Project Category: Software

Our Sponsor

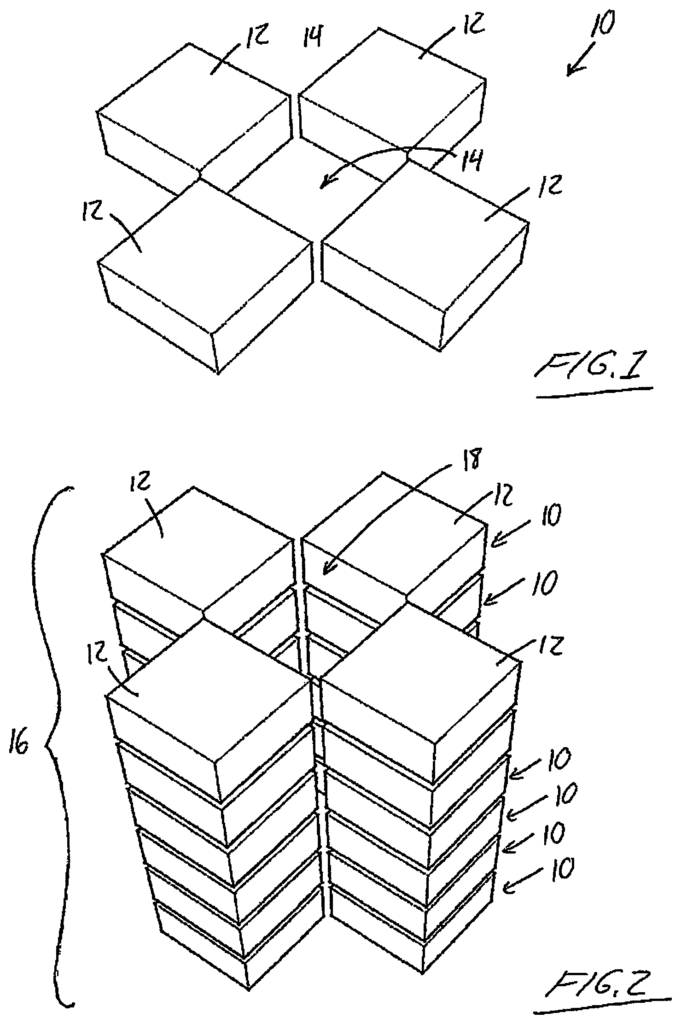

The sponsor for our capstone project is Attabotics – a Calgary based company that designs and manufactures innovative robotic warehousing solutions. Taking inspiration from an ant colony, Attabotics uses a dense cube based structure (nest) which stores inventory bins in cells. Robots (ants) travel within the structure and pick up bins, bringing them to an operator station where the product inside the bin can be retrieved.

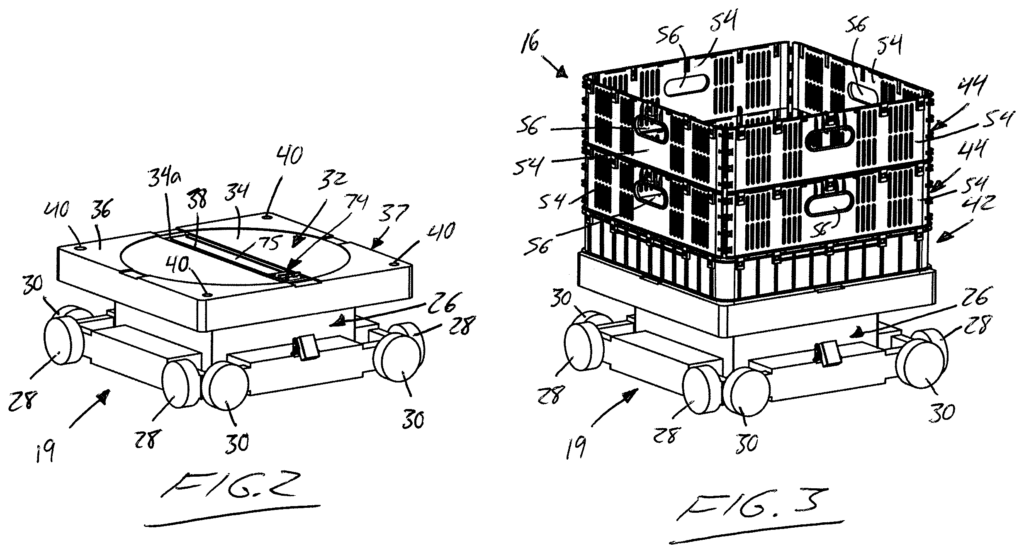

The Nest

Inside of the nest, there are columns for the ants to travel down. For each vertical layer of the nest, there are 4 bins adjacent to the column that are able to be retrieved by the robot as it ascends or descends the column.

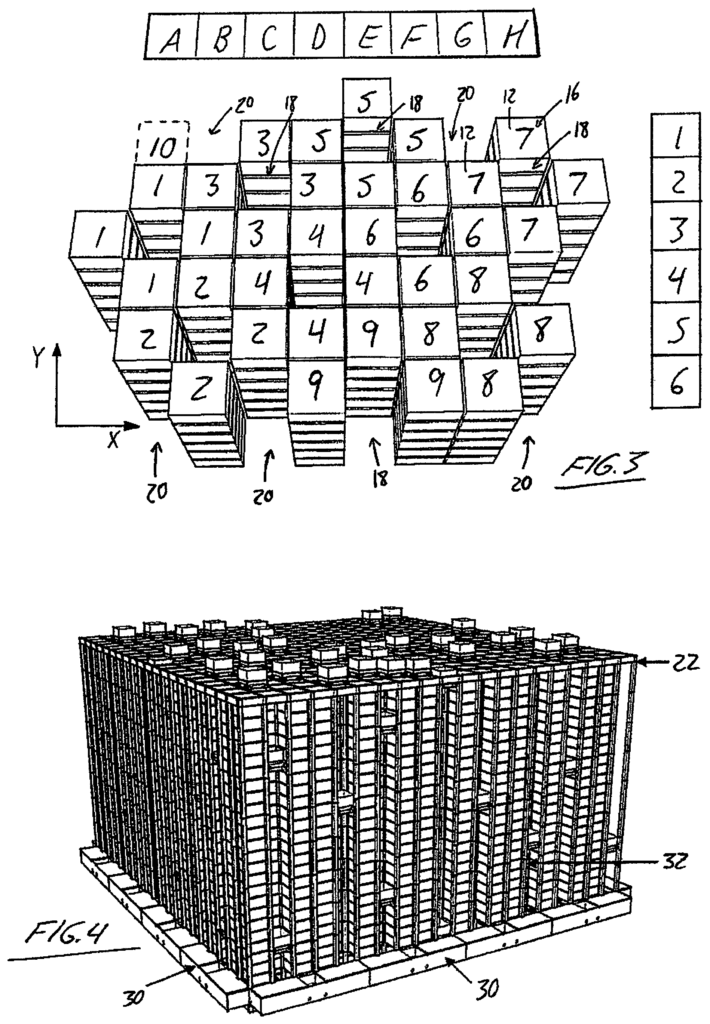

The Ants

The ant is a supercapacitor powered robot that can travel in the 3 XYZ directions. On the top of the ant is a picking arm which extends underneath a bin, pulling the bin on top of the ant for transport.

Compared to a shelf based warehouse with the same amount of inventory, an Attabotics nest will take up only 20% of the physical space. Since the structures can be made to fit any shape, this allows a warehouse solution to exist where it would have previously been impossible.

What is Our Project?

The Problem

Attabotics recently developed a new version of the ant, which comes with new technical capabilities. These new capabilities primarily enhance the routing behaviour, allowing new types of movements. Two new questions arose – how do they compare to the old generation ants, and what business impact will the new generation have on customers?

The tools available were unable to answer either of these questions. What Attabotics needed was a lightweight piece of software that could output quantitative data, and offer a visualization for new and existing clients.

Our Solution

We developed an application combining several different modules, each lead by an individual team member:

- Graphical User Interface (GUI)

- Routing Algorithm

- Simulator

- 3D Visualizer

- Data Output

The GUI allows a user to input several different parameters, which are then passed to the simulator. The simulator uses the routing algorithm with various different input options, ultimately generating a very large collection of optimal robot routes through the structure. These robot routes are analyzed to provide key metrics such as the average time it takes a robot to pick an item and return to the operator (cycle time).

With the completed robot routes, the user can launch a 3D visualizer from the GUI. This gives a high level overview of how the robots behaved in a given pick cycle, and offers the ability for high-level troubleshooting (such as robot congestion). Another option given to the user is the ability to output the robot routes into a large .csv file, which can be analyzed by other tools and spreadsheet programs.

All of these modules were integrated into a single lightweight application, which is demonstrated in the video below.

Backup video link

Attabotics is very pleased with the result of our project, and they have expressed interest in further developing it to solve other business problems.

Meet Our Team Members

Andrew Bright

Electrical & Computer Engineering

Technical Manager

Andrew is the technical manager of the project, coordinating the efforts of team members and designing the overall software structure. With a well developed combination of mechanical, electrical, and software design skills, he has found himself as an “engineering hobo”. A key part of his degree was a research exchange to Germany, where aside from day drinking and being able to bring up “my trip to europe” in every conversation, he worked on a project to integrate a neural network with optical sensors to perform a novel form of speech therapy.

Clark Dy

Electrical & Computer Engineering

Visualization Lead

Clark was the visualization lead for the project, responsible for the 3D visualizer tool. He is in his final year in Electrical Engineering student with a minor in Computer Engineering at the University of Calgary. Clark has worked as an engineering intern at Procter & Gamble, where he operated and maintained heavy machinery for their production line and evaluated the use of mixed reality to replace paper-copy lesson plans for line operators. Clark has also worked as a quality assurance intern at QuirkLogic Inc., a Calgary-based Startup developing e-ink writing devices, which stressed the importance of testing and iterative design. Clark’s interests and strengths lie in the field of embedded systems, software programming, hardware & electronics design, and prototyping. Once done his undergraduate degree, Clark plans on continuing to pursue a Master’s in Engineering degree in Software Engineering, completing his so-called “trifecta of embedded systems.”

Nielsen Tajonera

Electrical Engineering

Documentation & QA Lead

Nielsen is the documentation lead for the project. His main responsibility is document control but has also performed testing and output code development for the simulation. He is currently in his last year of Electrical Engineering. Nielsen interned with Emerson as a systems integrator, where he was able to advance his skills on professional communication, project management and systems integration. His main technical interests include power systems, electrical design, systems integration and energy sustainability. In his pastime, you’ll either find him crossing people in basketball courts or plating perfectly seasoned dishes.

Helen Tan

Electrical Engineering

Simulation Lead

Helen is the simulation lead for this project, responsible for connecting the GUI inputs to the routing, and for calculating metrics of each simulation. She is in her final year of Electrical Engineering with a broad spectrum of interests including but not limited to power systems, photovoltaics, and biomedical imaging. Helen interned at MEDAL where she worked on the design and development of printed electronics. Her second internship was with QuirkLogic where she was involved in testing their software and developing an automated test suite for their browser application. Outside of school, Helen is an avid enjoyer of escape rooms, creating art pieces, and cats.

Annelyse Tycholis

Software Engineering

Project Manager

Annelyse is finishing her fourth year of Software Engineering. Annelyse completed an internship with Arcurve as a business analyst and delved into development and quality assurance while also rebuilding a large-scale legacy system for a well-known local company. Through her internship, she acquired skills such as effective communication, problem solving and automating testing processes for large-scale data analysis. She has a passion for learning and developing her technical skills and currently has interests involving project management, learning how to manage a project from start to finish successfully and how to develop quality software to solve real world problems. Outside of school, Annelyse enjoys anything that involves being outdoors and horses, being a competitive equestrian athlete. (HORSE GIRL WARNING)

Will Zhuo

Electrical Engineering

Routing Lead

Will is currently in his 4th year of Electrical engineering. Will completed an internship with Semtech corporation as an Analog Design Intern, where he worked on semiconductor products that will be deployed in future 5G wireless base stations. Through this internship, he acquired valuable skills and experiences in the field of analog integrated circuit design, gained insights into research and development work and cutting-edge innovation, and developed interests in the semiconductor and telecommunications industries.

Further Details

What practical issues did we solve?

There were two primary issues posed to us:

- How do new routing behaviors impact cycle time?

- How does improved routing translate to business metrics?

Our design was able to evaluate the benefits and drawbacks of the additional routing capabilities offered by the new generation robot. By comparing the existing routing algorithm to the new one, we identified several areas of improvement.

By creating a visual demonstration, we were able to solve the second issue as well. Changing the routing method did not initially translate to business metrics, but our application is able to quantify the changes into product velocity (inventory per time) which is a key metric associated with cost. With a visualization, this can be communicated to customers.

What makes our design innovative?

Our design is innovative largely due to the unique nature of the features we implemented. After many weeks of research, we worked with Attabotics to implement a routing algorithm that closely models the existing architecture. From there, we were able to create different rules which allow the modeling of new robot routing features.

For the simulation, there were no open source packages available which could integrate the routing algorithm and return the metrics we needed. As a result, we created our own simulation packages to return exactly what Attabotics needed.

What makes our design solution effective?

Our design solution is effective because it provides a high level of practical problem-solving that was previously unavailable. The learning curve is small, and the outputs are easy to understand. Attabotics has explained that there will be a large positive impact for teams working with customers.

Testing and Validation

We developed the software in sprints, and utilized test-driven-development to ensure each module and feature worked prior to integration. After combining all of the modules, we performed system level tests to ensure the application behaved as expected.

To validate the real world accuracy of the data, we compared our results with known robot parameters including acceleration, velocity, and communication delays.

What can be added in the future?

Due to the modular nature of our project, future additions are very easy to implement. One of the interesting features to evaluate is a different way of storing inventory in the structure, and how it affects order fulfillment. Attabotics has expressed an interest to take over the development of the project.

Company Representatives and Technical Advisors

We would like to express our heartfelt gratitude to our TA, Tariq Al-Shoura, for providing his wisdom, guidance, and support during project impasses and in our times of need. Thank you to our technical advisors Professor Henry Leung and Professor Norm Bartley for their feedback and input. And lastly thanks to Attabotics and our contacts Mr. Mark Dickinson and Mr. Gordon Paynter for providing us with such a unique opportunity and project.

Tariq Al-Shoura

Norm Bartley

Henry Leung

Mark Dickinson

Gordon Paynter

References

[1] S. Gravelle, R.G. Cowley, A.B. Woolf, “Storage and retrieval system with shaft-traversing tracks,” U.S. Patent 11,008,165, 18 May 2021. [Online]. Available: https://uspto.report/patent/grant/11,008,165

[2] S. Gravelle, W. Hope, D. Rousseau, “Storage And Retrieval System For Managing Loading, Alignment, And Travel Of Storage Units And Robotic Vehicles,” U.S. Patent Application 16/973260, 18 Nov., 2021. [Online]. Available: https://uspto.report/patent/app/20210354922

[3] Attabotics, “Solutions,” Attabotics. [Website]. Available: https://www.attabotics.com/solutions

—

Image Links

UofC and Attabotics logos:

- https://pbs.twimg.com/profile_images/484375695854800896/EpJrE5C6_400x400.png

- https://media-exp1.licdn.com/dms/image/C560BAQHQXG_4gI6Hiw/company-logo_200_200/0/1626713391033?e=2147483647&v=beta&t=U36ie_d3Hot4RS39PQc2L_S_cplD76lE4c-2CCL2vPE

Extra amazing content

The seventh, and scariest of the team members: Lexi.