Project Category: Energy

Join our presentation

Please join our zoom session open from 10 am-12:30pm

About our project

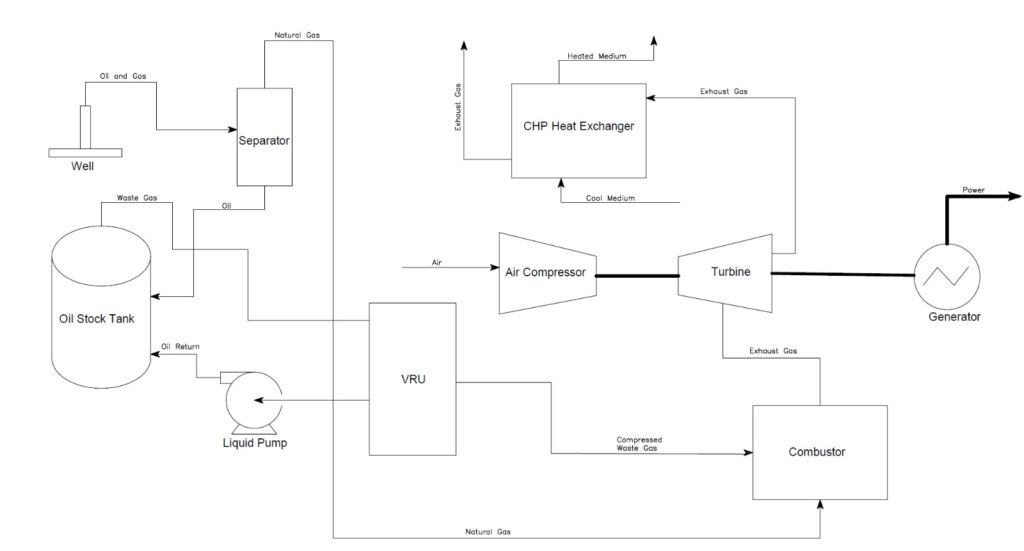

The venting and flaring of natural gas is a major emitter of greenhouse gases. This venting has negative environmental impacts and financial impacts for the companies involved in this practice. The energy sector is striving to reduce their carbon footprint and financial penalties related to carbon pollution. The purpose of this project is to find an economical and practical solution to limit the venting and flaring of natural gas at well-sites. After carefully considering various options, our design solution was determined to be a microturbine installation. The microturbine will combust the natural gas to create electricity that can be used on-site as well as sold to the grid. Combined heat and power is also implemented by extracting heat from the microturbine exhaust gas to provide on-site heating. Viable options for on-site heating include, space heating, line trace heating or process heat. The microturbine reduces emissions by combusting more efficiently when compared to a flare stack. The solution is also economical by limiting the cost of electricity required to run the well-site, while selling excess electricity back to the grid. The reduced GHG emissions also creates carbon offsets that will be very beneficial as the cost of carbon pollution increases.

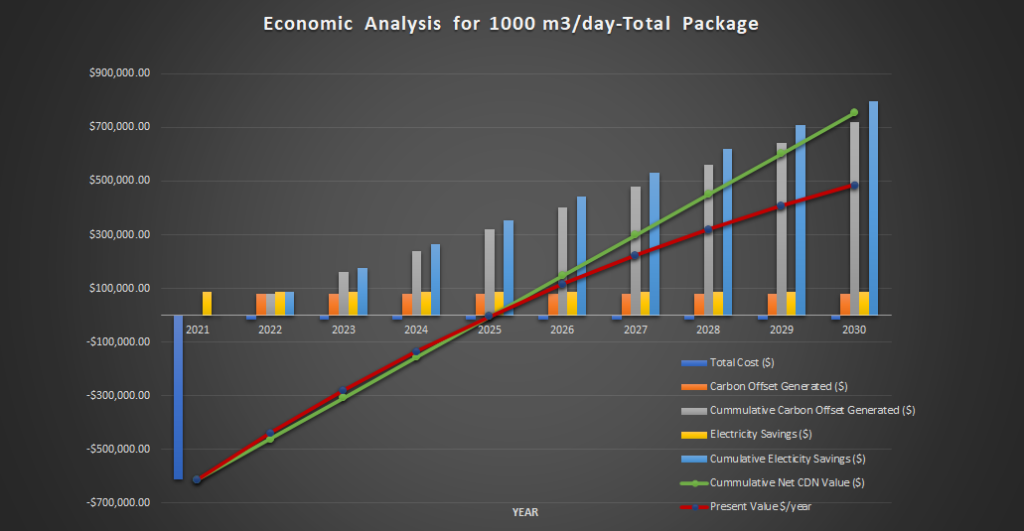

Complementing the microturbine solution, is a waste gas recovery system that helps capture the flashing losses from the crude oil in the separator and storage tank. These losses occur due to the change in pressure from the separation vessel to the storage tank (high-to-low pressure). Additionally, other losses from the tank such as breathing and working losses are recovered. This complementary solution allows the financial and economic benefits to exceed that of the microturbine on its own.

Details about our design

HOW OUR DESIGN ADDRESSES PRACTICAL ISSUES

As previously discussed, with a global warming potential of 25 times that of carbon dioxide, methane venting in the oil and gas industry presents a significant problem. Although various methods of capturing this waste gas have been presented in the past, none of them were economically viable. This made them unattractive to companies looking to reduce their emissions.

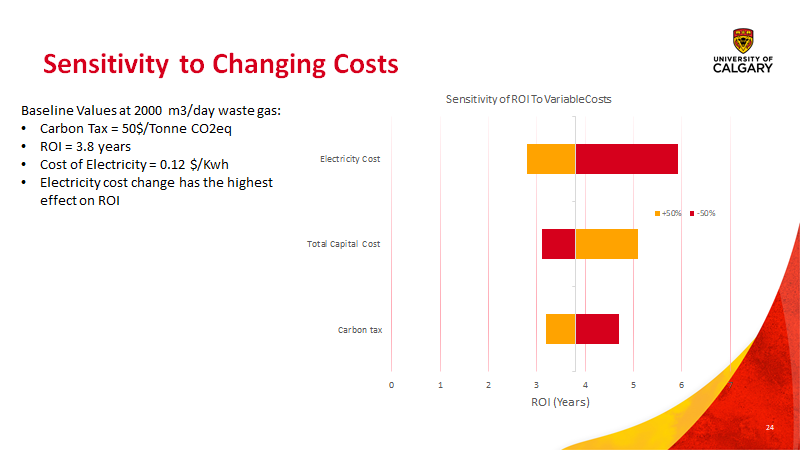

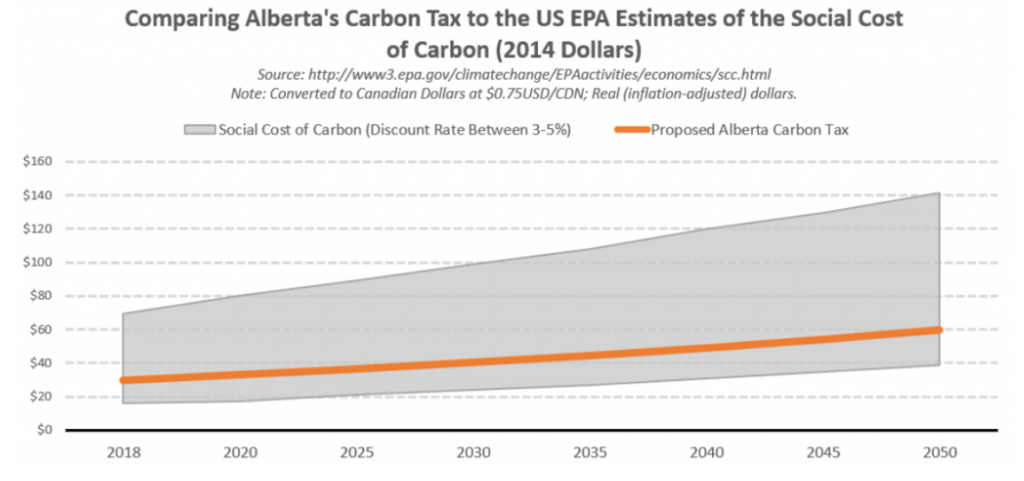

With the implementation of carbon credits and strides taken in improving technology, these systems can reduce emissions while also providing an economic benefit. The design of a microturbine coupled with a vapour recovery system will allow companies to reduce their environmental impact while possibly creating revenue. The practicality of the microturbine system will continue to grow as the price of carbon pollution increases. The financial penalty for emitting GHG will become so large that capturing and utilizing the gas will be required in the future. Installation of the microturbine provides a practical solution to this problem as it provides on-site heat and power with a high reliability and low maintenance required.

WHAT MAKES OUR DESIGN INNOVATIVE

Our microturbine design is modular and mobile, and hence can be applied to varying locations and conditions. It is compatible with well sites producing 1000-4000 m3/day waste gas. The electricity generated can replace GHG intensive power generation such as coal powered plants that would typically provide electricity to well-sites. The ability to extract heat from the exhaust provides operational benefit by reducing cost and increasing safety. The heat can limit freezing and hydrates in pipes or provide a heated area for workers to conduct maintenance and testing. A future addition to the microturbine could be carbon capture to create a net zero well-site. An example of this could be injecting carbon dioxide in the reservoir to increase production. Implementing this technology with a microturbine could create a completely self-sustaining site that has very little GHG emissions. This well-site could become the future of the energy industry.

HOW WE VALIDATED OUR DESIGN SOLUTION

Our project looked at three different solutions for using the waste gas instead of flaring it. The three options were: Using a fuel cell to generate power, processing the gas to create methanol, and combusting the gas in a micro turbine. The largest hurdle for our project was to create a design that was feasible economically due to the volatility of the energy industry. The lowest rate of return was used as the decision metric for the initial feasibility. The fuel cell used novel technology thus making the implementation of this design quite costly with too many unforeseen issues. The methanol production process resulted in high capital costs and large feed stock requirements making it unfeasible for this application. The microturbine allowed us a solution that was flexible, allowing for different flow rates, gas compositions, electrical and heat requirements at a particular site.

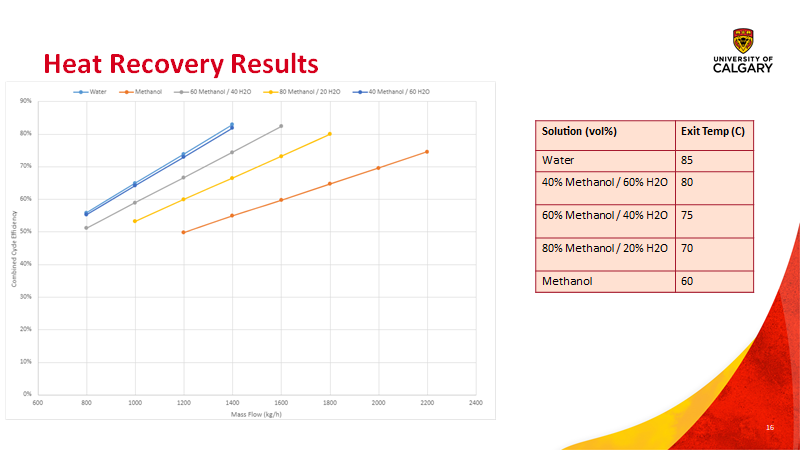

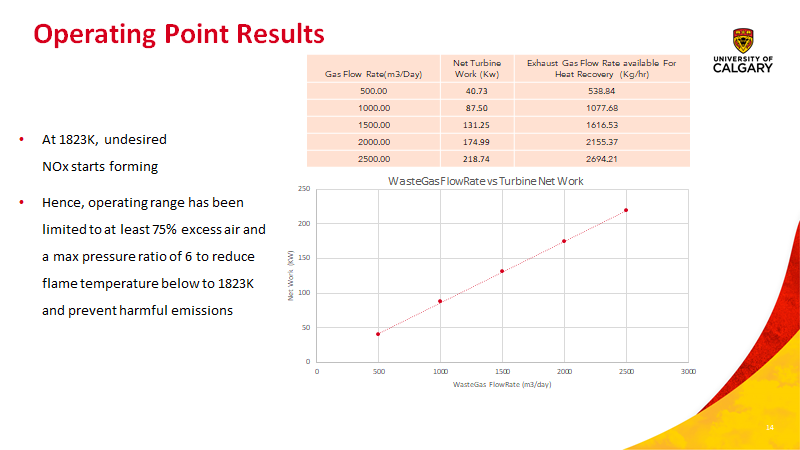

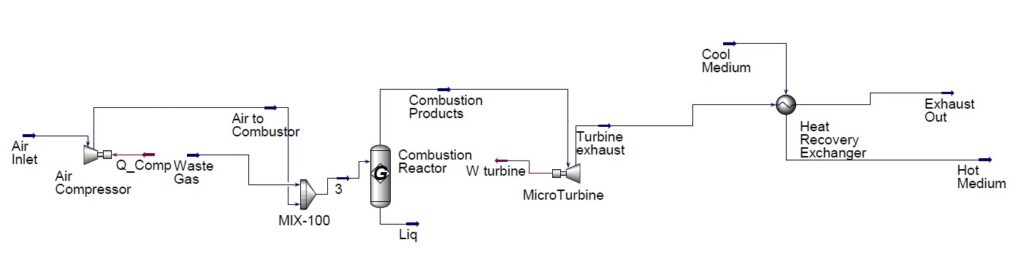

Once the microturbine was chosen for our design, the capabilities of the power generation and temperature/pressure at each stage of the thermodynamic cycle were verified by implementing the Brayton Cycle. Once a baseline was set up, we varied flowrates, inlet conditions and hence power generation to verify that the design would be practical and similar to the vendor specifications. Once an optimal case was selected, the heat transfer capabilities were verified with HYSYS software. We selected working fluids that would be able to handle harsh Canadian winters and not freeze. We varied flow rates and mixture composition to verify the heat generation capabilities for process heating, space heating or heat tracing.

The analysis performed showed that not only was the microturbine beneficial for the reduction of emissions but could also become an asset that would help the site financially in years to come.

WHAT MAKES OUR DESIGN SOLUTION EFFECTIVE

Our design solution addresses the on-going problem of releasing greenhouse gases from upstream oil operations. As regulations tighten, and carbon tax is increasing, there is no escape from eliminating these emissions to avoid large economic losses. Our design solution is not only successful in reducing methane emissions by capturing 95% of natural gas that would typically be vented, but provides additional revenue through power generation and heating that provide a 3-4 year return on initial investment

FEASIBILITY OF OUR DESIGN SOLUTION

The design solution is a practical and feasible option for energy companies striving to utilize waste gas. Microturbines have been implement in buildings to provide electricity and hot water to residential and commercial buildings. Microturbines have also been implemented on offshore rigs to deal with waste gas while providing power to a remote location. The microturbine solution can be implemented at a variety of sites with different waste gas flow rates, power, and heat requirements. The solution can be offered in remote location that is not grid connected or to a location that is tied into the grid while selling excess electricity to the power grid. Due to the small size and mobility of the microturbine, it is possible to continue its use on a new site after the original site has been abandoned Low maintenance costs, and little downtime add to the attractiveness of this option.

Partners and mentors

We want to thank the many people who helped us with this project. Special thanks to out academic advisor, Brian Van Vliet (P.Eng) from Spartan Controls who supervised our progress, and our industry sponsors, Brian Spiegelmann (P.Eng) and Dylan Brownlee(P.Eng) representing Whitecap Resources Inc who guided us through the process with patience and great advice. We also want to thank our Professor, Roes (Arief) Budiman and our TA, Jaehyun Yang for their continuous feedback and for helping keep us on track to deliver this project.

Our photo gallery