency with the cost of components. For example, while we originally investigated having all pumps and valves fully automated, we soon found that using a few manual operations would save component costs significantly. Additionally, many different configurations for the distribution setups were iterated to find the cheapest solution that still delivered water effectively.

Solar Powered

With no reliable power grid near the nursery site, solar power was deemed the best option to power the system. The amount of required solar irradiance was also checked against local weather data to observe how many days per month would receive insufficient sunlight to run the system. Storage tanks were then selected to store an additional 3 days’ worth of water as a backup. A capacitor and charge controller was also specified to regulate the power to the pump and smooth out the electrical flow.

Water Quality

One concern with any irrigation system is that sediments and particles will deposit in the lines over time. To address this, we added three stages of filtration into our design.

- First, water passes through a gravel-filled channel to filter out larger particles and debris before they reach the pump

- Before entering the pump, water passes through a wire mesh that has 120 micrometres pores to remove all gravels and most sands

- Before entering the storage tank and the distribution system, water will pass through a filter bag that has 50-micrometre openings to further filter all but fine silt and clay particles that can pass through the drip tape without clogging.

WHAT MAKES OUR DESIGN INNOVATIVE

High Density of Saplings

Most Irrigation systems we looked at had plants that were either spread out in large rows or tightly packed in a greenhouse building. Our design ended up using high densities of drip tape to ensure that water was reaching every tree without having to use high pressures and more expensive components required by sprinkler systems.

Gravity Fed

Many drip tape systems are connected to pressurized mains or pumps and use pressure reducers to moderate the water pressures entering the tape. Drip tape will emit varying amounts of flow at pressures between 6 to 10 psi. In order to make gravity-powered distribution work effectively, a code was built to check many iterations of piping and fittings to ensure that pressure losses were minimized and that flows were kept as consistent as possible across the site.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

Drip Application

Drip tape is used to apply water to the saplings to ensure that water is not wasted by overwatering the soil around the trees or by causing excess water to be evaporated. Additionally, drip tape reduces the flow rates of water required in the piping system, lowering energy losses due to friction, which helps keep component sizes and costs low.

Submersible Pump

Placing our pump directly in the intake channel we have designed removes the need for pump-priming and uses the temperatures of the water to provide natural cooling to the motor. A check valve installed just above the pump ensures that water only flows one way through the system.

HOW WE VALIDATED OUR DESIGN SOLUTION

EPAnet, GeoStudio, Excel VBA, PVSyst

- A free water modelling system called EPAnet was used to check head loss equations for our distribution system.

- A Microsoft Excel spreadsheet was created using VBA that could iterate hundreds of calculations checking a variety of piping configurations and optimizing cost and minimizing head losses.

- GeoStudio, an integrated software suite for modelling slope stability, was used to calculate the stability of the slope at the location where the tank will be placed.

- Industry-leading software PVSyst was used to determine optimal array orientation and synthetically generate solar irradiation level site data

AutoCAD and SOLIDWORKS

We used AutoCAD and SOLIDWORKS to draft 2-D and 3-D models of our entire system.

FEASIBILITY OF OUR DESIGN SOLUTION

Low Overall Cost

Our system relies on some human components instead of automation, keeping costs low and reducing the skill required to maintain. An entirely DC battery-less electrical system was chosen to further reduce costs and simplify our system.

Component costs were broken into the key design components. A total cost of $9,500 CAD is projected to service the nursery at full capacity. A 20% contingency was selected due to additional uncertainty for sourcing products from local vendors or importing some of the more specific components such as drip tape. Where possible, components are recommended to be sourced locally in Addis Ababa for increased sustainability.

Cost Estimate

Low Technical Knowledge Required

Parts and components were selected to be easy to use by locals, particularly during installation and maintenance. Documentation was also prepared to assist in execution and operation.

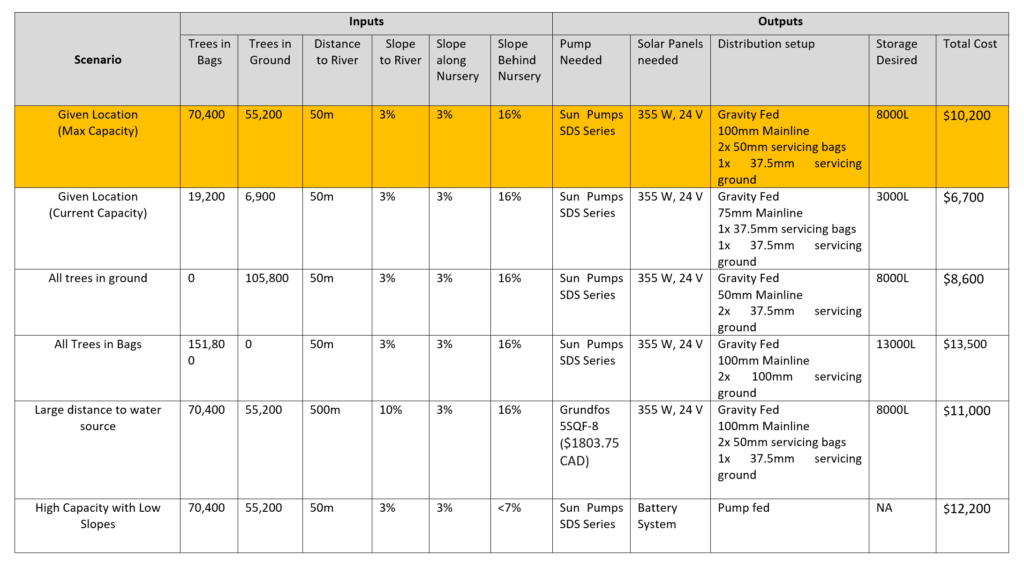

Look-up Table

We have also provided a look-up table for possible investors which summarizes different scenarios and suggested outputs for design and the total cost.

..

MEET OUR TEAM

PARTNERS AND MENTORS

HOPEthiopia is a not-for-profit organization founded in Calgary, Alberta, Canada with a focus on East Africa. HOPEthiopia is about bringing HOPE and restoration to the orphaned children and homeless retired pastors of Ethiopia. HOPEthiopia facilitates community development through improving education and health care, as well as clean water and reforestation.

A huge thank you to everyone who helped us with questions, and provided feedback, and support for our design; especially our Industry/NGO Partner and Sponsor, Wayne King, of HOPEthiopia, our Academic Advisor, Dr. Ed Nowicki, Advising Engineer, Gideon Mentie, Civil Designer, MAGNA Engineering Services Inc., our Course Instructor, Dr. Roes Budiman, and TAs Penny Gong and Haobin Chen, all of whom provided great support and questions. We also wish to thank our Consulting Engineer in Ethiopia, Obsa Negesso, who helped us tremendously to acquire valuable site information.

Wayne King, P.Eng

Sponsor

Principal of King Engineering with work in structural, mechanical, electrical, automation, energy modeling, process, piping, and non-destructive testing. Wayne is a board member of Clear Water Clarification (CWC). CWC is based in Saskatchewan, with patented technology for cleaning wastewater.

His real passion however is in Eastern Africa, going back to 1995. He is a Director and Co-founder of HOPEthiopia / Rwanda, a not-for-profit NGO, providing capacity building in areas such as: agricultural food growth, educational assistance, medical clinic support, reforestation, orphan village construction, and other infrastructure construction. Wayne is not one to sit still, with additional work in Uganda through Watoto and Kenya with EA Hockey Foundation.

Edwin Nowicki, PhD, P.Eng

Academic Advisor

Dr. Ed Nowicki is an Associate Professor in the Department of Electrical and Software Engineering in the Schulich School of Engineering. His research projects are in switch mode converter design applied to renewable energy, especially for small systems (1kW to 100kW) in the developing world and power electronics for solar, wind, and microhydro. He enjoys consulting work with inventors and was the lead innovator for a patent on a grid-connected inverter. He was involved in a team project that provided microhydro improvements in the village of Ghodasin, Nepal in 2014. Dr. Ed has also taught power electronics for a masters degree program in renewable energy, Addis Ababa, Ethiopia.

OUR PHOTO GALLERY

MORE PHOTOS