Project Category: Multidisciplinary

Join our presentation

Note: this link is valid from 10am until 12:30pm on April 13th

About our project

Alberta’s Oil Sands operators are facing unprecedented headwinds in light of stricter environmental regulations and a lack of new and existing pipeline capacity with which to transport the crude. These external factors have weighted heavily on the industry, which has seen significantly reduced investment capital from financial institutions.

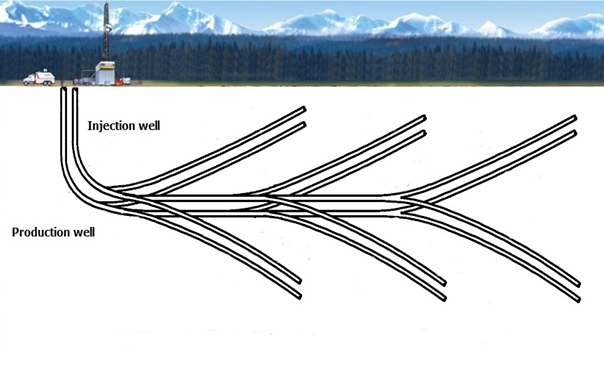

The production of oil and gas within Alberta’s SAGD industry releases a lot of emissions and uses a lot of water to produce 1 m3 of oil. This is formally known as the Steam to Oil Ratio (SOR) and the industry standard is 3 m3 of steam to produce 1 m3 of oil. The biggest issue with our industry is that emissions are very high for the amount of production. As well, companies have been divesting outside of Alberta given how heavily viscous our oil sands are. Our project focuses on a Fishbone (aka multilaterals) SAGD operations in an Alberta Oil Sands reservoir. With this is mind, we sought out to reduce the overall emissions, increase production, and reduce the SOR value below 3, becoming an economically viable solution.

After simulating many different fishbone designs, we were able to find a design that reduced the cumulative SOR to 2.93 m3/m3 while increasing oil production from 278000 m3 to 333000 m3. Further optimizations can be made by manipulating the operating parameters, such as steam injection rate, bottom-hole pressure and flow rates, which could allow for further improvements, pushing the performance to the limits.

Meet our team members

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

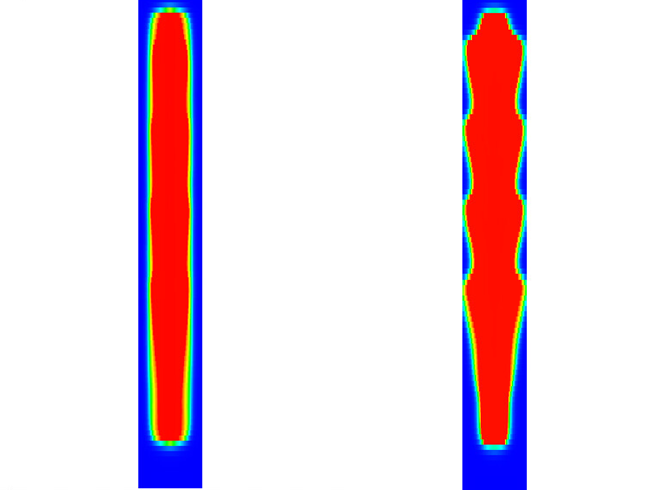

One of the biggest issues with SAGD is steam chamber growth in heterogenous reservoirs. Using this technology, the steam chamber is able to extend from multiple locations in the reservoir allowing for steam to travel through the reservoir easier. This allows for faster steam chamber growth and more sweep efficiency. Fishbones can also be used in place of infill wells, saving time in the future while producing oil from day 1.

WHAT MAKES OUR DESIGN INNOVATIVE

Reducing the Steam-Oil Ratio (SOR) of thermal projects such as SAGD typically consist of new injection methods such as co-injection using polymers or solvents. What if we think bigger? What if we change the way we think about SAGD completions? With a change in bottom-hole configuration, not only can we adjust the shape and size of the steam chamber, but we could continue to add onto it. Fishbone completions in SAGD operations have only been attempted by one company in Alberta and the configurations were used only as infill wells. We wanted to see how the field could change with a new take on an already proficient design.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

In order to determine how effective our designs were, we compared them to a base SAGD case run through the same reservoir and injection process, and along the same timeline of five years. Our design proved to produce about 20% more oil when compared over the first 5 years while reducing the SOR from 3.5 to 2.93. A detailed economic analysis was also performed showing significant improvement of the fishbone designs when compared to the base case. The design also allows for many optimizations to be made depending on the specifics of the reservoir.

HOW WE VALIDATED OUR DESIGN SOLUTION

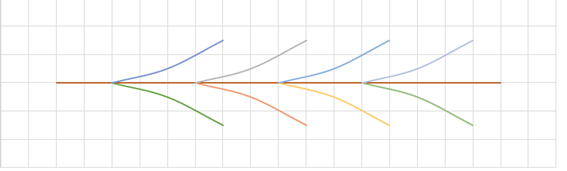

In order to validate the fishbone, design the group simulated different fishbone architectures until the SOR decreased to under three using the program CMG Stars. The fishbones were simulated in a reservoir with the same heterogeneity as a typical McMurray reservoir. For the different fishbone architectures, the group started out with doing simulations with four flat (no elevation change) symmetrical fishbones (two on each side on the well) on just the producer or injector well, then had fishbones ramp up on those two cases. Finally, the team did the exact same simulations with the difference being that the four symmetrical fishbones were on both the injector and producer wells, with the fishbones being both flat and ramped up. Once these simulations were completed the team performed the exact same set of simulations but where the number of fishbones changed to six and eight fishbones. The final design that produced the lowest SOR of 2.93 was eight flat fishbones on both the producer and injector wells.

FEASIBILITY OF OUR DESIGN SOLUTION

An important consideration when tackling this design project was the potential feasibility of this design in a real world SAGD operation. The reality of this technology is that practically all SAGD operations in Alberta are completed using standard vertical well configurations, or in some cases with a single parallel multilateral, however fishbone configurations have rarely been attempted here. However, fishbone style multilaterals have been used more commonly in other production markets around the world and have been proven to be effective in many cases. The technology to drill angled branches from the mother wellbore is readily available and the process for doing so is not brand new. The main barrier to the feasibility of the project is that drilling many fishbones could greatly increase initial capital cost, presenting higher financial risk for a project. With this in mind, the design was considered to be feasible to implement, with the understanding that the main barrier to implementation would be higher capital cost. An economic analysis of our designs was performed after simulation to gain further insight into the financial impacts of drilling fishbones compared to the gains of increased production.

Partners and mentors

We would like to thank Dr. Ian Gates and graduate researcher Benjamin Edafiaga for their wealth of knowledge and guidance in pursuing this project. We would also like to thank our industry contacts, Dr. Da Zhu and others, for offering us valuable mentorship. Finally, we would like to thank Dr. Arief Budiman and Jaehyun Yang for their constant engagement with our project, and for pushing us to find our path to the finish line.

Our photo gallery

Side-by-side comparison of base case (left) and fishbone steam chamber at final state